Method for dyeing cotton fibers by using natural dye

A dyeing method and technology of natural dyes, applied in the direction of dyeing method, fiber treatment, textile and paper making, etc., can solve the problems of long-term boiling and low dyeing rate, etc., and achieve uniform modification or dyeing, natural color and light, The effect of improving fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

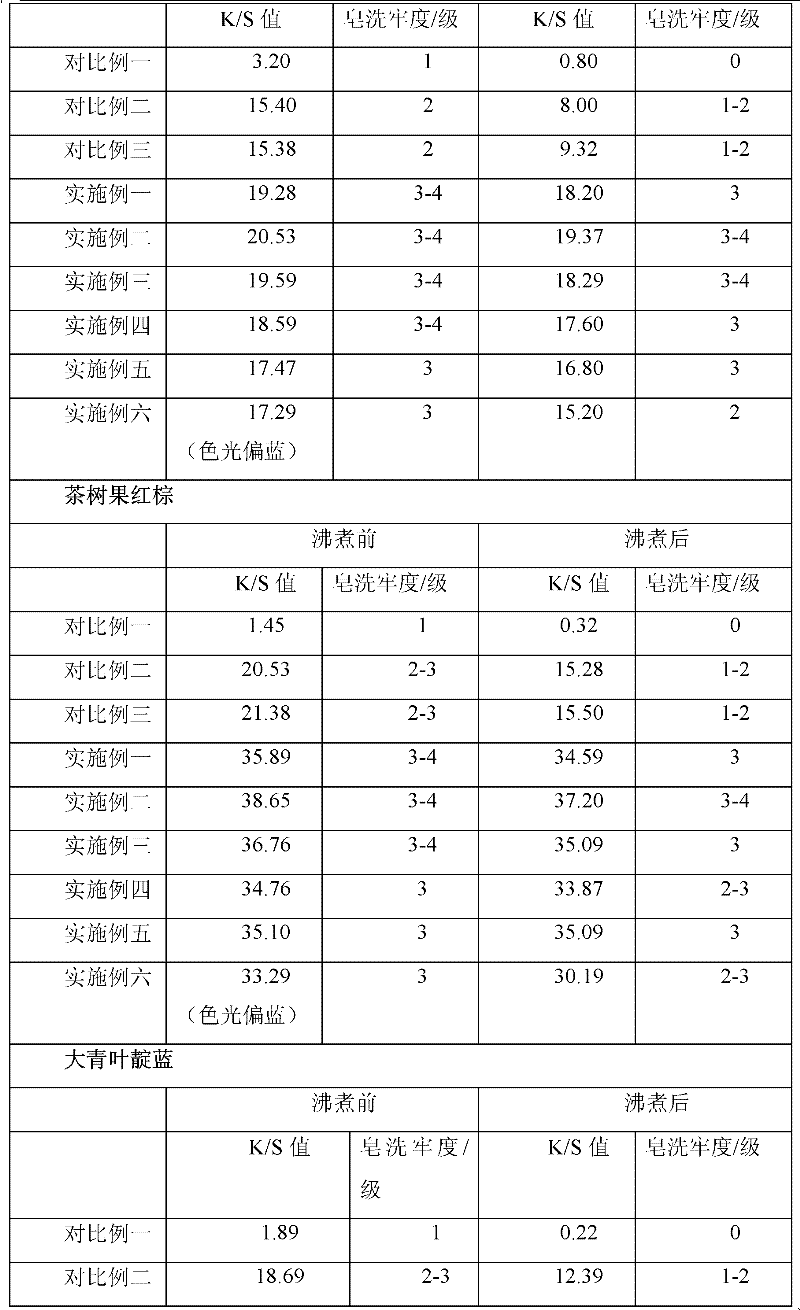

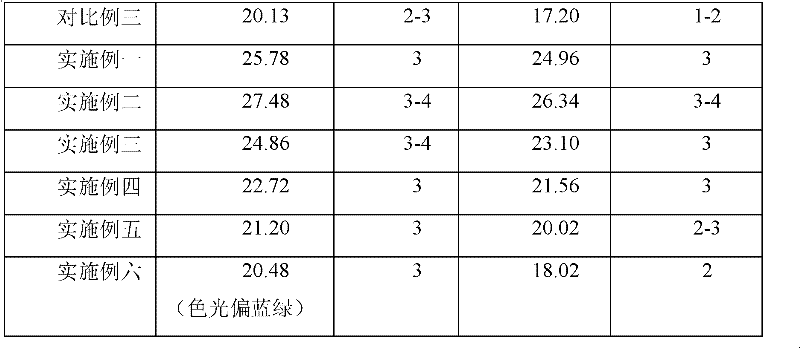

Embodiment 1

[0023] Cotton thread 5g, after boiling in boiling water for 5 minutes, take it out and set aside. Put the above-mentioned treated cotton thread into the chitosan modifier solution with a concentration of 2% (relative to the weight of the cotton thread), the bath ratio is 1:50, the modification temperature is 65°C, and after the modification time is 30min, take it out and wash it for later use ; Adopt gardenia yellow, tea tree fruit red brown, and Daqingye indigo to dye the above-mentioned cotton threads respectively, the dyeing solution formula: dye concentration (mass ratio of dyestuff to cotton thread) is 2%, bath ratio 1: 50, dyeing temperature is 75 ℃, pH value is 7, after the dyeing time is 80min, take out and wash with water for later use; color fixing liquid formula: the amount of color fixing agent sodium chloride (relative to the weight of cotton thread) is 5%, put the above dyed cotton thread into it for color fixing , the color fixing temperature is 50°C, and after ...

Embodiment 2

[0025] Cotton thread 5g, after boiling in boiling water for 3 minutes, take it out and set aside. Put the above-mentioned treated cotton thread into the chitosan modifier solution with a concentration of 3% (relative to the weight of the cotton thread), the bath ratio is 1:30, the modification temperature is 90°C, and after the modification time is 40min, take it out and wash it for later use ; adopt gardenia yellow, tea tree fruit red brown, and Daqingye indigo to dye the above-mentioned cotton thread respectively, and the dye solution formula: the dye concentration (mass ratio of dyestuff to cotton thread) is 8%, the bath ratio is 1: 30, and the dyeing temperature is 85 ℃, the pH value is 4-5, after the dyeing time is 30 minutes, take it out and wash it for later use; the fixation liquid formula: the amount of the fixation agent sodium sulfite (relative to the weight of the cotton thread) is 4%, put the above-mentioned dyed cotton thread into it for color fixation , the colo...

Embodiment 3

[0027] Cotton thread 5g, after boiling in boiling water for 4 minutes, take it out and set aside. Put the above-mentioned treated cotton thread into the chitosan modifier solution with a concentration of 4% (relative to the weight of the cotton thread), the bath ratio is 1:40, the modification temperature is 95°C, and after the modification time is 35 minutes, take it out and wash it for later use ; Adopt gardenia yellow, tea tree fruit red brown, and Daqingye indigo to dye the above-mentioned cotton thread respectively, the dyeing solution formula: the dye concentration (mass ratio of dyestuff to cotton thread) is 5%, the bath ratio is 1: 30, and the dyeing temperature is 95 ℃, the pH value is 3-4, after the dyeing time is 60min, take it out and wash it for later use; the color fixing liquid formula: the amount of color fixing agent potassium aluminum sulfate dodecahydrate (relative to the weight of the cotton thread) is 1%, put the above dyed cotton thread Put it into it for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com