Bidirectional anti-explosion floor drain

A floor drain and body technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of increasing the thickness of the structural bottom plate, small drainage, water loss of the floor drain water seal, etc., to achieve the reduction of its own volume, increase of drainage, and drainage powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

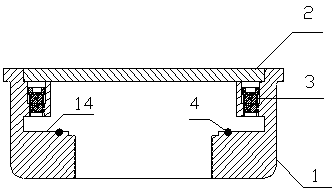

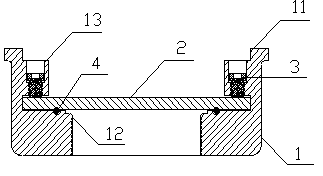

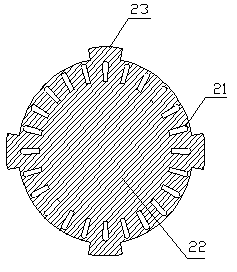

[0029] Such as figure 1 As shown, the two-way explosion-proof floor drain of the present invention includes a body 1 and a grate 2. The body 1 has an upper port 11 as a water inlet and a lower port 12 as a water outlet. There is a water hole 21 on the grate 2. The body The inner side of the upper opening 11 is provided with a plurality of radial recesses 13 (i.e., the inner side of the upper opening of the leak body in the prior art), and the outer edge of the grate 2 is provided with a plurality of radial protrusions 23 (i.e., the inner side of the upper opening of the prior art). The upper edge of the middle drain cover is radially convex corresponding to the block), and the body 1 is provided with a locking device 3 that positions the protruding portion 23 on the grate 2 below the concave portion 13 on the body 1 to seal the floor drain.

[0030] The locking device 3 is a bolt that is screwed into the recessed portion 13 .

[0031] Such as figure 1 As shown, in normal use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com