Patents

Literature

30results about How to "Improve induction heating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

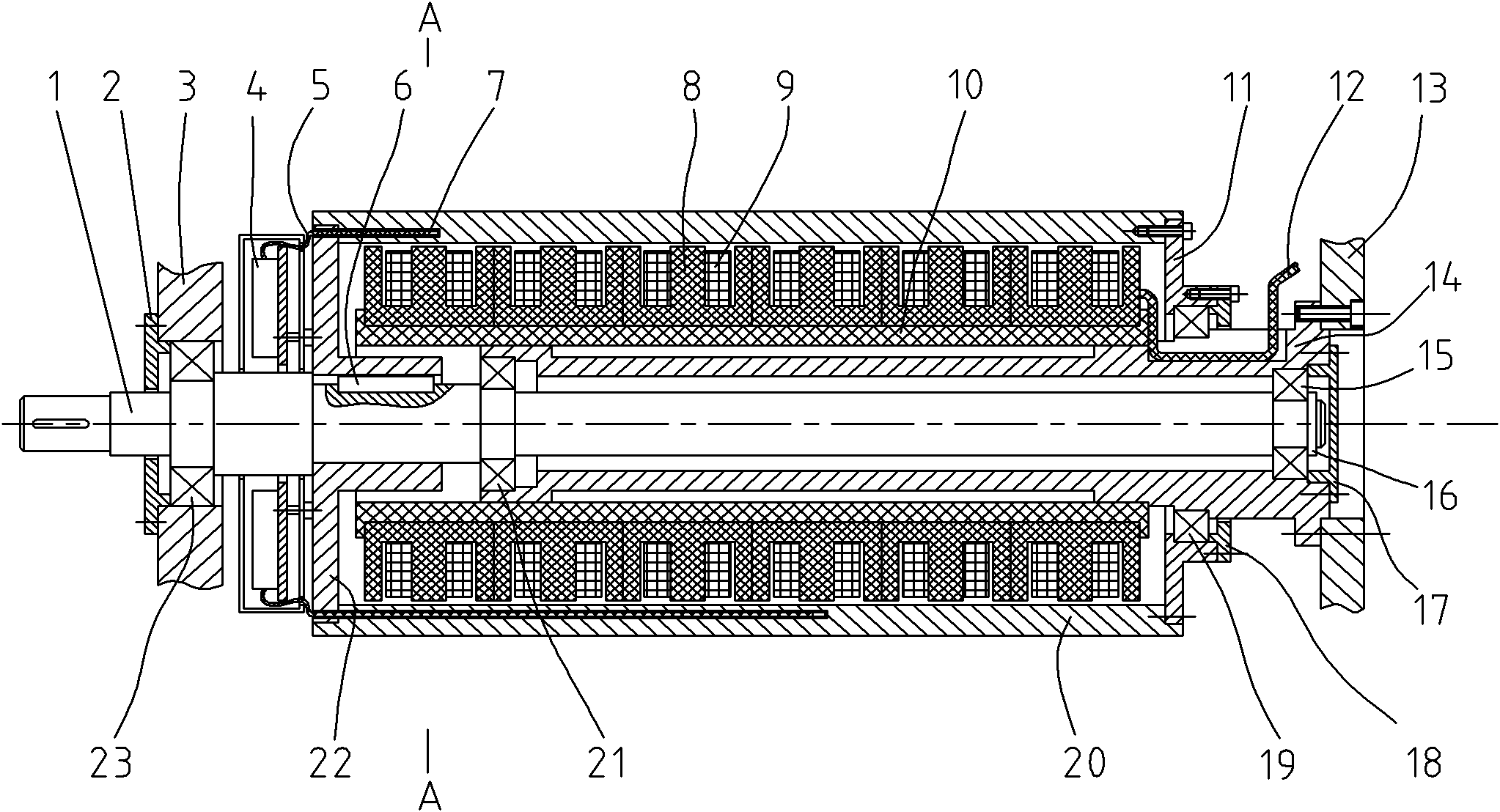

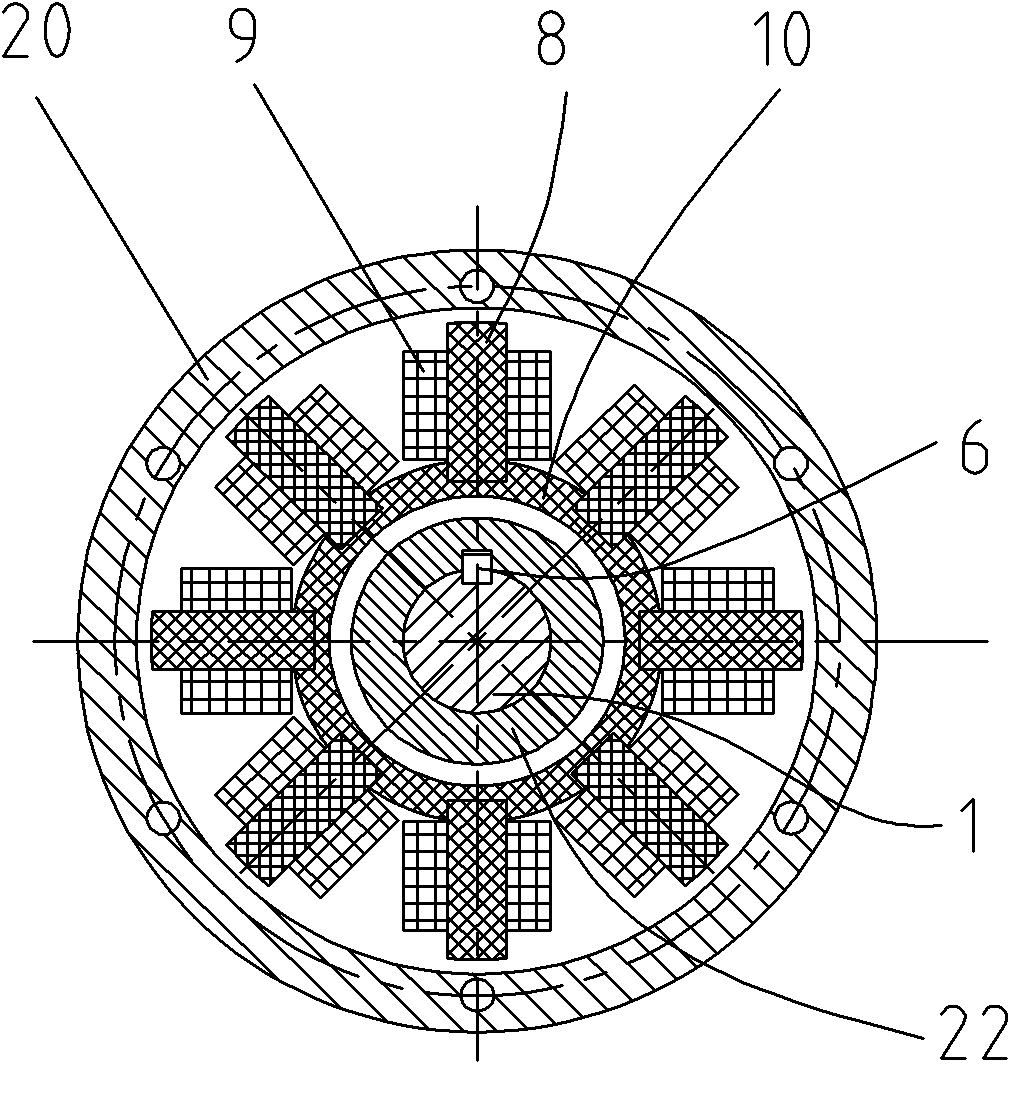

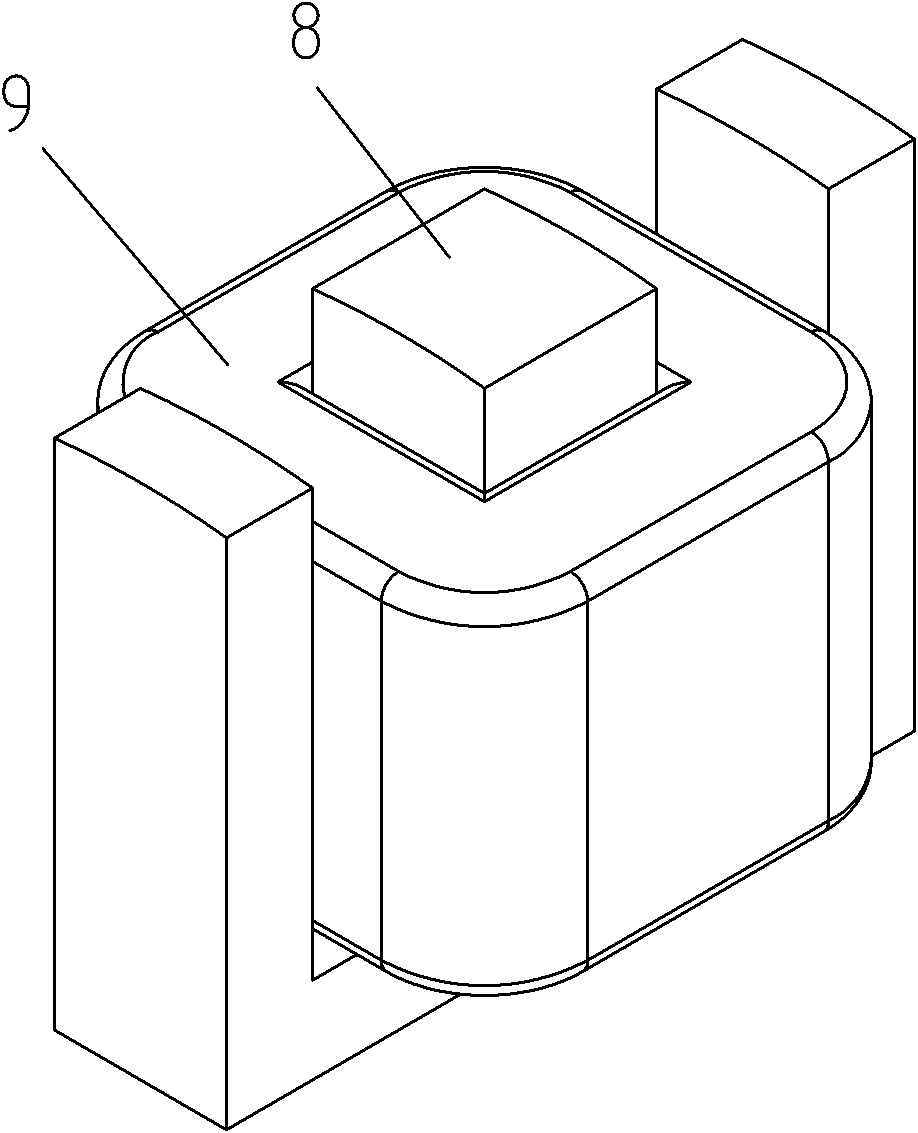

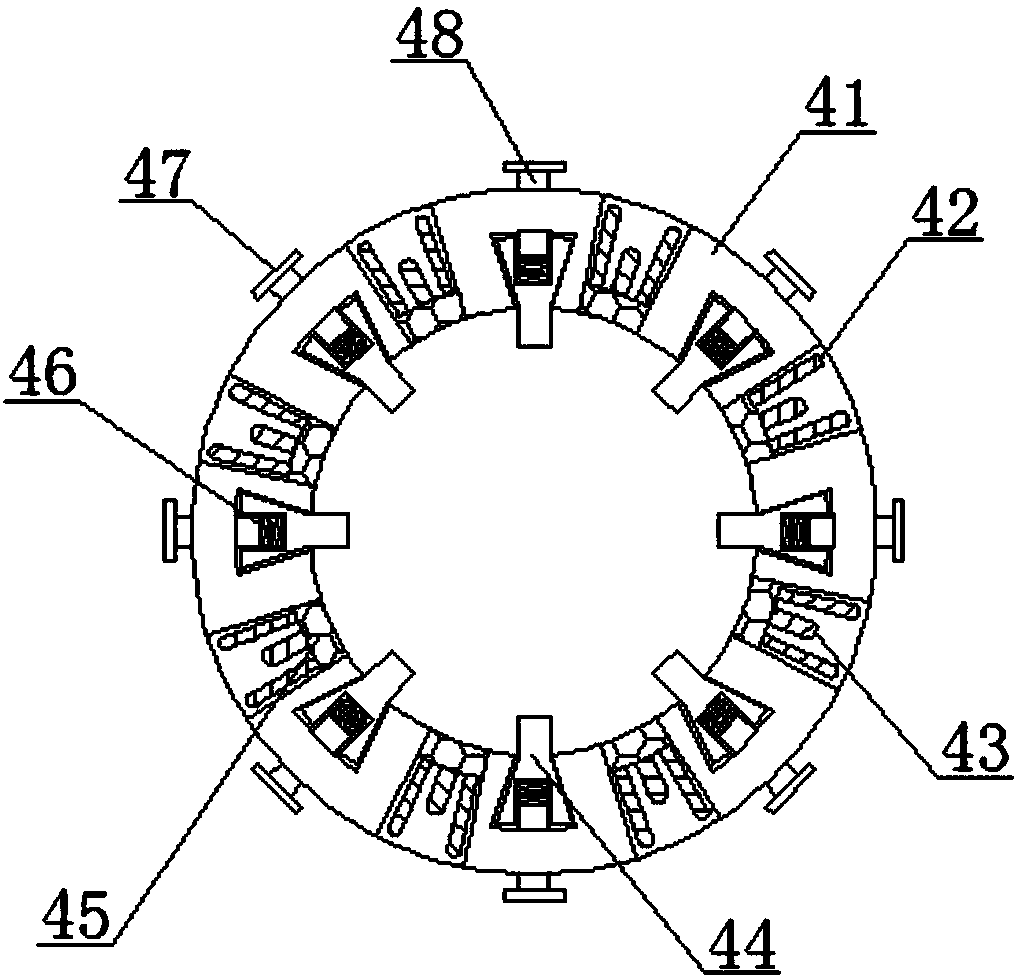

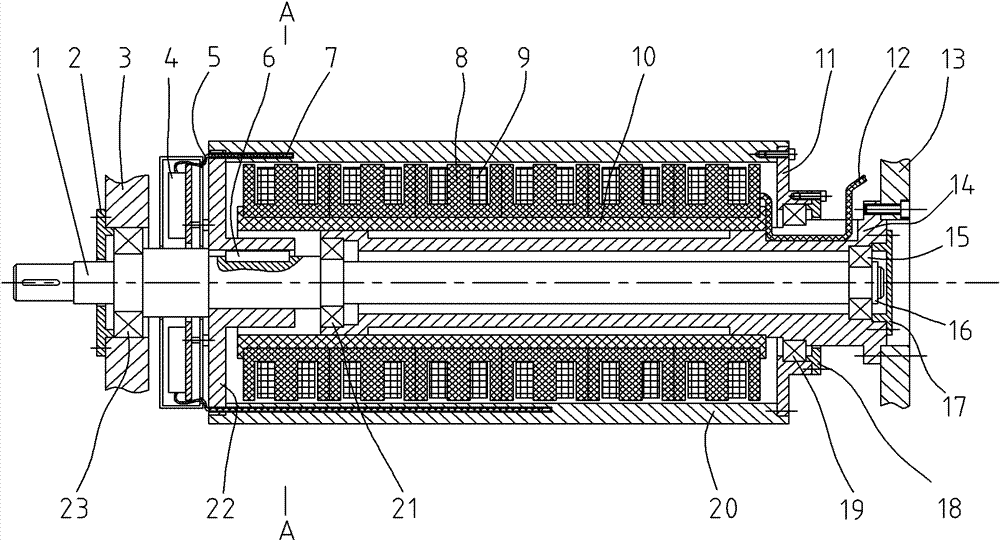

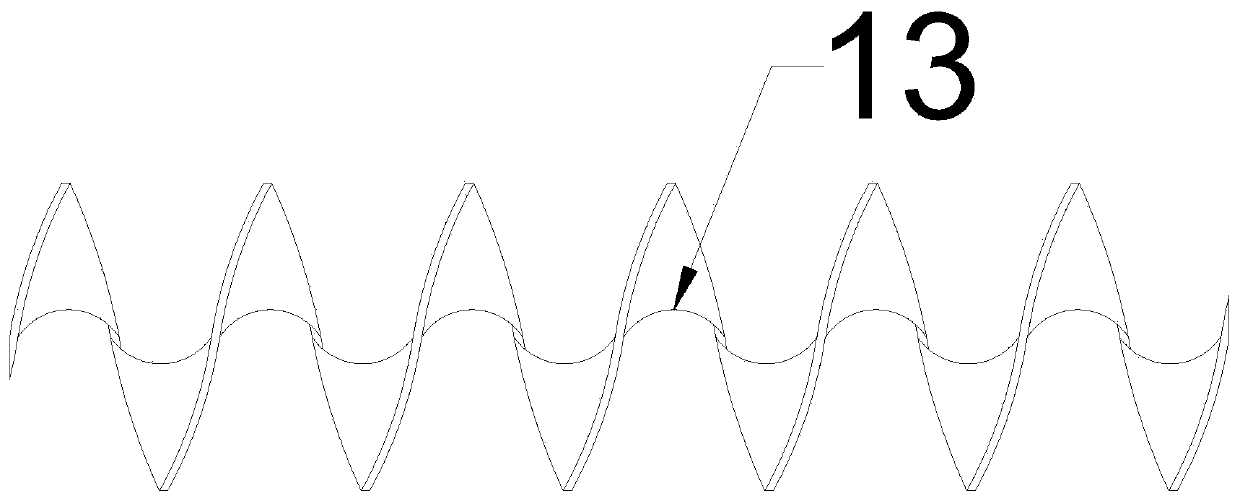

Electromagnetic induction heating press-roller

InactiveCN102137523AImprove induction heating efficiencyAvoid overall overheatingInduction heating apparatusMachine partsExcitation current

