Downer-moving bed coupling pyrolysis reaction device

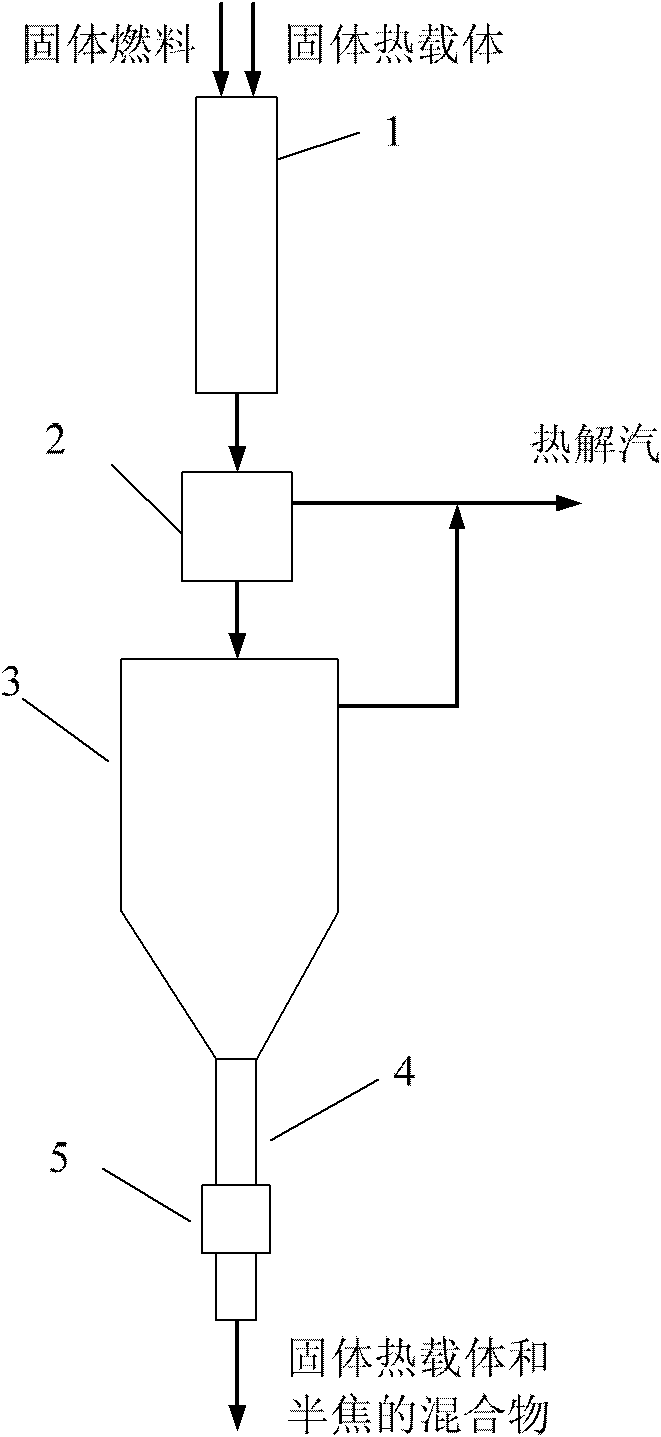

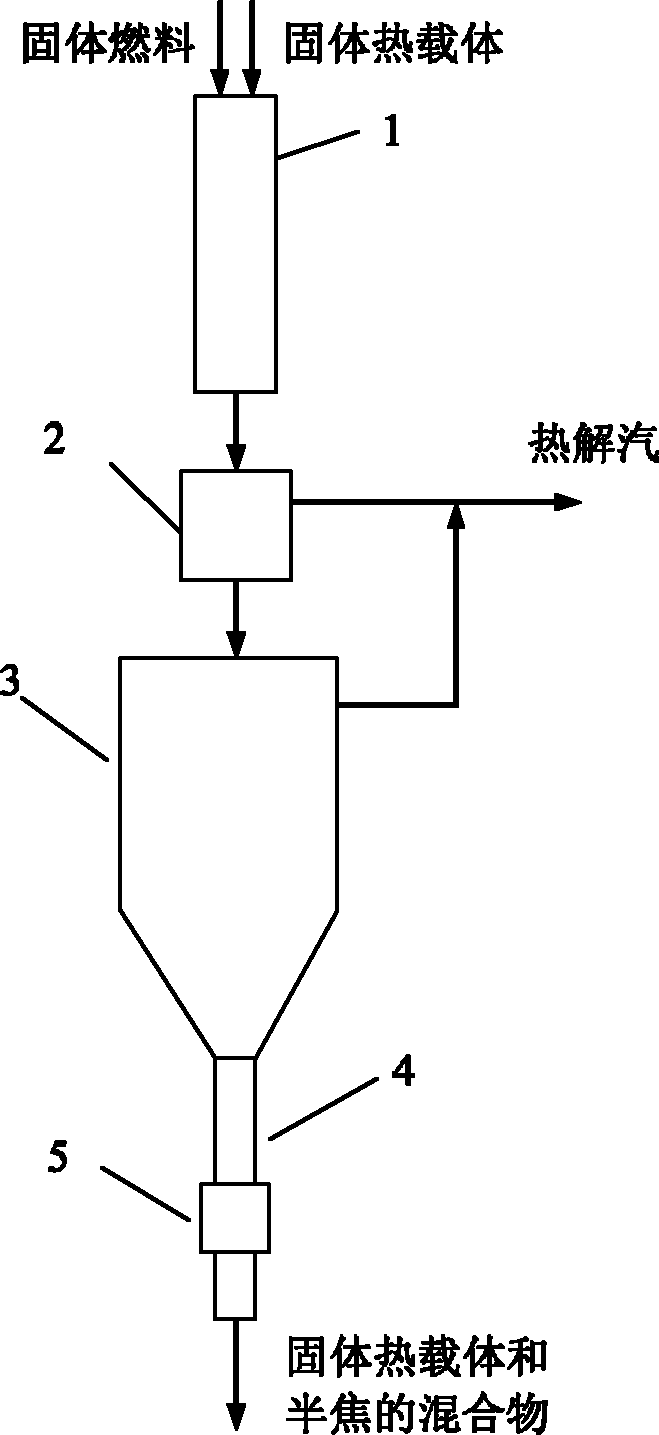

A technology of moving bed reactor and reaction device, which is applied in the direction of direct heating dry distillation, preparation of liquid hydrocarbon mixture, special form of dry distillation, etc. It can solve the problems of short residence time of solid fuel and long residence time of pyrolysis gas, and achieve high thermal efficiency , The process is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

