Patents

Literature

71results about How to "Anti-channeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

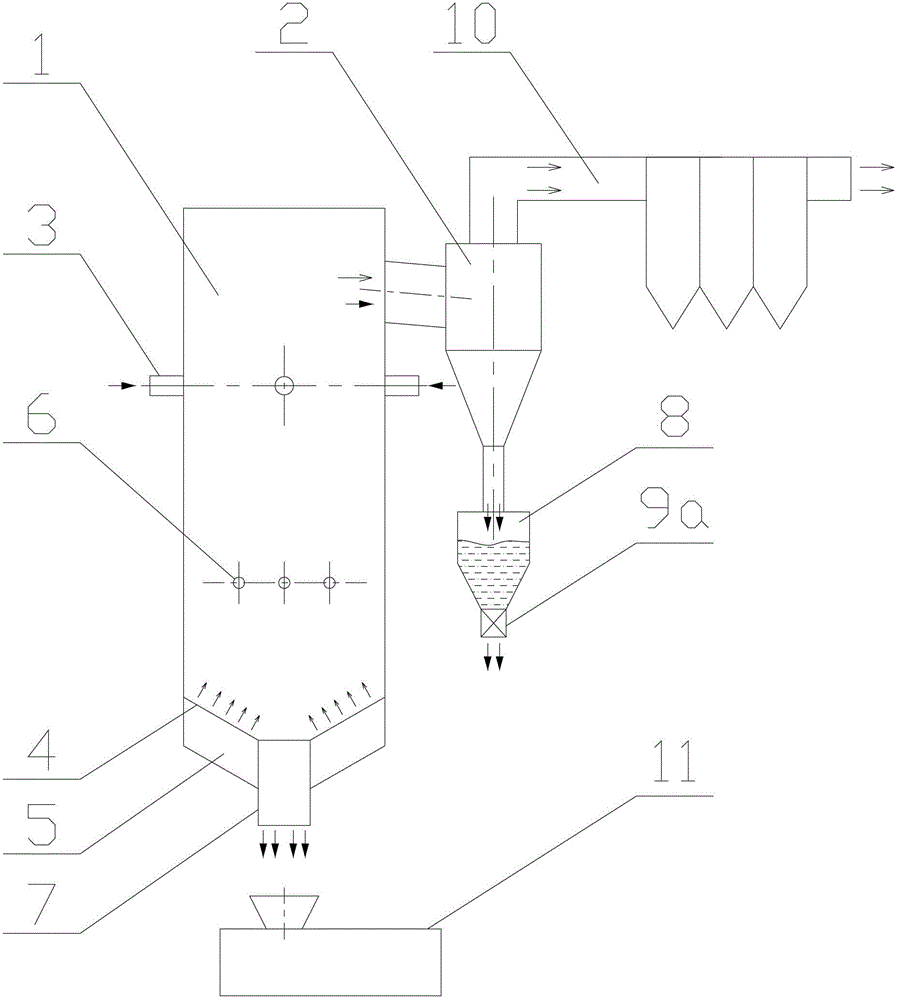

Pneumatic particle size classifying device for solid particles

InactiveCN102716857AAffect balanceAffect normal working conditionsGas current separationSolid particleEngineering

A pneumatic particle size classifying device for solid particles comprises a fluidized bed main body, a cyclone separator, material inlets, an air distributing system, a secondary air port, a coarse material outlet and a fine material collecting and discharging system. The material inlets are positioned on the middle upper portion of the fluidized bed main body and are distributed on four walls in a multi-point manner, the hopper-shaped air distributing system consists of an inclined air distributing plate, the coarse material outlet is arranged in the center of the inclined air distributing plate, the fine material collecting and discharging system consists of a fine material collecting chamber and an intermittent discharging valve and is directly connected with a lower particle outlet of the cyclone separator, or the fine material collecting and discharging system can consist of a fine material collecting chamber and a fine material discharge port and is connected with a particle outlet of a feedback valve. The pneumatic particle size classifying device is simple in structure, effective pneumatic particle size classification for selective coking coal particles is carried out by fluidization technology, retaining time of the particles in the bed body can be effectively prolonged, the pneumatic particle size classifying device is stable in running and fine in separation effect, and energy and coking coal resources are greatly saved.

Owner:TSINGHUA UNIV

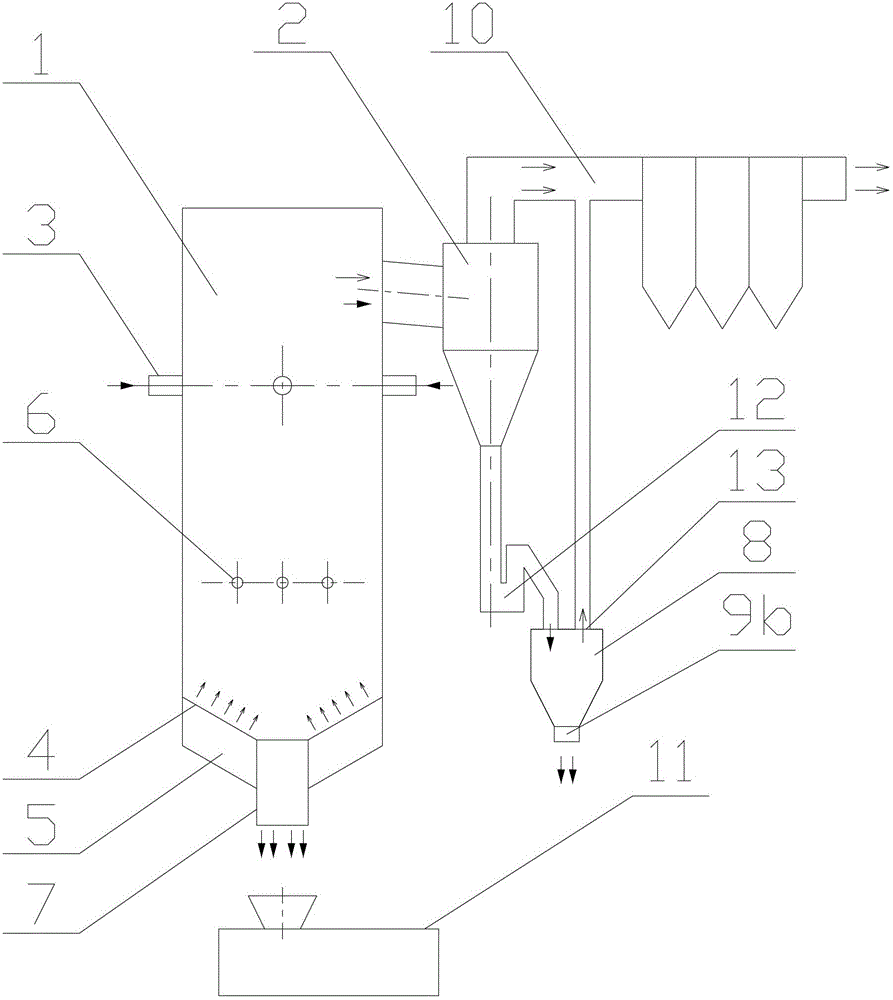

Internal combustion type heating rotating cone type biomass pyrolysis liquefaction device

ActiveCN101445737ARealize inverse motionImprove heat transfer effectBiofuelsSpecial form destructive distillationFlue gasFuel tank

The invention relates to an internal combustion type heating rotating cone type biomass pyrolysis liquefaction device. The device is characterized in that two concentric cones are arranged in a reactor, the outer cone is a rotating cone, and the inner cone is a fixed cone; a charging barrel is sectionally arranged into an upper section charging barrel and a lower section charging barrel, the upper part of the rotating cone is connected with the lower section charging barrel, and the upper section charging barrel is communicated with a spiral feeding mechanism; the upper part of the fixed cone is communicated with a flue gas pipeline; the end surface at the bottom part of the fixed cone is closed, and the lower part of the fixed cone is tangentially connected with a burning pipeline; a porous filter tube is arranged in the reactor, a reactor is led out form the other end of the porous filter tube, and the reactor is communicated with a cyclone dust collector positioned outside the reactor, the output end of the bottom part of the cyclone dust collector is connected with a carbon collecting box, and a gas outlet opening at the top part is connected with a condenser through a pyrolysis gas pipeline; an oil outlet opening on the condenser is communicated with an oil collecting tank, the air outlet opening of the condenser is accessed into a pyrolysis gas burner through a pyrolysis gas return pipeline. The invention realizes biomass self-heating type pyrolysis liquefaction, effectively improves the utilization ratio of the pyrolysis byproduct and reduces the total cost for biomass liquefaction.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

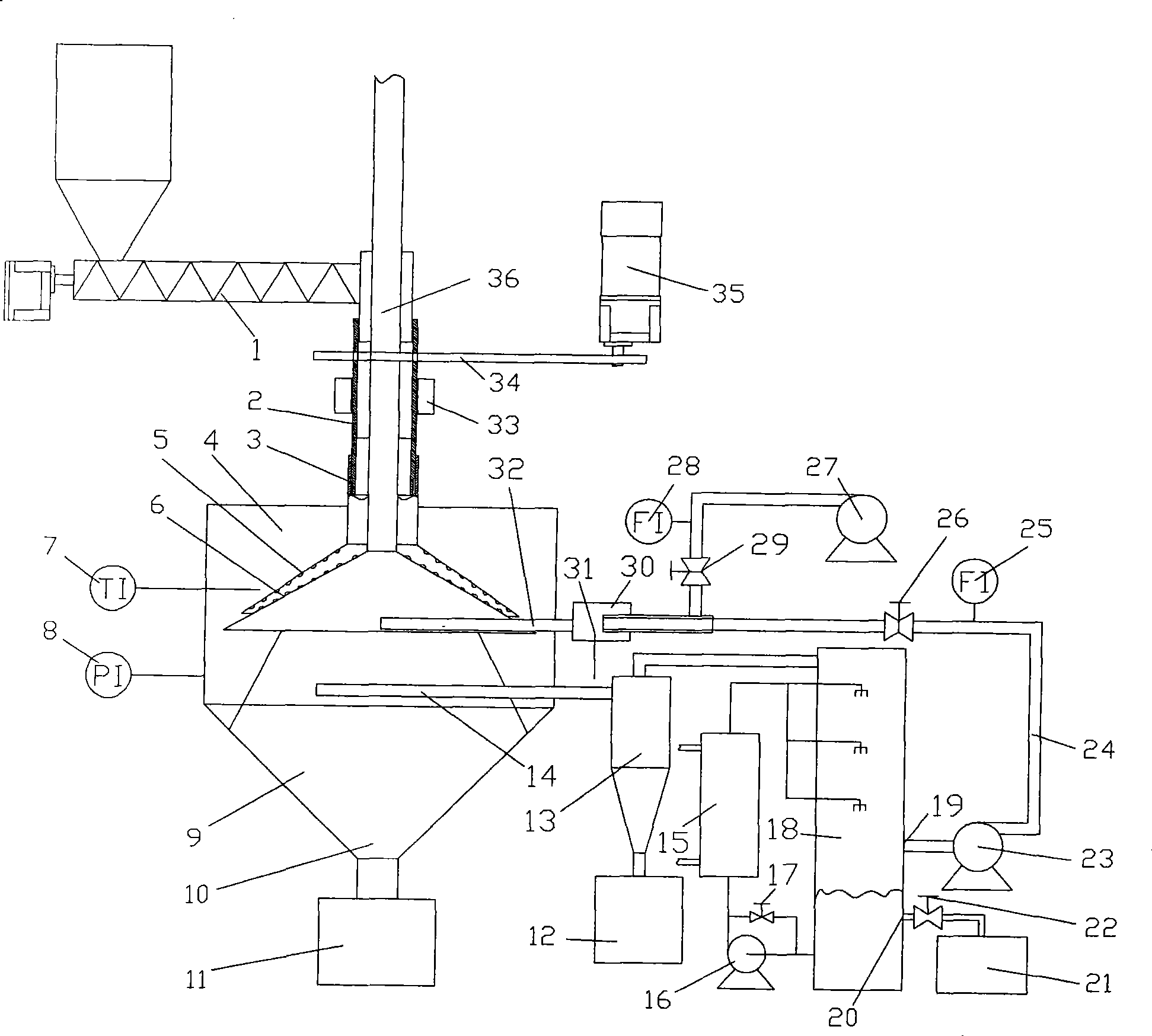

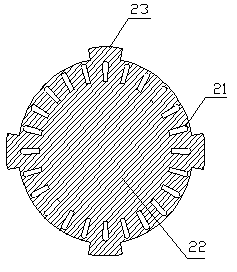

Internal combustion heating moving-bed type biomass pyrolysis liquefying apparatus

InactiveCN101376814AIncrease profitReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionBiomassPyrolysis

The invention discloses an internal combustion heating movable-bed biomass-pyrolysis liquefaction device which includes a reactor (7); the inside of the reactor is provided with an internal combustion pipeline (5); both the inlet and the outlet of the internal combustion pipeline (5) are arranged outside the reactor (7); a hopper (1) is arranged above the reactor (7); a blanking control valve (2) is arranged on the hopper (1); a rotary shaft (6) is arranged in the center of the reactor (7); conical hoppers (4) are arranged on the rotary shaft (6); conical material dividing umbrellas are arranged between the conical hoppers (4); the material inlet of the hopper (1) is arranged above the conical hoppers (4); a pyrolysis gas outlet (20) is arranged on the reactor (7); the bottom part of the reactor (7) is provided with a slag discharge opening (14); a cyclone separator (23) is connected on the gas pipeline of the pyrolysis gas outlet (20); the flue gas outlet of the cyclone separator (23) is connected into a condenser (26); an oil outlet and an outlet for non-condensable gas are arranged on the condenser (26); the outlet for non-condensable gas is connected to a gas buffer tank (28) through a draught fan. The biomass-pyrolysis liquefaction device reduces the liquefaction cost of bio-oil, has a simple structure and a low processing and manufacture cost as well as is simply and conveniently operated, managed and maintained.