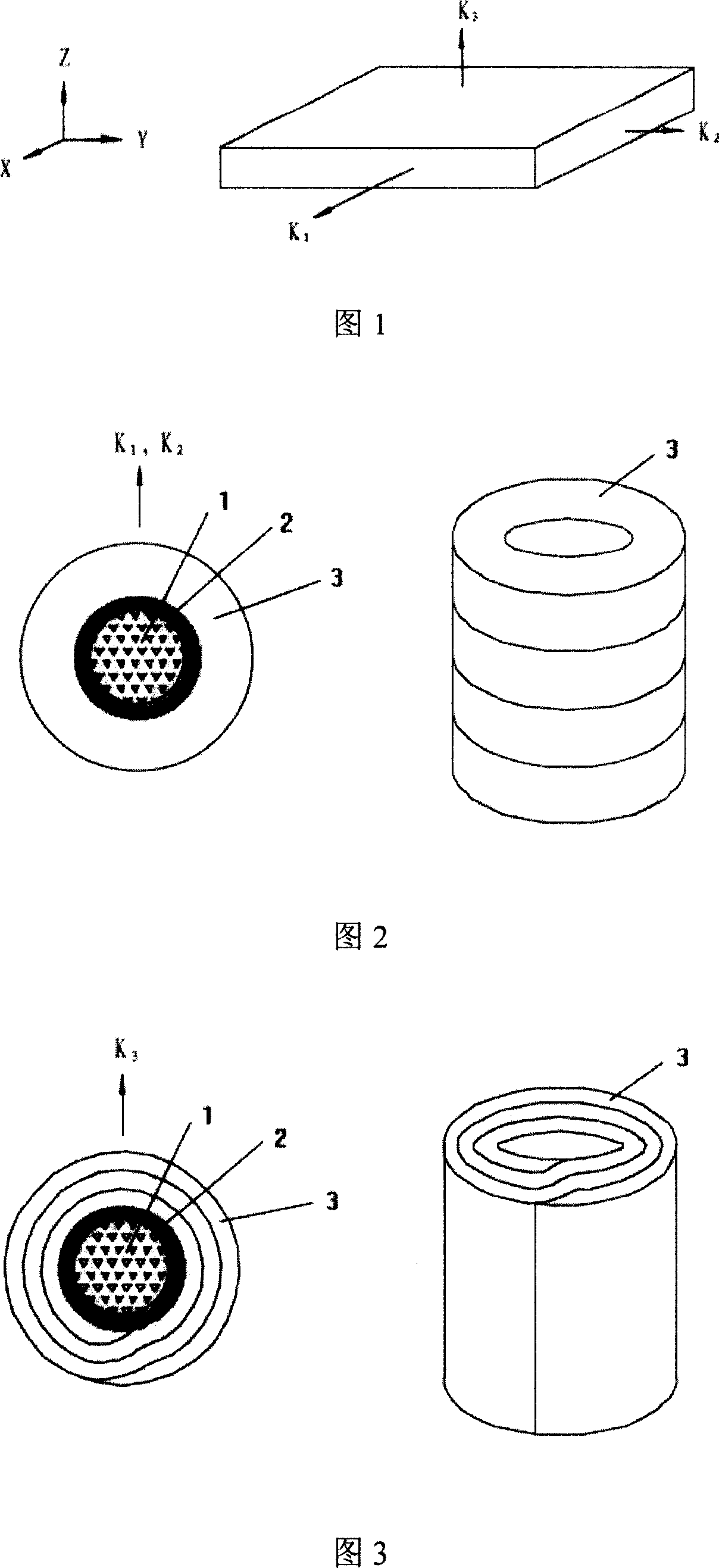

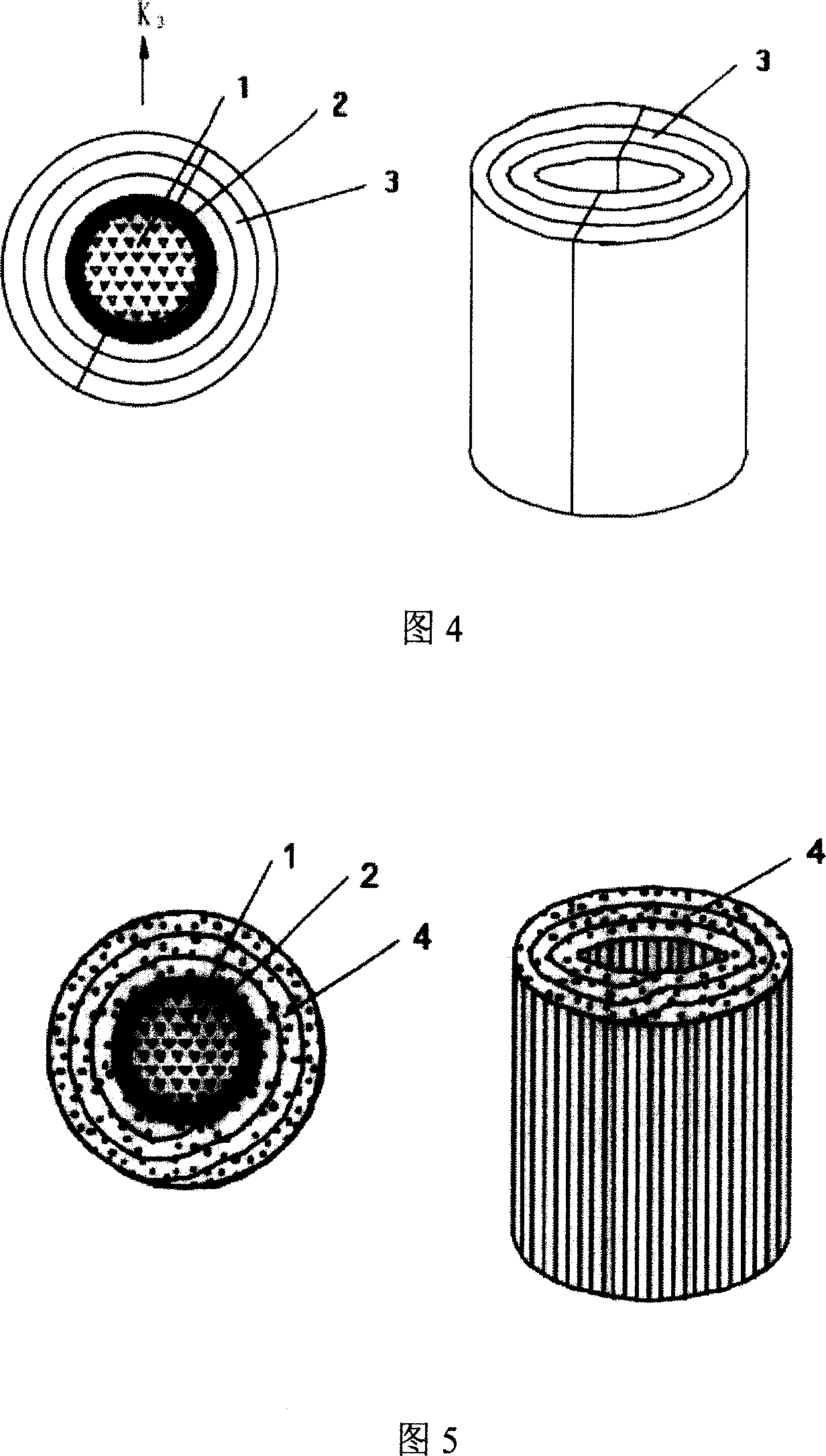

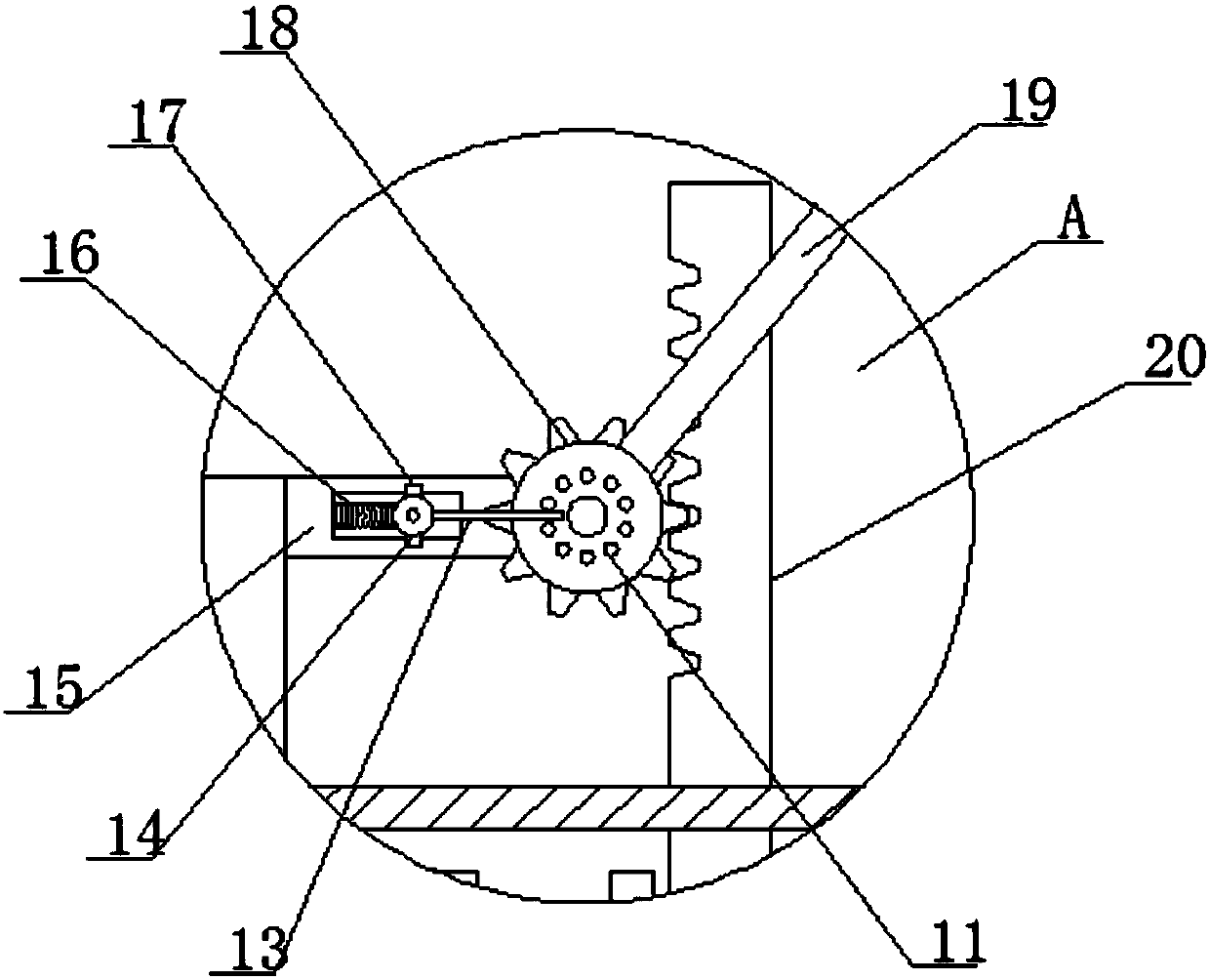

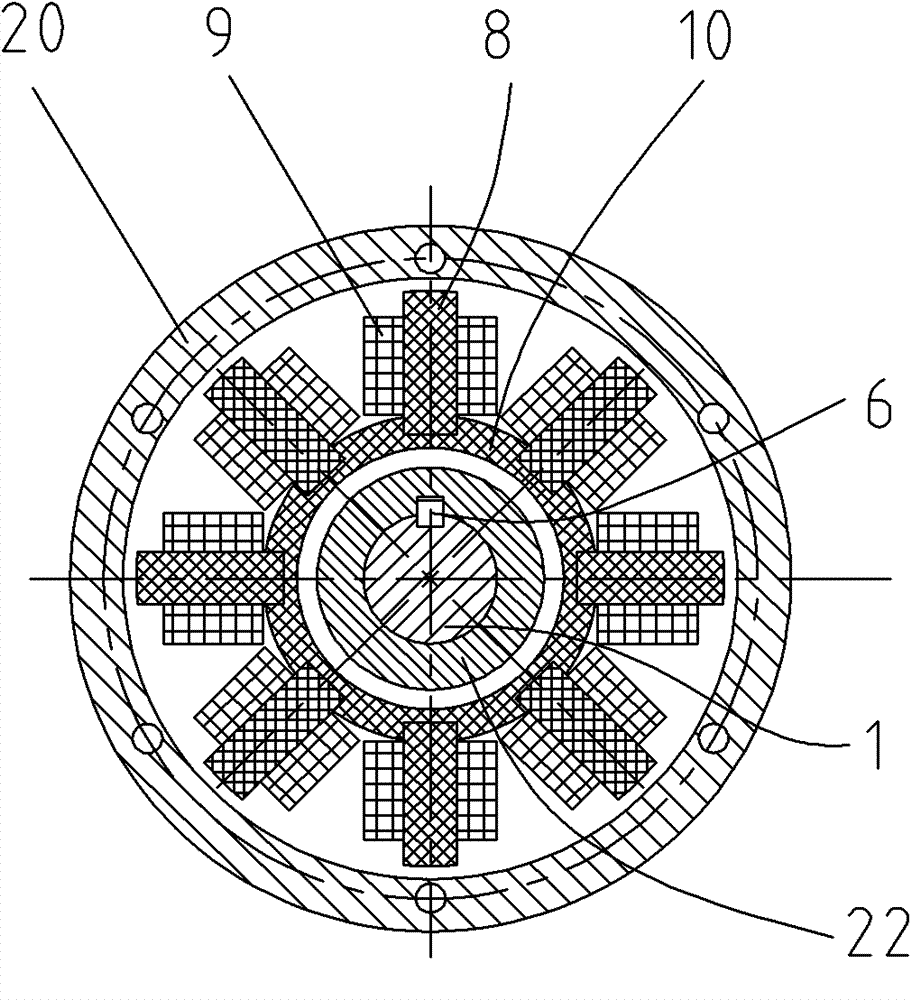

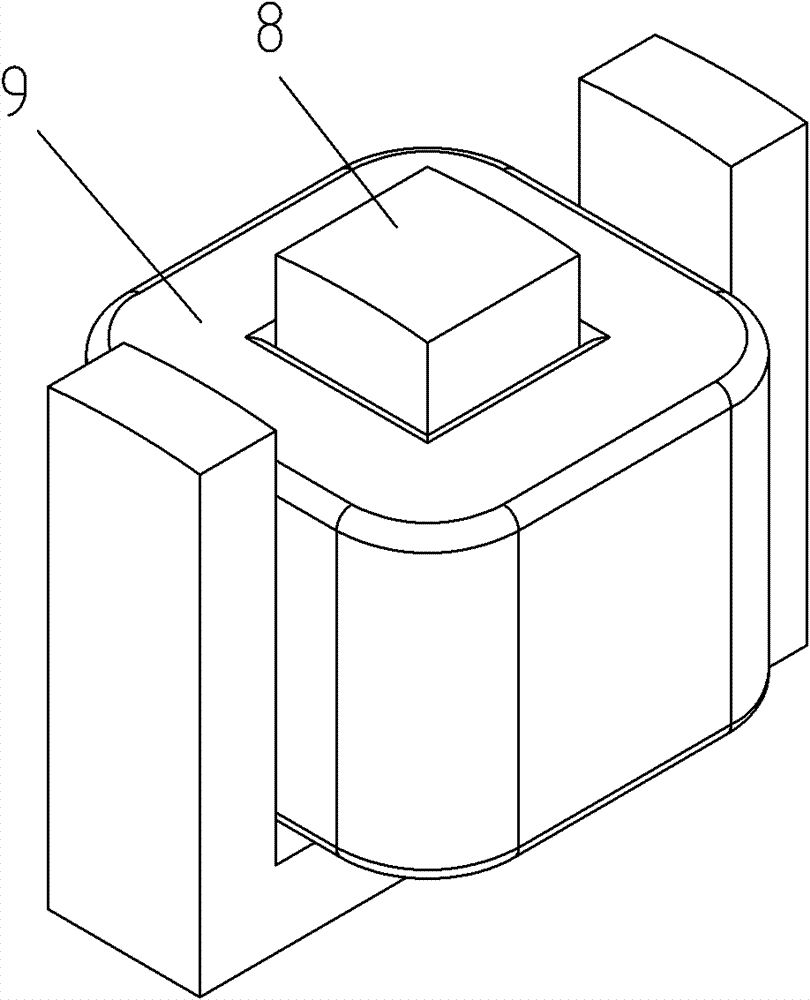

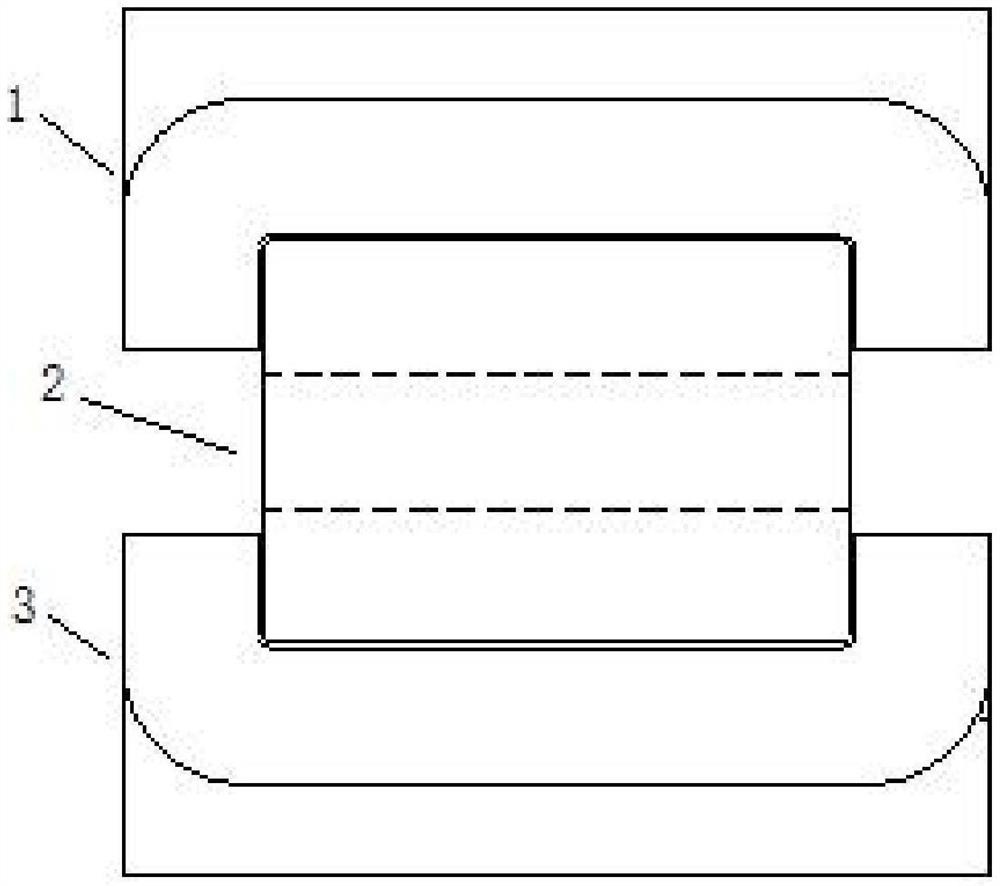

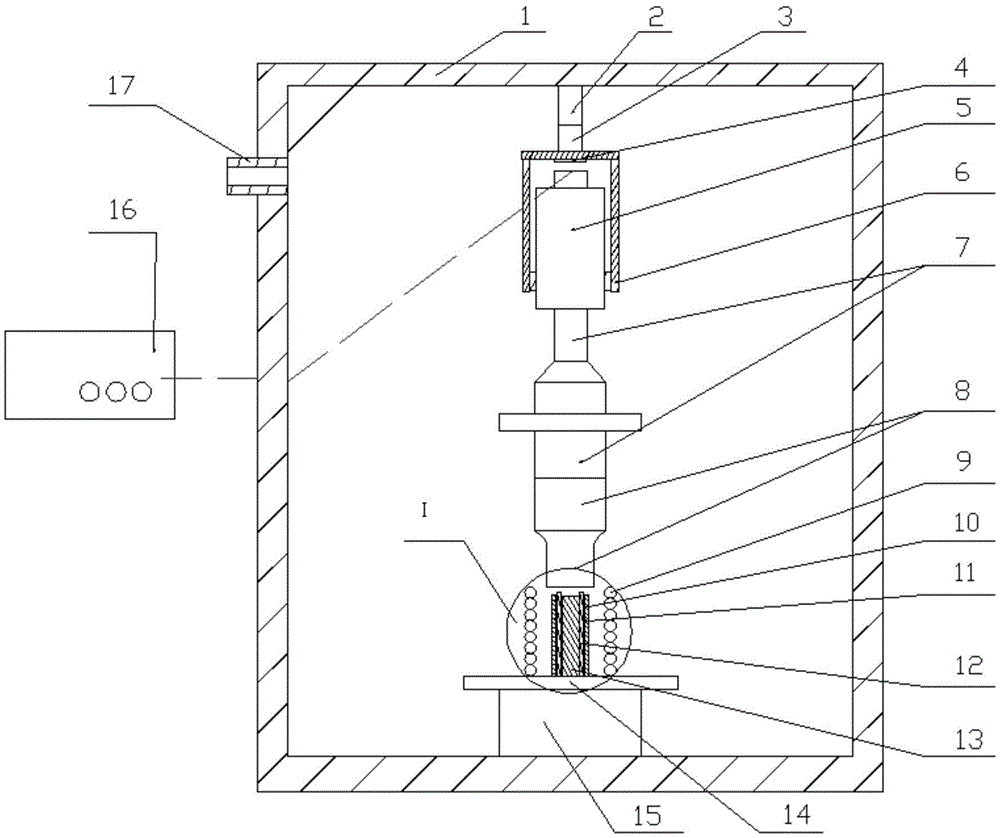

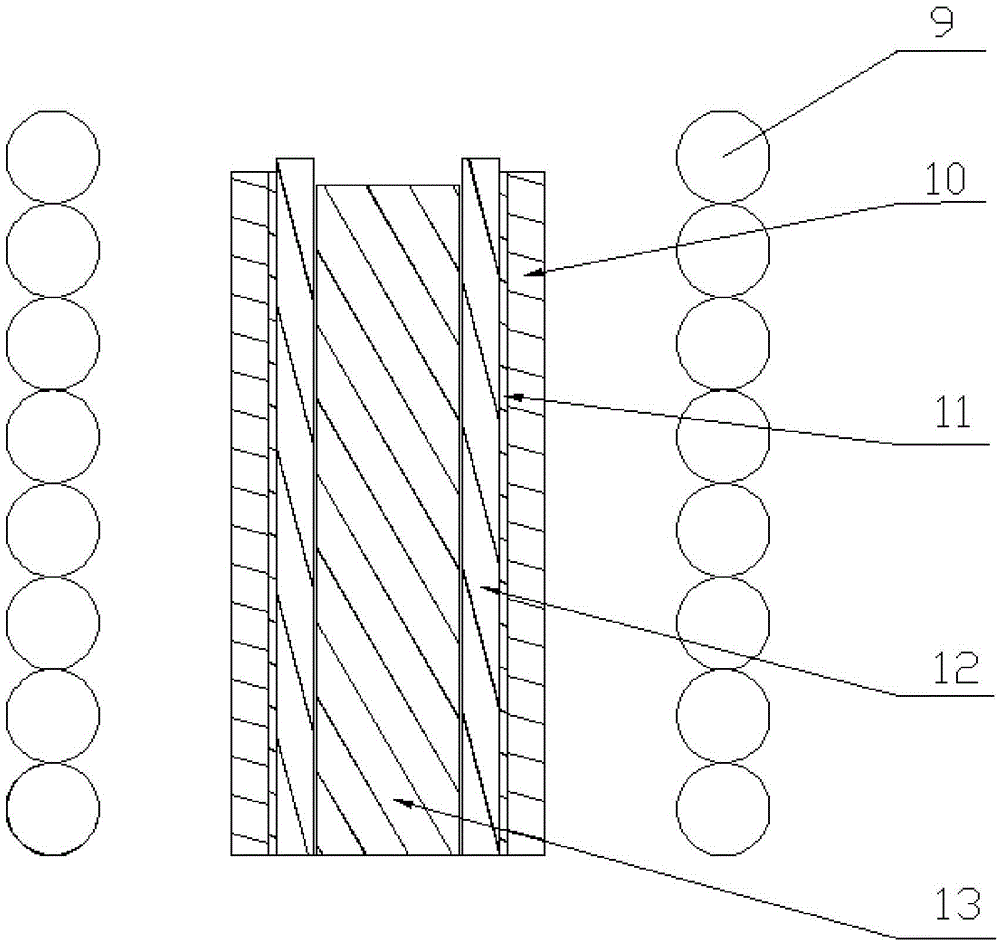

The invention discloses an electromagnetic induction heating press-roller, which has an integral double-end supporting structure and comprises a rotating device and a fixing device, wherein the rotating device consists of an action roller and a rotating shaft which are connected; the rotating shaft inputs a rotating torque to drive the action roller to rotate; the fixing device consists of a fixed shaft, a sleeve arranged on the outer side of the fixed shaft, magnetizers and excitation coils; through the magnetizers and excitation coils segmentedly installed outside the sleeve, a magnetic airgap is formed between the outside end face of the fixed magnetizer and the inner circular face