Integral inductor and preparation method thereof

A manufacturing method and inductor technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve problems such as stab wounds and short circuits, and achieve the effect of preventing quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

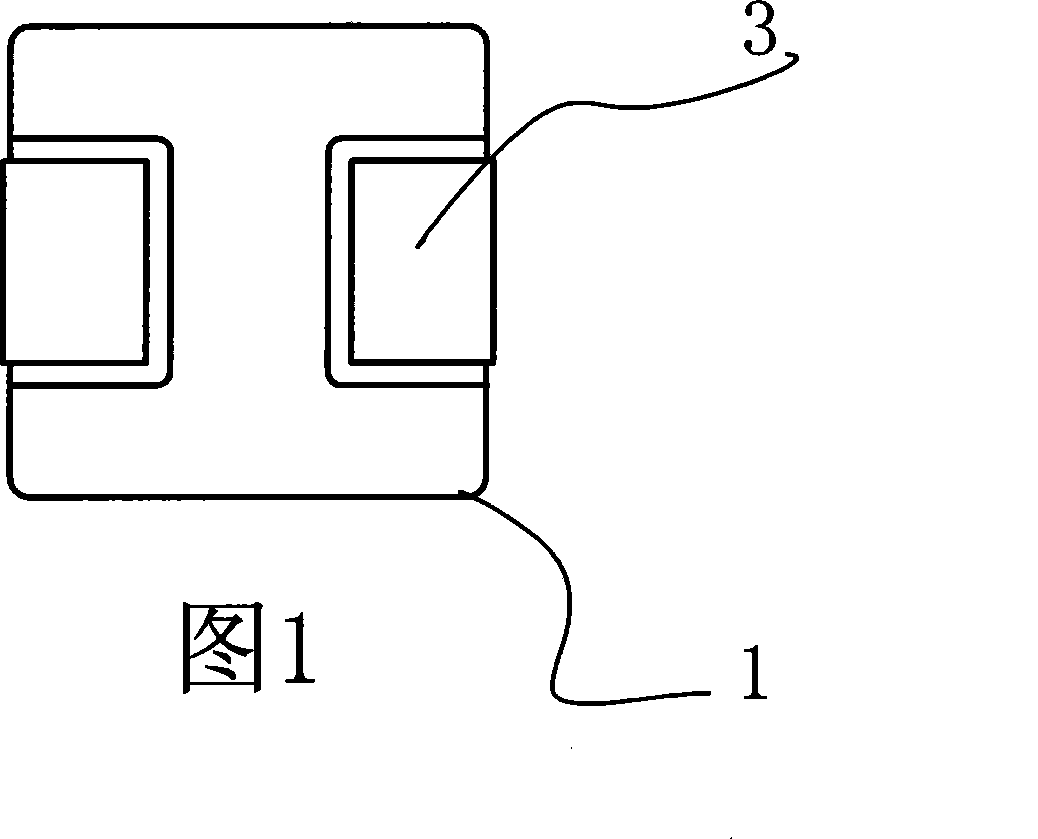

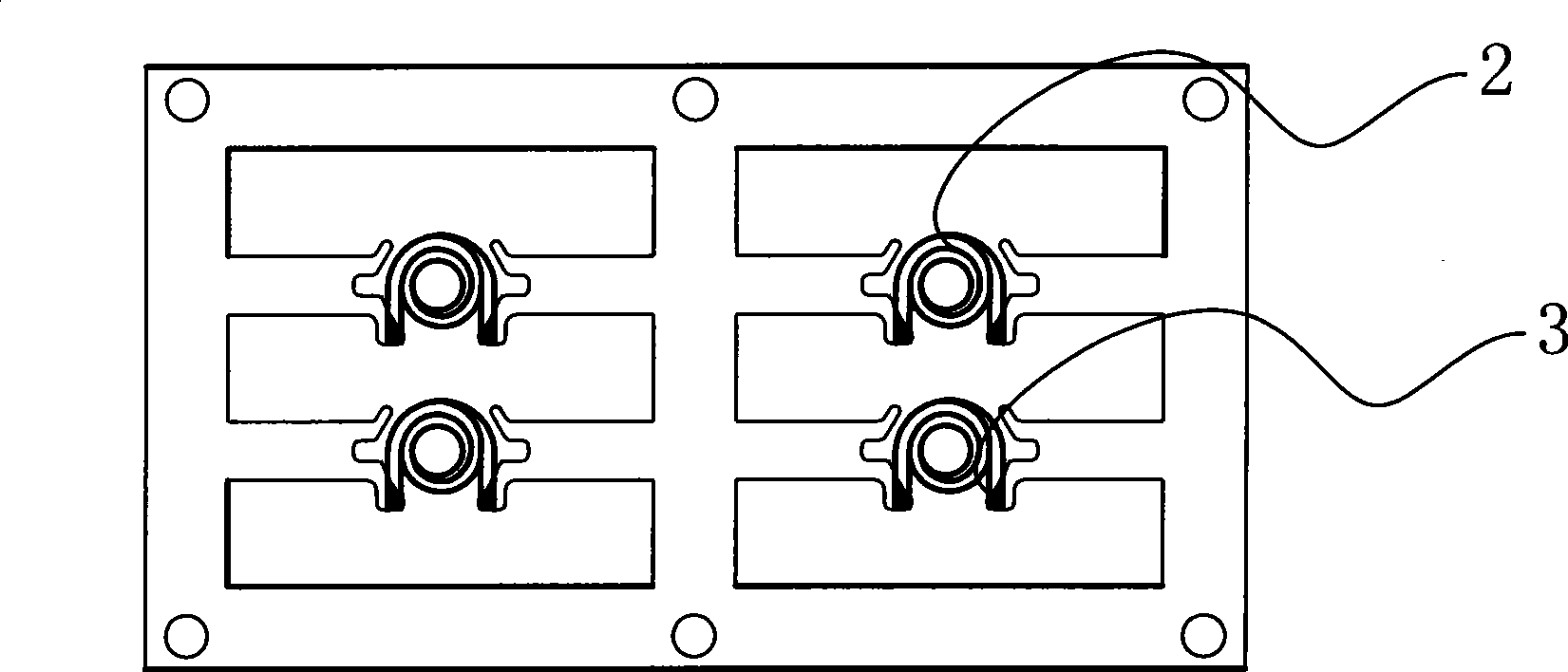

[0036] The integrated inductor 1 , as shown in FIG. 1 , includes two terminals 3 protruding from the magnetic powder block. The terminals 3 are flat, and their larger planes are parallel to the larger plane of the magnetic powder block. Among them, the coil body of the inductance coil 2 is completely wrapped in the magnetic powder block, and the coil body adopts a bidirectional helical structure, that is, the coil body of the inductance coil starts from the center and winds one circle to both ends in the axial direction, and then coils to the center. 1 circle around. Its product size is 10.0×10.0×4.0mm, and its production process is as follows:

[0037] A) The coil adopts flat enameled wire coil

[0038] B) The metal powder is pure iron powder. In order to obtain better electrical characteristics and mechanical strength, the metal powder is insulated with phosphoric acid. Adhesive, the addition amount is 1% Wt. Zinc stearate was added as a lubricant in an amount of 0.1% Wt....

Embodiment 2

[0045] The product size is 10.0×10.0×4.0mm, and the production process is as follows:

[0046] A) The coil adopts a round enameled wire coil

[0047] B) The metal powder is pure iron powder. In order to obtain better electrical properties and mechanical strength, the metal powder is insulated with a silane coupling agent. Amide resin is used as a binder, and the addition amount is 8% Wt. Zinc stearate was added as a lubricant in an amount of 0.5% Wt.