Owner:HEFEI UNIV OF TECH

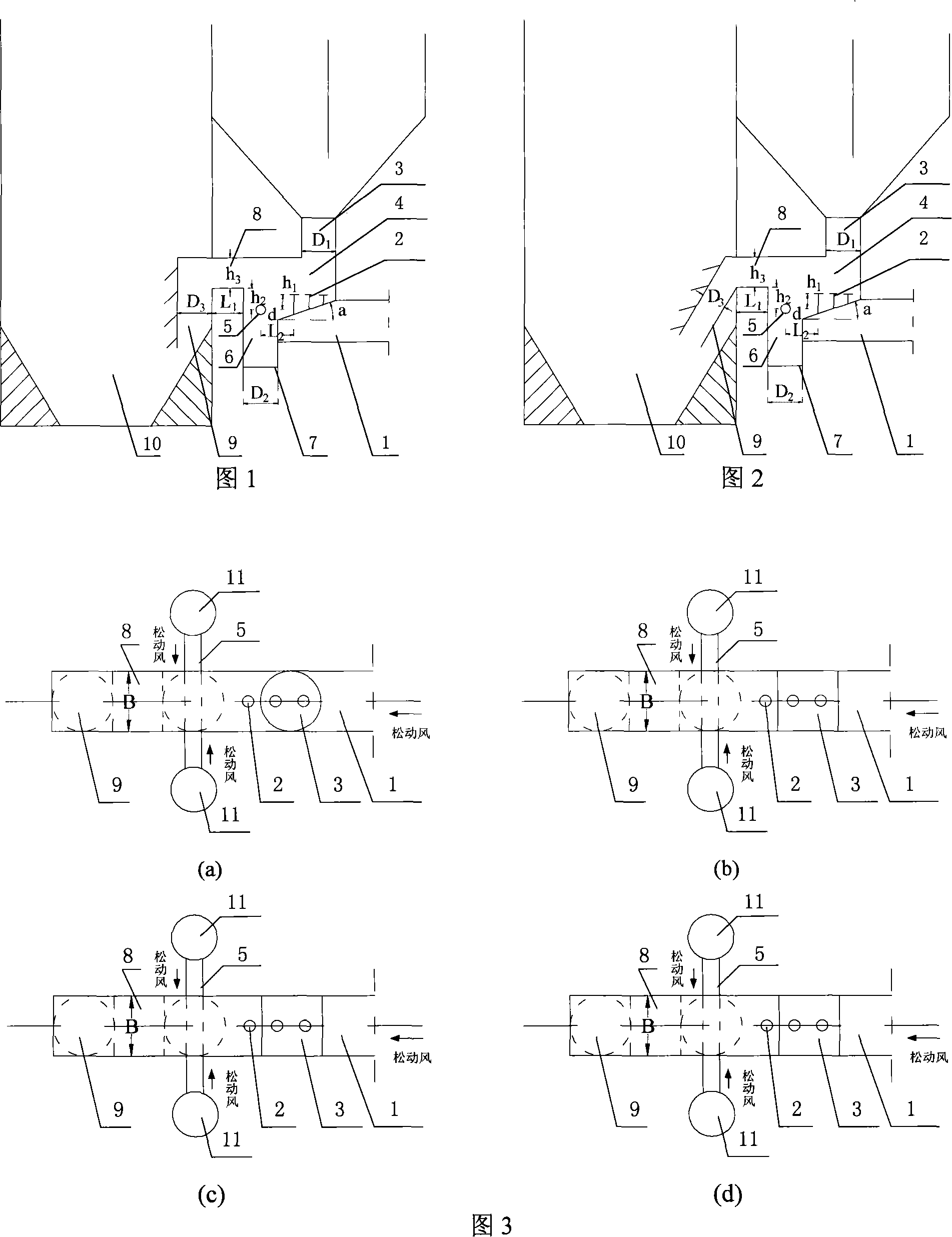

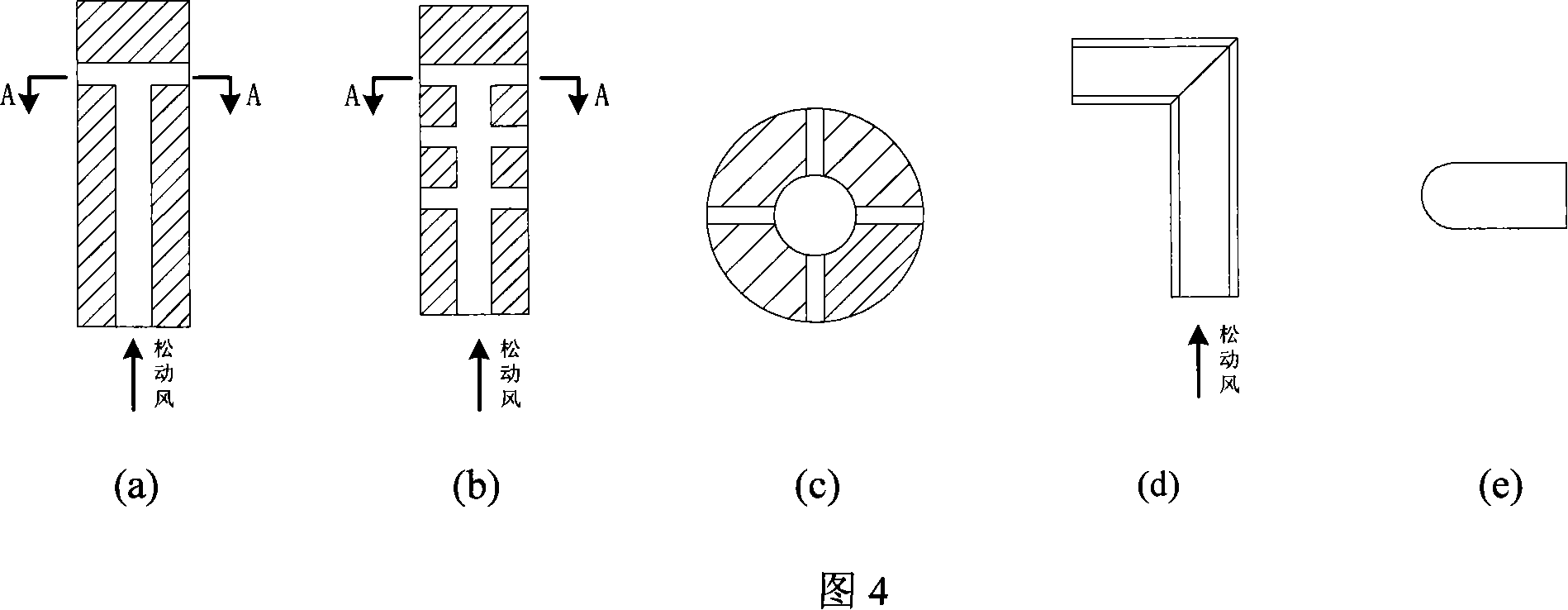

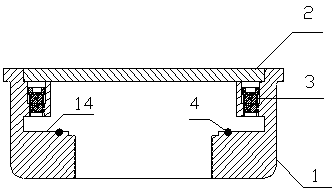

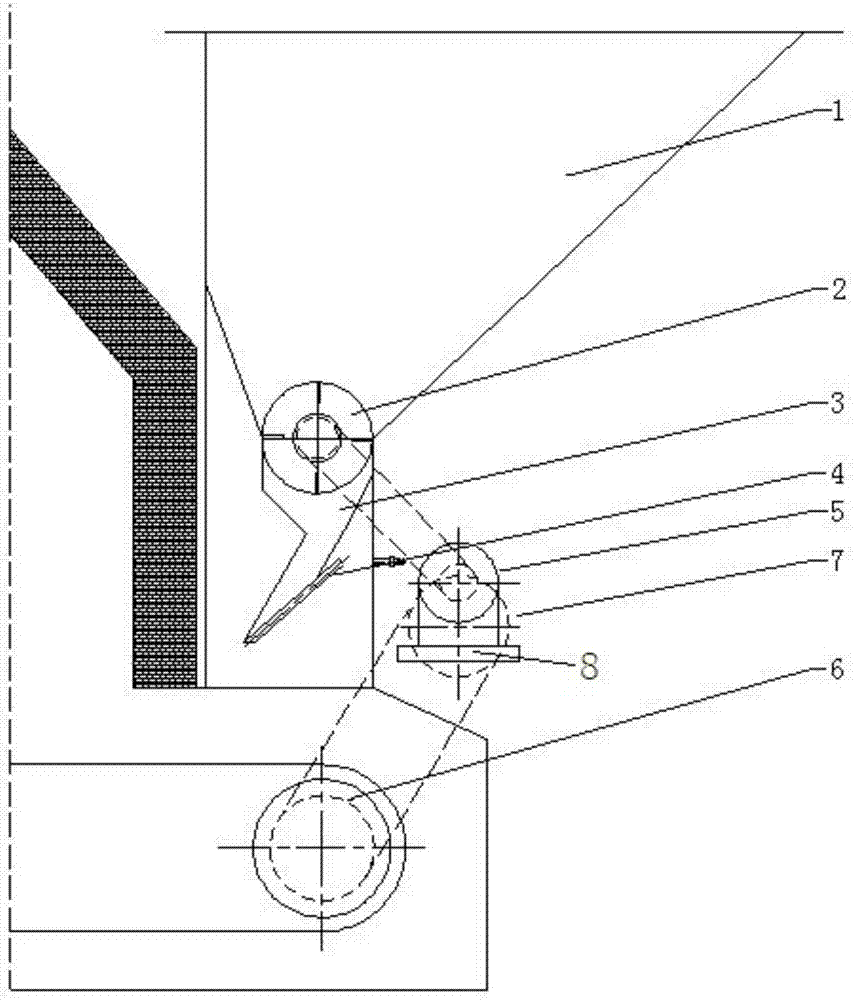

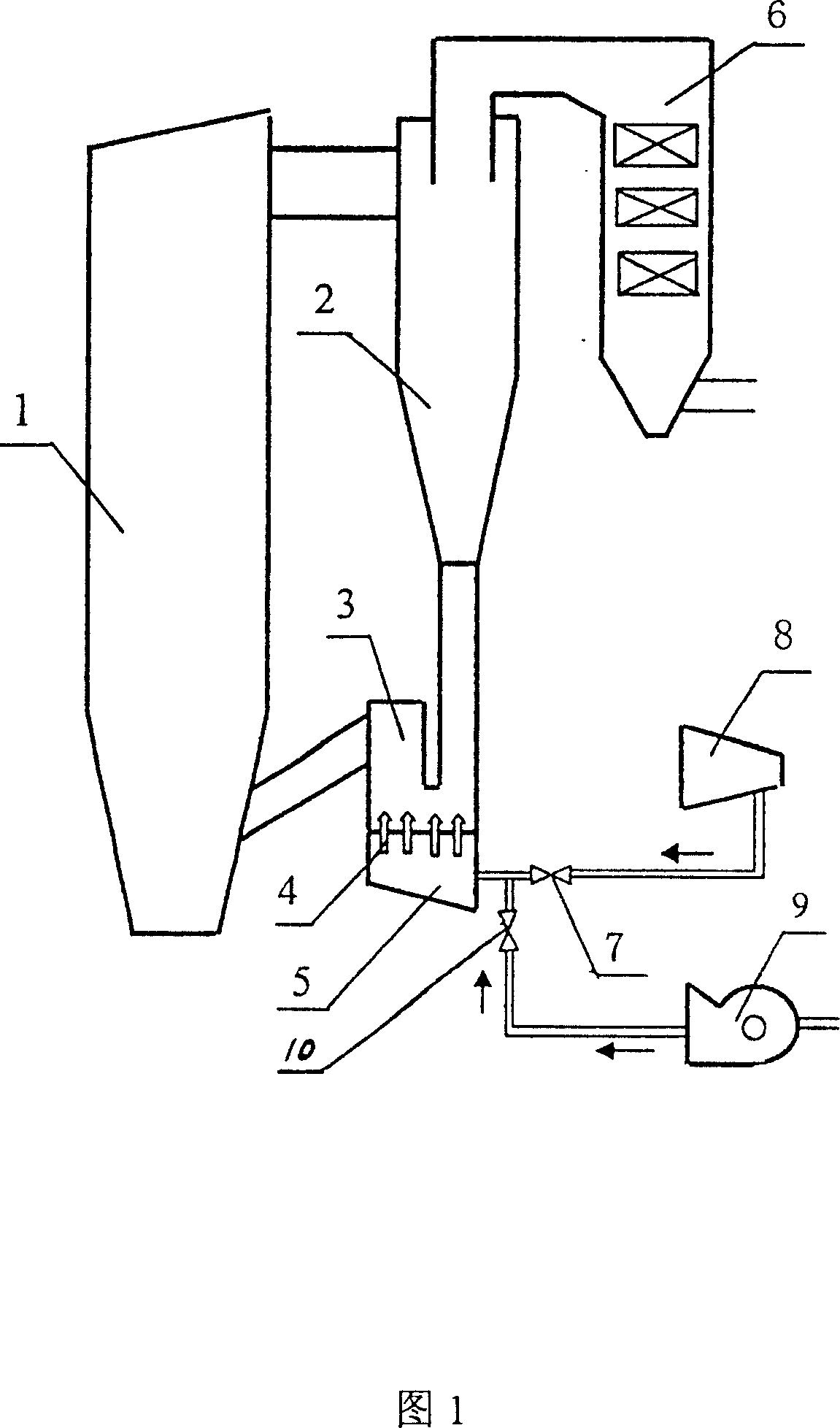

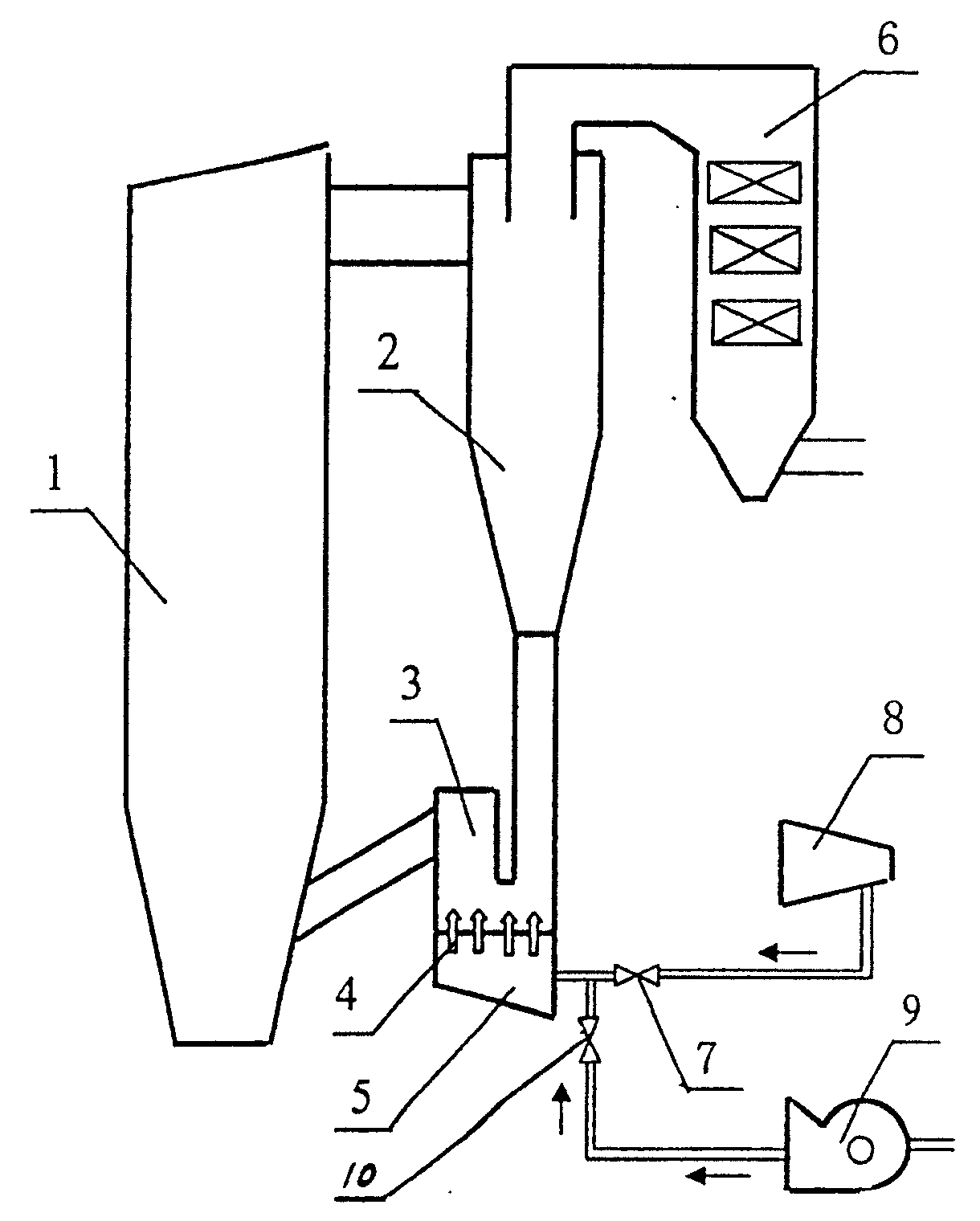

Self-balancing throughflow type material returning device

ActiveCN101109505AAnti-channelingGuaranteed uptimeFluidized bed combustionApparatus for fluidised bed combustionSlagSolid particle

A self-balancing through-flow charge returner is provided, which comprises a stage-I loosening plenum, a stage-I loosening nozzle button, a material-falling pipe, an adjusting section, a stage-II loosening air hose, an ash releasing pipe, a spile valve, a horizontal conveying section, an outlet section and a stage-II loosening plenum. The invention is basically characterized in that, two stages of loosening air are provided, the stage-I loosening air is at the adjusting section and inside the central line of the material-falling pipe; air is distributed by a cylindrical (not oriented) nozzle button or an oriented nozzle button; the stage-II loosening air hose is like a flute, passes into the returner from the side of the adjusting section, is located above the ash releasing pipe; the two stages of loosening air distribute air independently, the air pressure of the stage-II loosening air is higher than that of the state-I loosening air. The returner is additionally characterized in that, the included angle between the bottom plate of the adjusting section and the level is 0-15 degree; the through-flow area of the horizontal conveying section is 1 / 2-1 of the through-flow area of the material-falling pipe; the outlet section is a round or square pipe, the diameter is bigger than that of the material-falling pipe; the outlet section uses a baffle to stop the influence of air flow. The invention is controllable and self balancing, can not only prevent back flowing of air flow in the furnace tank, but also can adjust the flow of solid material, also can solve the instantaneous choking due to small slag by releasing material timely, and is applicable for returning solid particles of circulating fluid bed.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

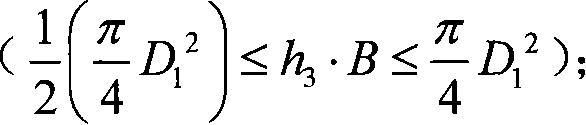

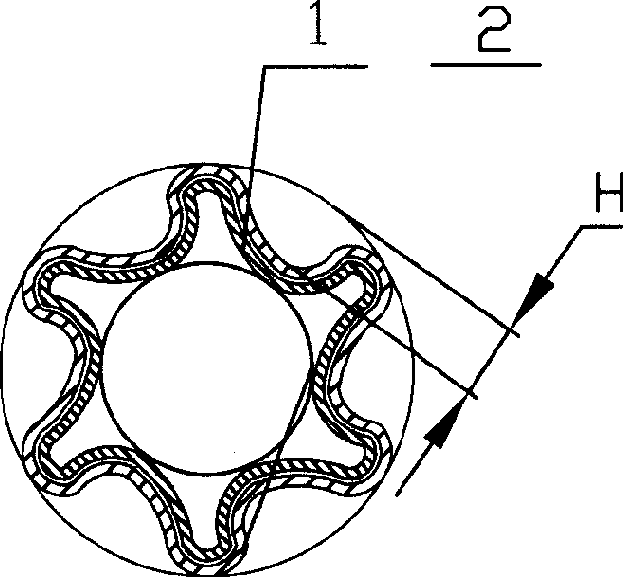

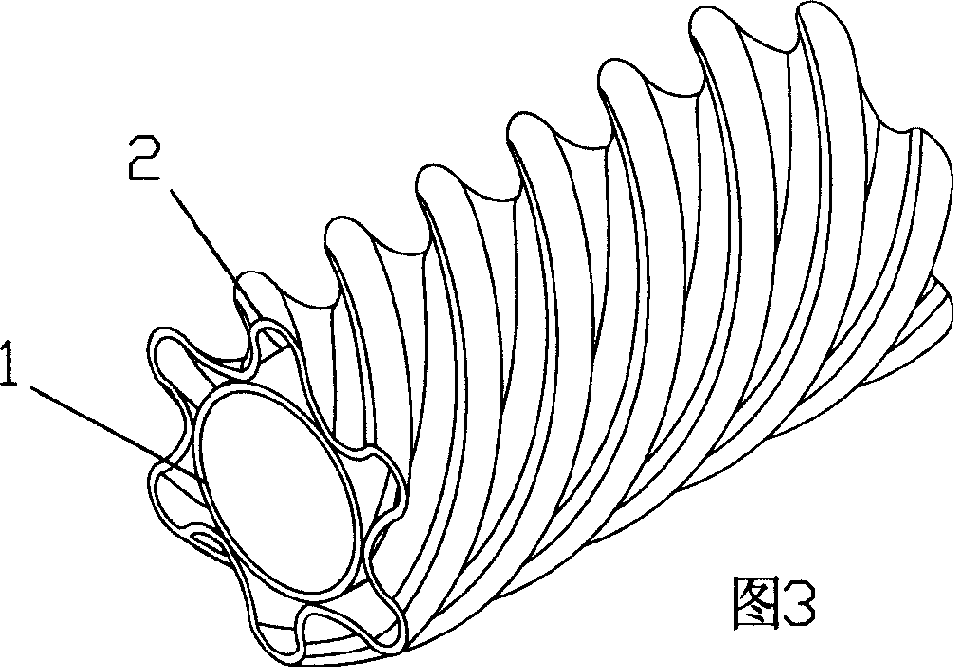

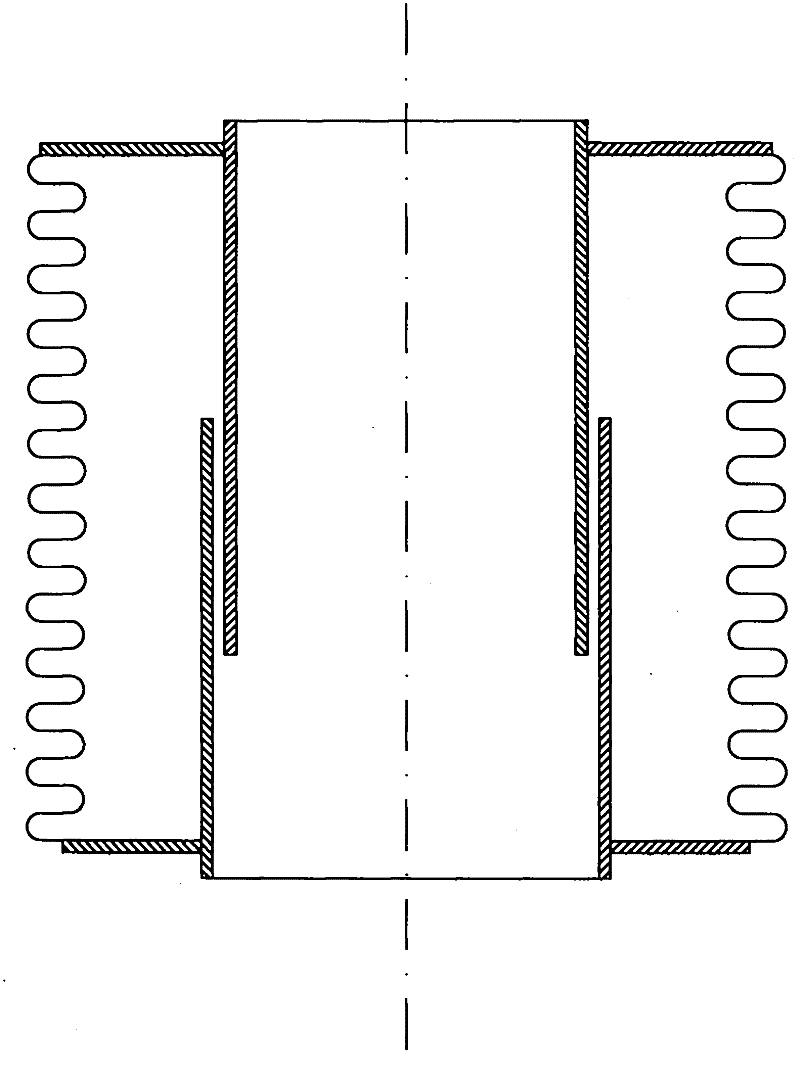

Double-walled helical corrugation metal tube and method of processing the same

ActiveCN101368801AImprove surface structureAnti-channelingStationary tubular conduit assembliesTubular elementsDouble wallEngineering

The invention relates to a heat exchange component, in particular to a double-wall multi-head spiral corrugated metal pipe used for a heat exchanger and a machining method thereof. The pipe body comprises an inner pipe body and an outer pipe body; the outer pipe is a spiral corrugated pipe, while the inner pipe is a smooth pipe or a spiral corrugated pipe; and a gap is arranged between the inner pipe wall and the outer pipe wall. The invention mainly provides a durable double-wall spiral corrugated metal pipe which has simple structure, high heat exchange efficiency and high safety coefficient, and a machining method thereof so as to solve the technical problems in the prior art that the metal pipe in the existing heat exchanger is single-layered and has low safety factor and heat exchange efficiency.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

Method of fluidizing wind at high pressure using steam to replace air

InactiveCN1566749AAvoid cokingAvoid burnsFluidized bed combustionApparatus for fluidised bed combustionEngineeringHigh pressure

The invention relates to a method of implementing high pressure fluidization blast using steam in place of air, characterized in that: steam is used for high pressure fluidization blast in normal running of a boiler. The method includes: connecting a turbine exhaust or intermediate extraction with a stock recycler using a steam conduit; starting high pressure fluidization blower and fluidizing recycle material in the stock recycler using air when the boiler begins to start; opening stop valve of the turbine steam conduit, fluidizing recycle material in the stock recycler using steam, shutting down the high pressure fluidization blower and closing the stop valve when the temperature of recycle material in the stock recycler is above 300 Celsius degree, the fluidization steam vapor source pressure parameter is greater than 60Kpa, and the superheat degree is larger than 30 Celsius degree; starting the high pressure fluidization blower, fluidizing recycle material in the stock recycler using air, and closing the stop valve on steam turbine when the temperature of the stock recycler is under 300 Celsius degree in blow off process of the boiler. Advantages of the invention consist in that coking of the stock recycler or other high temperature zones can be prevented or abated and boiler operation reliability can be improved by using steam for replacing high pressure fluidization blast. At the same time, circulating fluid bed boiler desulfurizer utilization rate can be improved, Nox discharge concentration can be reduced, and power plant running cost can be saved by utilizing steam fluidization.