of the rotating action roller; the alternating magnetic field forms a circuit through the magnetizer, the air gap and the action roller metal; the magnetic field in the action roller forms an eddy current so as to uniformly heat the working face of the rotating action roller. Since a structure of axially segmented magnetizers and excitation coils is adopted, a magnetic circuit is formed on the working face metal of the heating roller only to avoid the magnetic circuit penetration of the non-heating working part and reduce the excitation current, and simultaneously prevent the machine parts from overheating; besides, the induction heating efficiency can be improved so as to control the axial temperature gratitude of the heating roller continently.

Owner:WUHAN UNIV OF TECH

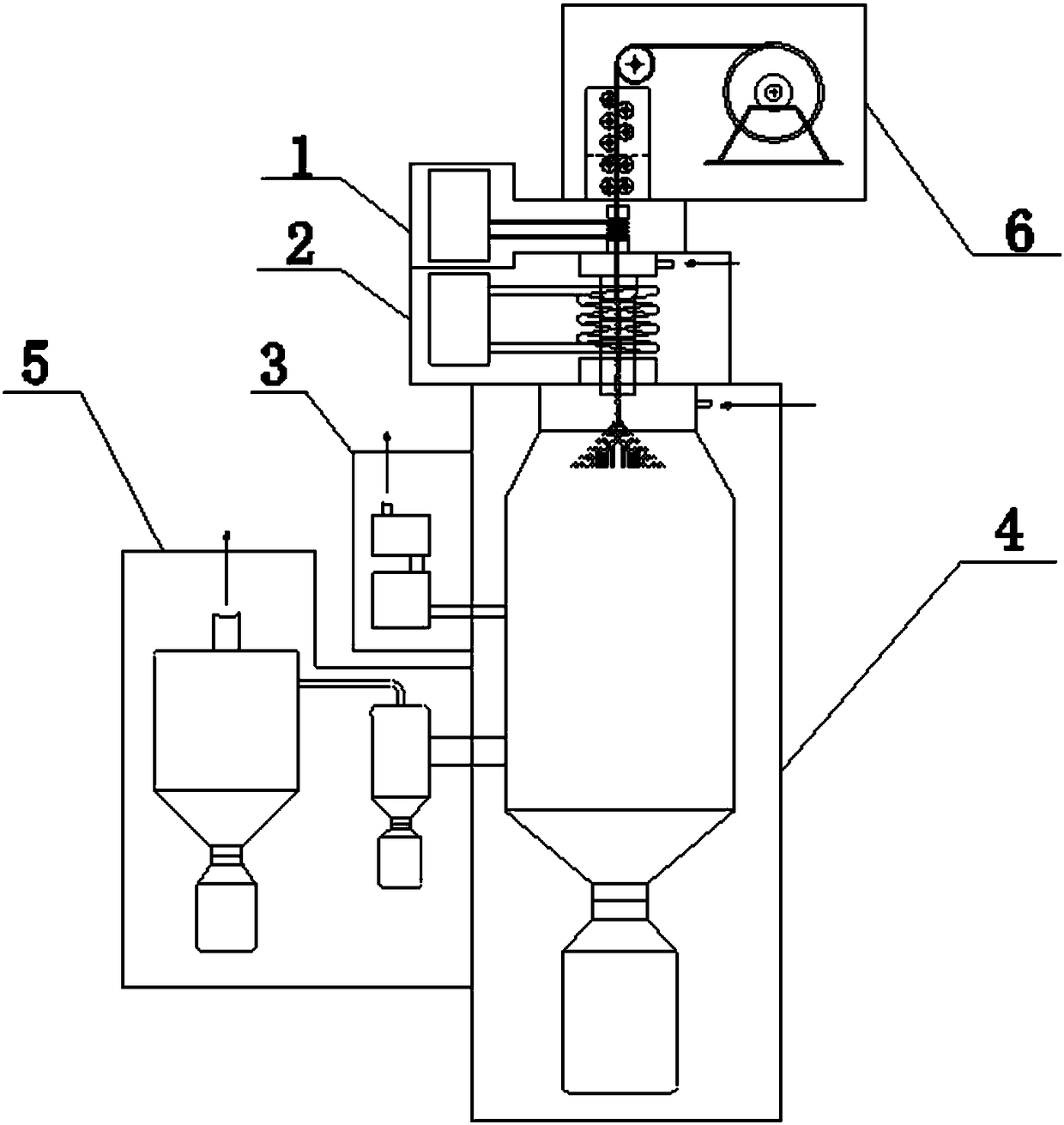

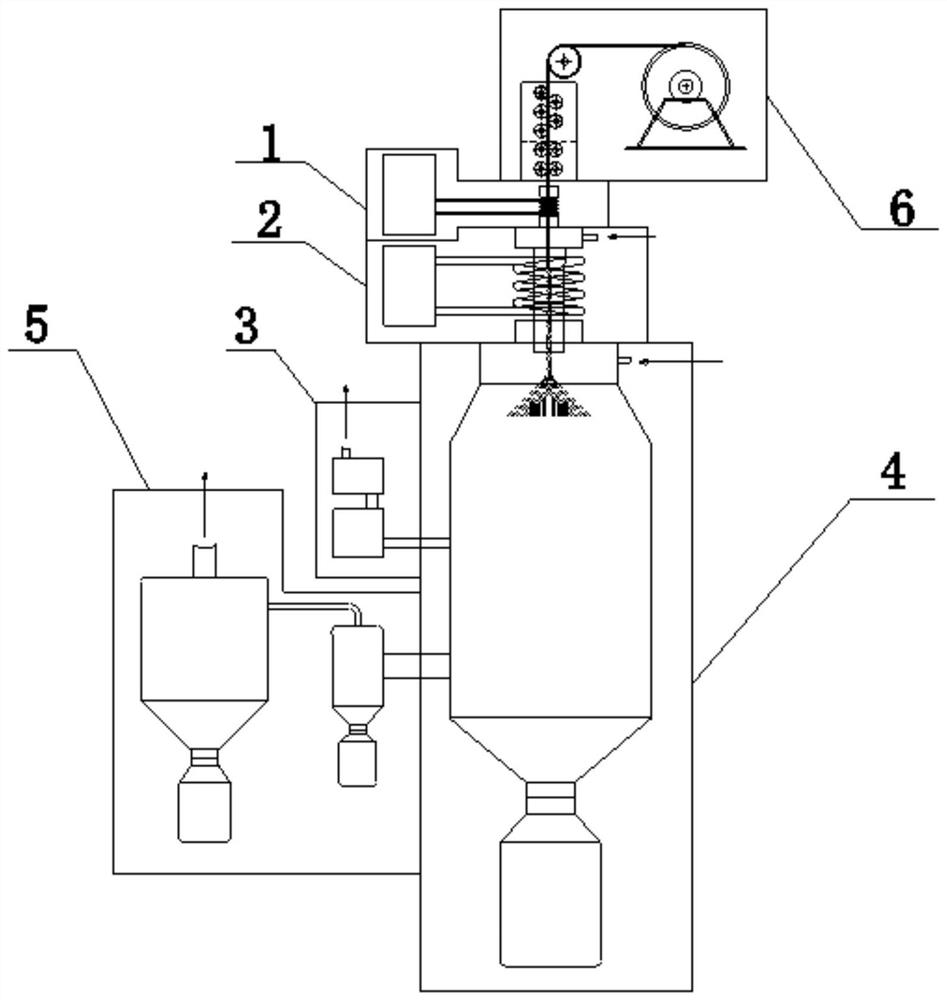

Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

ActiveCN108161019AHigh purityPrevent purityAdditive manufacturing apparatusHigh pressureRadio frequency