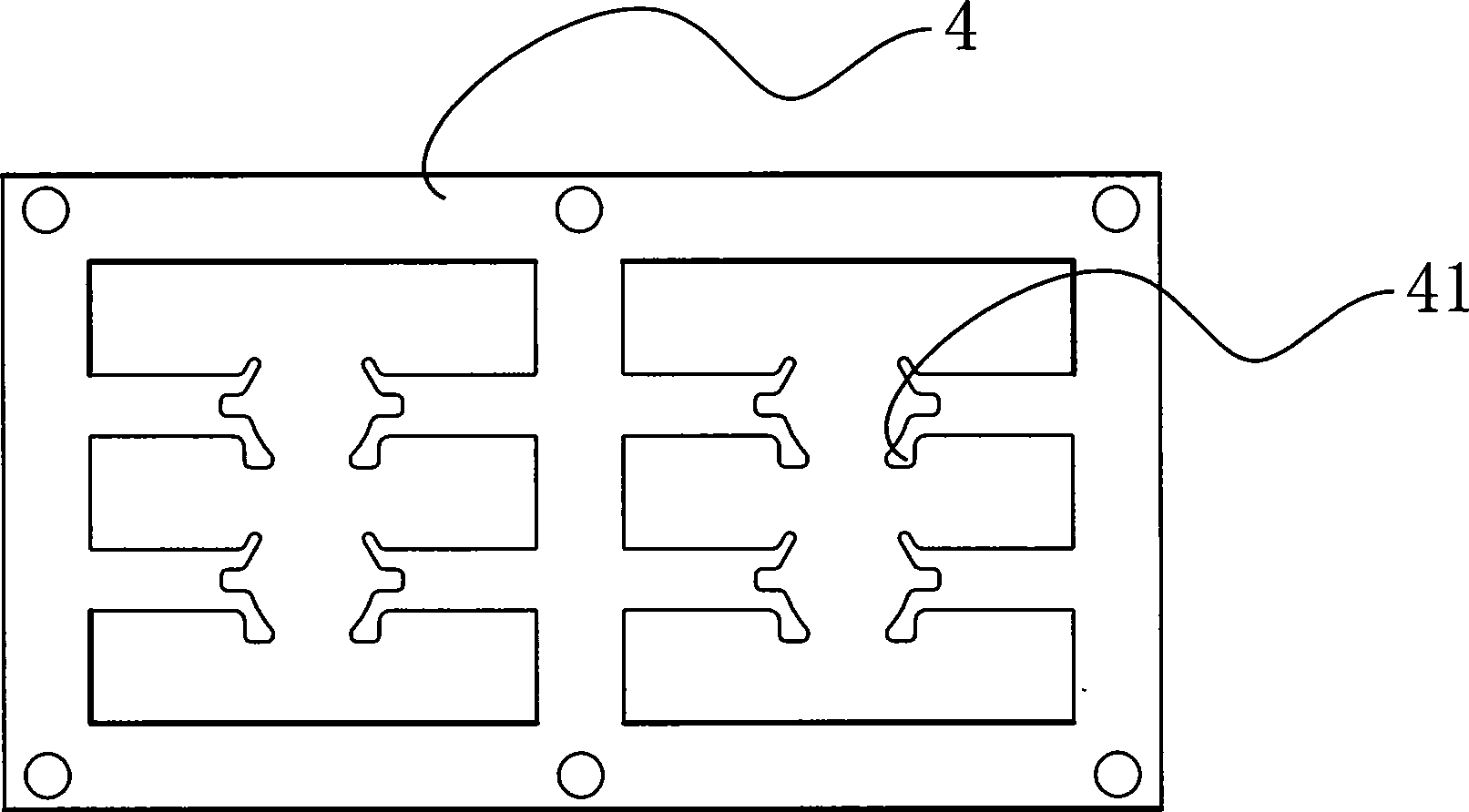

[0048] C) Using a 25T multi-stage step formwork press, place the coil produced in step A) in the equipment coil device, add the metal powder produced in step B) to the equipment hopper, press the molding unit pressure 80KN in a jogging manner / cm2, magnetic core compression density 6.2g / cm3 Adjust the size and weight of the product until the size, weight, and electrical special electrical characteristics meet the set requirements.

[0049] D) The semi-finished product made in step C) is baked to cure the adhesive and release ...

Embodiment 3

[0055] The product size is 10.0×10.0×4.0mm, and the production process is as follows:

[0056] A) The coil adopts flat enameled wire coil

[0057] B) The metal powder is alloy iron powder. In order to obtain better electrical properties and mechanical strength, the metal powder is insulated with sodium silicate and silane coupling agent, and the addition amount is 3% Wt. The metal powder that has been insulated Then add phenolic resin as adhesive, the addition amount is 6%wt. Zinc stearate was added as a lubricant in an amount of 0.3% Wt.

[0058] C) Using a 25T multi-stage step formwork press, place the coil produced in step A) in the equipment coil device, add the metal powder produced in step B) to the equipment hopper, and press the forming unit pressure 70KN by jogging / cm2, magnetic core compression density 5.9g / cm3 Adjust the size and weight of the product until the size, weight, and electrical special electrical characteristics meet the set requirements.

[0059] D)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com