Owner:SHANGHAI BOILER WORKS

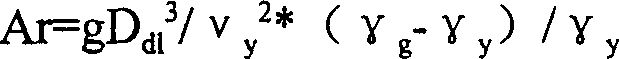

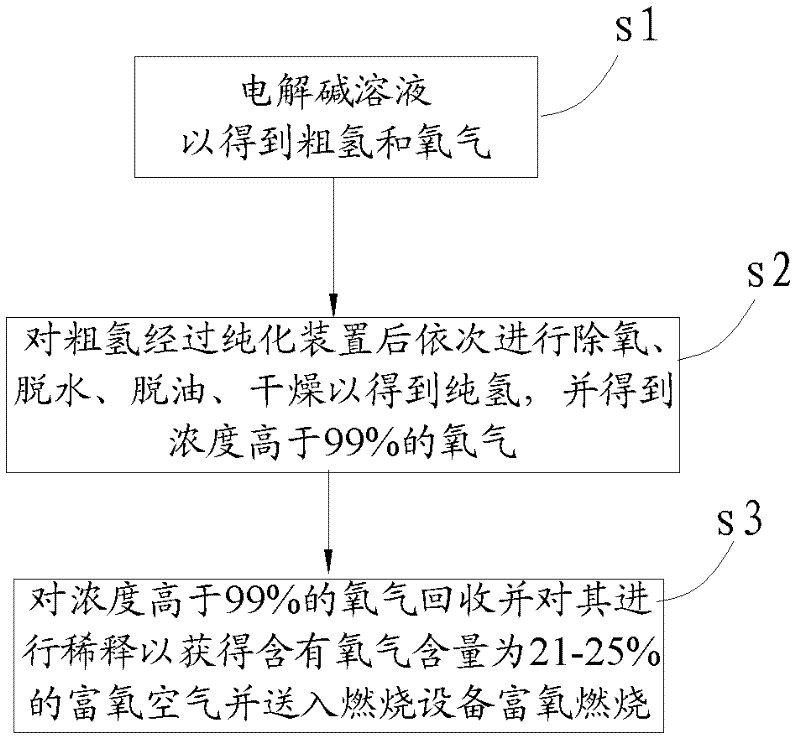

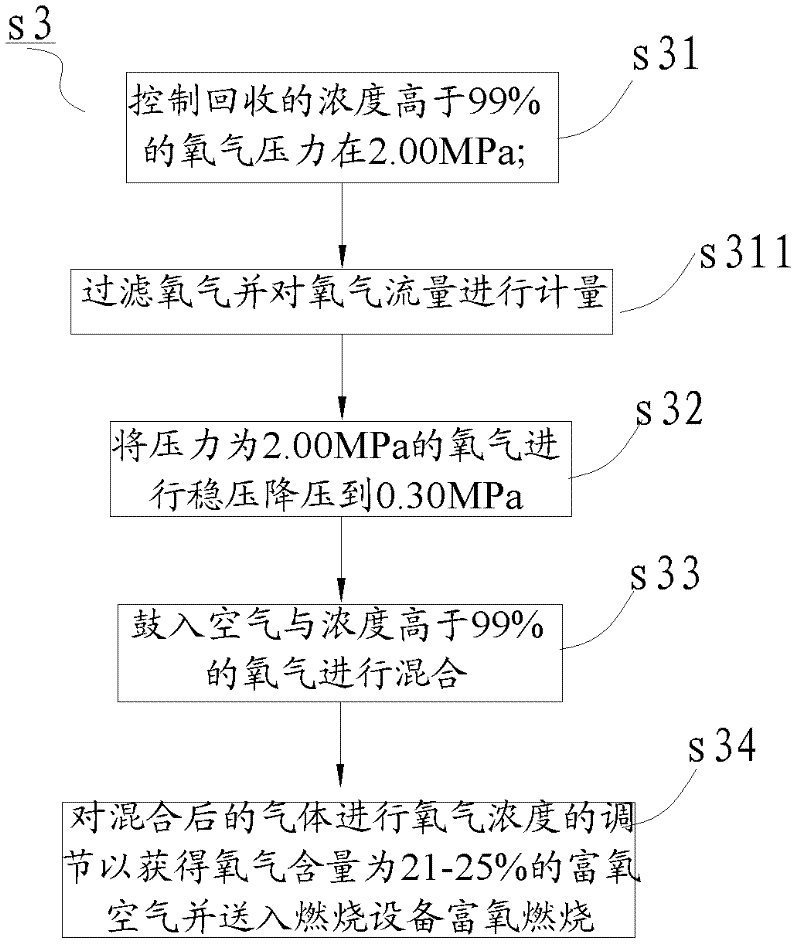

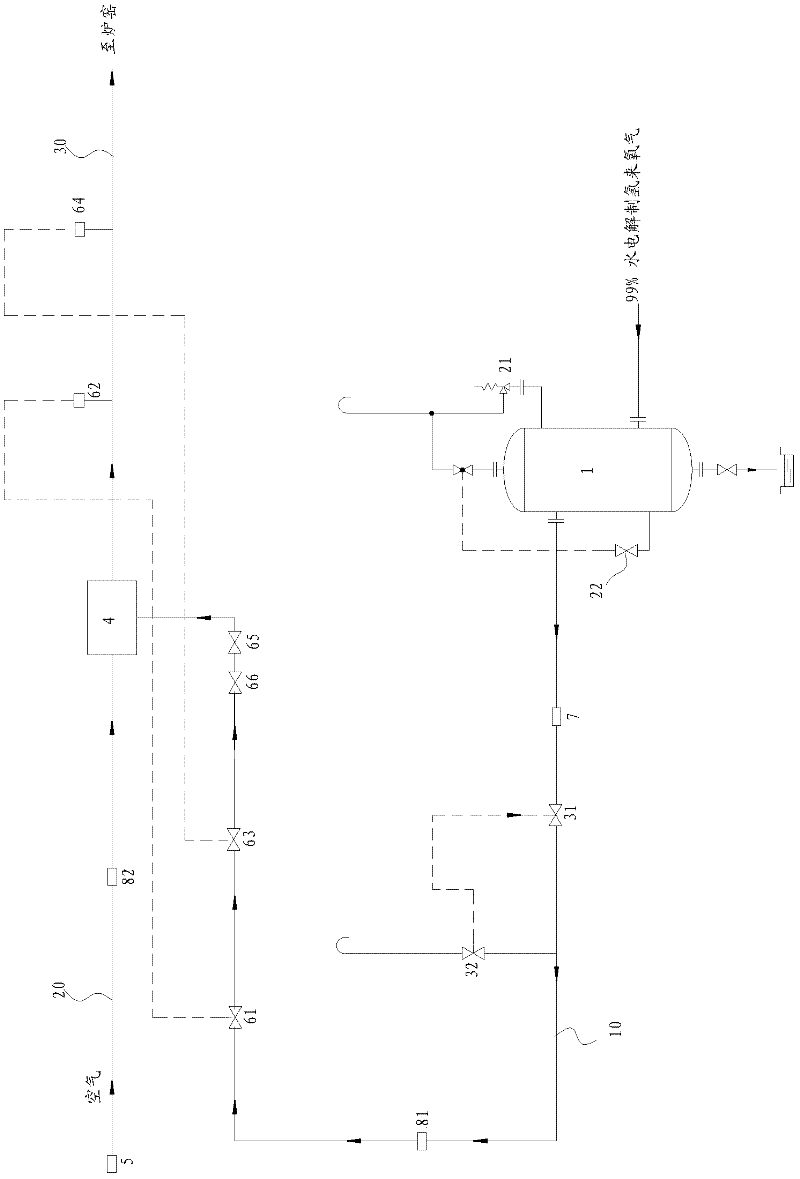

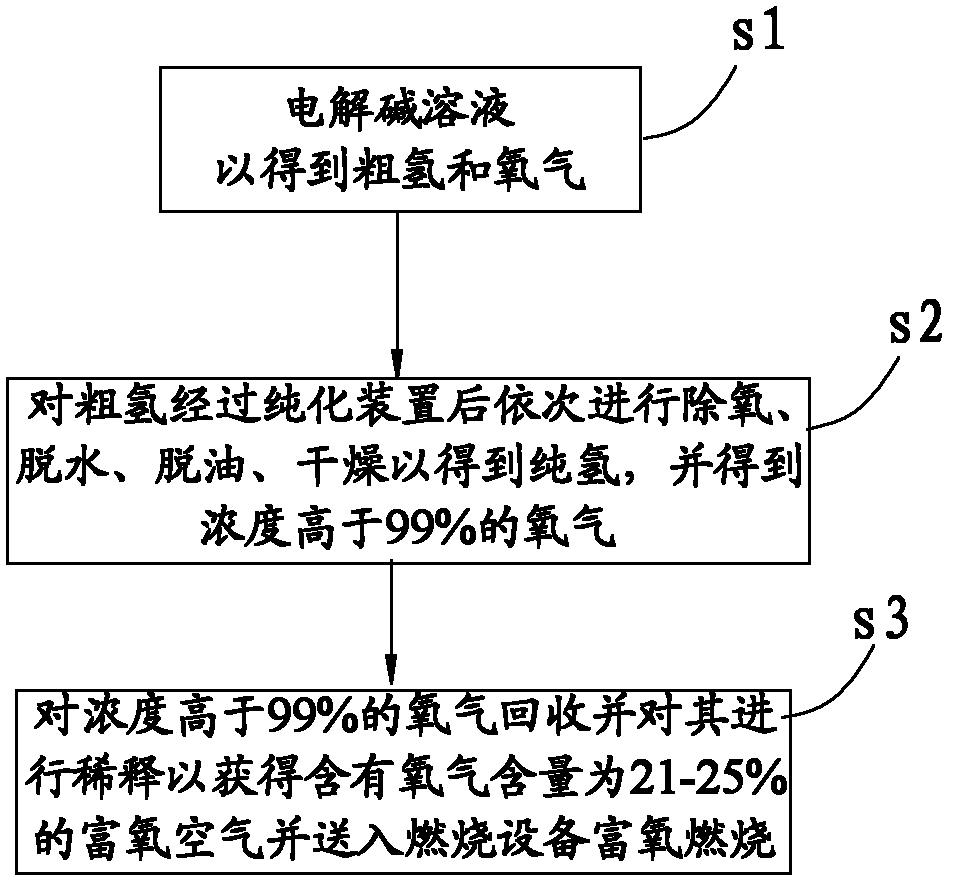

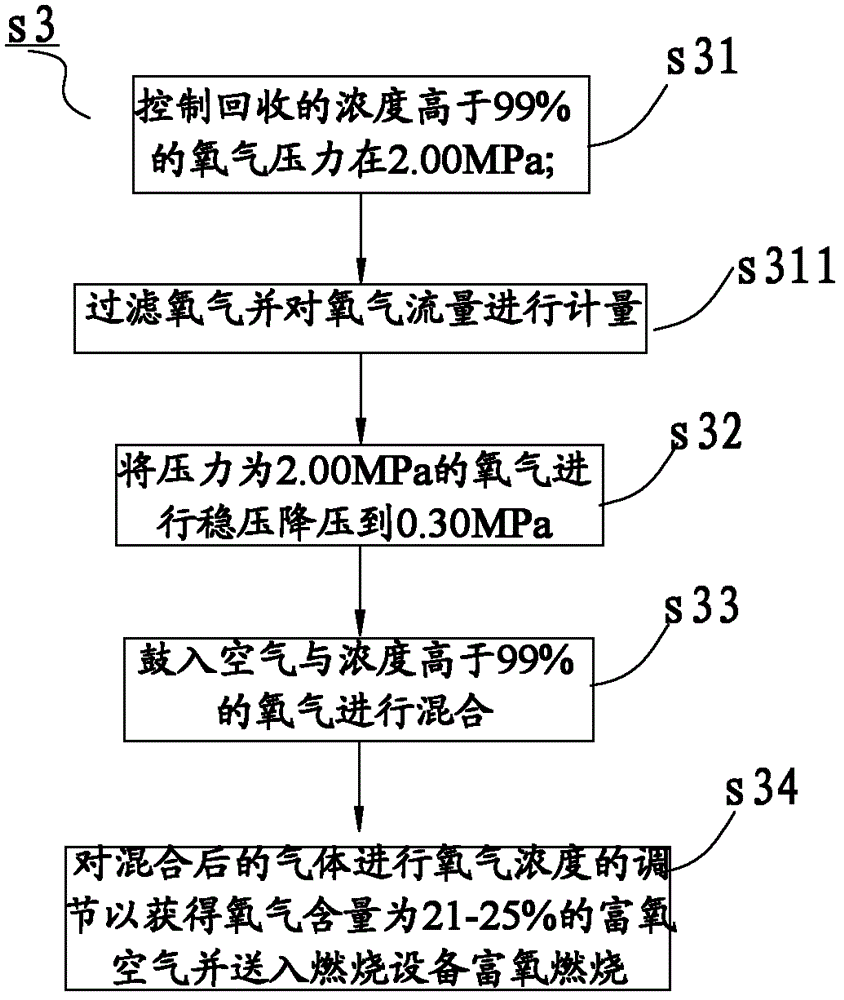

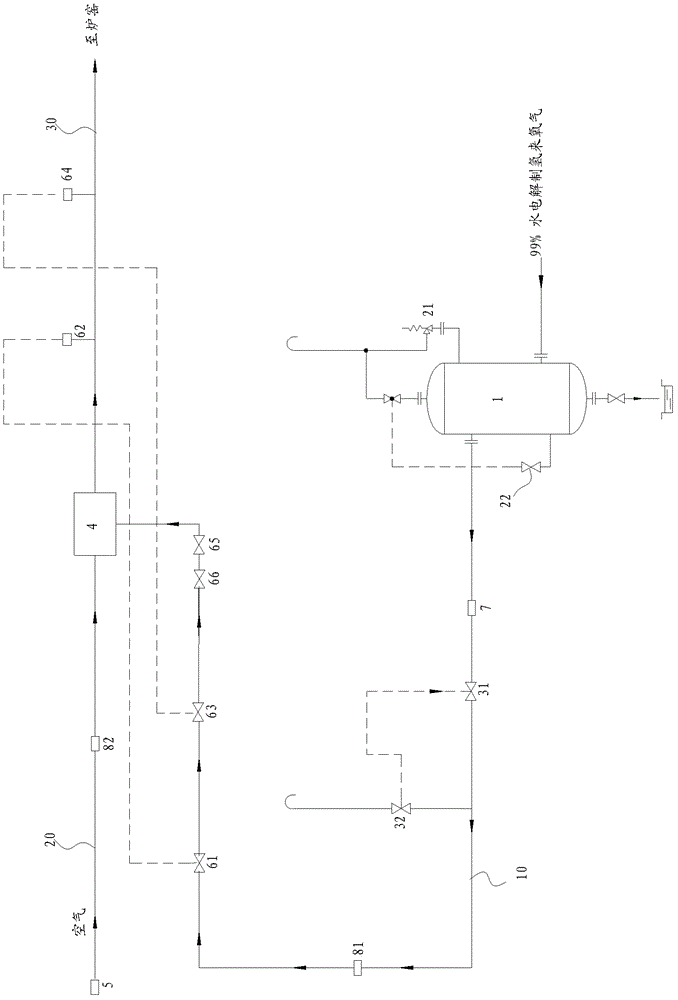

Electrolytic Hydrogen Production Process and Oxygen Recovery System in Polysilicon Production

ActiveCN102296321AReduce manufacturing costRealize energy saving and consumption reductionElectrolysis componentsHydrogen separationElectrolysisOxygen content

The invention discloses an electrolytic hydrogen production process during production of polysilicon. The electrolytic hydrogen production process during the production of the polysilicon comprises the following steps of: electrolyzing alkaline solution to obtain coarse hydrogen and oxygen; allowing the coarse hydrogen to pass through a purification device; deoxidizing, dehydrating and drying thecoarse hydrogen to obtain pure hydrogen with purity of higher than 99.999 percent and oxygen at the concentration of higher than 99 percent; recovering and diluting the oxygen at the concentration ofhigher than 99 percent to obtain oxygen-enriched air with the oxygen content of 21 to 25 percent; and feeding the oxygen-enriched air into combustion equipment to perform oxygen-enriched combustion. According to the electrolytic hydrogen production process during the production of the polysilicon of the embodiment of the invention, the byproduct, namely the high-purity oxygen during electrolytic hydrogen production is recycled and not directly discharged, so energy is saved, energy consumption is reduced, and manufacturing cost of the oxygen applied to oxygen-enriched combustion is saved. Theinvention also discloses an oxygen recovery system applied to the electrolytic hydrogen production process during the production of the polysilicon.

Owner:CHINA ENFI ENGINEERING CORPORATION

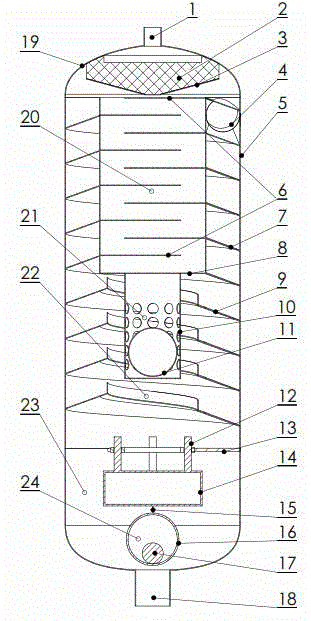

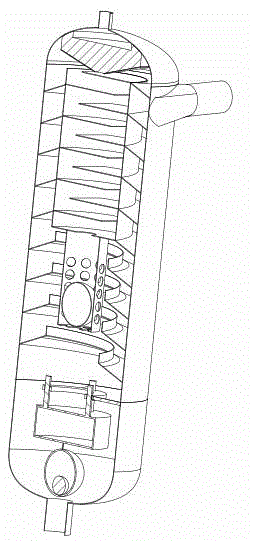

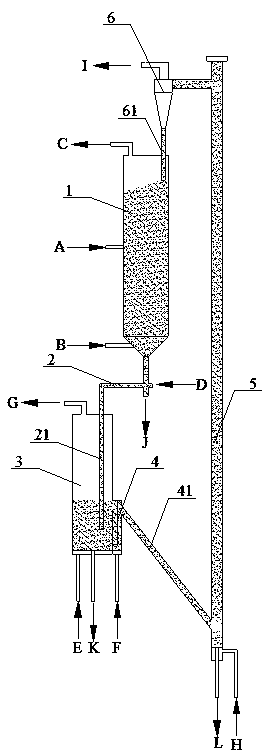

Compound anti-channeling gas-liquid separator

InactiveCN102974187AGuaranteed pureCompact structureCombination devicesVapor–liquid separatorAutomatic control

The invention discloses a compound anti-channeling gas-liquid separator. The technical scheme of the invention is as follows: the top end of a vertically-arranged cylindrical shell is provided with a top cover, the upper part of the shell is provided with a feed inlet, the inner side of the shell is provided with a spiral duct, the inlet of the spiral duct is connected with the feed inlet, the lower end of the shell is provided with a liquid collecting cavity, and a central shaft is provided with a cylindrical gas cavity; the upper end of the top cover is provided with an exhaust pipe, the center of the inside surface of the top cover is provided with an adsorption filter, and the bottom of the adsorption filter is provided with an inverted conical partition plate; the top of the liquid collecting cavity is provided with a centralizer, the center of the liquid collecting cavity is provided with a drainage automatic control valve, and the lower end of the liquid collecting cavity is provided with a drainage pipe; and the inner wall surface of a gas cavity is provided with a horizontal baffle plate, the bottom of the gas cavity is provided with a gas-liquid cavity partition plate, the center of the gas-liquid cavity partition plate is provided with a gas guide hole, and the lower end of the gas-liquid cavity partition plate is provided with an exhaust automatic control valve. The compound anti-channeling gas-liquid separator disclosed by the invention is compact in structure; various separation mechanisms such as centrifugal separation, impact, condensed capturing, gravity separation, adsorption filtration and inertial separation are integrated in one separator; and the separator has a function of preventing gas and liquid from channeling, and can meet the efficient separation of gas and liquid.