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

Chamber component and metal organic compound chemical vapor deposition equipment with same

The invention discloses a chamber component which comprises a chamber outer cylinder, an induction coil and a graphite sleeve, wherein an outer cylinder cavity serving as a reaction cavity is limited in the chamber outer cylinder; the induction coil is arranged around the chamber outer cylinder; and the graphite sleeve is sleeved in the outer cylinder cavity of the chamber outer cylinder. According to the chamber component disclosed by the embodiment of the invention, a graphite sleeve is arranged between a pallet and an induction coil and is closer to the induction coil than the pallet, thus the graphite sleeve experiences the induction heating of the induction coil before the pallet and can form a hot wall around the pallet, the pallet can be heated and subjected to heat preservation very easily, and the induction heating efficiency is improved. The invention also discloses metal organic compound chemical vapor deposition equipment with the chamber component.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

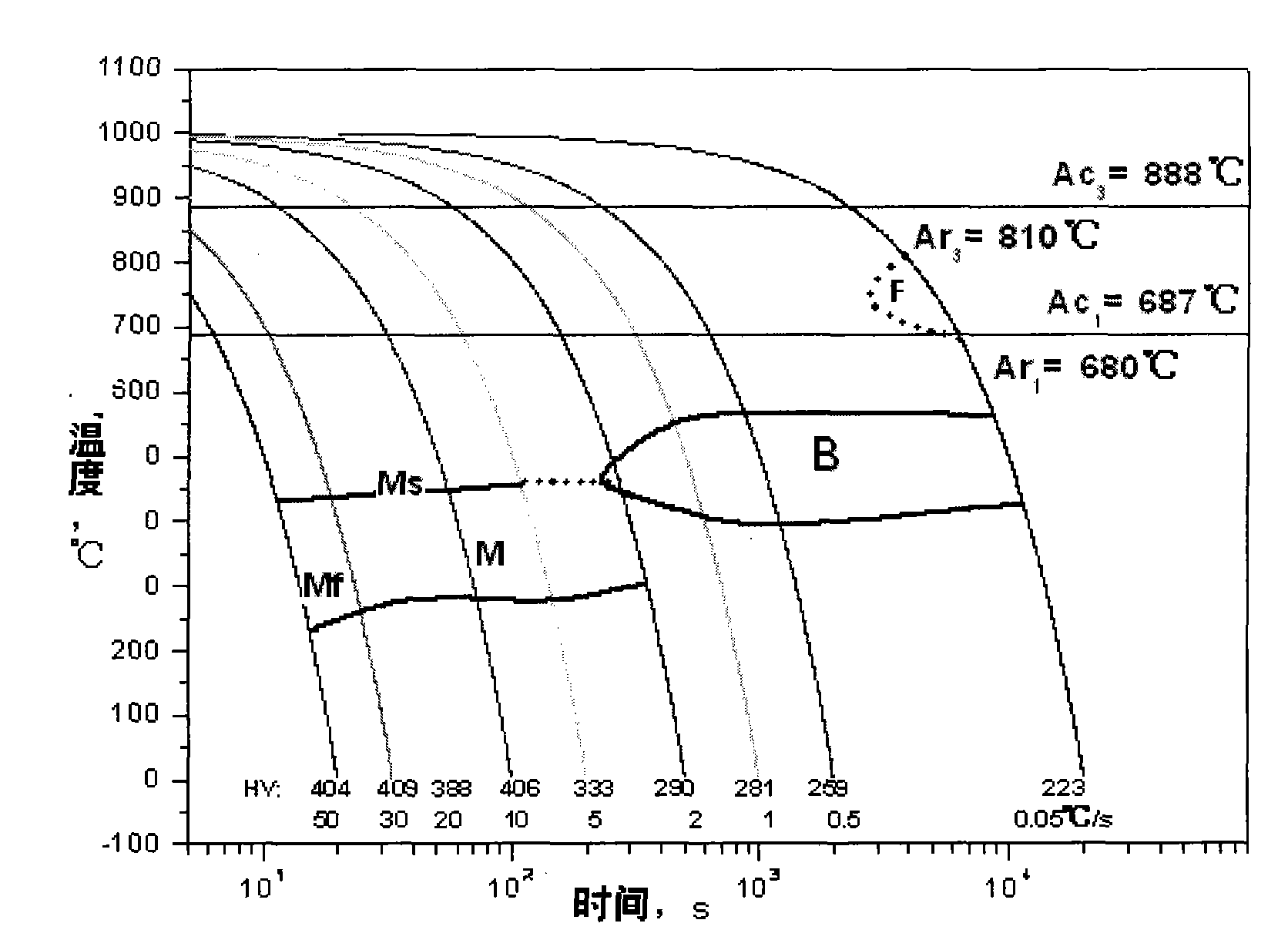

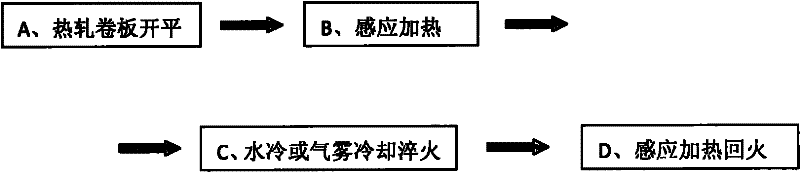

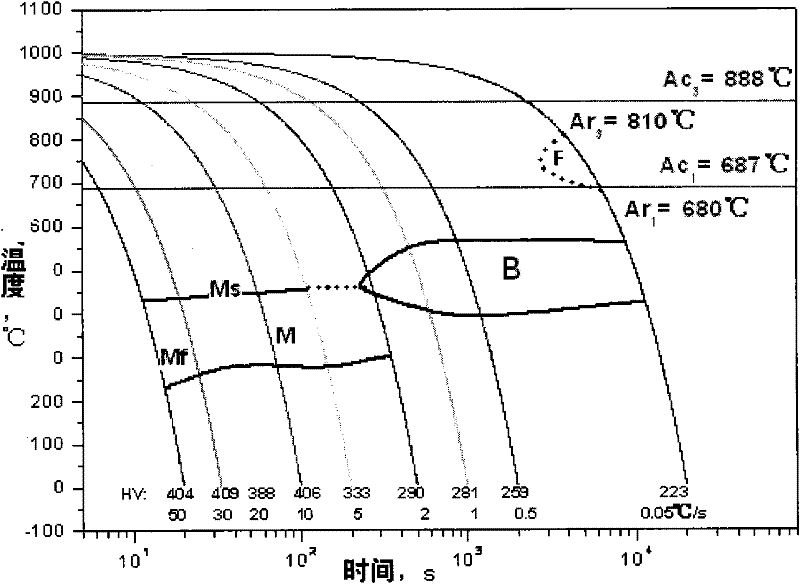

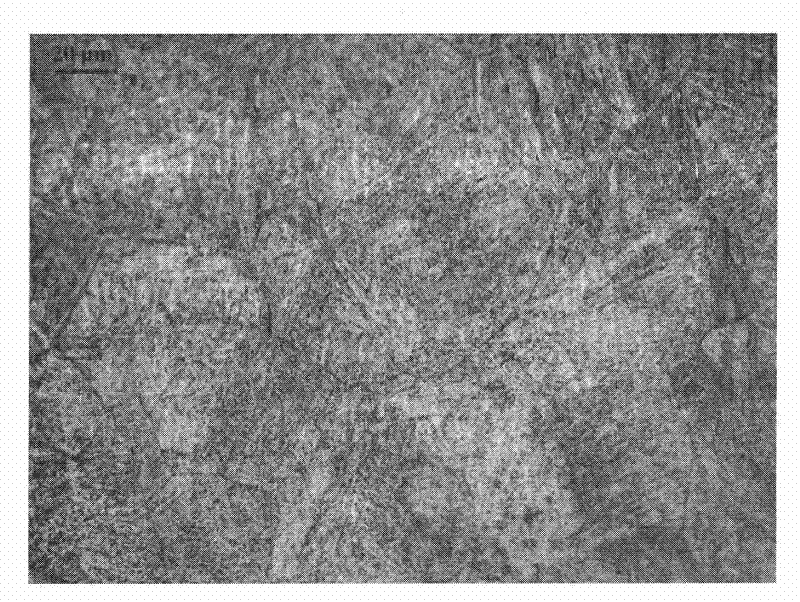

Manufacture method for manufacturing cantilever steel pipe with high strength and high toughness by using hot-rolling coiled plate

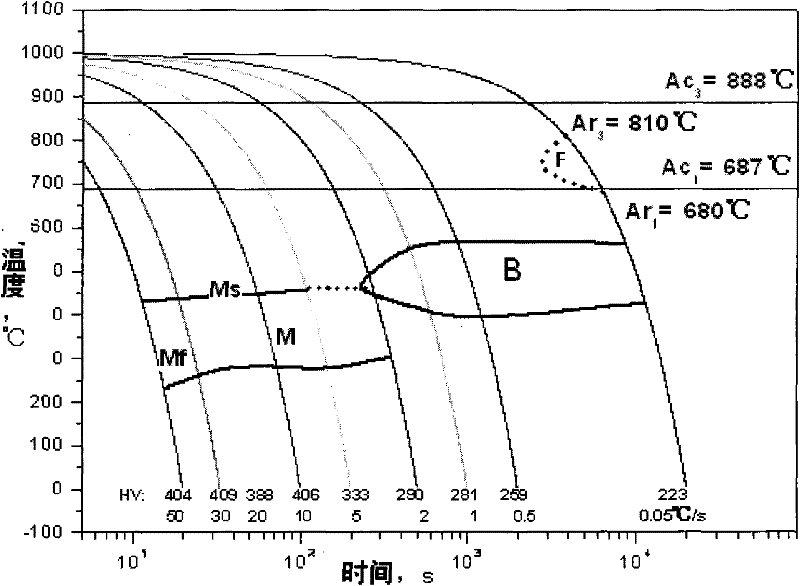

ActiveCN101603156AAccurate heating temperature controlLess investmentIncreasing energy efficiencyFurnace typesHeating timeSmall footprint

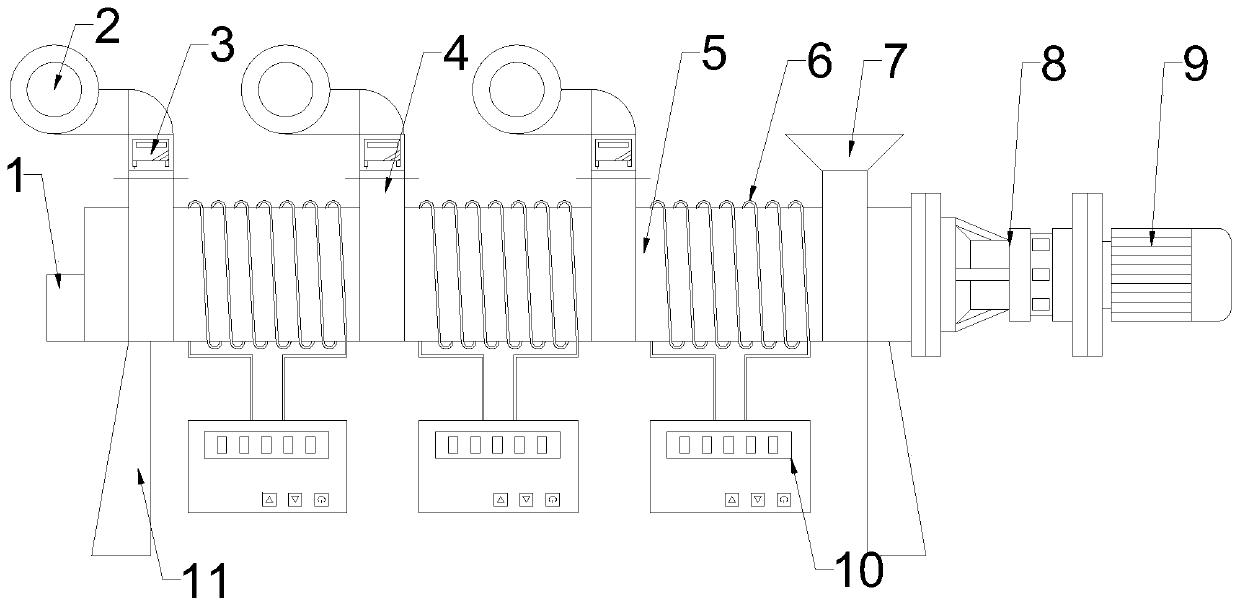

The invention relates to a manufacture method for manufacturing a cantilever steel pipe with high strength and high toughness by using a hot-rolling coiled plate. The method comprises the following steps that: firstly, a hot-rolling coiled plate is rolled into an ERW welding pipe by using an ERW pipe welding machine set, the ERW welding pipe is heated by induction in induction heating equipment, the heating time is within 60-140s, the ERW welding pipe is heated to 910DEG C to 960DEG C, and austenitizing is carried out; then, the ERW welding pipe enters a water-cooling or steam-cooling quenching machine set to carry out quenching, the quenching and cooling speed of the ERW welding pipe is greater than or equal to 5DEG C / s, and a quenched martensite organization is obtained after quenching; tempering is carried out after quenching, induction heating is carried out by adopting the induction heating equipment in the tempering, the heating temperature of the quenched martensite organization is 220DEG C to 440DEG C, the tempering time is 80 to 180s, and a tempered martensite organization is obtained; and finally, straightening, flaw detection, surface inspection and sampling inspection are carried out to finally obtain the cantilever steel pipe with excellent performance, high strength and high toughness. The invention has the advantages that the invention adopts a heat treatment method of induction heating to cause the heated cantilever steel pipe to be evenly heated, decomposes the residual austenite when obtaining the tempered martensite after induction tempering and has low equipment investment, little maintenance cost of the equipment, small occupation area and small environmental pollution.

Owner:武汉武钢实业机电材料工程有限公司

Insulation cover for crucible, and fabricating method

InactiveCN101003914AImprove insulation effectReduce heat transferAfter-treatment apparatusCrucible furnacesFiberThermal insulation

This invention discloses a method for producing thermal insulation sleeve of crucible with good thermal insulation performance by using highly oriented long-fiber graphite thermal insulation felt. The fibers in the thermal insulation felt are mainly oriented parallel to the axis of the crucible. The thermal insulation sleeve of crucible with this material and structure has good thermal insulation performance, and can better inhibit the generation of induced eddy current in the thermal insulation sleeve than traditional thermal insulation sleeve during induction heating of the crucible.