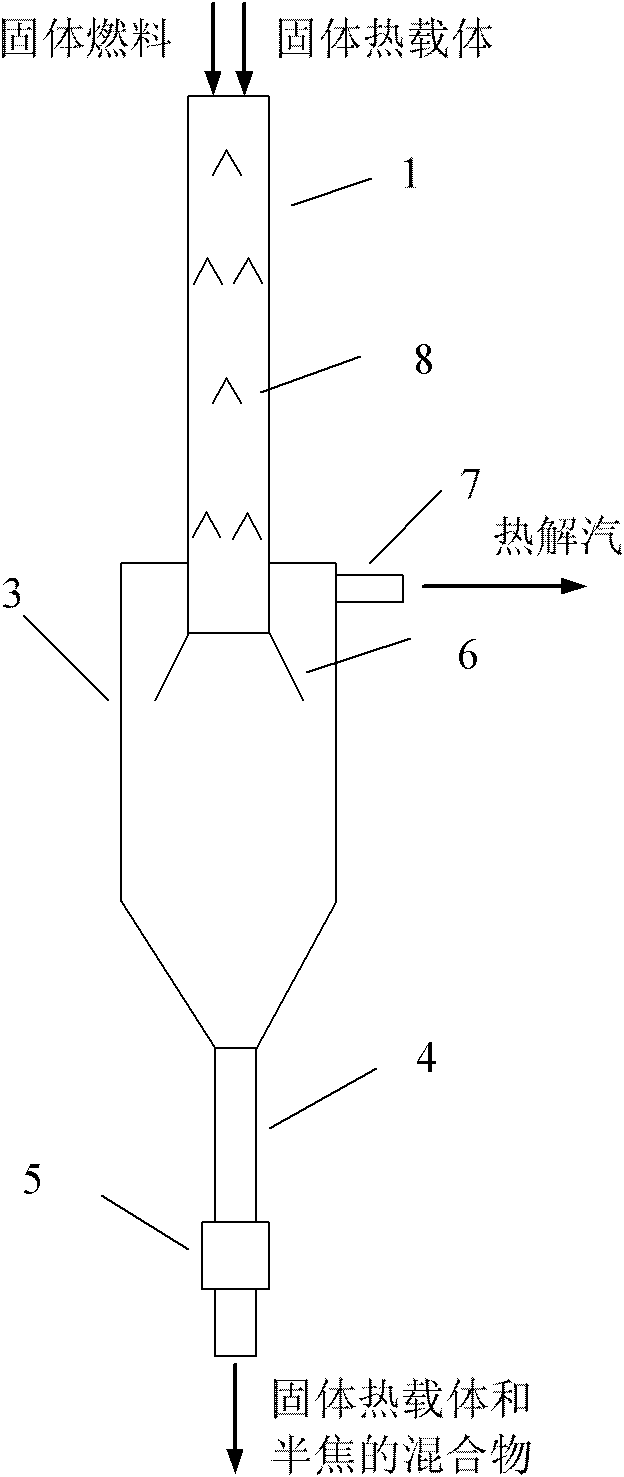

[0032] Example 1 Pyrolysis of coal in a down bed-moving bed coupled rapid pyrolysis reactor

[0033] Such as figure 2 As shown, the 850°C hot ash separated from the cyclone separator of the circulating fluidized bed boiler and the coal with a particle size of less than 1mm enter the descending bed reactor 1. The descending bed reactor 1 is equipped with a baffle-type gravity solid-solid mixer 8. The hot ash and coal have fully mixed heat transfer, and pyrolysis reaction occurs. The outlet of the descending bed reactor 1 is equipped with a baffle 6, relying on the difference of gas-solid inertia, the pyrolysis vapor and the solid mixture are quickly separated. The pyrolysis vapor leaves the pyrolysis reactor from the pyrolysis gas outlet 7 of the moving bed and enters In the subsequent quenching device, in the moving bed reactor 3, the temperature of the solid mixture drops to 650°C, the large solid fuel particles that are not fully pyrolyzed continue to be pyrolyzed, and the mi...

example 2

[0034] Example 2 Pyrolysis of oil shale in a down bed-moving bed coupled fast pyrolysis reactor

[0035] Such as figure 2 As shown, the 850°C hot sand separated from the cyclone separator of the circulating fluidized bed boiler and the oil shale with a particle size of less than 1mm are mixed and transferred in the descending bed reactor 1, and the temperature of the solid mixture drops to 550 after reaching the moving bed. ℃, the pyrolysis steam is quenched to obtain shale oil and coal gas. The mixture of hot ash and semi-coke enters the combustion furnace to burn, and the hot ash is heated and circulated again.

example 3

[0036] Example 3 Pyrolysis of biomass in a down-bed-moving-bed coupled fast pyrolysis reactor

[0037] Such as figure 2 As shown, the 850°C hot sand separated from the cyclone separator of the circulating fluidized bed combustion furnace and the biomass with a particle size of less than 1mm are mixed and transferred in the descending bed reactor 1, and the temperature of the solid mixture drops to 500 after reaching the moving bed. ℃, the biomass pyrolysis steam is quenched to obtain biomass pyrolysis oil and coal gas. The mixture of hot sand and biomass semi-coke enters the combustion furnace for combustion, and the hot sand is heated and circulated again.

[0038] When using the descending bed-moving bed coupled rapid pyrolysis reaction device of the present invention to pyrolyze solid fuels in Examples 1 to 3, compared with using a descending bed pyrolysis reactor alone or a moving bed pyrolysis reactor alone , The residence time of the gas phase can be controlled within 1 sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com