Owner:邢学军

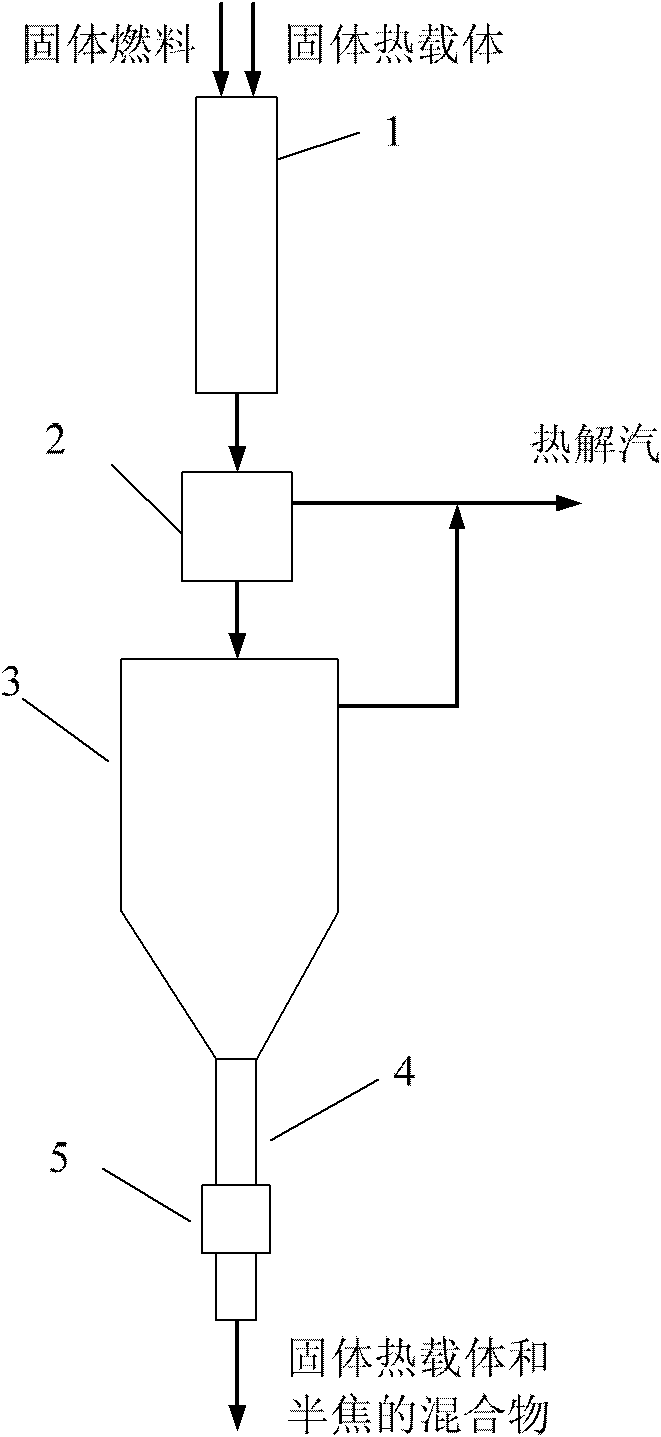

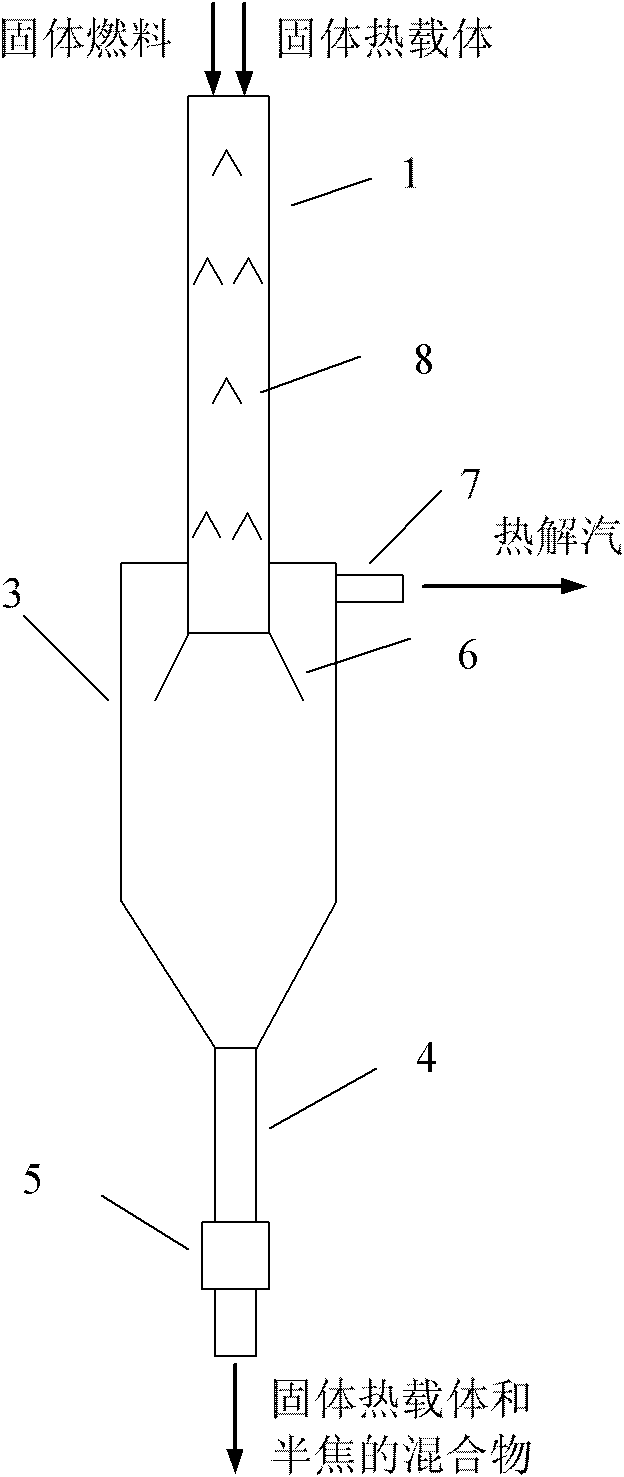

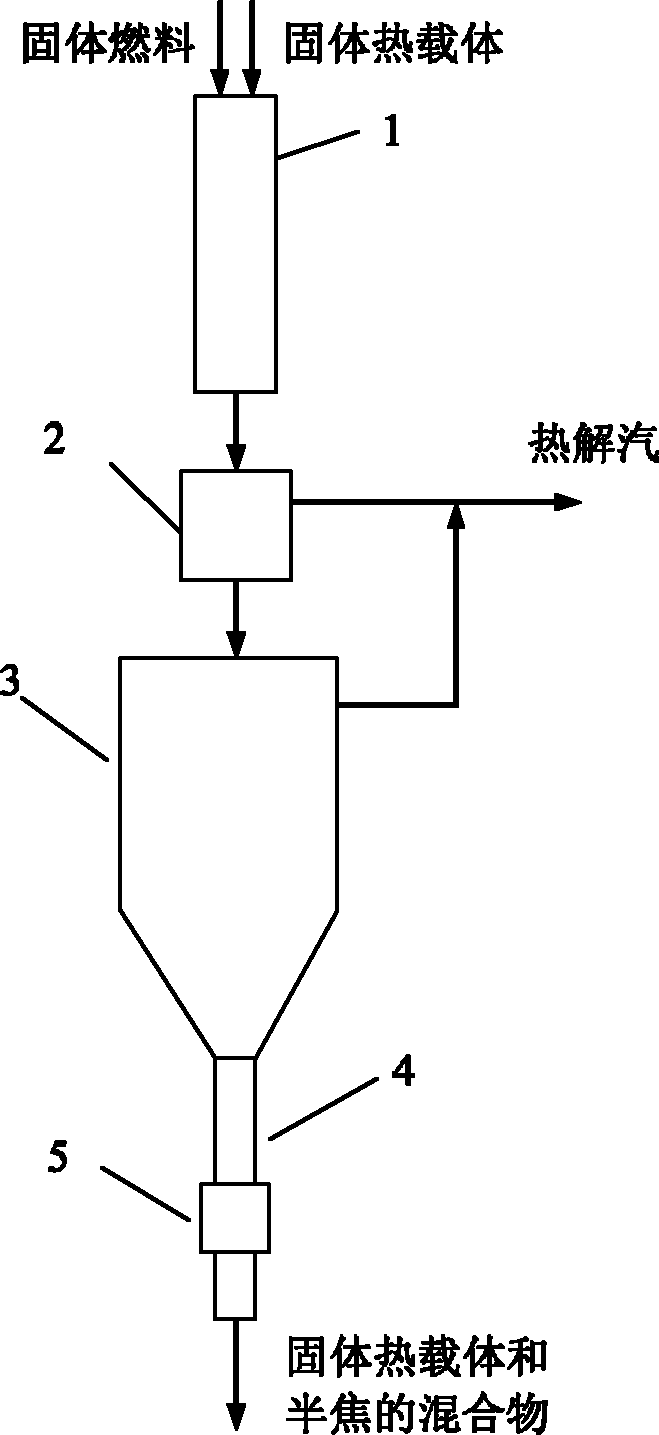

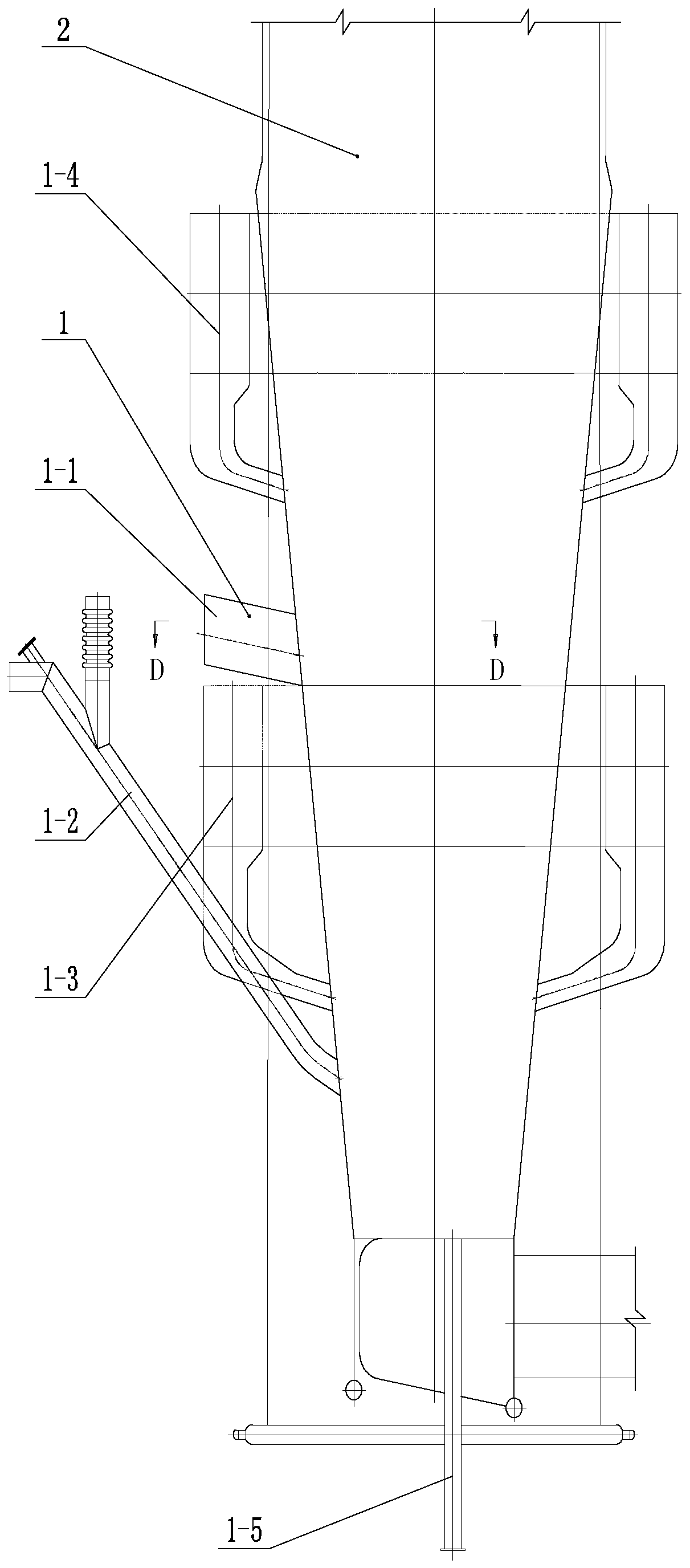

Downer-moving bed coupling pyrolysis reaction device

InactiveCN102653682AThe process is simple and reliableImprove thermal efficiencyDirect heating destructive distillationBiofuelsLiquid productGas phase

The invention relates to a downer-moving bed coupling pyrolysis reaction device. The pyrolysis reaction device comprises a downer reactor (1) and a moving bed reactor (3), wherein the mixture of a solid thermal carrier and solid fuel isolated from the bottom of the downer reactor (1) further enters the moving bed reactor (3) to enable the solid fuel and the solid thermal carrier to be fully mixed and transfer heat for pyrolysis, pyrolysis gas generated by pyrolysis enters a subsequent quenching device through a pyrolysis gas outlet (7) at the upper end of the moving bed reactor (3), and products - liquid fuel and coal gas are obtained after condensation. The downer-moving bed coupling pyrolysis reaction device has the advantages that by adopting the device, the residence time of gas phase can be controlled within 1 second, the residence time of solid fuel particles can be prolonged by tens of minutes, the yield of the liquid product can be increased by about 20% to the maximum extent, the whole process is simpler and more reliable, and the thermal efficiency is higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Waterproof leak-repairing construction method using non-cured rubber asphalt waterproof paint

InactiveCN110984406ASelf-healingWaterproofUnderground chambersBuild-up roofsMetallic materialsStructural engineering

Provided is a waterproof leak-repairing construction method using non-cured rubber asphalt waterproof paint. The non-cured rubber asphalt waterproof paint has the advantages of self-healing, water seepage prevention, water channeling prevention, aging resistance and never curing. The non-cured rubber asphalt waterproof paint can fill capillary holes and cracks of a base layer, a waterproof layer can be self-repaired when broken, and the water channeling problem of the waterproof layer is solved; the used non-cured rubber asphalt waterproof paint has excellent bonding performance, can be adhered to a wet base surface and can be bonded with wood or metal materials; and the waterproof leak-repairing construction method using the non-cured rubber asphalt waterproof paint can be applied to building roofs, basement top plates and side walls, subways, tunnels, bridges, pipe openings, external corners, internal corners and deformation joints.

Owner:广州百能建筑科技有限公司

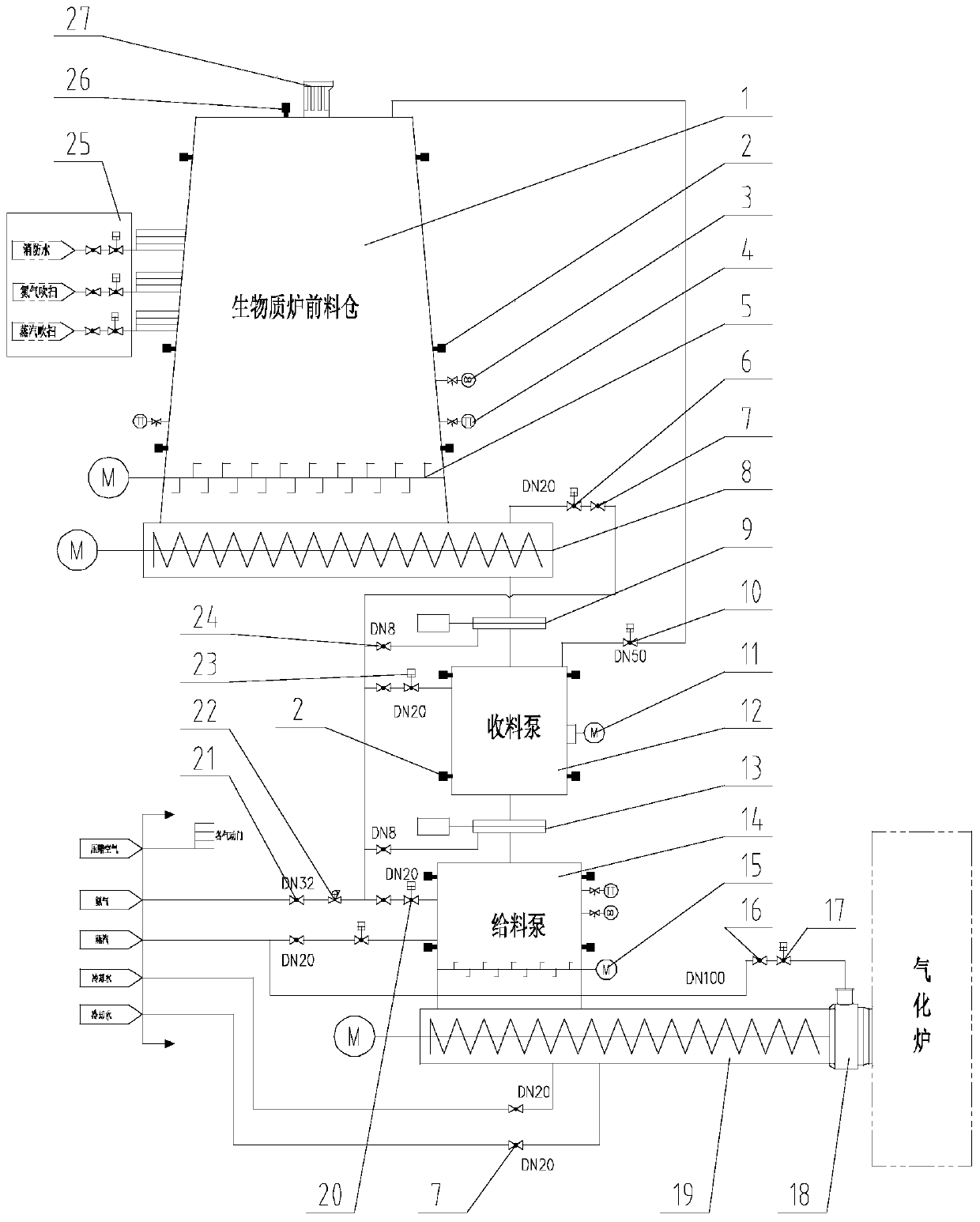

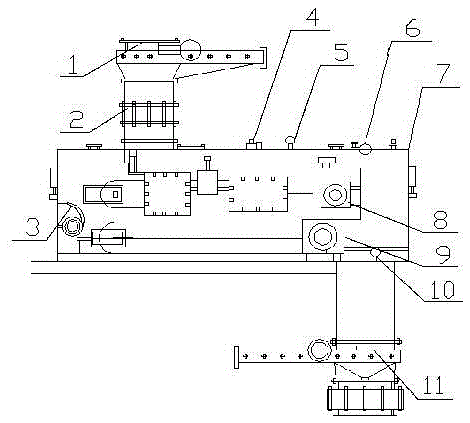

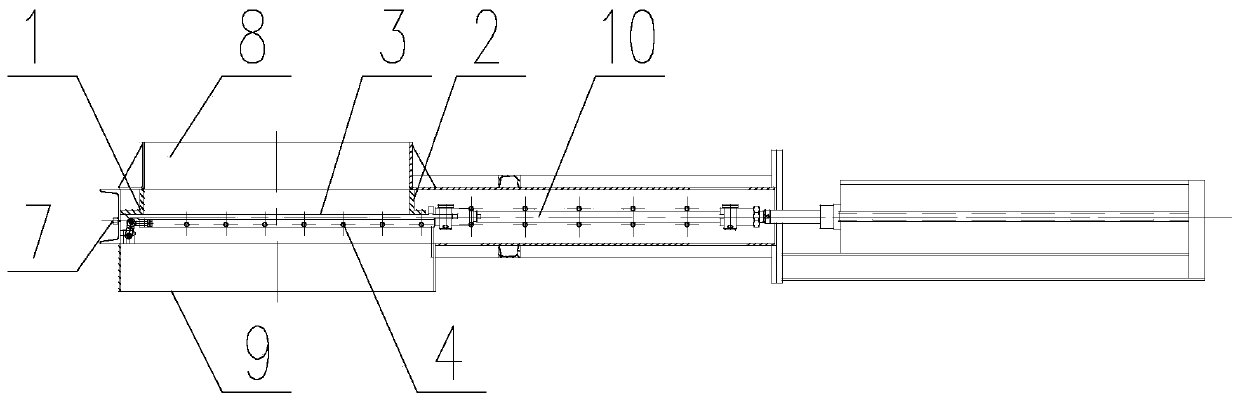

Biomass feeding device

A biomass feed device comprises a biomass furnace front hopper, a double screw feeder, a material receiving pump, a material feeding pump, a single screw feeder and a mixer which are communicated in turn, wherein the biomass furnace front hopper is directly communicated with the shell of the double screw feeder, the bottom of the biomass furnace front hopper has no beveled edge, the material receiving pump and the material feeding pump are two square sealed containers, a material receiving pump feeding valve is arranged at that upper part of the material receiving pump, a material receiving pump discharging valve is arranged at the lower part of the material receive pump, the material entering and leaving are controlled by the material receiving pump feeding valve and the material receiving pump discharging valve, nitrogen is introduced into the material receiving pump and the material feeding pump through a nitrogen master valve, a material receiving pump intake valve and a material feeding pump intake valve, and the mixer is communicated with a gasifier. The technical scheme adopted by the invention solves the problem that the boiler safely and stably transports biomass materialsto the boiler under the positive pressure condition.

Owner:大连森雅能源环保设备有限公司

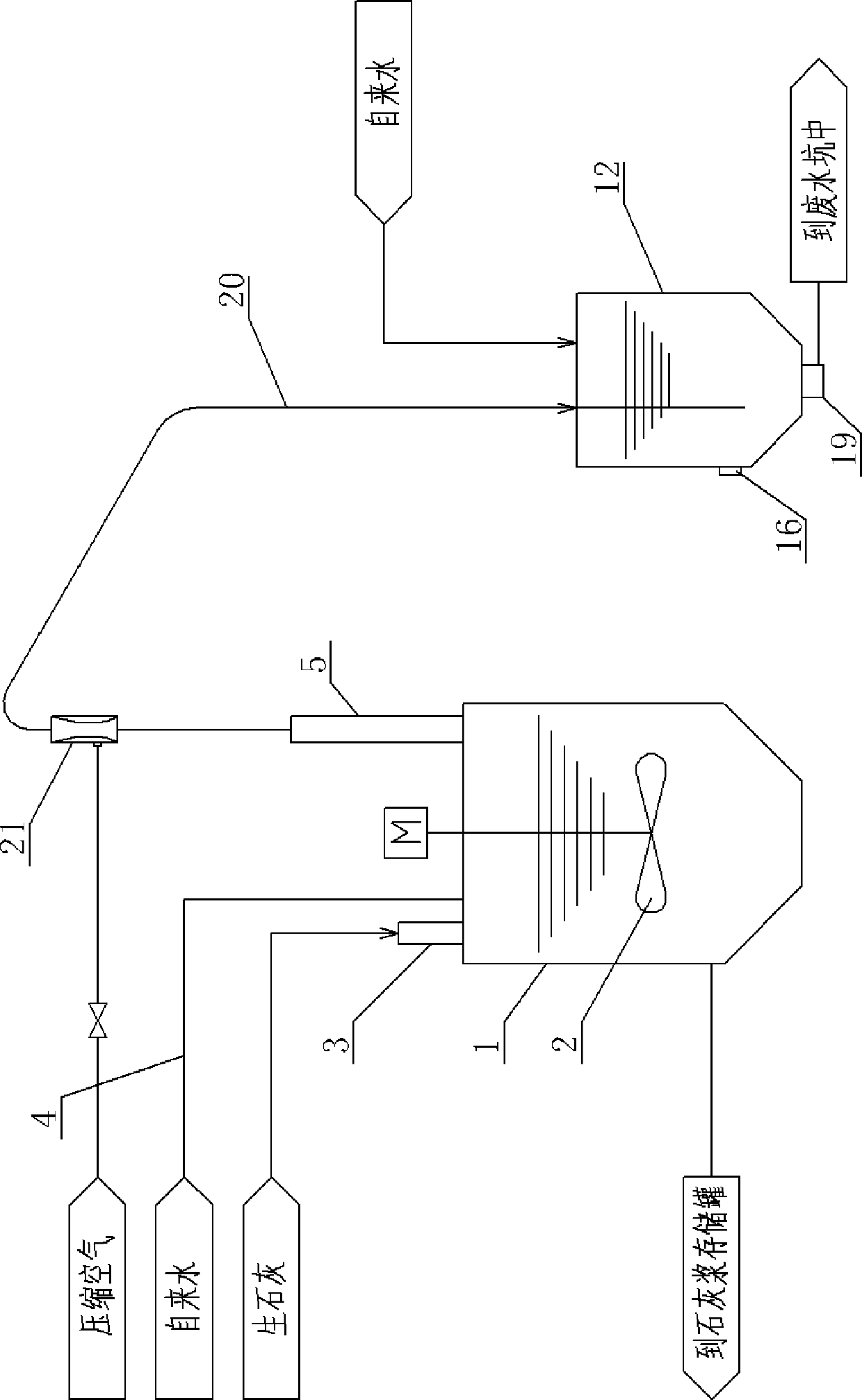

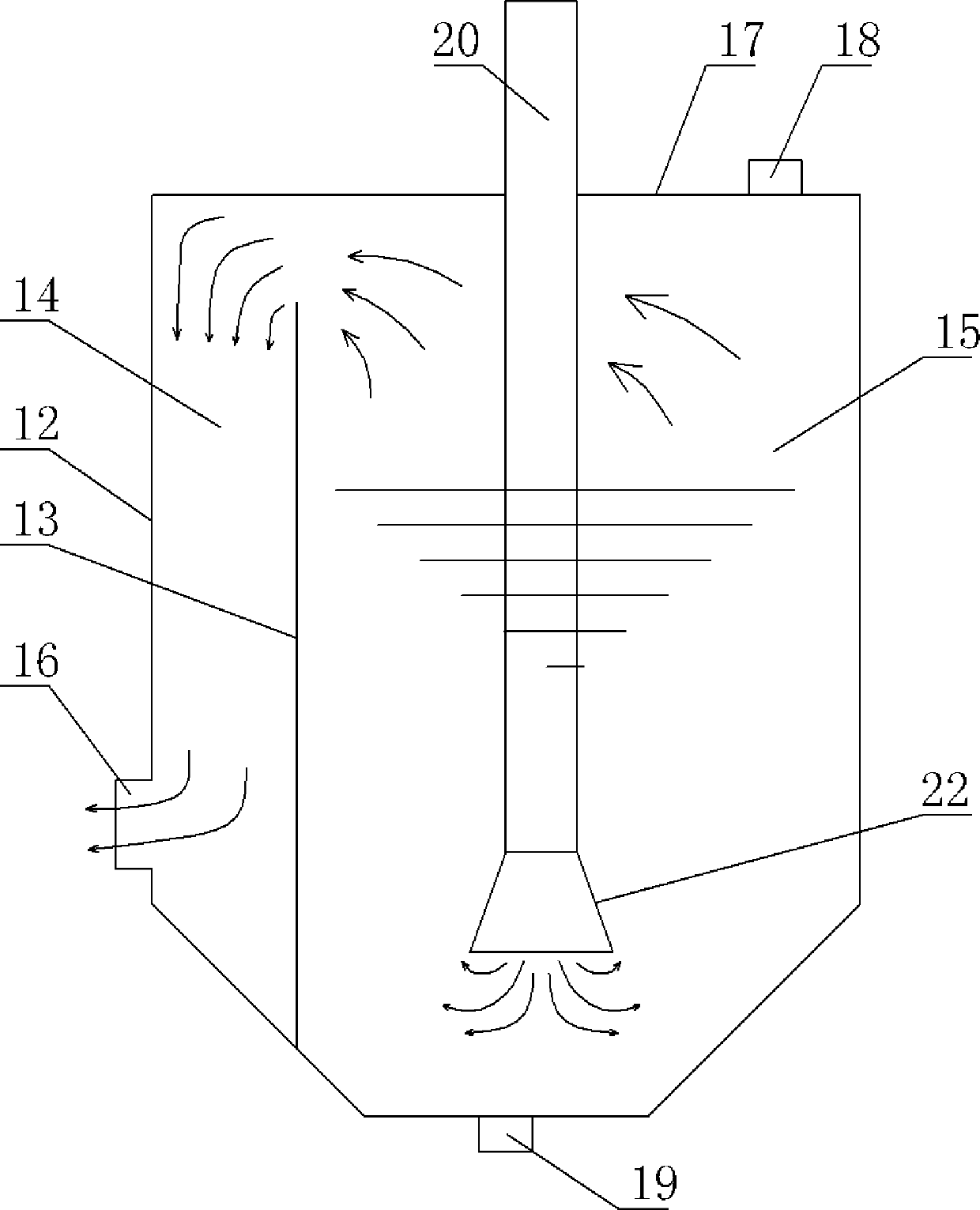

Lime slaking steam treatment device

ActiveCN104193193AGuaranteed uniformityEnsuring sufficient homogeneity of quicklimeUsing liquid separation agentSlurryGuide tube