Owner:SHENZHEN UNIV

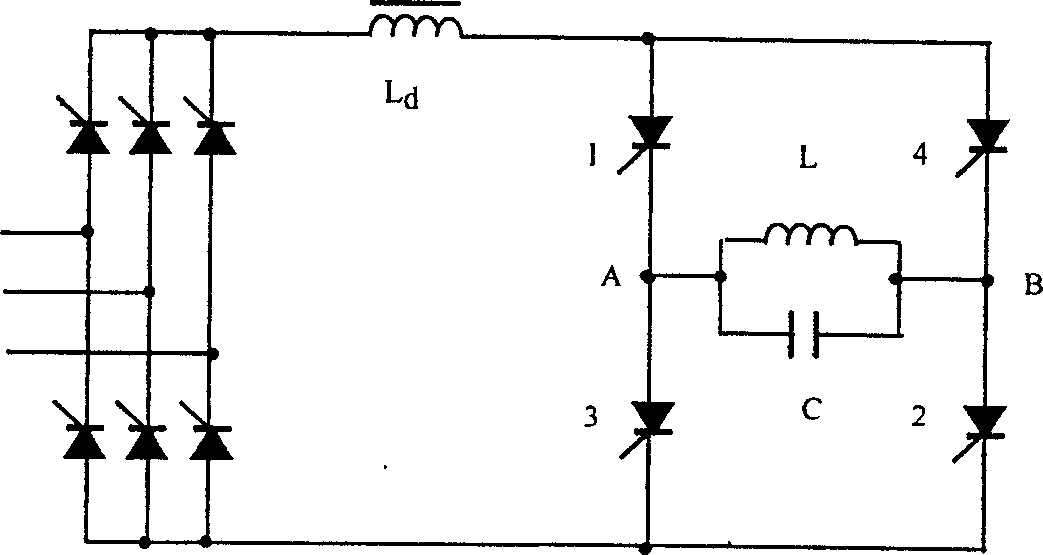

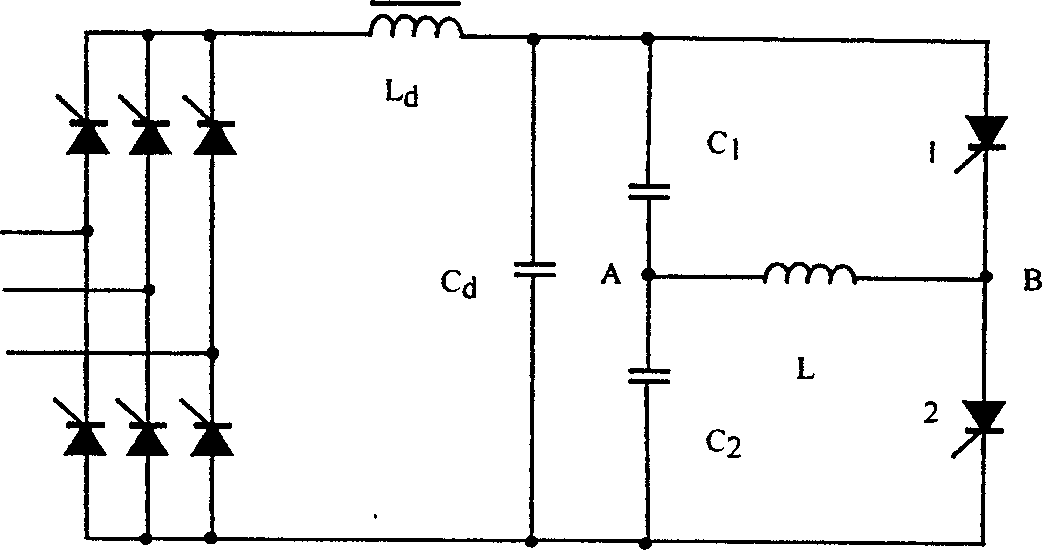

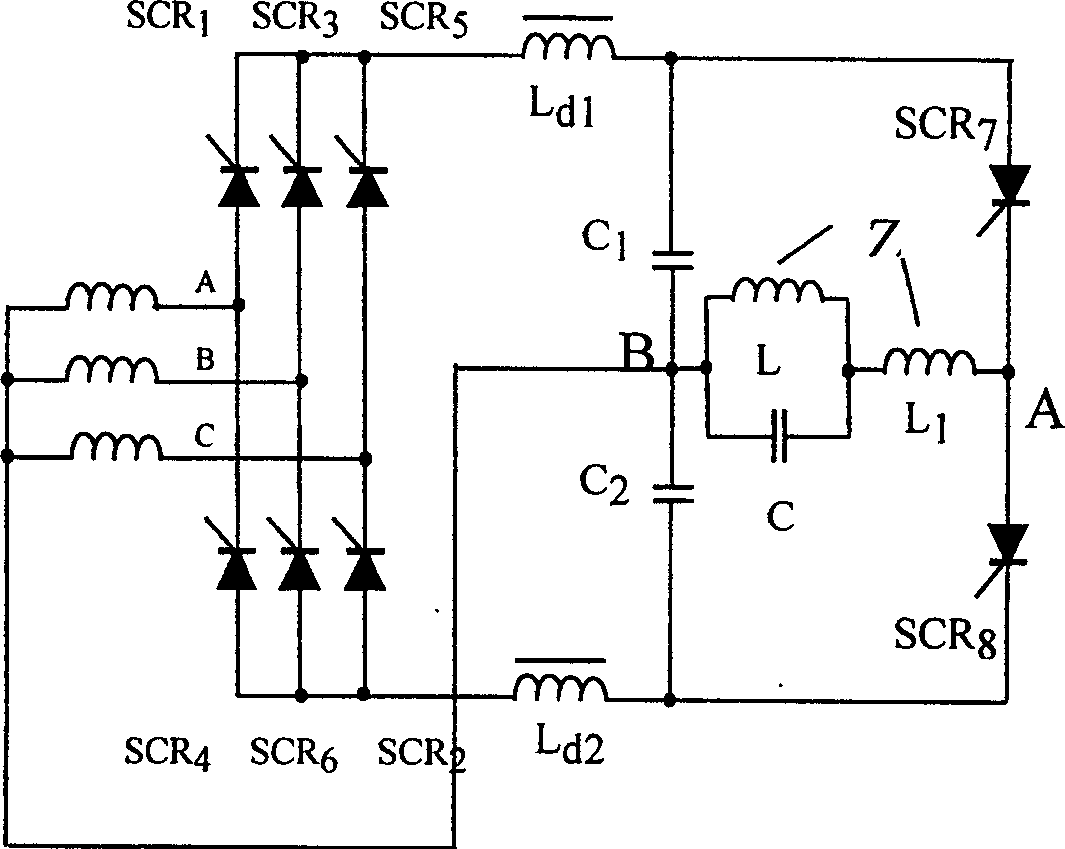

Great power IF power source with double parallel resonant inversion circuit

InactiveCN1507143AInhibition of voltage increaseLower Q valueAc-dc conversionAc-ac conversionOvervoltageIntermediate frequency

The great power IF power source includes two, one positive and one negative, independent constant-current sources comprising triphase half-wave rectifier. In the case the parallel furnace load LC circuit is equivalent to an impedance R, each of the circuit comprising C1, SCR7, L1 and R and the circuit comprising C2, SCR8, L1 and R constitutes one parallel channel powered by the positive and the negative constant-current sources. Together with the altered conducting of SCR7 and SCR8, these two parallel channels complete the positive and the negative half-wave IF current resonance separately. The current resonance of C1L1 or C2L1 can turn off SCR7 or SCR8 naturally to avoid inversion turning and result in reliable starting of oscillation. The resonance capacitors C1 and C2 are powered separately by independent positive and negative constant-current sources without voltage accumulation and overvoltage.

