Fat emulsion tail liquid treatment apparatus and method thereof

A treatment method and fat emulsion technology, which can be used in emulsion transportation, pharmaceutical formulations, metabolic diseases, etc. It can solve problems such as difficult product quality assurance, long storage time, and difficult operation, so as to eliminate quality risks and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following non-limiting examples illustrate the invention.

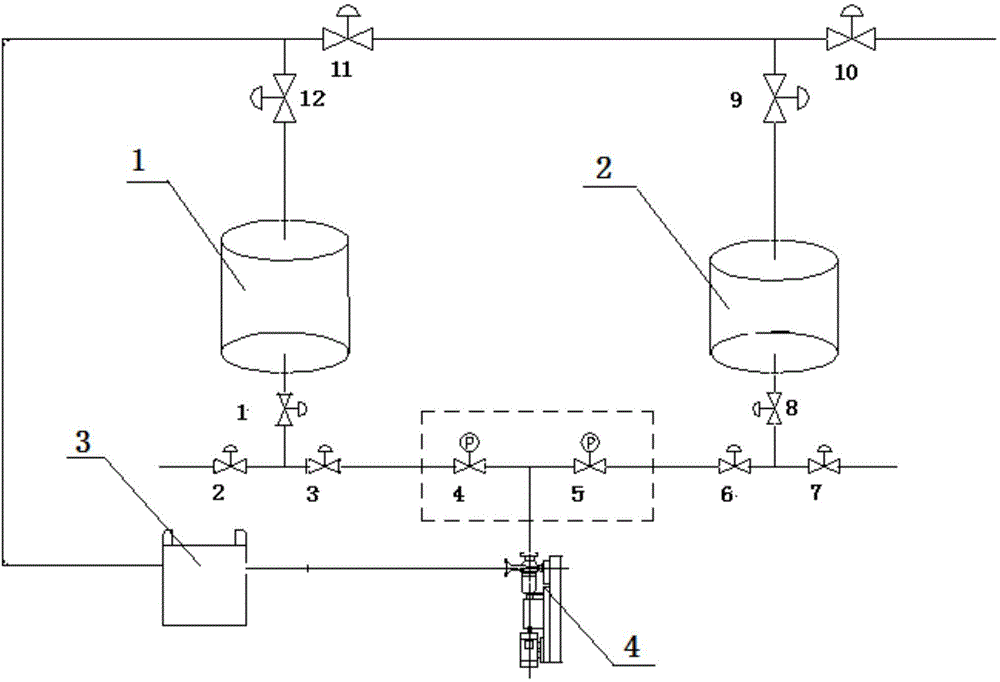

[0036] Such as figure 1 As shown, a fat emulsion tail liquid processing system includes a colostrum tank 1, a homogenizing tank 2, a transfer pump 4 and a homogenizer 3, a colostrum tank 1, a homogenizing tank 2, a transfer pump 4 and a homogenizer 3 The pipeline and its upper valve are connected to form a circulation system. The delivery pump 4 is connected in series with the homogenizer 3, and is further connected in series with the colostrum tank 1 and the homogenizer tank 2 in parallel, and the colostrum tank 1 and the homogenizer tank 2 are connected in series. The outlet port of the delivery pump 4 is communicated with the inlet port of the transfer pump 4, the outlet port of the homogenizer 3 is connected with the inlet ports of the colostrum tank 1 and the homogenization tank 2 respectively, and the outlet port of the transfer pump 4 and the inlet port of the homogenization tank 2 are connected. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com