The invention provides a lime slaking steam treatment device. According to the device, steam in a slaking tank can be smoothly discharged, so that the steam does not enter a lime discharging device, smooth discharging of the lime discharging device is ensured, the discharged steam is purified and discharged into an ambient environment, and environment friendliness is ensured. The lime slaking steam treatment device comprises a quick lime slaking tank, wherein a stirrer is arranged in the quick lime slaking tank; a feeding pipe, a water inlet pipe and a steam exhaust smoke pipe are respectively arranged on the quick lime slaking tank; and an outlet is formed in the bottom of the quick lime slaking tank and is communicated with a lime slurry storage tank. The lime slaking steam treatment device is characterized in that a lime guide tube structure which is closed up from top to bottom is formed in the middle of an inner cavity of the feeding pipe; an air supply hole is formed in an outer wall of the feeding pipe corresponding to the lime guide tube structure; an external air supply pipe is communicated with the air supply hole; the lime slaking steam treatment device further comprises a smoke washing tank which is of a closed structure; and the steam exhaust smoke pipe is communicated with the bottom of the smoke washing tank by virtue of an air delivery pipeline.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

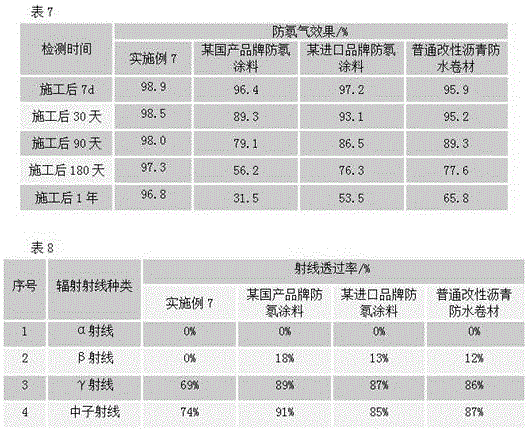

Radon-resisting waterproof roll roofing and preparation method thereof

InactiveCN107177207ACreep Crack ResistantSelf-healingBuilding insulationsPolymer modifiedDip-coating

The invention relates to radon-resisting waterproofing roll roofing. The radon-resisting waterproofing roll roofing is prepared by carrying out roll coating / blade coating / dip coating on a radon radiation resisting modified asphalt compound on a matrix / an isolating membrane, controlling the thickness and setting, laminating, rolling and the like. The radon radiation resisting modified asphalt compound is prepared from 20 to 90 percent of matrix asphalt, 0.1 to 30 percent of polymer modifier, 1 to 50 percent of radon radiation resisting elementary material and 0.1 to 20 percent of additive. The invention also provides a preparation method of the radon-resisting waterproofing roll roofing. The radon-resisting waterproofing roll roofing disclosed by the invention has excellent water-proof property, and the functions of radon radiation resistance, air purification and the like.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

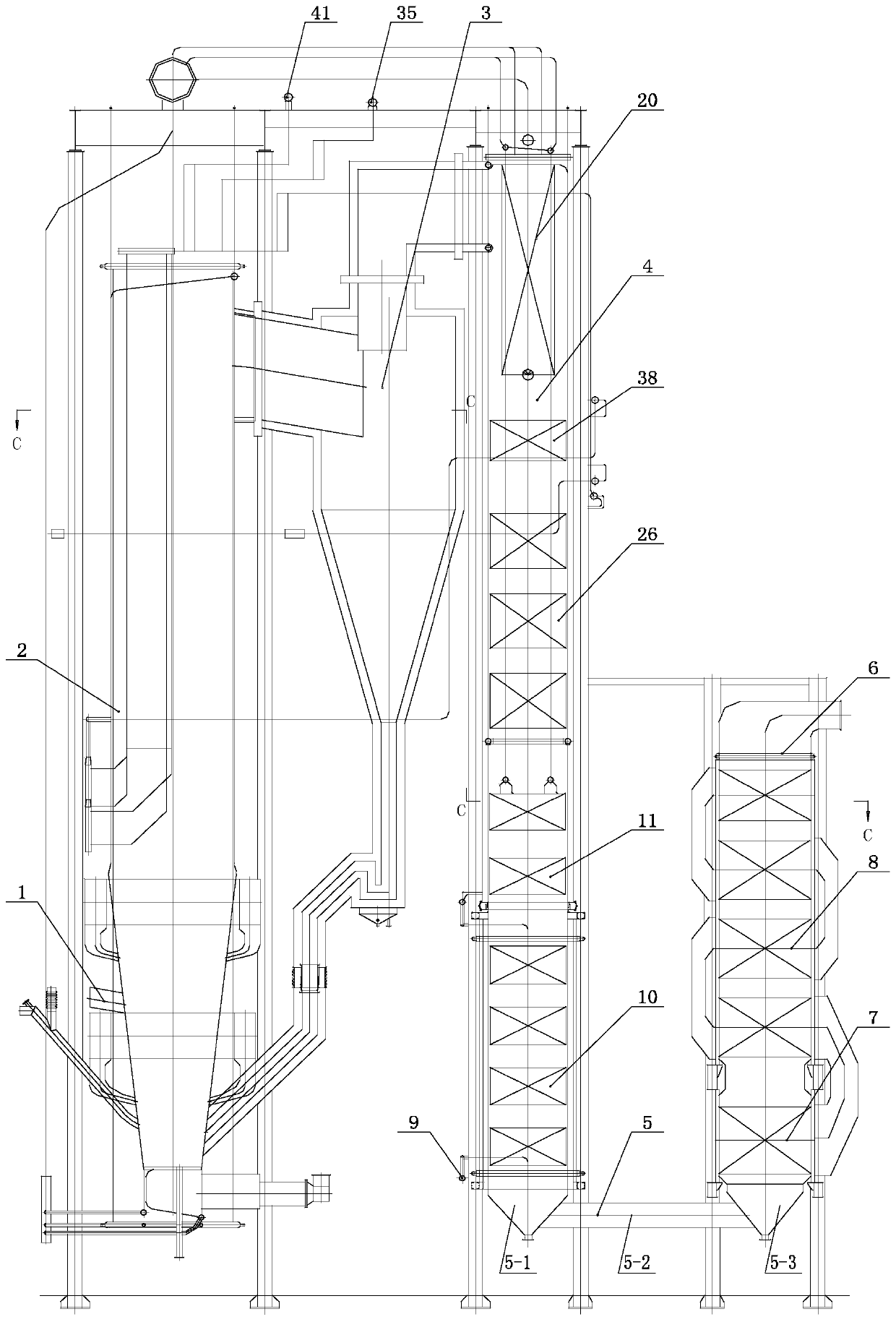

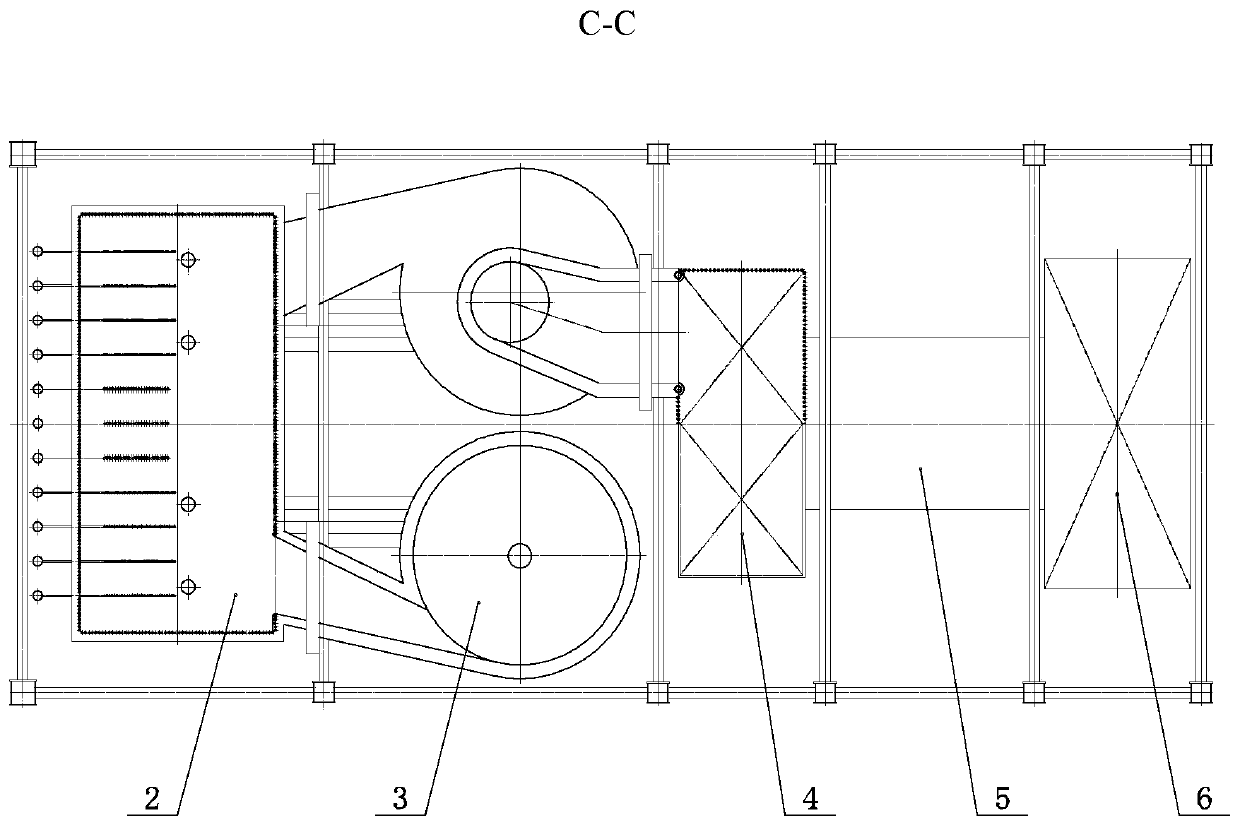

High-temperature and ultrahigh-pressure reheat steam boiler of biomass direct combination energy-conservation circulating fluidized bed

PendingCN110220182AImprove efficiencyEasy dischargeFluidized bed combustionSteam superheatersFailure rateUltra high pressure

The invention discloses a high-temperature and ultrahigh-pressure reheat steam boiler of a biomass direct combination energy-conservation circulating fluidized bed, relates to the high-temperature andultrahigh-pressure reheat steam boiler, in particular to the high-temperature and ultrahigh-pressure reheat steam boiler of the biomass direct combination energy-conservation circulating fluidized bed, and solves the problems of difficult direct combustion of yellow straw biomasses, shorter continuous operation time, low boiler unit efficiency, more pollution discharge, blocked feeding, weak reliability, higher boiler failure rate and difficult biomass formation. A biomass direct combustion system is mounted at the lower part of a hearth; the upper part of the hearth is connected with the upper part of a separation and return system; the lower part of the hearth is connected with the lower part of the separation and return system; a smoke inlet of a first tail flue is connected with the upper part of the separation and return system; and the lower part of the first tail flue is connected with the lower part of a second tail flue through a connecting flue. The high-temperature and ultrahigh-pressure reheat steam boiler of the biomass direct combination energy-conservation circulating fluidized bed belongs to the field of power generation and combined heat and power generation.

Owner:哈尔滨红光锅炉总厂有限责任公司

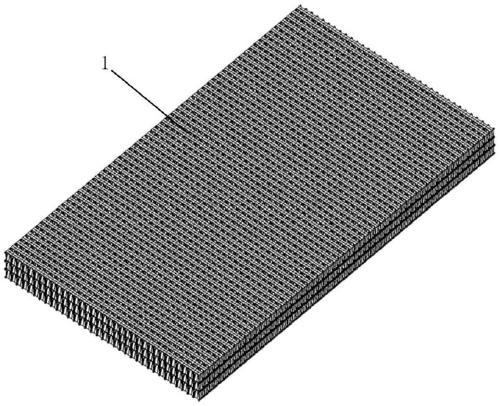

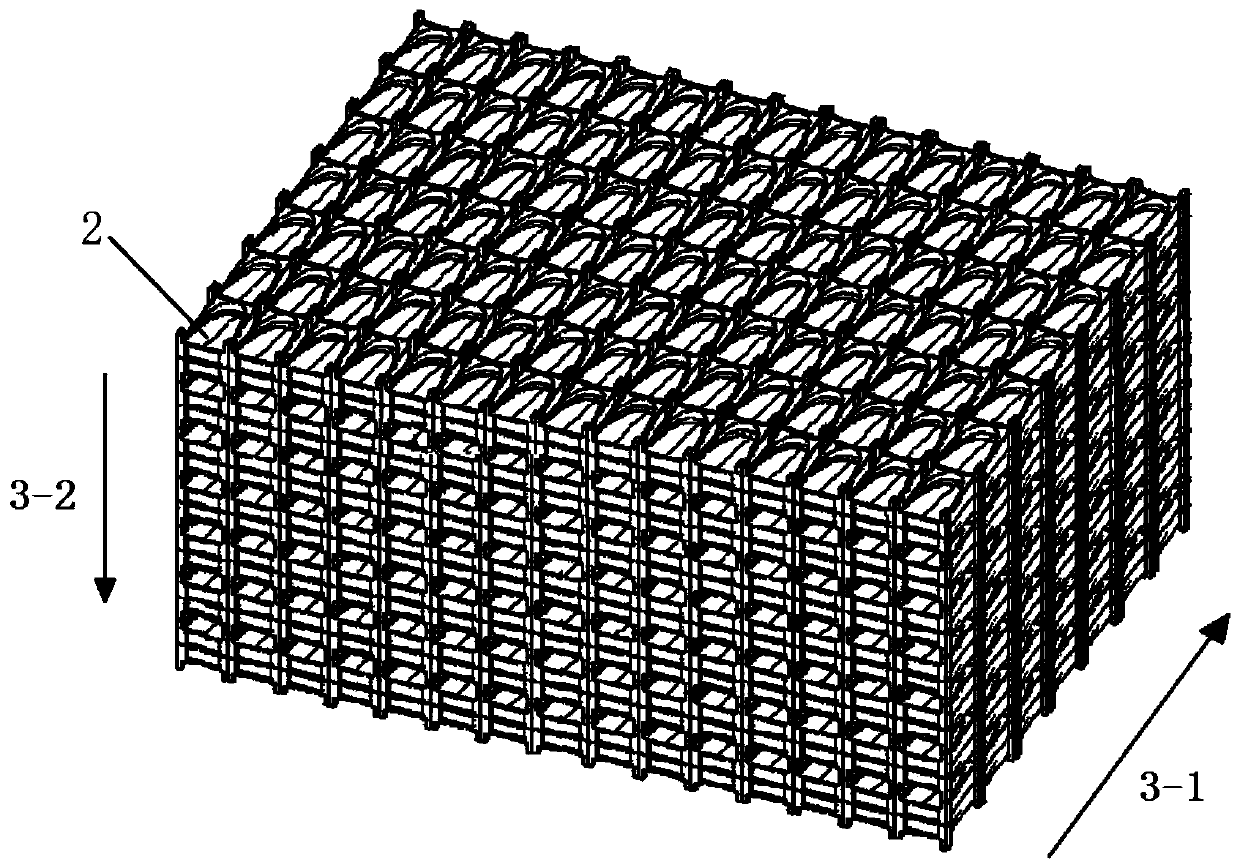

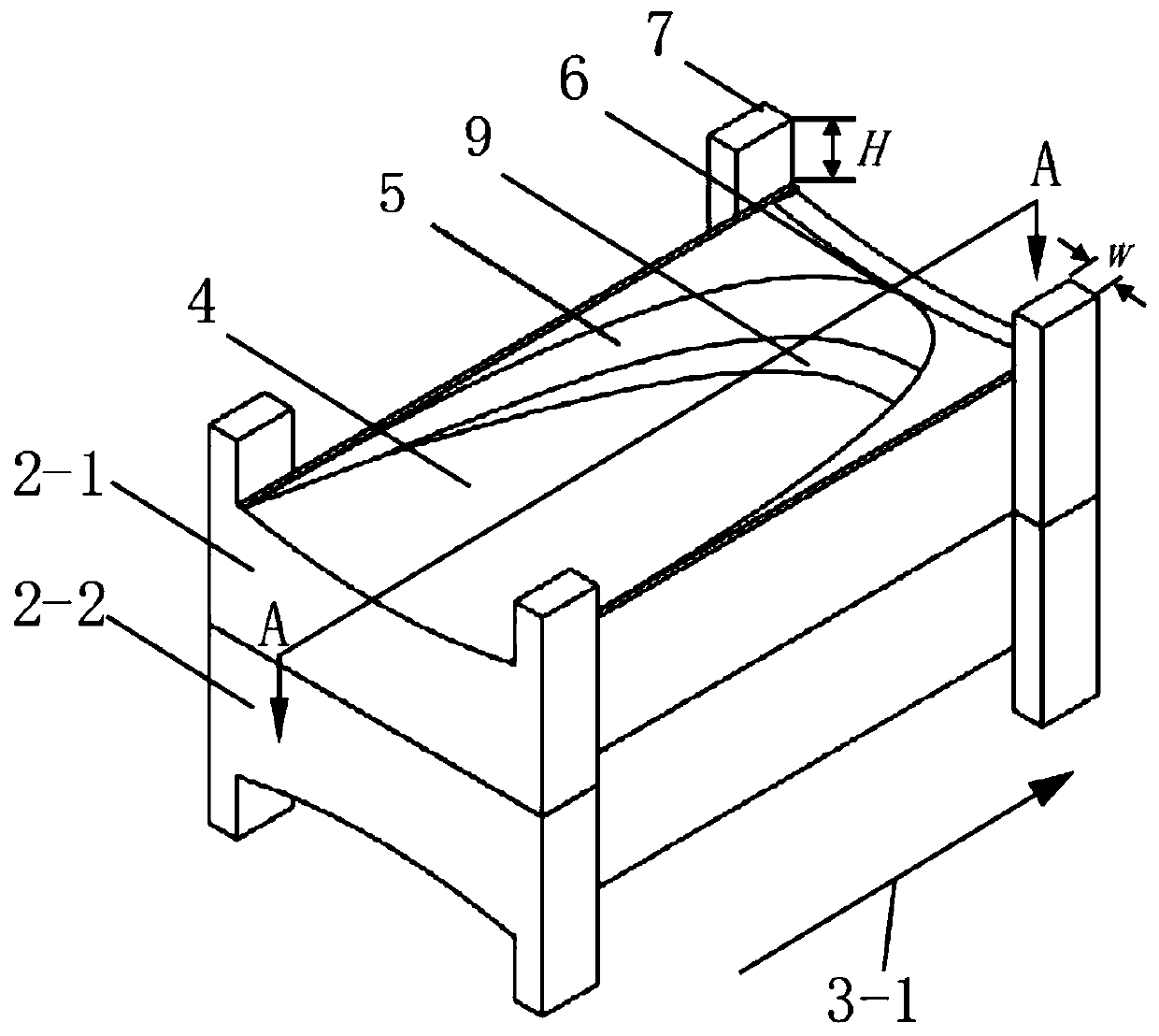

Surface energy gradient bionic liquid absorption core and application thereof

ActiveCN111174615AEnsure normal flowAvoid flowIndirect heat exchangersLoop heat pipeMechanical engineering

The invention discloses a surface energy gradient bionic liquid absorption core and an application thereof. The surface energy gradient bionic liquid absorption core comprises a plurality of bionic units arranged in a 3D array mode. Each bionic unit is provided with a flow guide groove. The projection of each flow guide groove is semi-elliptical. Each flow guide groove comprises a bevel, a curvedsurface and a flange, the bevel is provided with a structure with the gradually increasing groove body depth in the liquid flow direction, the tail end of the bevel is connected with the curved surface, the side, close to the bevel, of the curved surface is a concave surface, the upper end of the curved surface extends back to the bevel to form the flange, and the flange is in smooth connection with the bevel of the next bionic unit. Each bionic unit simulates microstructural features of the surface of common nepenthes. The surface energy gradient bionic liquid absorption core is applied to aloop heat pipe and other phase change radiators. The capillary suction force of the liquid absorption core can be increased, and directional transmission of liquid can be guaranteed. The problems of insufficient capillary suction force and back heat conduction of a loop heat pipe are effectively solved. The surface energy gradient bionic liquid absorption core has great significance in engineeringapplication.

Owner:XIAMEN UNIV

Bidirectional anti-explosion floor drain

InactiveCN103774741AAvoid crossingImprove sealingSewerage structuresShock waveStructural engineering

The invention discloses a bidirectional anti-explosion floor drain, comprising a main body with an upper opening and a lower opening, and a grate with water holes, wherein the inner side of the upper opening of the main body is provided with a plurality of radial concave parts, the outer edge of the grate is provided with a plurality of radial convex parts, and the main body is provided with a locking device for positioning the convex parts on the grate into the concave parts on the main body and then sealing the floor drain. The bidirectional anti-explosion floor drain provided by the invention is simple in structure and reliable in seal, and can prevent being penetrated by shock wave from any direction.