Owner:NANKAI UNIV

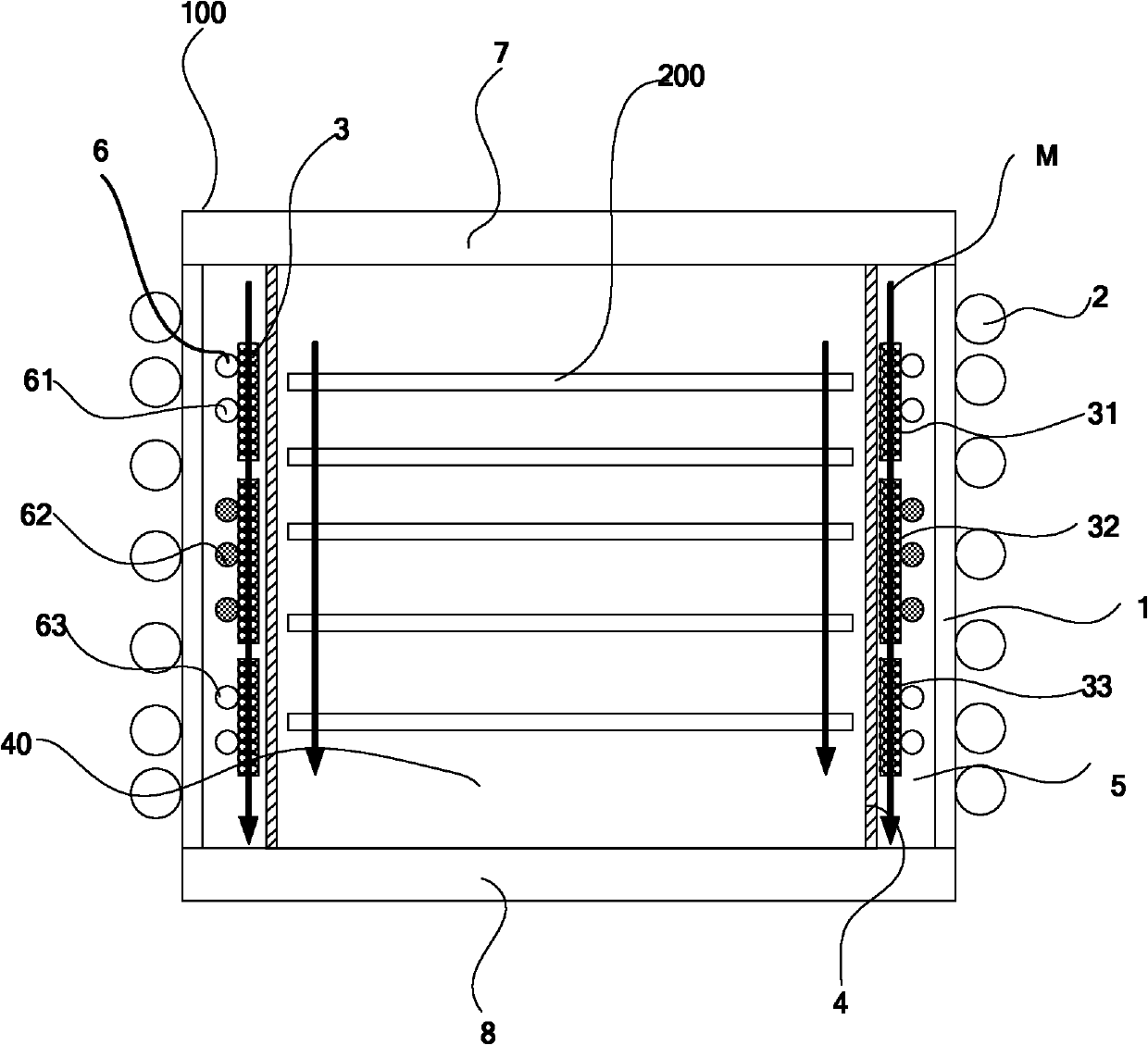

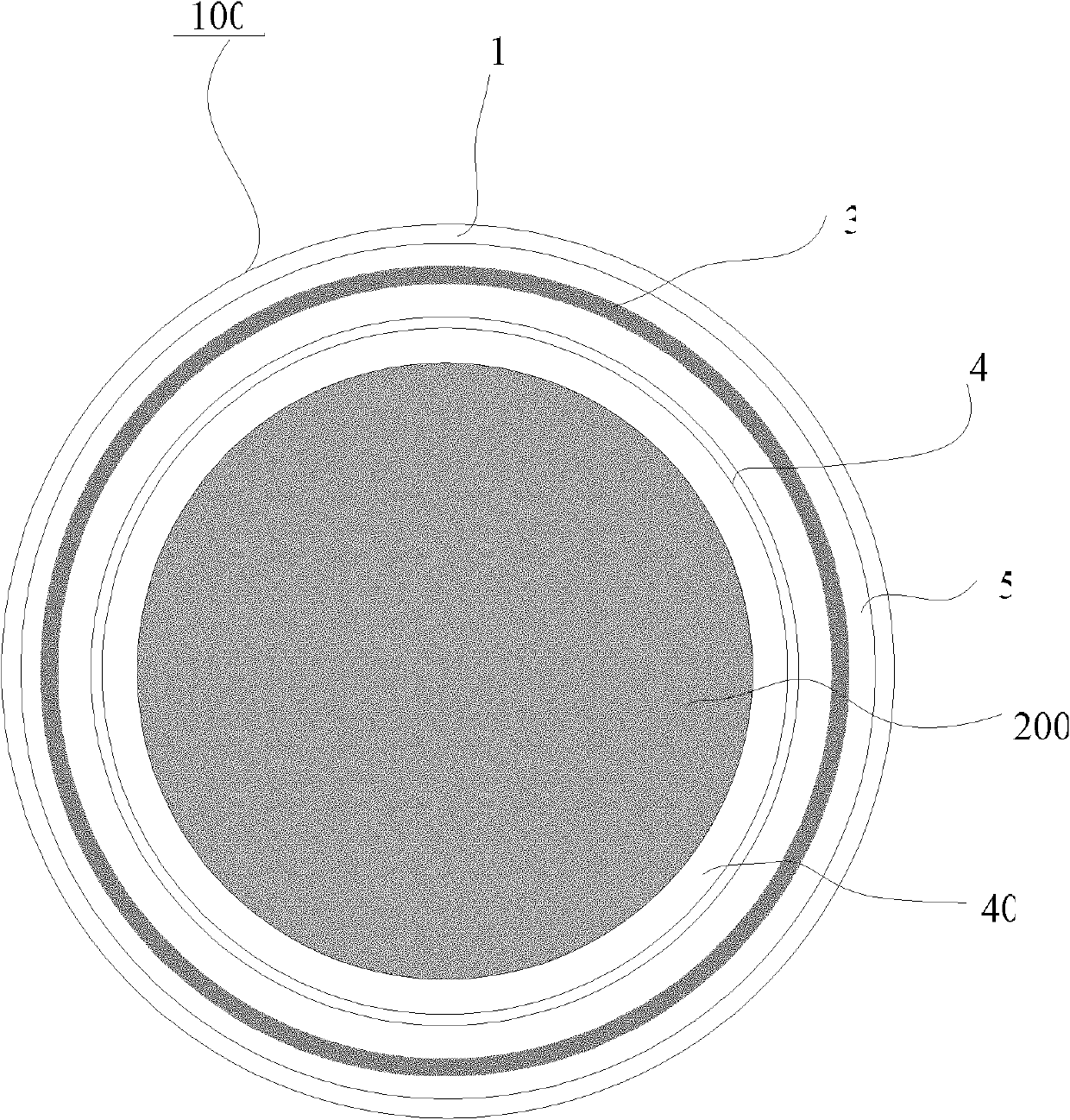

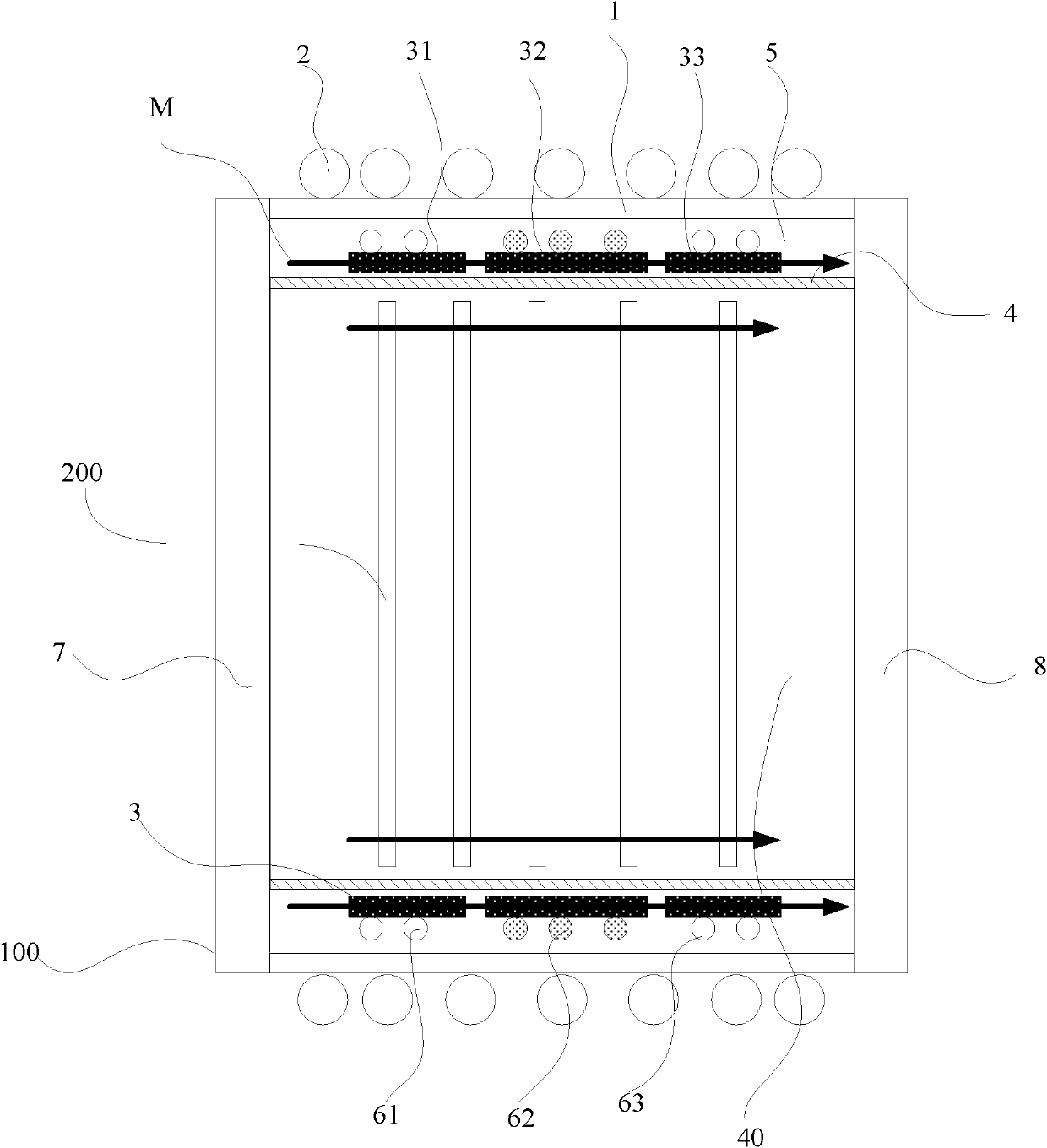

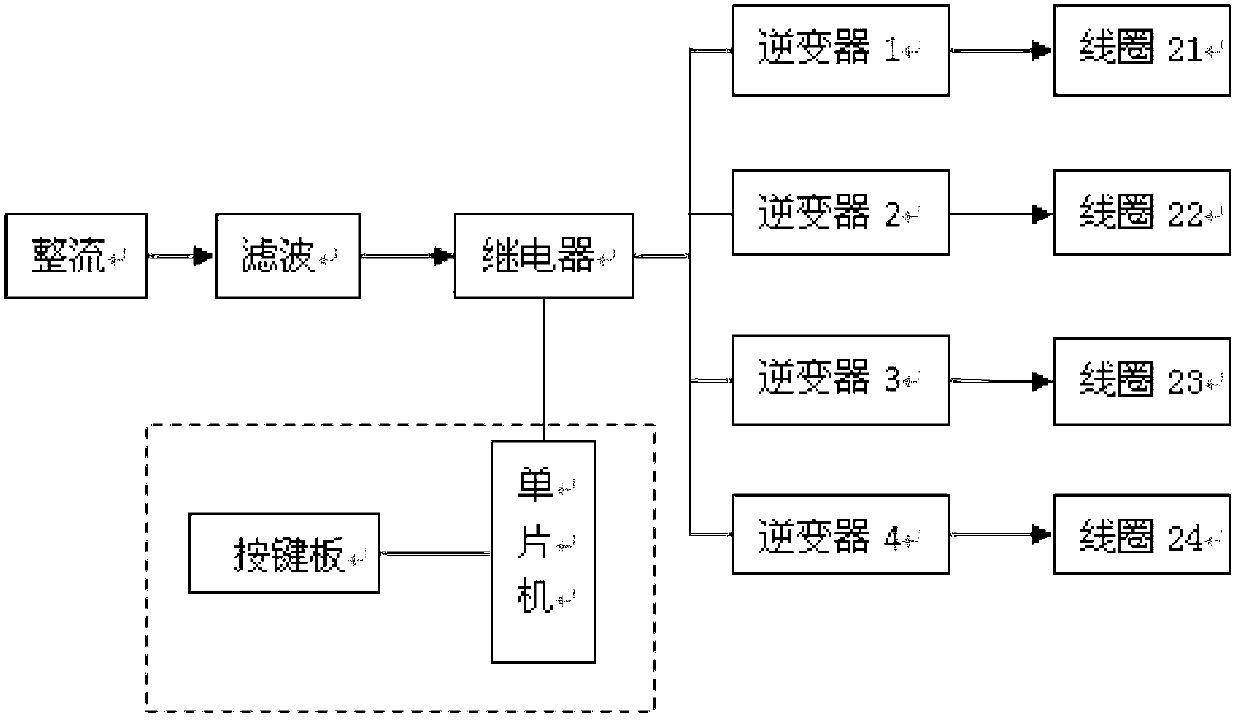

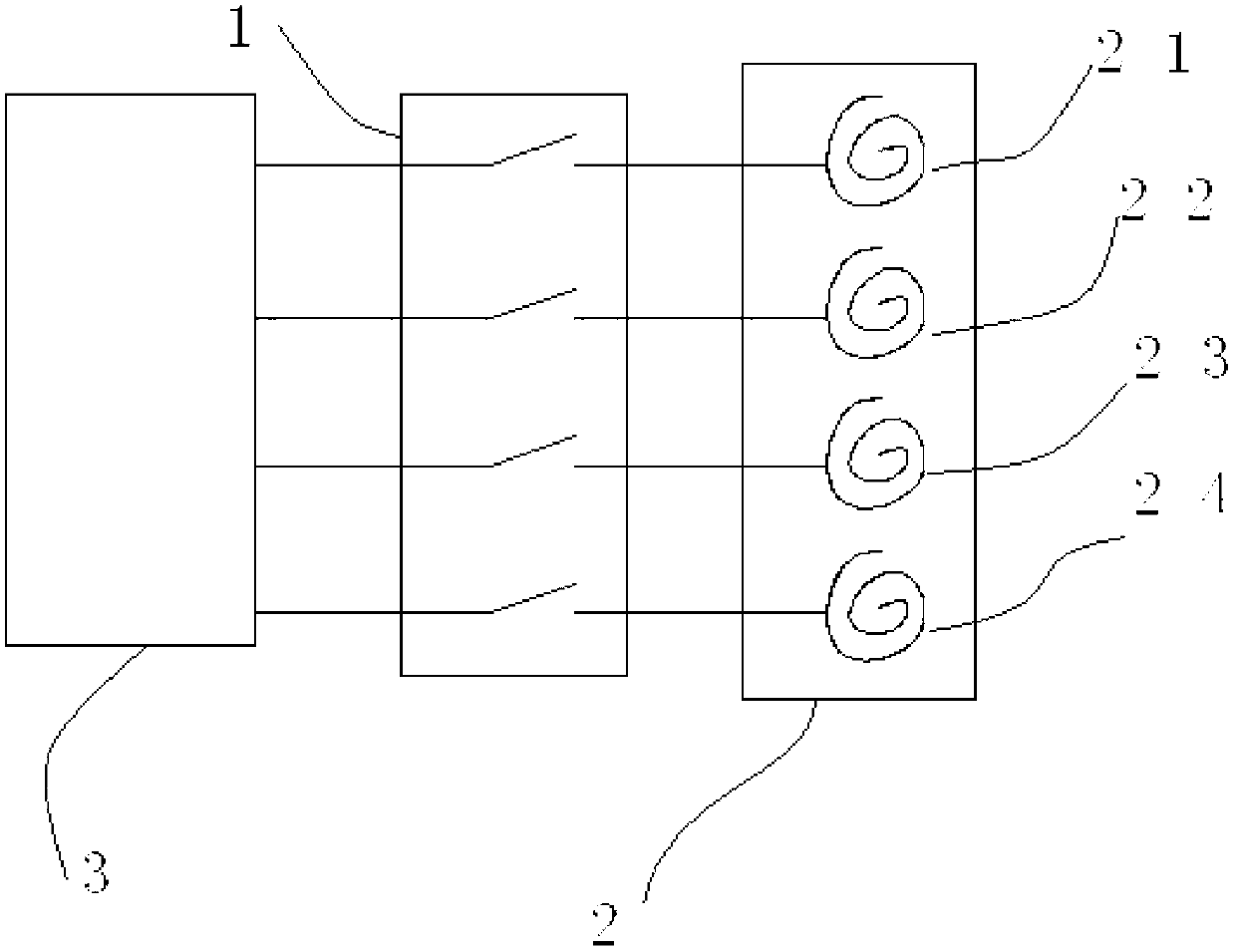

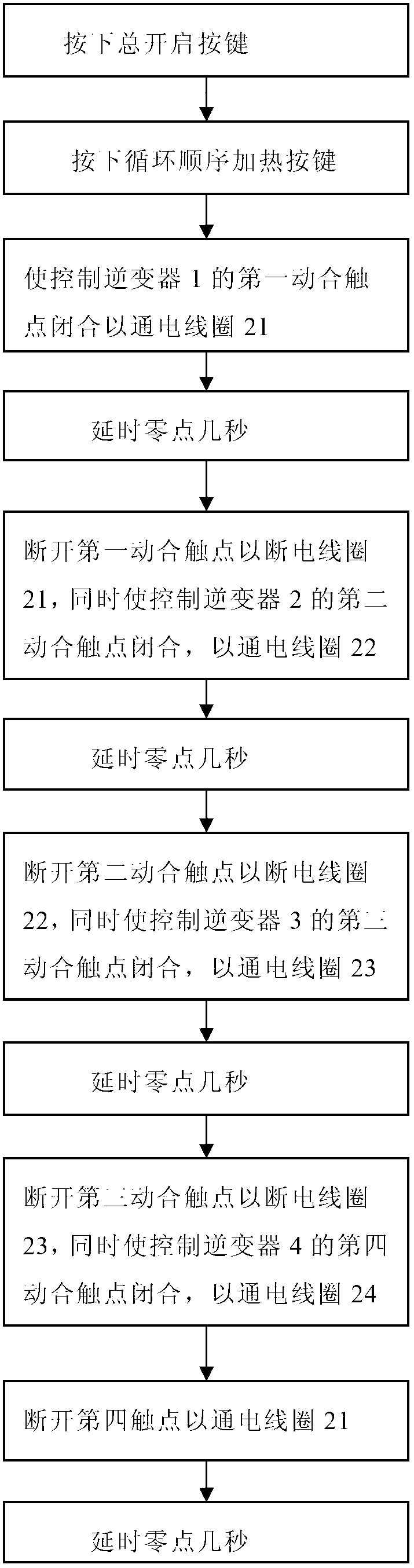

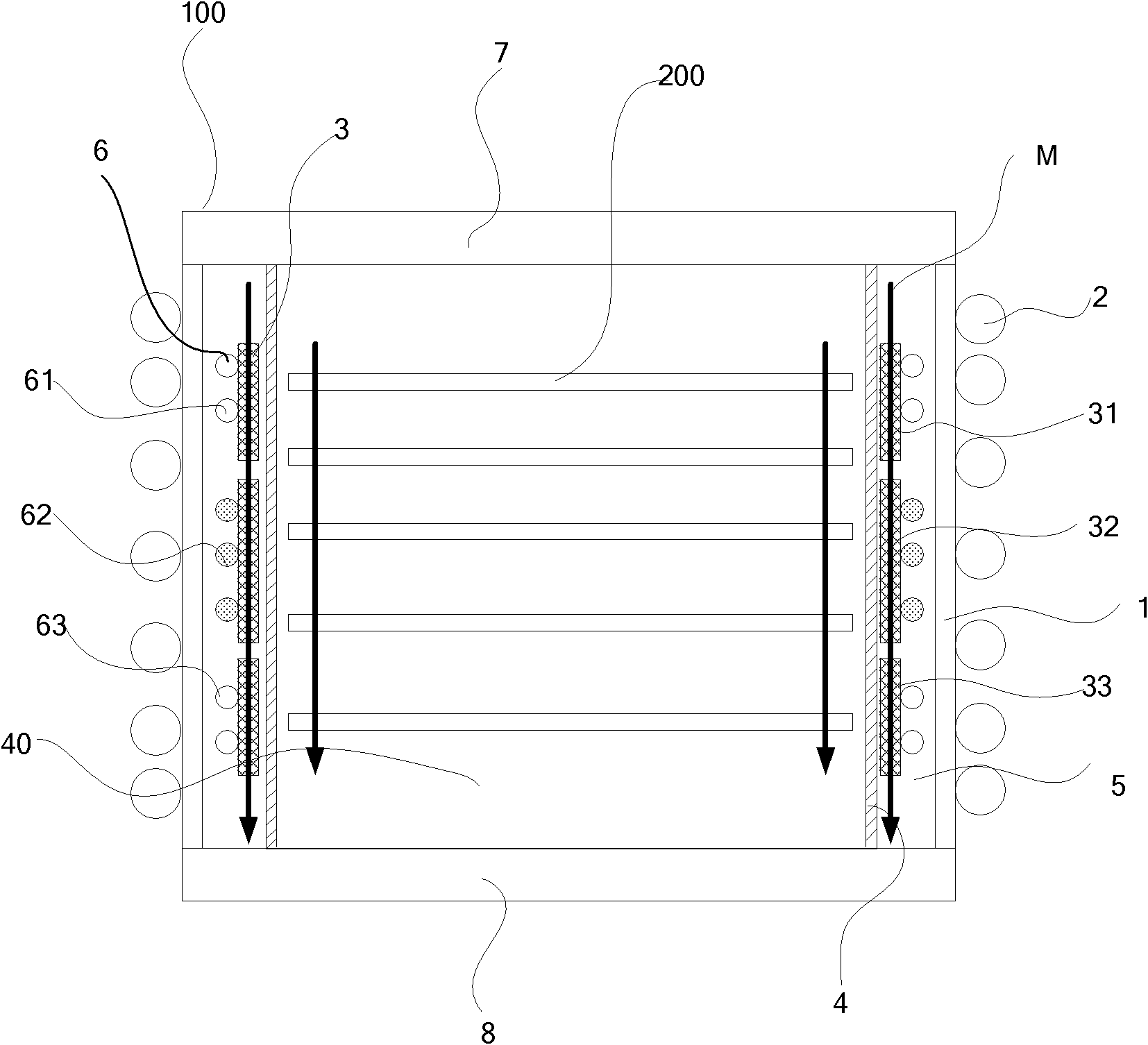

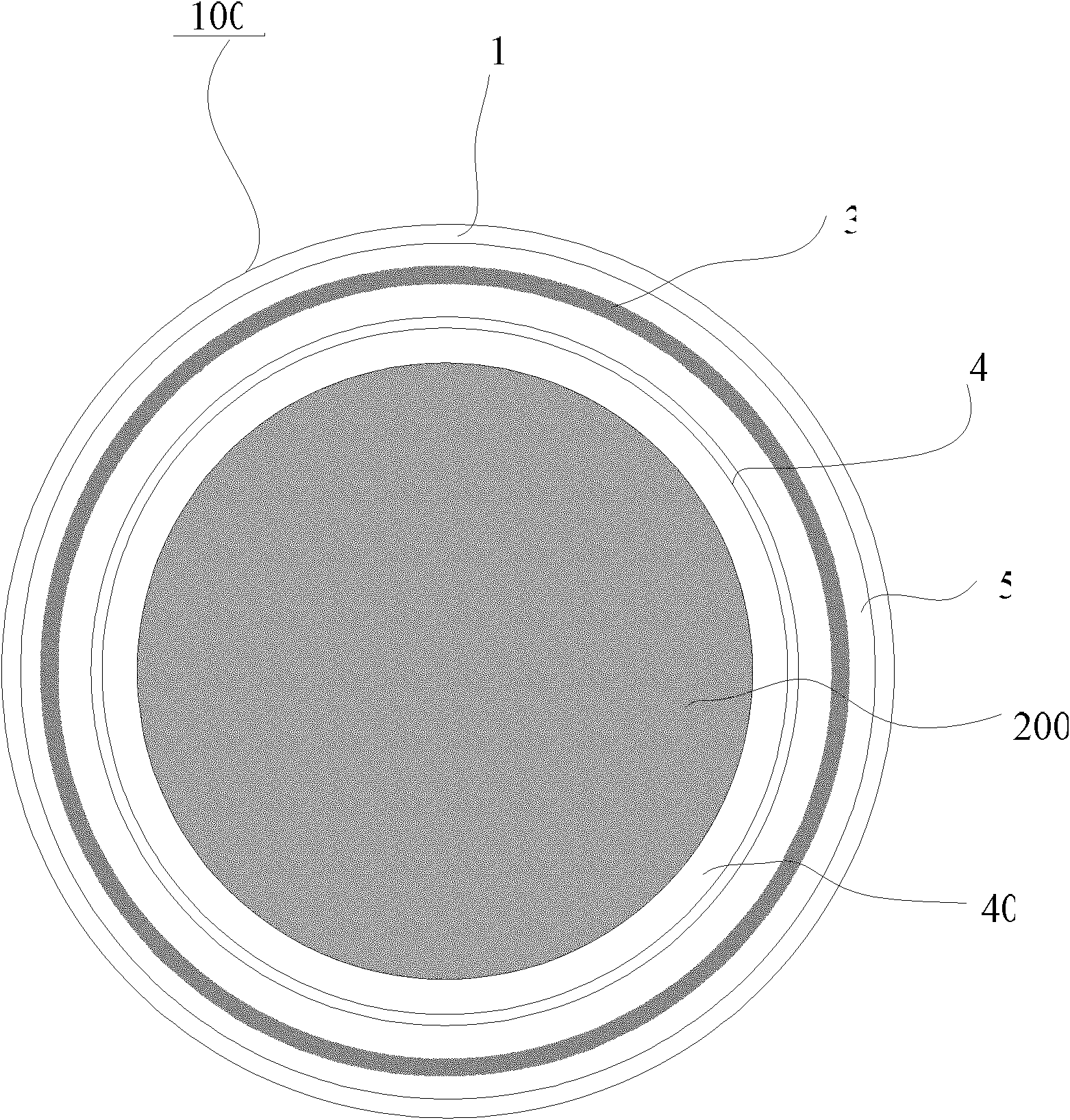

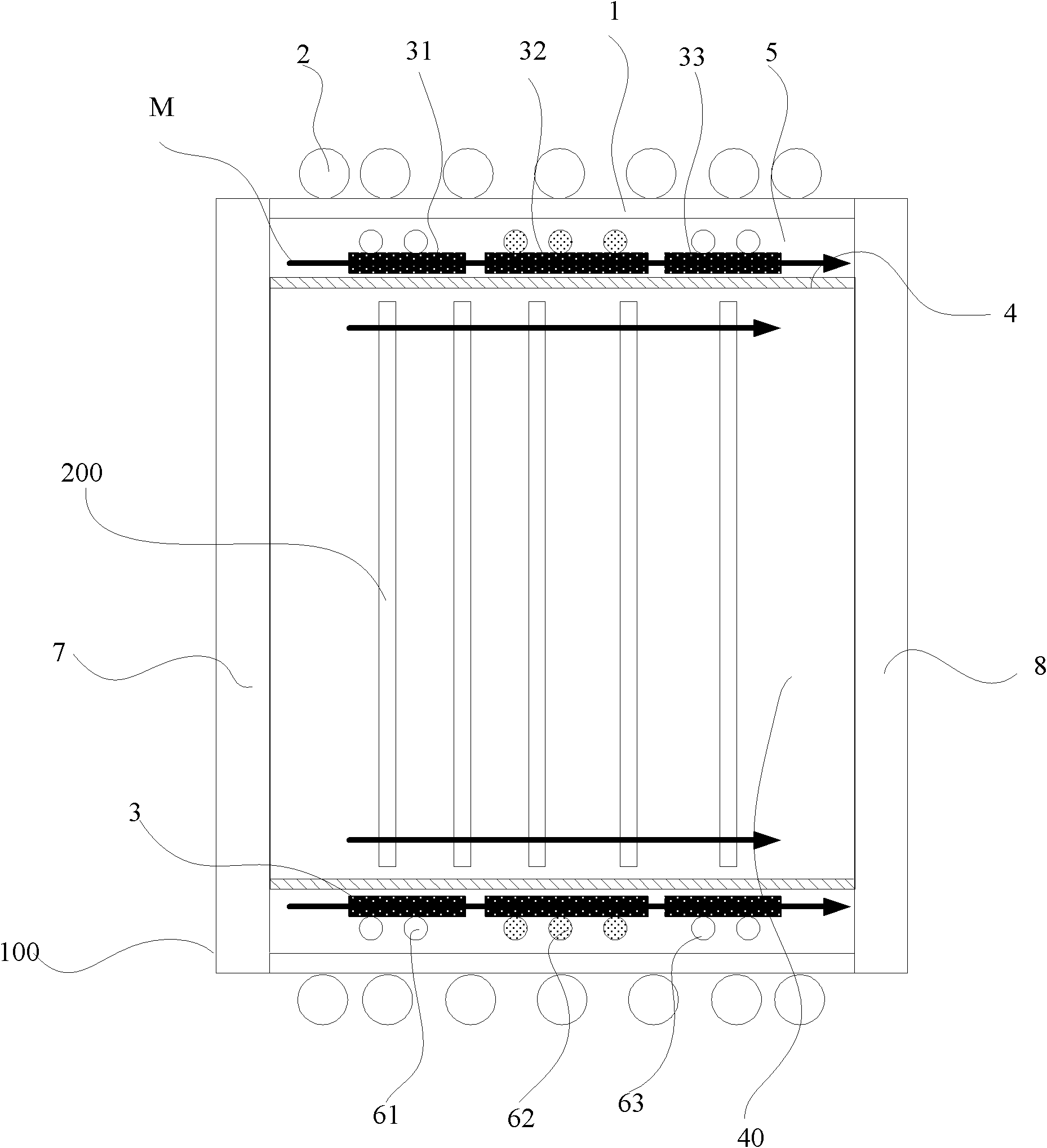

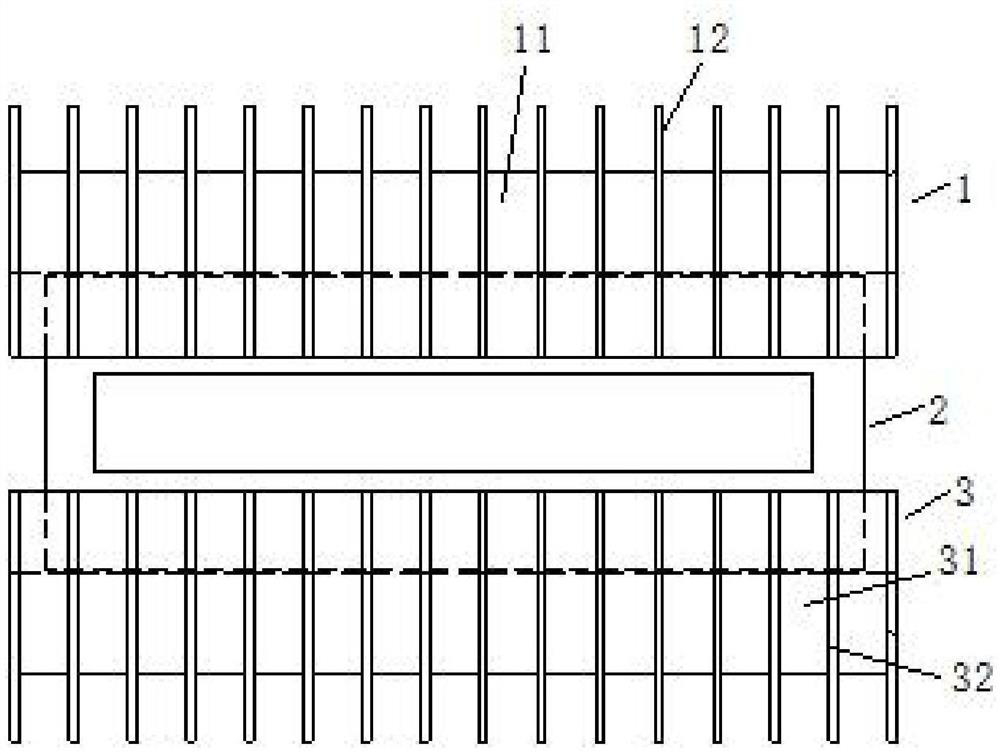

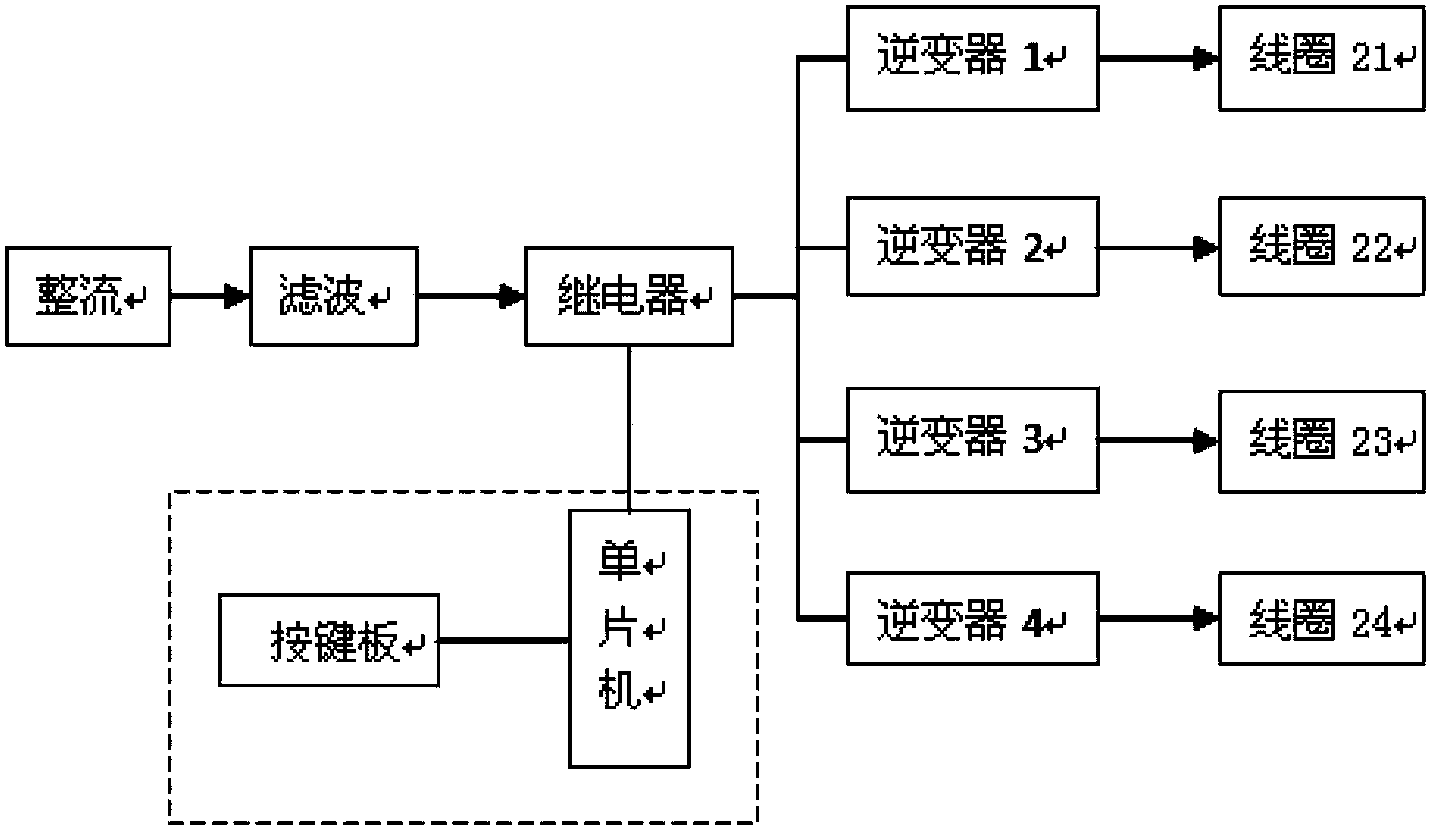

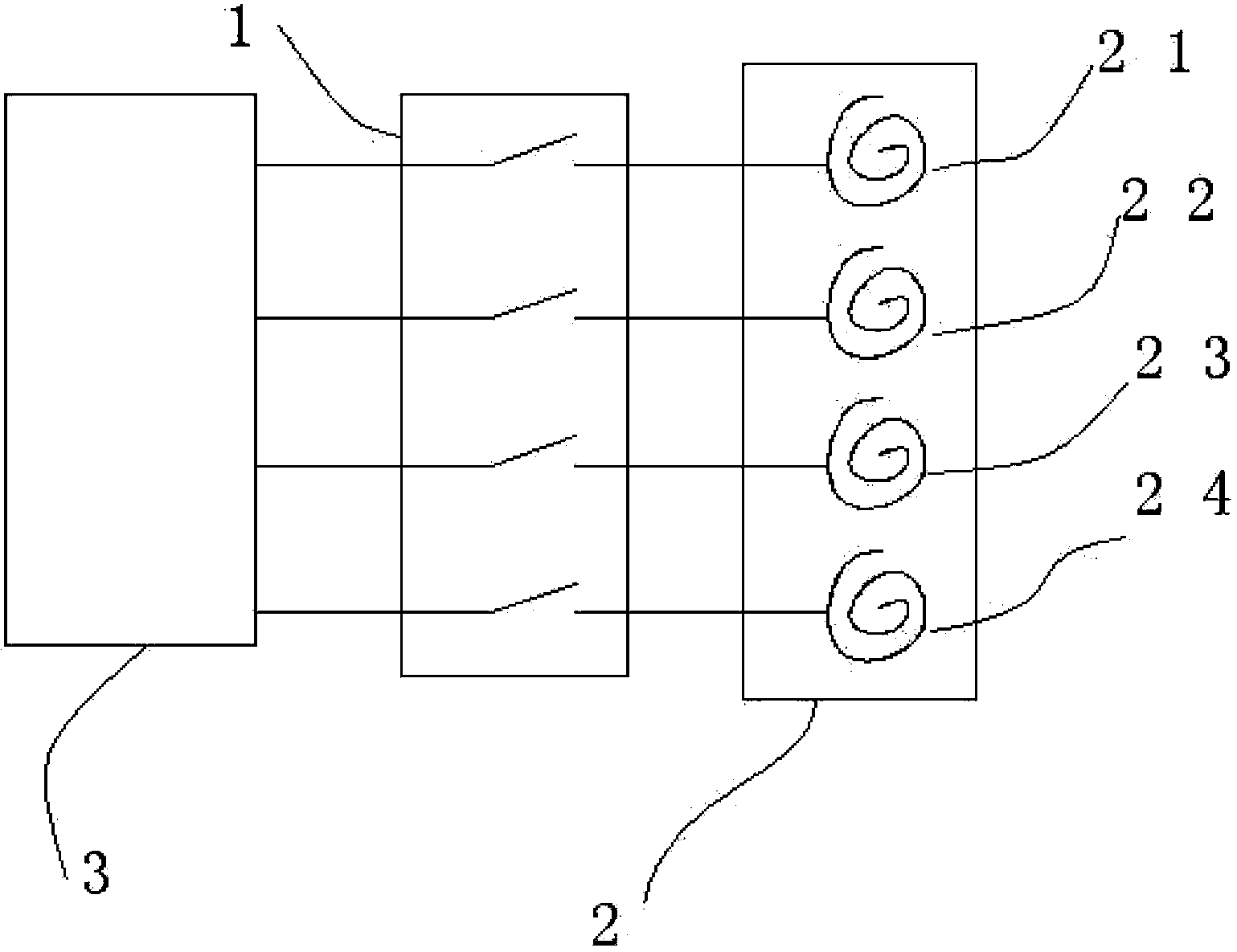

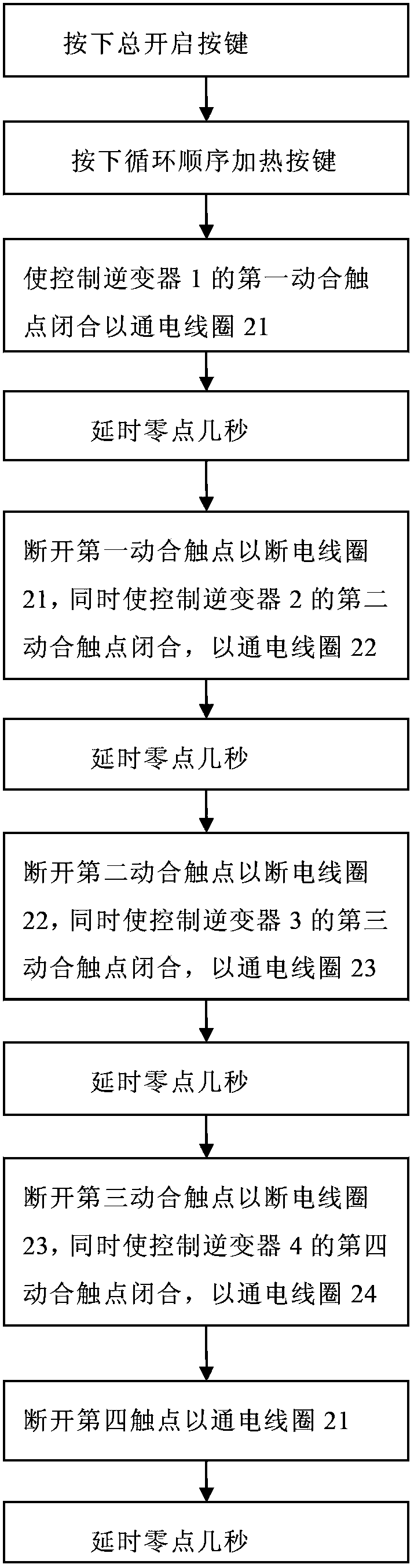

Induction heating system with external combined induction heating coil phased arrays and application for induction heating system

ActiveCN102740520AEliminate interactionAchieve localized heatingInduction heating controlMicrocontrollerCompression molding

The invention discloses an induction heating system which is provided with external combined induction heating coil phased arrays and used for an injection molding process and an application for the induction heating system, and belongs to the field of methods for manufacturing injection molding products. According to the technical scheme, a singlechip, a relay, inverters, coils and a keyboard are provided, wherein a program for controlling each heating mode states is pre-set in the singlechip; and switching among the heating mode states is realized by the keyboard; induction coils is powered on or powered off according to the preset program sequence or other ways, so that mutual influence of magnetic fields among the coils is eliminated, and the heating efficiency is improved; and meanwhile, the coils also can be separately or synchronously powered on or powered off according to the specific sequence, so that local temperature of a mould cavity can be controlled, and the heating flexibility is increased; and therefore, the system is particularly suitable for performing injection molding on parts which are made of thermoplastic or thermosetting composite materials or heating complicated mould cavities of injection moulds and locally heating the mould cavities of the injection moulds during compression molding production.