Owner:杜青

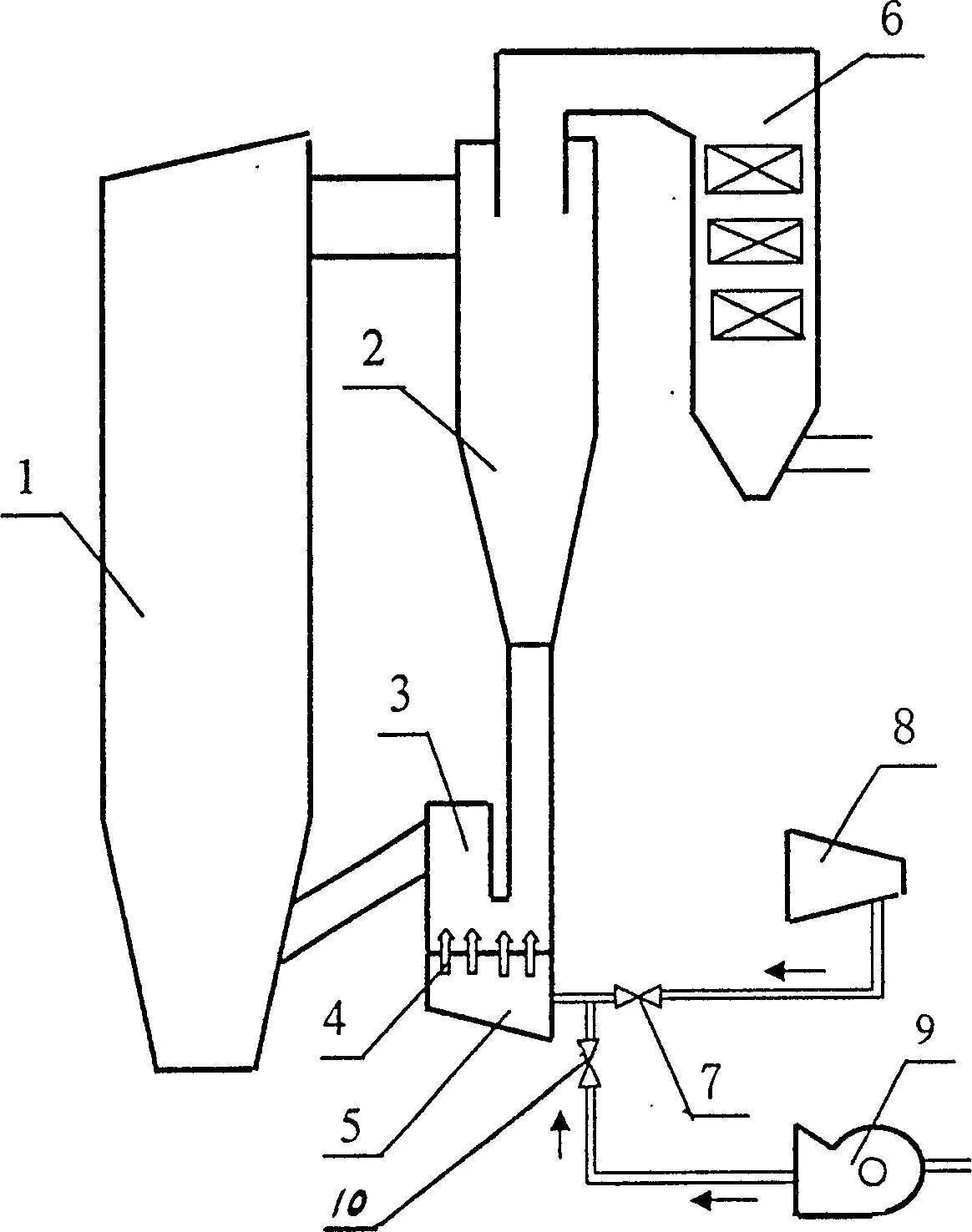

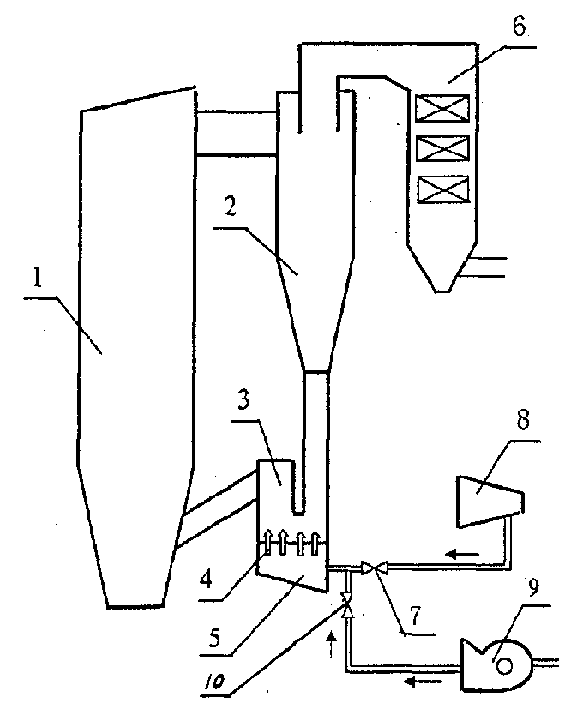

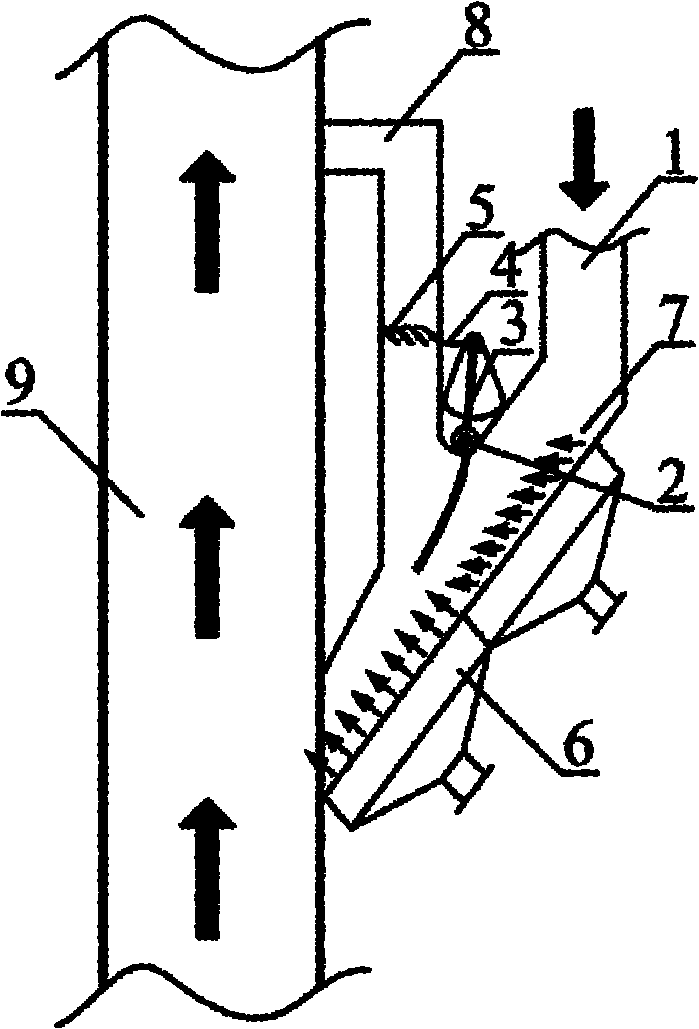

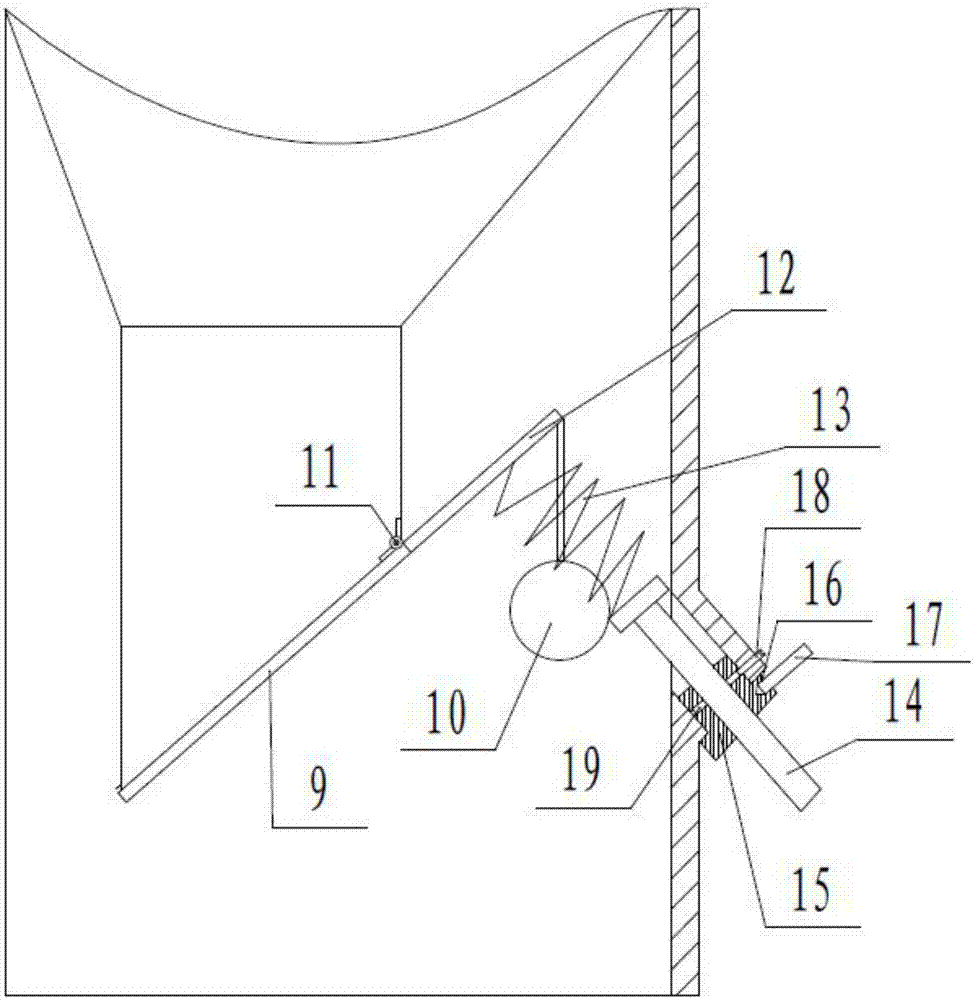

Smoke gas reverse flowing prevention device of biomass circulating fluid bed boiler

InactiveCN101995017AAnti-channelingFlexible adjustmentFluidized bed combustionApparatus for fluidised bed combustionFlueBiomass

The invention discloses a smoke gas reverse flowing prevention device of a biomass circulating fluid bed boiler, which comprises a baiting groove arranged on a hearth, wherein a return flue, a self-balancing smoke baffle door mechanism, a linkage air door mechanism and a two-stage air distribution mechanism are also arranged in the device, one end of the return flue is connected with the top of the baiting groove, the other end of the return flue is connected with a negative pressure region of the upper part of the hearth, the self-balancing smoke baffle door mechanism is formed by sequentially and fixedly connecting a baffle plate, a sleeve, a connecting rod and round steel, the linkage air door mechanism is arranged in the return flue and is connected with the round steel in the self-balancing smoke baffle door mechanism through a linkage rod, and the two-stage air distribution mechanism is arranged at the bottom part of the baiting groove. The smoke gas reverse flowing prevention device adopts the combined utilization mode of the two-stage air distribution mechanism and the self-balancing smoke baffle door mechanism, the two-stage air distribution mechanism stops the reverse flowing of a small amount of smoke gas, and the self-balancing smoke baffle door mechanism guides a large amount of smoke gas to the negative pressure region of the upper part of the hearth, so the reverse flowing of the smoke gas can be effectively prevented on the basis of realizing the flexible regulation of the whole device.

Owner:SOUTHEAST UNIV

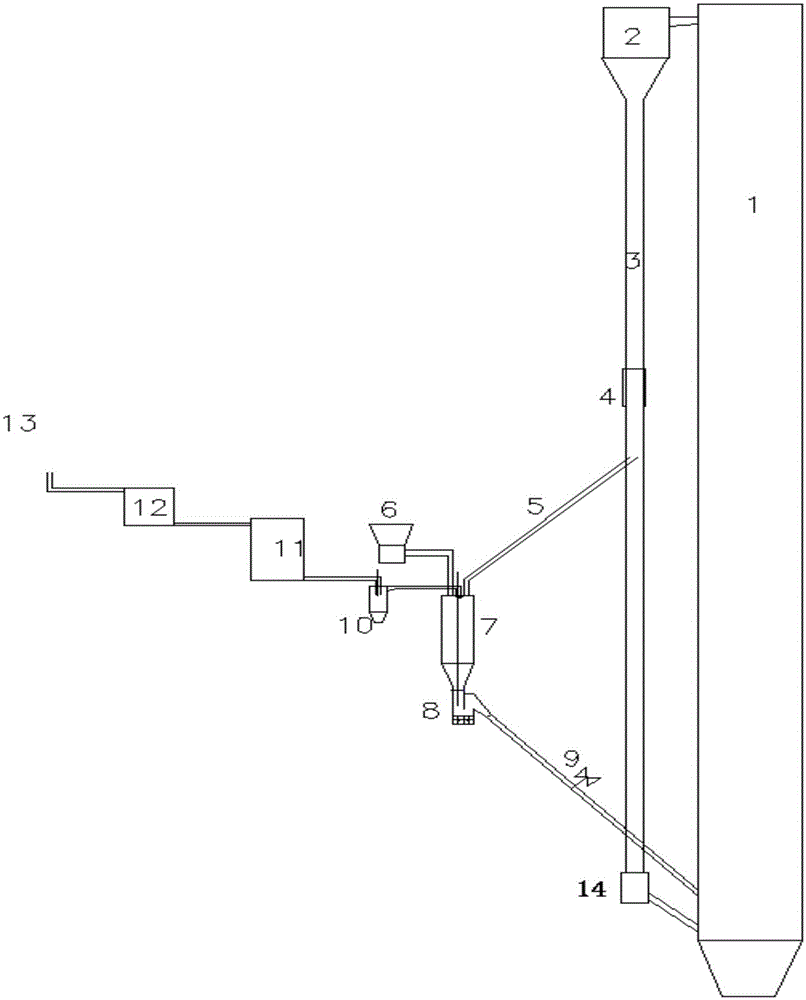

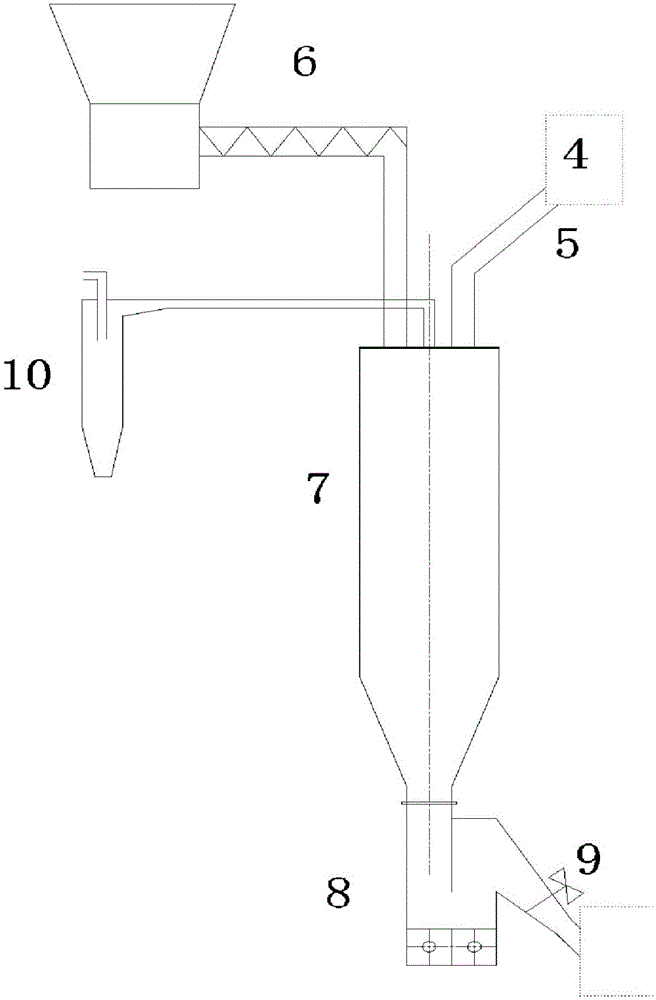

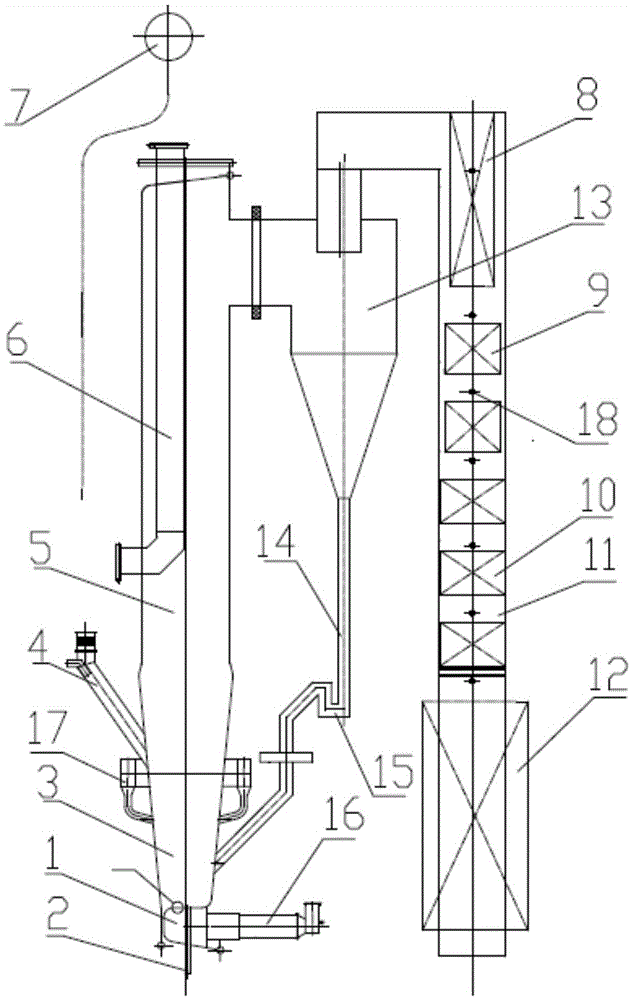

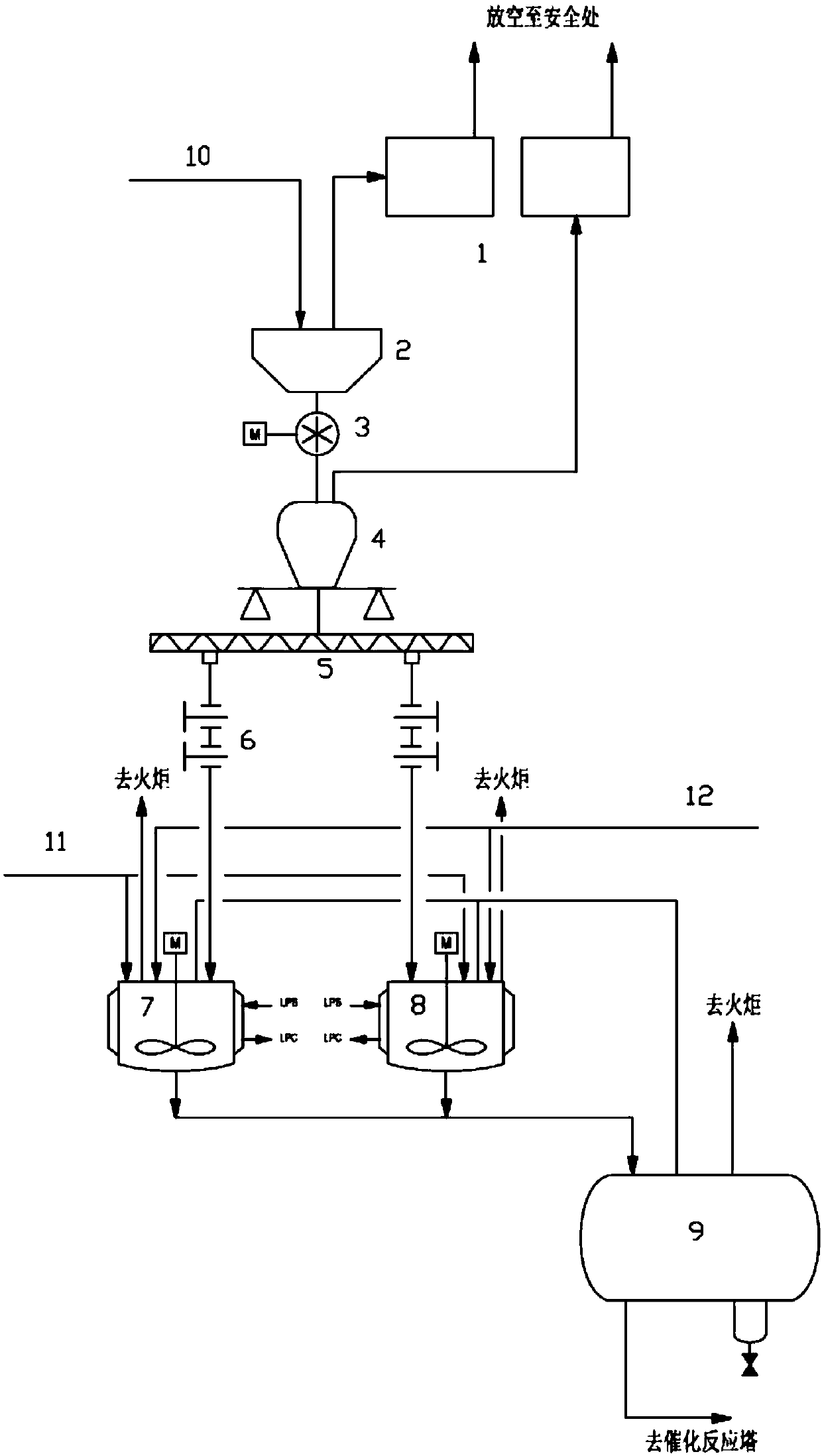

Moving bed coal pyrolysis based polygeneration device and method

InactiveCN105087025ARealize comprehensive utilizationImprove utilization efficiencyFluidized bed combustionDirect heating destructive distillationBoiler furnaceFluidized bed

The invention provides a moving bed coal pyrolysis based polygeneration device and method. The device comprises a circulating fluidized bed (CFB) boiler furnace, wherein the top of the CFB boiler furnace is communicated with a boiler separator; the bottom of the boiler separator is communicated with a riser; the bottom of the riser is communicated with the bottom of the CFB boiler furnace by a boiler return feeder; a hot ash shunting device is arranged in the middle of the riser and is communicated with the top of a moving bed pyrolysis reactor by a moving bed hot ash shunting pipeline; the top of the moving bed pyrolysis reactor is also communicated with a moving bed reactor feeding device and a cyclone dust collector; the cyclone dust collector is also communicated with a coal gas cooler and a coal gas bag-type dust collector in sequence; an outlet of the coal gas bag-type dust collector is connected with a chimney; a moving bed return device is arranged at the bottom of the moving bed pyrolysis reactor and is communicated with the bottom of the CFB boiler furnace by a return pipeline; and a return gate valve is arranged on the return pipeline. The invention also discloses the coal pyrolysis based polygeneration method. A set of polygeneration process of heat, power and gas in systems is achieved by adopting the device and the method.

Owner:HUANENG CLEAN ENERGY RES INST

Novel coal machine communication equipment

InactiveCN105523367AAdaptableSignal delivery is clearControl devices for conveyorsEarth drilling and miningBiochemical engineeringCoal

The invention provides novel coal machine communication equipment which comprises an inlet gate, an adjustable joint coupler, a sealing hole, a dustproof interface, an illuminating lamp, a coal poking hole, a housing, a primary drive box, a cleaning drive box, a material blockage detector and an outlet gate, wherein one side of the inlet gate is provided with the adjustable joint coupler, and the adjustable joint coupler is connected to the surface of the housing; the dustproof interface is arranged on the upper surface of the housing; one side of the dustproof interface is provided with the illuminating lamp, and the illuminating lamp is tightly connected to the housing; one side of the illuminating lamp is provided with the coal poking hole which is embedded into the surface of the housing; the inner part of the housing is provided with the sealing hole, and one end of the sealing hole is communicated with the housing; one side of the coal poking hole is provided with the primary drive box, and the bottom of the primary drive box is connected to the cleaning drive box; one side of the cleaning drive box is provided with the material blockage detector, and the material blockage detector is communicated with the cleaning drive box; and the bottom of the housing is provided with the outlet gate. The novel coal machine communication equipment is simple in design, and is convenient to mount and use.

Owner:WUXI HUISHAN HELI HEAT TRANSFER EQUIP FACTORY

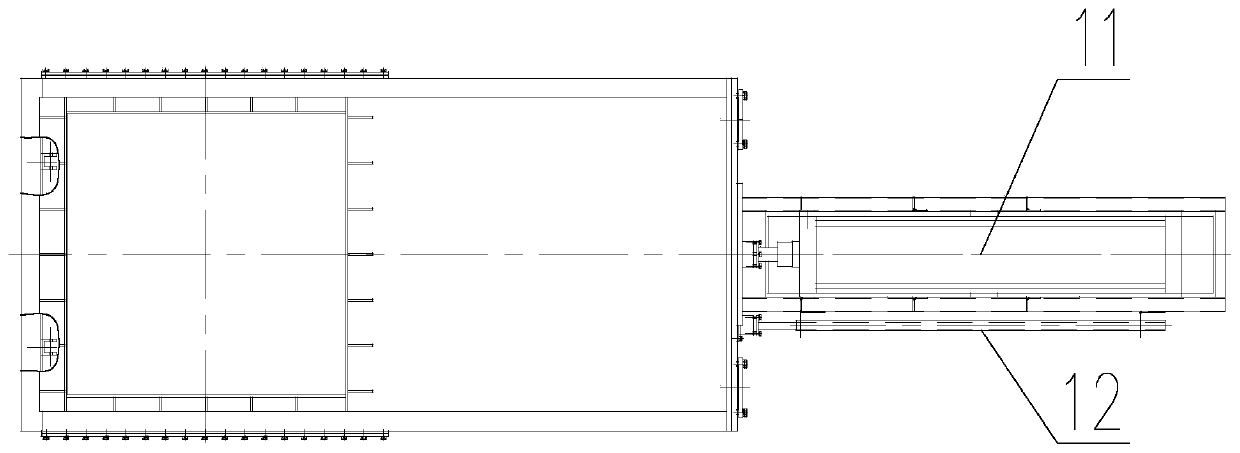

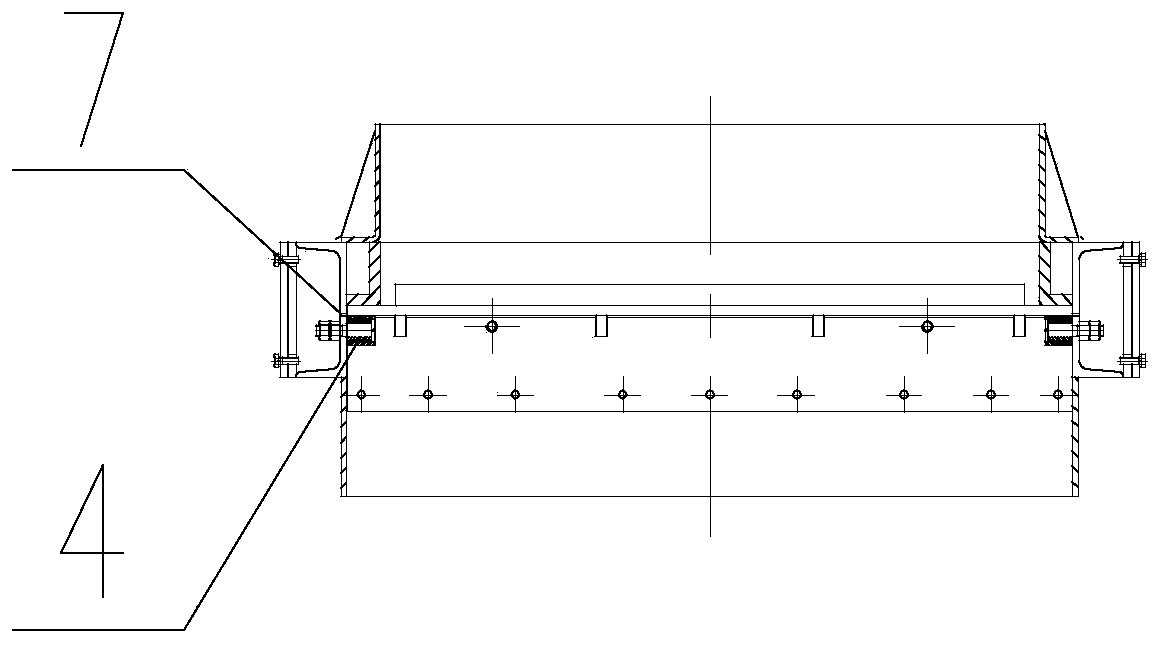

Sealing flashboard door for biomass feeding

PendingCN111473125AAnti-channelingGuaranteed zero leakageOperating means/releasing devices for valvesSlide valveStructural engineeringMechanical engineering

The invention relates to a sealing flashboard door, in particular to a sealing flashboard door for biomass feeding, and solves the problems of poor sealing effect, unsmooth opening and closing, jamming and blockage of an existing flashboard door. The sealing flashboard door for biomass feeding comprises a valve body front end, a valve body rear end, a feed port and a discharge port, wherein the valve body front end and the valve body rear end are both positioned at the front end and the rear end inside a valve body, the feed port is fixedly installed between the front end of the valve body andthe rear end of the valve body and located on the upper portion of the valve body, and the discharge port is located on the lower portion of the valve body. The sealing flashboard door for biomass feeding also comprises a plugboard assembly and a locking assembly, the plugboard assembly is in sliding connection with the bottom of the front end of the valve body and the bottom of the rear end of the valve body, and the locking mechanism is connected with the plugboard assembly. The sealing flashboard door can effectively solve the problems of unsmooth opening and closing, jamming, blocking, high failure rate and the like after frequent opening and closing.

Owner:HARBIN BOILER

Hot air protection device for wet-type electrostatic precipitator

ActiveCN106733190AReduce power consumptionPrevent smoke from blowing backExternal electric electrostatic seperatorElectrostatic separation detailsAir volumeElectrostatic precipitator

The invention discloses a hot air protection device, in particular to a hot air protection device for a wet-type electrostatic precipitator, and belongs to the technical field of wet-type electrostatic precipitators. The hot air protection device for the wet-type electrostatic precipitator comprises an insulation barrel body (1), an insulation barrel top cap (2), an insulator body (3), an insulator cover plate (4), an external protection system and an internal protection system (7). A connection chamber hot air duct (10) is arranged on the outer wall of an insulation barrel connection block (10). The connection chamber hot air duct (8) is perpendicular to the outer wall of the insulation barrel connection block (10) and communicates with an insulation barrel connection chamber (13). An insulation barrel inner chamber (12) is separated from the insulation barrel connection chamber (13) through the insulator cover plate (4). The insulator cover plate (4) is an integrated cover plate. The hot air protection device for the wet-type electrostatic precipitator greatly reduces the air volume of a fan and power consumption on an electric heater, prevents flue gas from flowing backwards, and avoids condensation of the insulation barrel and the insulator, and accordingly the stable operation of the wet-type electrostatic precipitator is guaranteed.

Owner:CHINA HUADIAN ENG +1

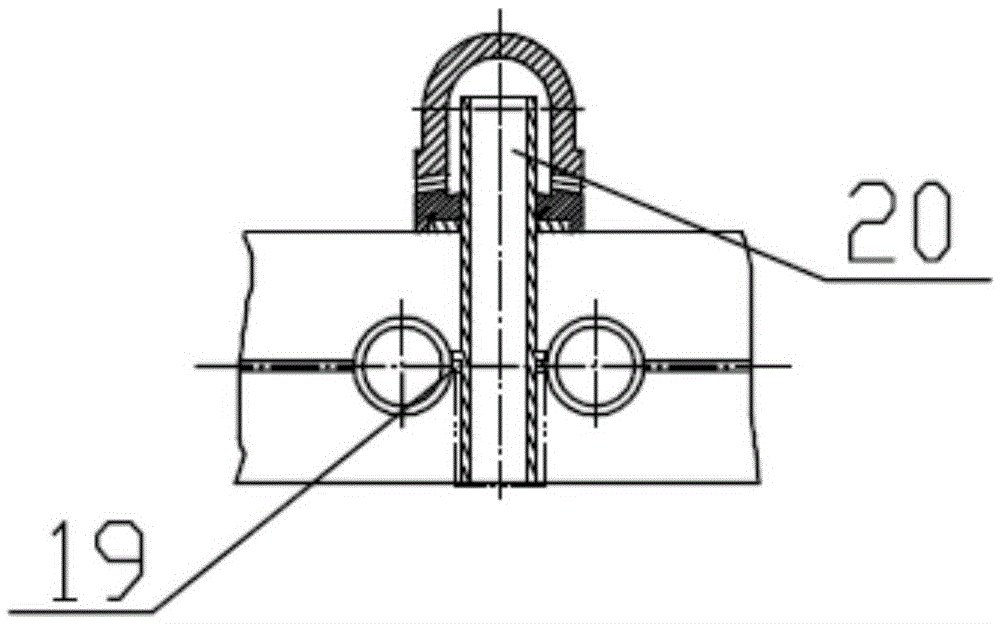

Annular sleeve type gas sealing device for feeding system of positive-pressure biomass gasifier and gas sealing method thereof

InactiveCN109207201AGuaranteed fluencyAnti-channelingGasifier feeding meansGasification processes detailsFlue gasPositive pressure

The invention provides an annular sleeve type gas sealing device for a feeding system of a positive-pressure biomass gasifier and a gas sealing method thereof. In recent years, a biomass gasificationtechnology has become increasingly mature, and a positive-pressure biomass gasification technology has its unique advantages compared with a negative-pressure gasification technology. However, the positive-pressure gasification technology requires sealing of a feeding system due to positive pressure in a furnace so as to prevent positive-pressure toxic and flammable flue gas in the furnace from entering a feeding pipe and causing the problems of leakage and poor feeding. The annular sleeve type gas sealing device of the invention comprises a feeding pipe (3); the orifice of the feeding pipe issleeved with a feeding sleeve (2); a group of cushion blocks (4) are arranged between the feeding pipe and the feeding sleeve, so slits are formed; the feeding sleeve has a group of inert gas inlet pipes (1); and the inert gas inlet pipes communicate with the orifice of the feeding pipe via the slits. The device of the invention is applied to annular sleeve type gas sealing of the feeding systemof the positive-pressure biomass gasifier.

Owner:HARBIN BOILER

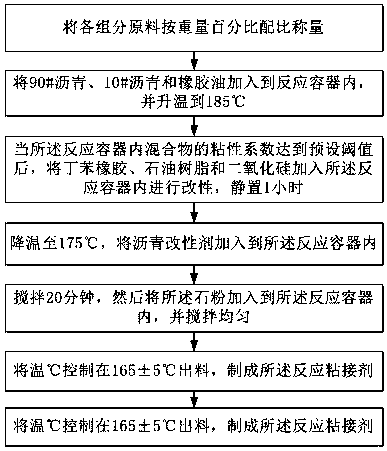

Reaction adhesive and preparation method thereof

The present disclosure relates to a reaction adhesive and a preparation method thereof, the reaction adhesive comprises 90# asphalt, 10# asphalt, rubber oil, SBS, PE, styrene butadiene rubber, petroleum resin, an asphalt modifier, a silane coupling agent, stone powder and silica. By adding of the silane coupling agent and the silica, the asphalt is modified, and by modifying of the characteristicsof the asphalt, when the reaction adhesive is applied, lean concrete grout is first used for paving, and then the reaction adhesive is laid on the surface of cement. During the solidification of thecement, hydration heat is formed, free silica molecules are released, the free silica molecules can be combined with active silica molecules released in the reaction adhesive, chemical bonds are formed in capillary pores of a cement base layer for crosslinking, and the bond strength is improved.

Owner:金华一方金雨伞防水科技有限公司

Electrolytic hydrogen production process during production of polysilicon and oxygen recovery system thereof

ActiveCN102296321BAnti-channelingElectrolysis componentsHydrogen separationElectrolysisPhysical chemistry

The invention discloses an electrolytic hydrogen production process during production of polysilicon. The electrolytic hydrogen production process during the production of the polysilicon comprises the following steps of: electrolyzing alkaline solution to obtain coarse hydrogen and oxygen; allowing the coarse hydrogen to pass through a purification device; deoxidizing, dehydrating and drying thecoarse hydrogen to obtain pure hydrogen with purity of higher than 99.999 percent and oxygen at the concentration of higher than 99 percent; recovering and diluting the oxygen at the concentration ofhigher than 99 percent to obtain oxygen-enriched air with the oxygen content of 21 to 25 percent; and feeding the oxygen-enriched air into combustion equipment to perform oxygen-enriched combustion. According to the electrolytic hydrogen production process during the production of the polysilicon of the embodiment of the invention, the byproduct, namely the high-purity oxygen during electrolytic hydrogen production is recycled and not directly discharged, so energy is saved, energy consumption is reduced, and manufacturing cost of the oxygen applied to oxygen-enriched combustion is saved. Theinvention also discloses an oxygen recovery system applied to the electrolytic hydrogen production process during the production of the polysilicon.

Owner:CHINA ENFI ENGINEERING CORPORATION

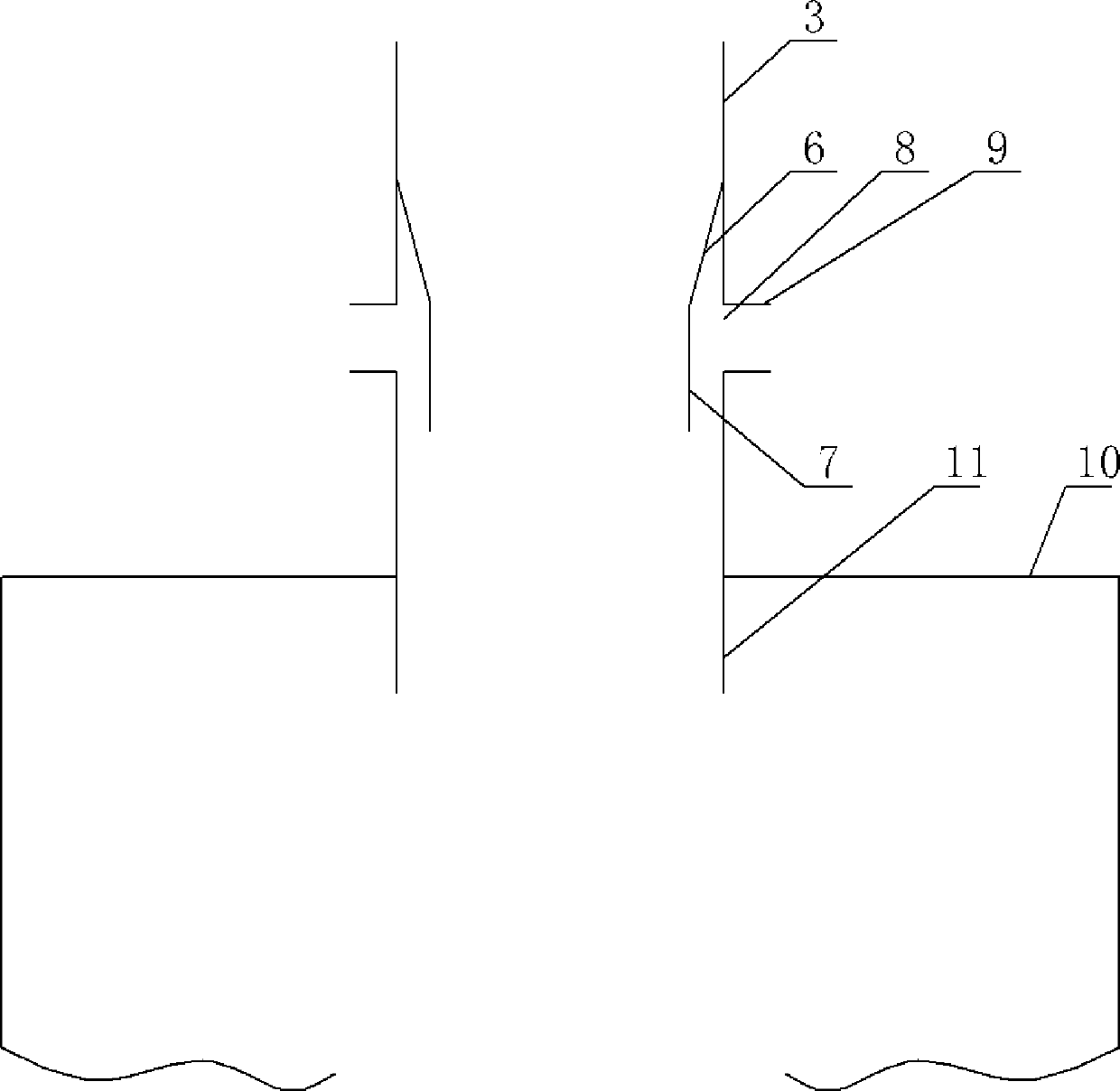

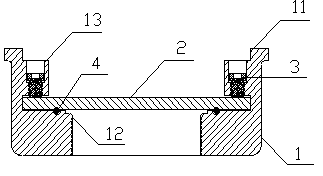

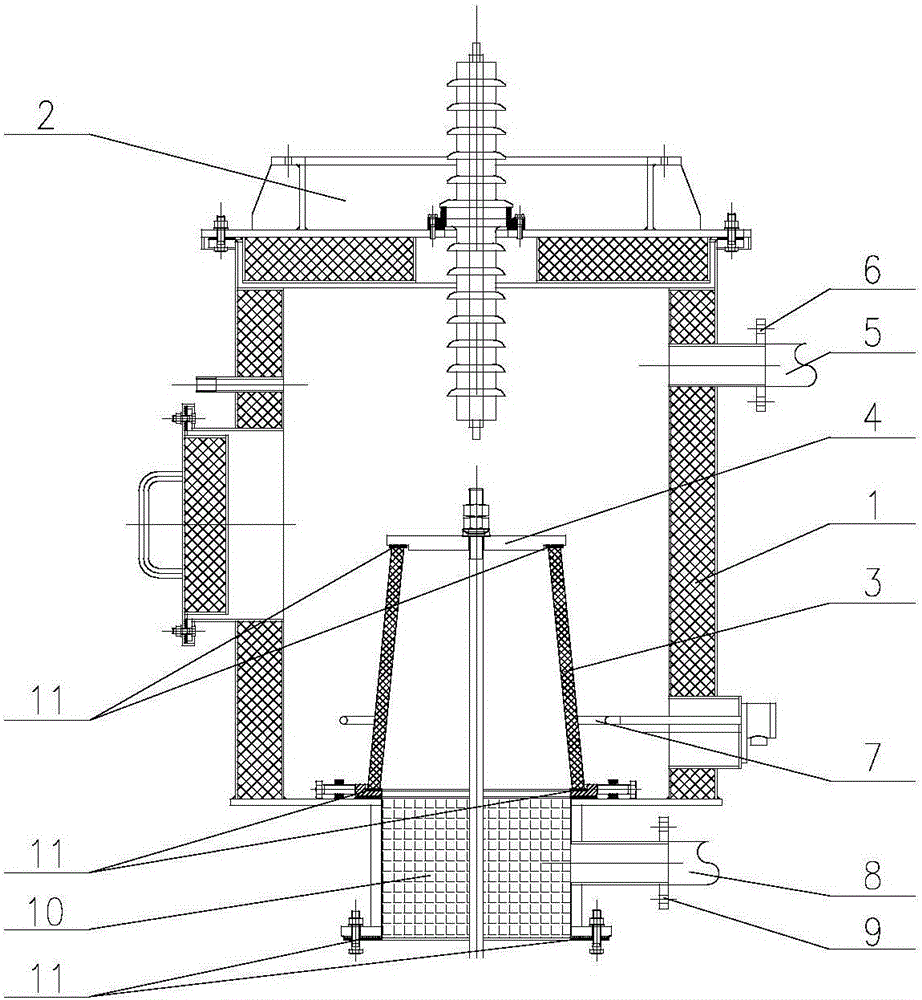

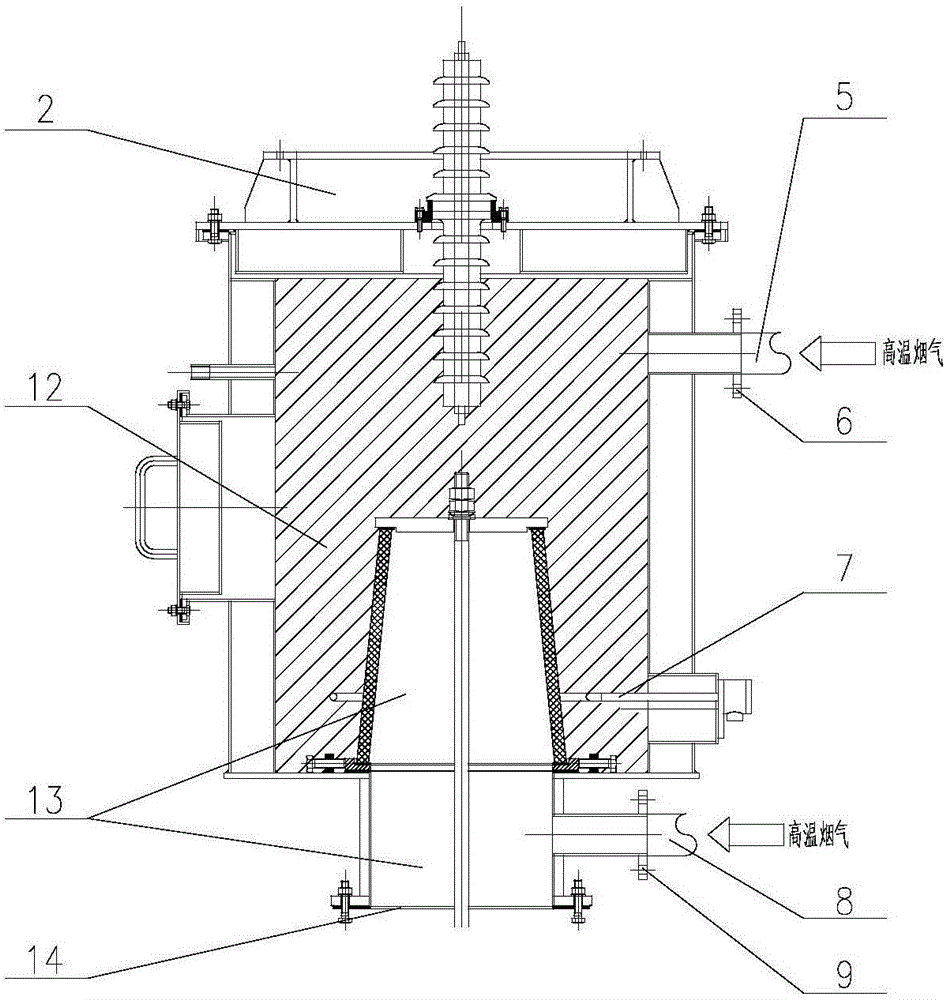

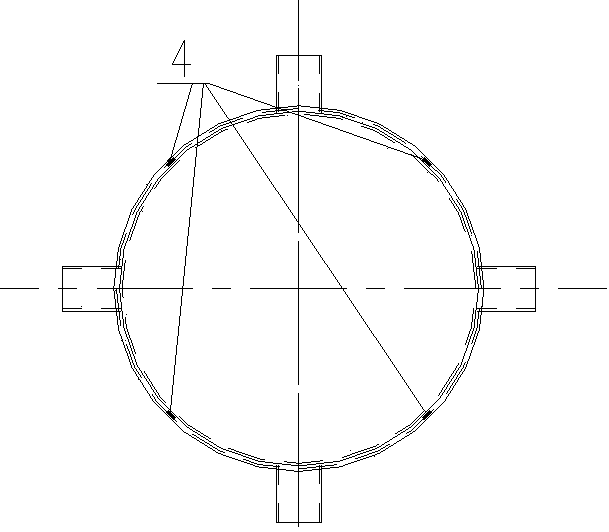

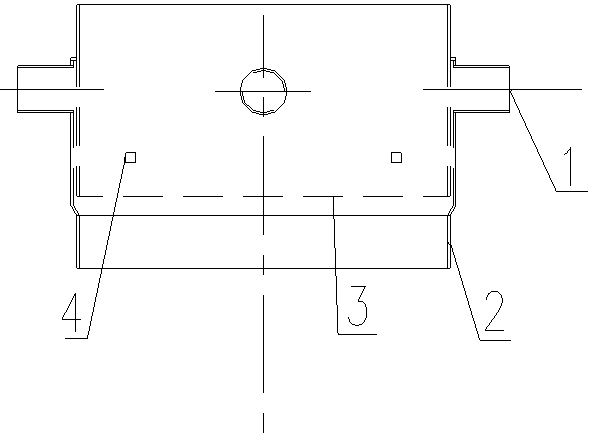

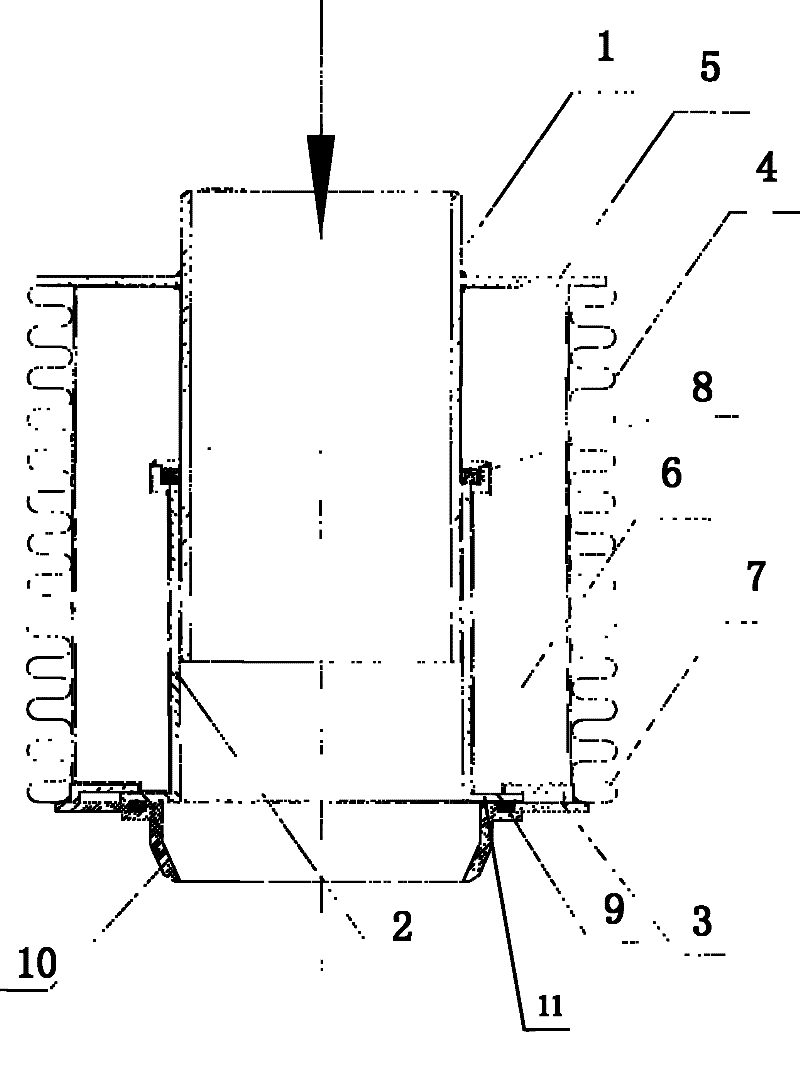

Stainless steel three-dimensional expansion joint used for sealing high temperature ash and slag

InactiveCN102221202AAnti-channelingImprove sealingFluidized bed combustionApparatus for fluidised bed combustionFiberSlag

The invention discloses a stainless steel three-dimensional expansion joint used for sealing high temperature ash and slag. The expansion joint comprises an upper inner guiding tube 1, a lower inner guiding tube 2, a horizontal expansion chamber 3, a fluted tube 4, an upper cap 5, an alumina silicate fiber punched carpet tied by stainless steel wire net 6, an alumina silicate fiber punched carpet 7, a sealing filler chamber 8 between the upper inner guiding tube and the lower inner guiding tube, a horizontal expansion ring 11, an expansion joint outlet cap 10, and a sealing filler chamber 9 arranged between the horizontal expansion ring and the expansion joint. A gap of only 1mm is configured between 1 and 2, and the gap can be reliably sealed by the sealing filler chamber 8, such that flue gas refluxing can be prevented, and ash and grains in the slag can be prevented from refluxing to the fluted tube. The horizontal expansion ring 11 is provided in the lower inner guiding tube. The sealing filler chamber 9 and the horizontal expansion chamber 3 are provided between the horizontal expansion ring 11 and the expansion joint outlet cap 10, such that sufficient expansion and reliable sealing can both be ensured. The alumina silicate fiber punched carpet tied by stainless steel wire net is filled between the sealing filler chambers 8 and 9.

Owner:张全胜

Circulating fluidized bed boiler for purely burning furfural residues

InactiveCN105627301AAvoid troubleAnti-channelingFluidized bed combustionApparatus for fluidised bed combustionAir preheaterCombustion chamber

The invention belongs to the technical field of fluidized bed boilers and particularly relates to a circulating fluidized bed boiler for purely burning furfural residues. According to the circulating fluidized bed boiler for purely burning the furfural residues, a high-temperature platen superheater is arranged in a hearth; a fluidized bed combustion chamber is arranged on the lower portion of the interior of the hearth; a wind distribution plate is arranged at the bottom of the fluidized bed combustion chamber; a wind cap is arranged on the wind distribution plate; a wind chamber is arranged below the wind distribution plate; a residue discharge pipe is arranged in the wind chamber; an ignition device is arranged on the wind chamber; the upper portion of a separator communicates with an outlet in the upper portion of the hearth; a lower vertical pipe of the separator is connected with the upper portion of a material return system; the lower portion of the material return system communicates with the fluidized bed combustion chamber; a low-energy-consumption self-balancing material return valve is mounted on a vertical pipe of the material return system; an inlet of a vertical shaft flue communicates with an outlet tube in the center of the upper portion of the separator; an evaporation pipe bundle, low-temperature superheaters, economizers and an air preheater are all arranged in the vertical shaft flue; and the vertical shaft flue is further provided with soot blowing points.

Owner:TAIYUAN BOILER GROUP

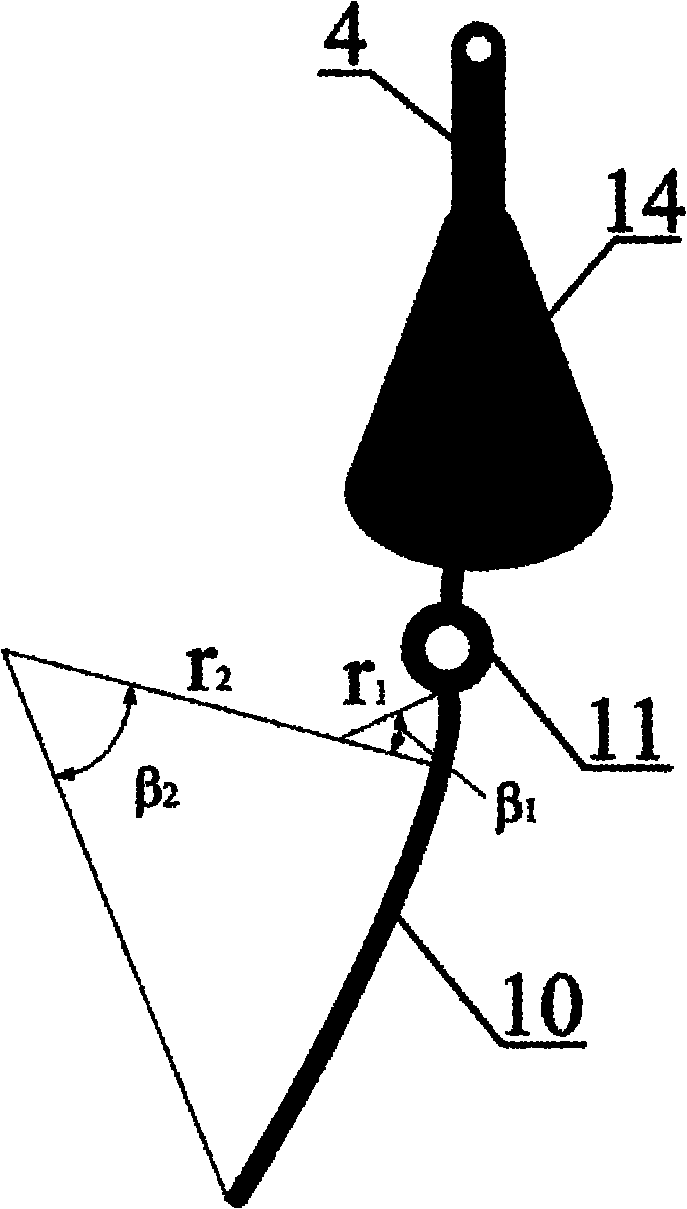

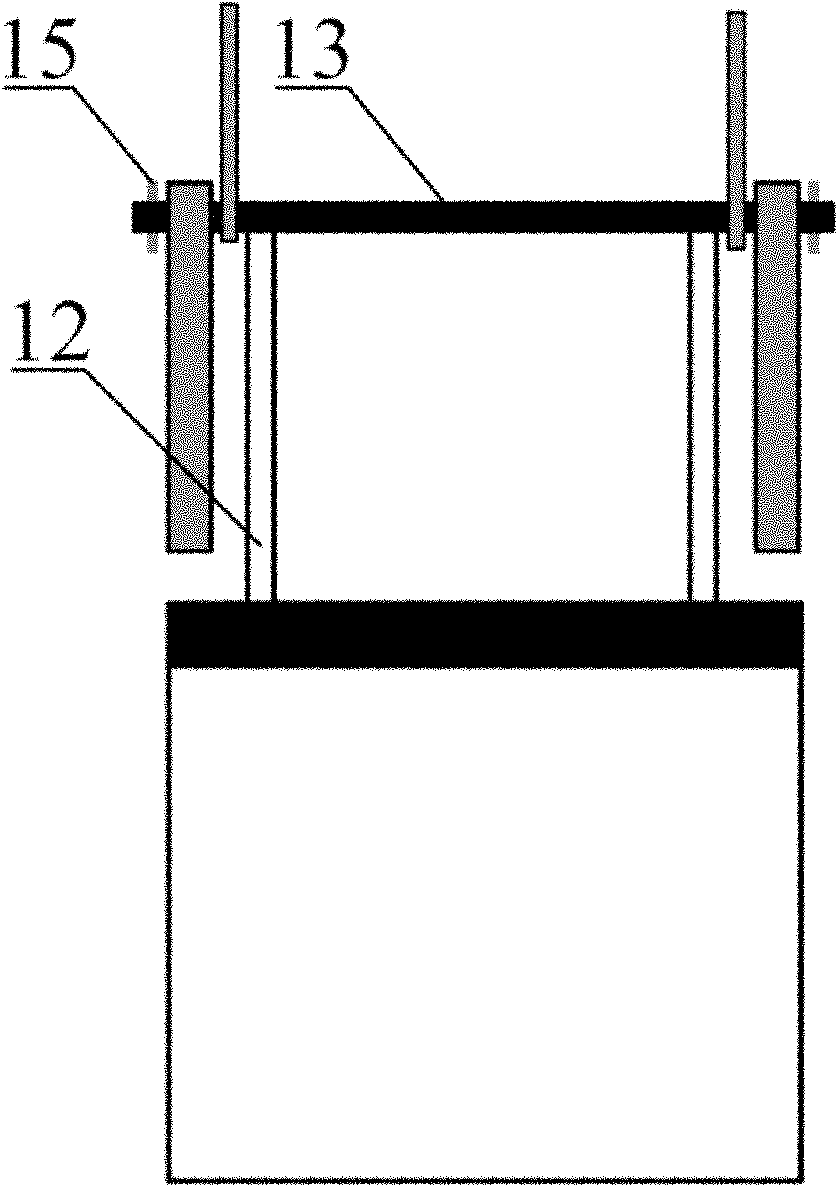

Feeding adjustable locking device for biomass forming fuel boiler

PendingCN107990347ASimple structureSelf-locking is convenient and easyFuel feeding arrangementsLump/pulverulent fuel feeder/distributionCantileverBiomass fuels

The invention discloses a feeding adjustable locking device for a biomass forming fuel boiler. The feeding adjustable locking device comprises an oblique overturning plate and a gravity hammer. The overturning plate is connected to the lower end of a blanking pipe in a covering mode and connected to the side portion of the lower end of the blanking pipe through a hinge, and a section of cantileverrod extends out of the connecting end of the overturning plate. The end of the cantilever rod is connected with the gravity hammer. A force adjusting device is installed on the cantilever rod. According to the feeding adjustable locking device for the biomass forming fuel boiler, the force adjusting device is arranged, the torque of the connecting end of the gravity hammer can be adjusted, thus,weight adjusting can be achieved when different biomass fuels are fed, the application range is greatly enlarged, and the equipment transformation cost is reduced.

Owner:GUIZHOU UNIV

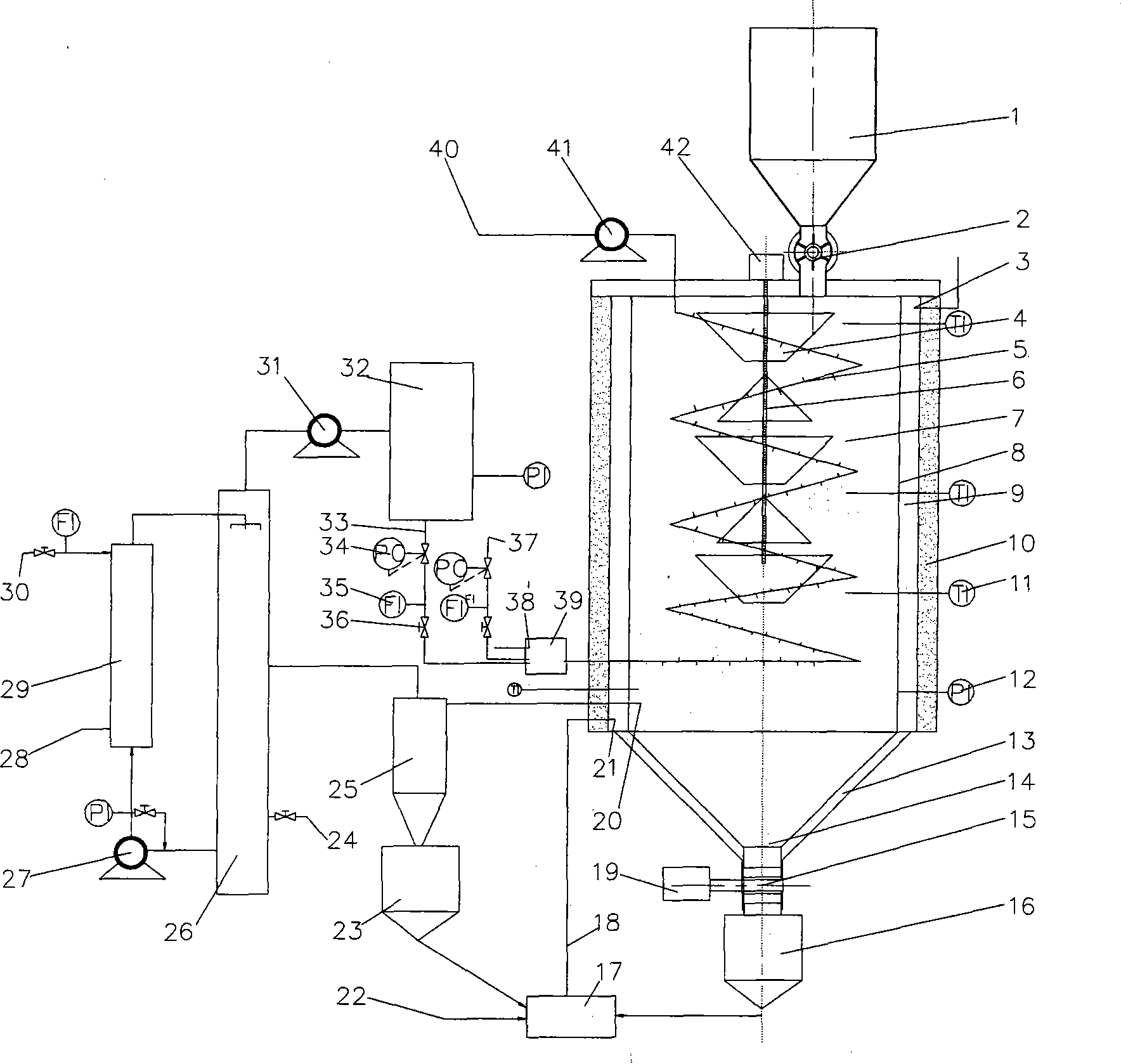

Method and apparatus for producing hydrogen from bio-oil in chained mode and separating CO2

The invention discloses a method and an apparatus for producing hydrogen from bio-oil in chained mode and separating CO2. The method comprises: pre-placing Fe2O3 in a moving-bed reactor, spraying the bio-oil from the central part of the moving-bed reactor to perform a cleavage reaction in the moving bed for generation of H2, CO, micromolecular hydrocarbons and solid carbon, reducing Fe2O3 with H2, CO and the micromolecular hydrocarbons and generating CO2, vapour and FeO, depositing solid carbon on the surface of FeO and reducing the reaction activity of FeO; introducing vapour from the bottom of the moving-bed reactor to reduce the deposited carbon on FeO surface, enabling FeO to enter into a bubbling fluidized bed reactor via an L valve, reacting FeO with vapour in the bubbling fluidized bed reactor to generate hydrogen and Fe3O4, enabling Fe34 to enter into a cycle fluidized bed reactor via an external separator; and reacting Fe3O4 with air in the cycle fluidized bed reactor to generate Fe2O3 which is lifted to a cyclone separator for gas-solid separation, enabling Fe2O3 to enter into the moving-bed reactor via the blanking tube of the cyclone separator, so as to realize cyclic utilization of Fe2O3.

Owner:SOUTHEAST UNIV

Adipic acid monoesterification production device capable of realizing continuous feeding and application thereof

ActiveCN109534994AAvoid cloggingReduce leakageOrganic compound preparationCarboxylic acid esters preparationAdipic acidEsterification reaction

The invention relates to an adipic acid monoesterification production device capable of realizing continuous feeding and an application thereof. The invention is mainly to solve the problems of largegas leakage amount and methanol gas reverse channeling in the prior art. The adipic acid monoesterification production device capable of realizing continuous feeding provided by the invention comprises a pre-esterification reaction kettle, a weighing feed hopper, an intermediate feed hopper, a pre-esterification buffer tank and a screw conveyor, wherein an adipic acid feeding pipe is successivelyconnected with the weighing feed hopper and the intermediate feed hopper; the outlet of the intermediate feed hopper is connected with the screw conveyor; the outlet of the screw conveyor is connectedwith the pre-esterification reaction kettle; and the outlet of the pre-esterification reaction kettle is connected with the pre-esterification buffer tank. Thus, the above-mentioned problems are wellsolved. The adipic acid monoesterification production device capable of realizing continuous feeding provided by the invention can be used in adipic acid monoesterification production.

Owner:SINOPEC SHANGHAI ENG +1

Method of fluidizing wind at high pressure using steam to replace air

InactiveCN1313766CAvoid cokingAvoid burnsFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringTurbine

The invention relates to a method of implementing high pressure fluidization blast using steam in place of air, characterized in that: steam is used for high pressure fluidization blast in normal running of a boiler. The method includes: connecting a turbine exhaust or intermediate extraction with a stock recycler using a steam conduit; starting high pressure fluidization blower and fluidizing recycle material in the stock recycler using air when the boiler begins to start; opening stop valve of the turbine steam conduit, fluidizing recycle material in the stock recycler using steam, shutting down the high pressure fluidization blower and closing the stop valve when the temperature of recycle material in the stock recycler is above 300 Celsius degree, the fluidization steam vapor source pressure parameter is greater than 60Kpa, and the superheat degree is larger than 30 Celsius degree; starting the high pressure fluidization blower, fluidizing recycle material in the stock recycler using air, and closing the stop valve on steam turbine when the temperature of the stock recycler is under 300 Celsius degree in blow off process of the boiler. Advantages of the invention consist in that coking of the stock recycler or other high temperature zones can be prevented or abated and boiler operation reliability can be improved by using steam for replacing high pressure fluidization blast. At the same time, circulating fluid bed boiler desulfurizer utilization rate can be improved, Nox discharge concentration can be reduced, and power plant running cost can be saved by utilizing steam fluidization.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com