Owner:芜湖精益达模塑股份有限公司

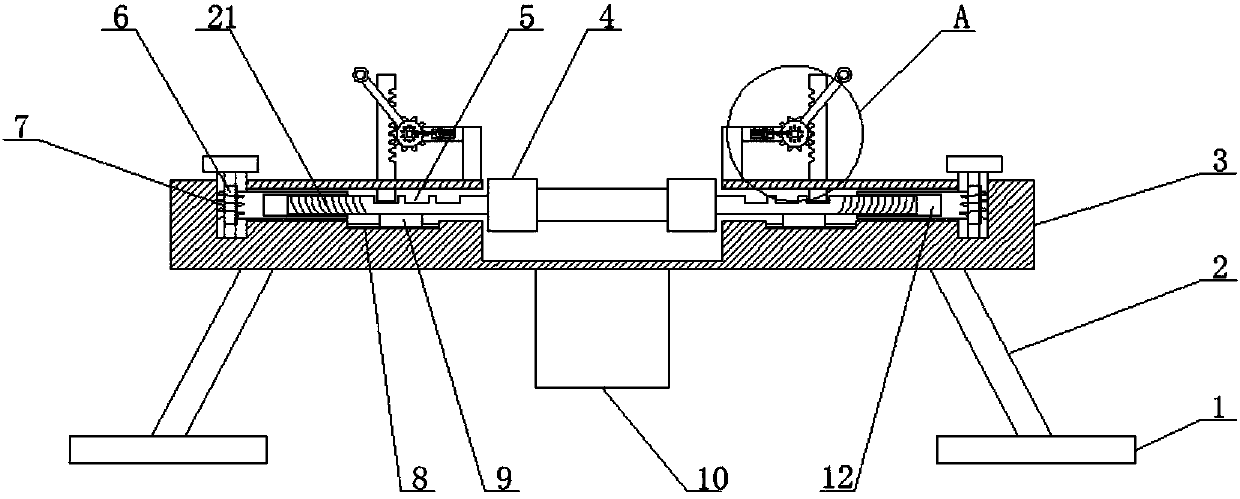

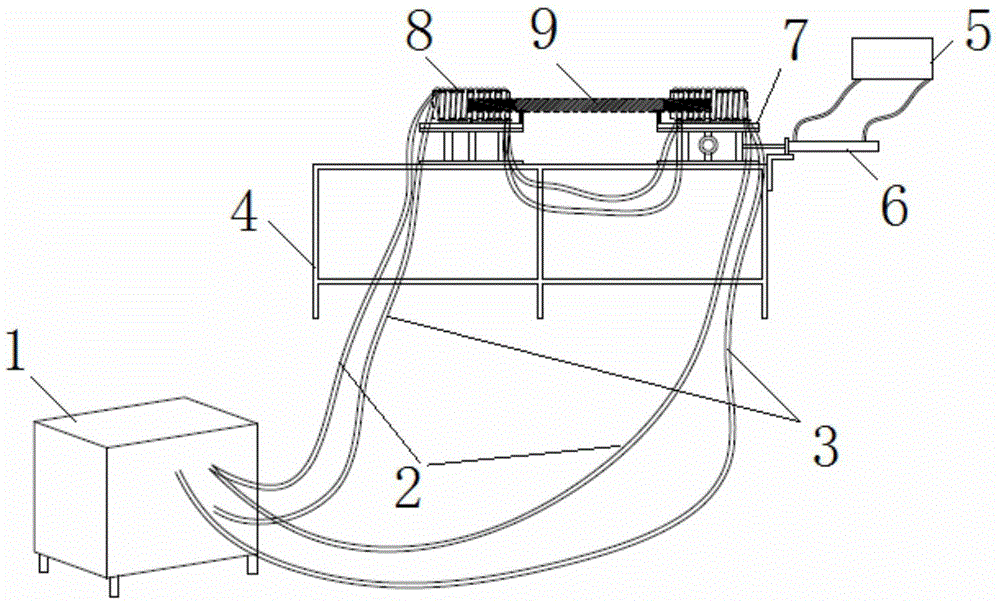

Equipment for simultaneously heating pier heads at two end parts of torsion bar

PendingCN108044008AReduce energy consumptionReasonable structural designIncreasing energy efficiencyEngineeringEnergy consumption

The invention discloses equipment for simultaneously heating pier heads at two end parts of a torsion bar. The equipment comprises a pedestal; an operation groove is arranged at the upper end of the pedestal; the upper end of the pedestal is provided with two device chambers; the two device chambers are separately positioned at the two sides of the operation groove; two worm rods are arranged at the upper end of the pedestal in a penetrating manner; one end of each worm rod is rotationally connected to the inner wall of the corresponding device chamber; one end, far away from the inner wall ofthe corresponding device chamber, of each worm rod is provided with a rotating wheel; the inner wall of each device chamber is rotationally connected with a worm gear; each worm gear is meshed with the corresponding worm rod; the opposite inner walls of the operation groove are each provided with a first circular chamber; and each first circular chamber communicates with the corresponding devicechamber. The equipment disclosed by the invention is reasonable in structural design, simple to operate, low in energy consumption by simultaneously heating the two ends of the torsion bar by using induction coils, high in induction heating efficiency and capable of saving time and efforts and greatly improving the production efficiency; the two ends are heated simultaneously, so the two ends areconsistent in temperature, the machining quality is guaranteed, and the equipment can be used for heating different specifications of torsion bars.

Owner:马鞍山云林百成机械制造有限公司

High-strength magnesium alloy extruded profile and manufacturing method thereof

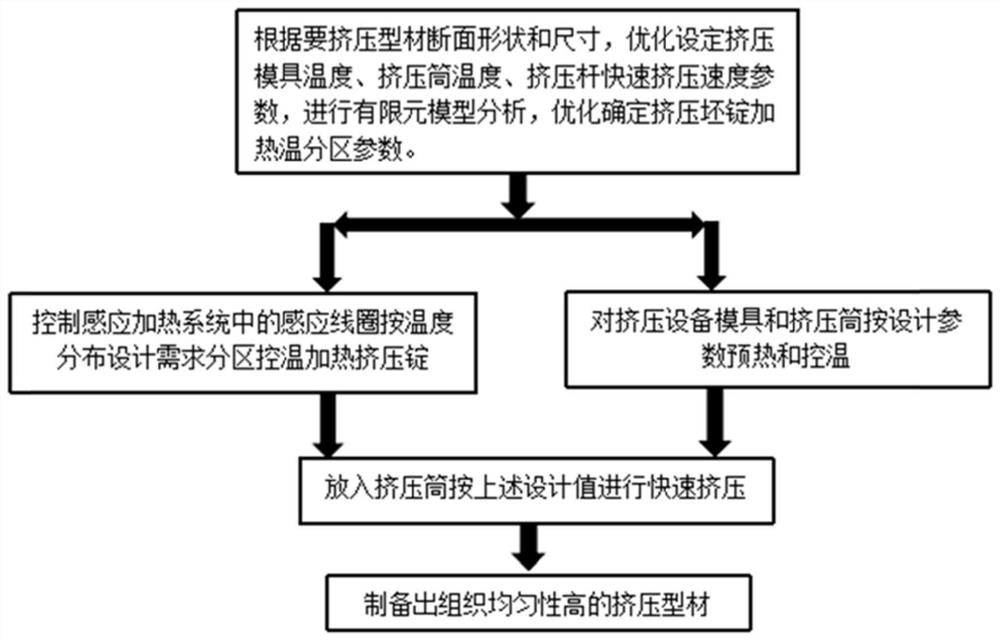

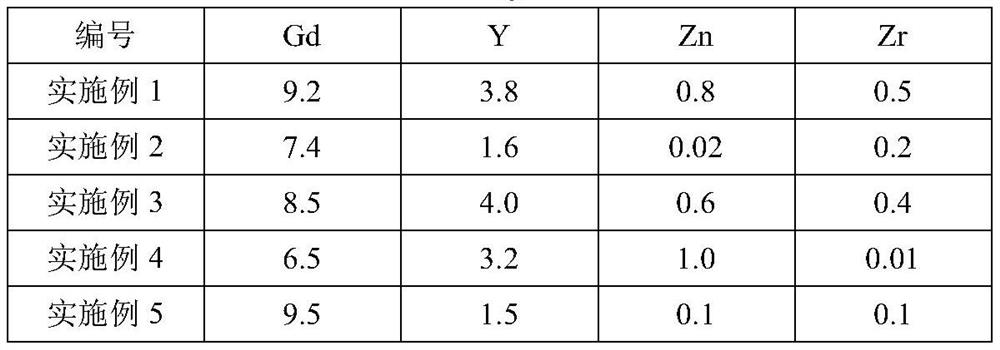

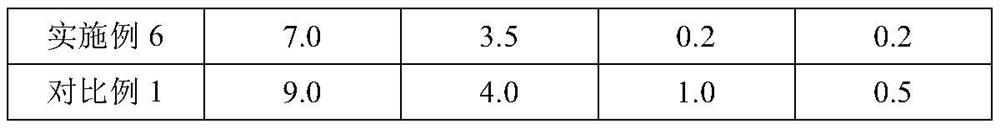

PendingCN113832371AFacilitates local temperature regulationHigh temperature control accuracyMetallurgyIngot

The invention discloses a high-strength magnesium alloy extruded profile. The high-strength magnesium alloy extruded profile comprises the following chemical elements in percentage by mass besides Mg: 6.5-9.5% of Gd; 1.5-4.0% of Y; 0.02-1.0% of Zn; and 0.01-0.5% of Zr. Correspondingly, the invention also discloses a manufacturing method of the high-strength magnesium alloy extruded profile, the manufacturing method comprises the following steps that an extruded ingot is prepared; the temperature distribution of the extruded ingot in each direction is determined based on finite element simulation software; an induction heating system is adopted to heat the extruded ingot according to the temperature distribution; and the heated extruded ingot is immediately placed in a preheated extrusion cylinder and an extrusion die to be extruded. The high-strength magnesium alloy extruded profile has good structure property uniformity, is excellent in performance and high in product quality, and has good popularization prospects and application values.

Owner:BAOSHAN IRON & STEEL CO LTD

Molten steel cleaning agent

PendingCN111876557AImprove qualityReduce energy consumptionProcess efficiency improvementSlagNon-metallic inclusions

The invention discloses a molten steel cleaning agent which is used for removing suspended non-metallic inclusions in molten steel in a molten state and gas dissolved in a metal solution, improving the quality of the molten steel and reducing the slag hole and pore rate of a casting product. The molten steel cleaning agent comprises 70%-80% of cement and 30%-20% of fluorite powder. By adding the molten steel cleaning agent into a furnace, the quality of molten steel can be improved, the slag hole and pore rate of casting products is reduced, and the percent of pass of the casting finished products is greatly increased. Different from the situation that similar products are limited to slagging in a ladle outside a furnace, extra temperature drop is caused by standing of molten steel, and heat is lost, the in-furnace slagging characteristic of the molten steel cleaning agent can reduce furnace wall slag adhesion, lower the furnace wall thickness, improve the induction heating efficiencyand reduce the energy consumption, the use amount of the molten steel cleaning agent is smaller than that of similar products on the market, the capacity of removing gas and inclusions in molten steelis better, the economic benefit is higher, and the molten steel cleaning agent is suitable for wide application and popularization.

Owner:姚玉美

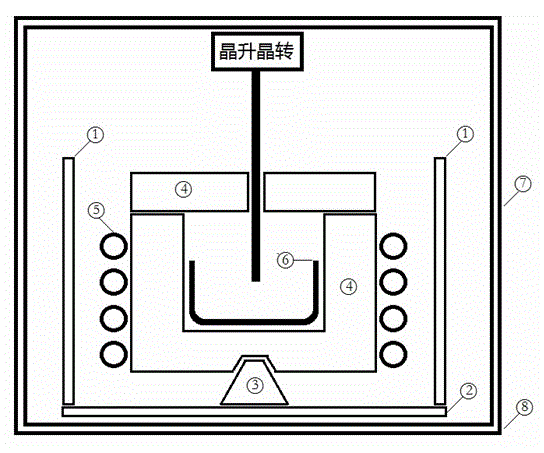

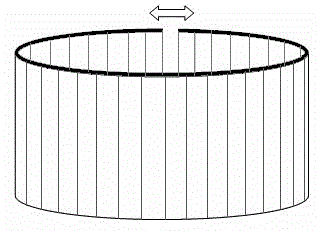

Energy-saving magnetic shielding device for induction heating crystal furnace

InactiveCN103338541AAvoid lossImprove induction heating efficiencyAfter-treatment apparatusFurnaces without endless coreEngineeringElectrical and Electronics engineering

The invention relates to an energy-saving magnetic shielding device for an induction heating crystal furnace. The energy-saving magnetic shielding device comprises a furnace and a magnetic induction heating mechanism arranged in the furnace, wherein a magnetic shielding structure is arranged between the furnace and the magnetic induction heating mechanism; the magnetic shielding structure comprises a magnetic bundle fence arranged at the periphery of the side wall of the magnetic induction heating mechanism and a magnetic bundle base arranged at the periphery of the bottom wall of the magnetic induction heating mechanism, and the magnetic bundle fence and the magnetic bundle base are both made from a magnetic conducting material. The energy-saving magnetic shielding device can effectively improve the energy efficiency and lower the manufacturing cost.

Owner:SUN YAT SEN UNIV

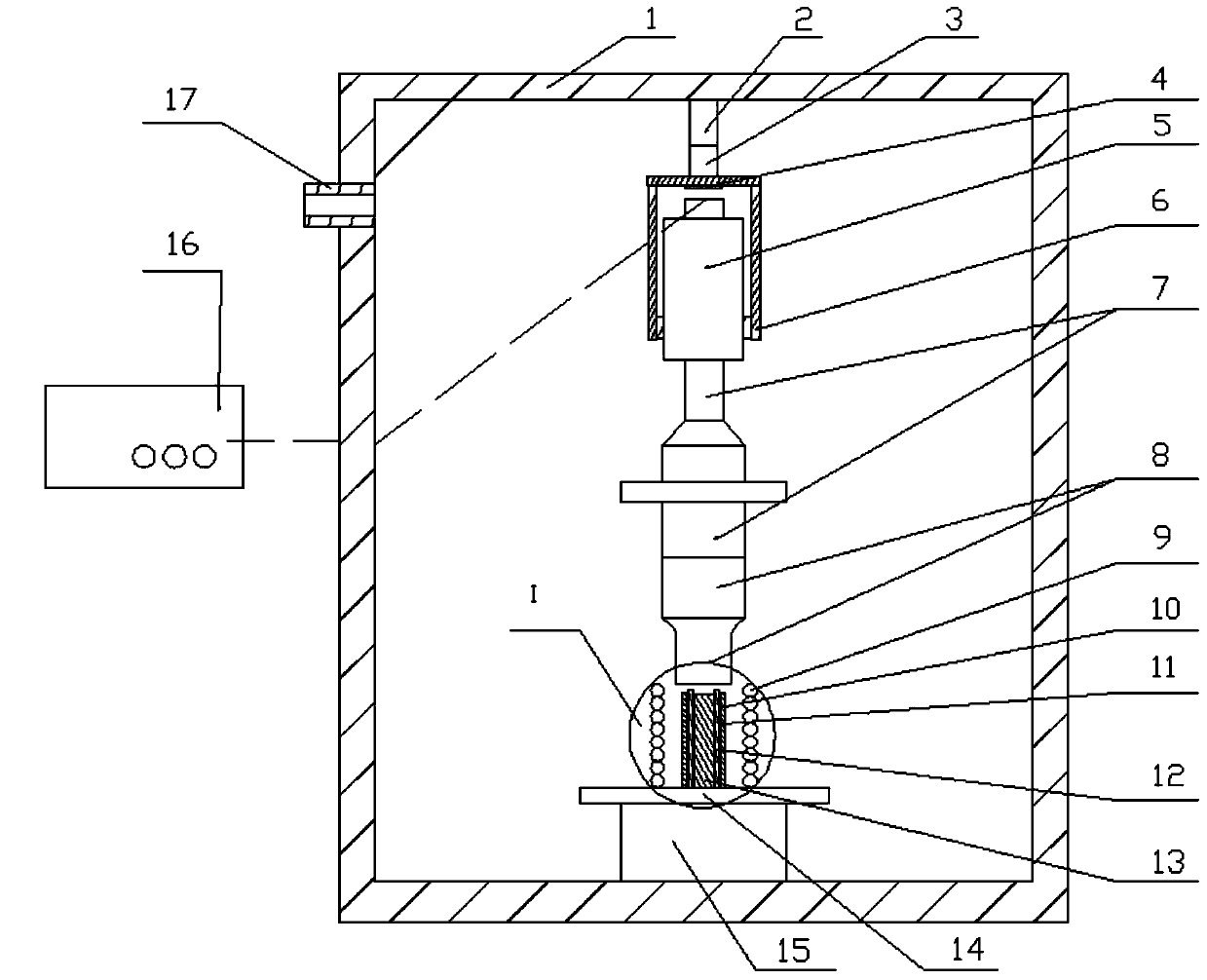

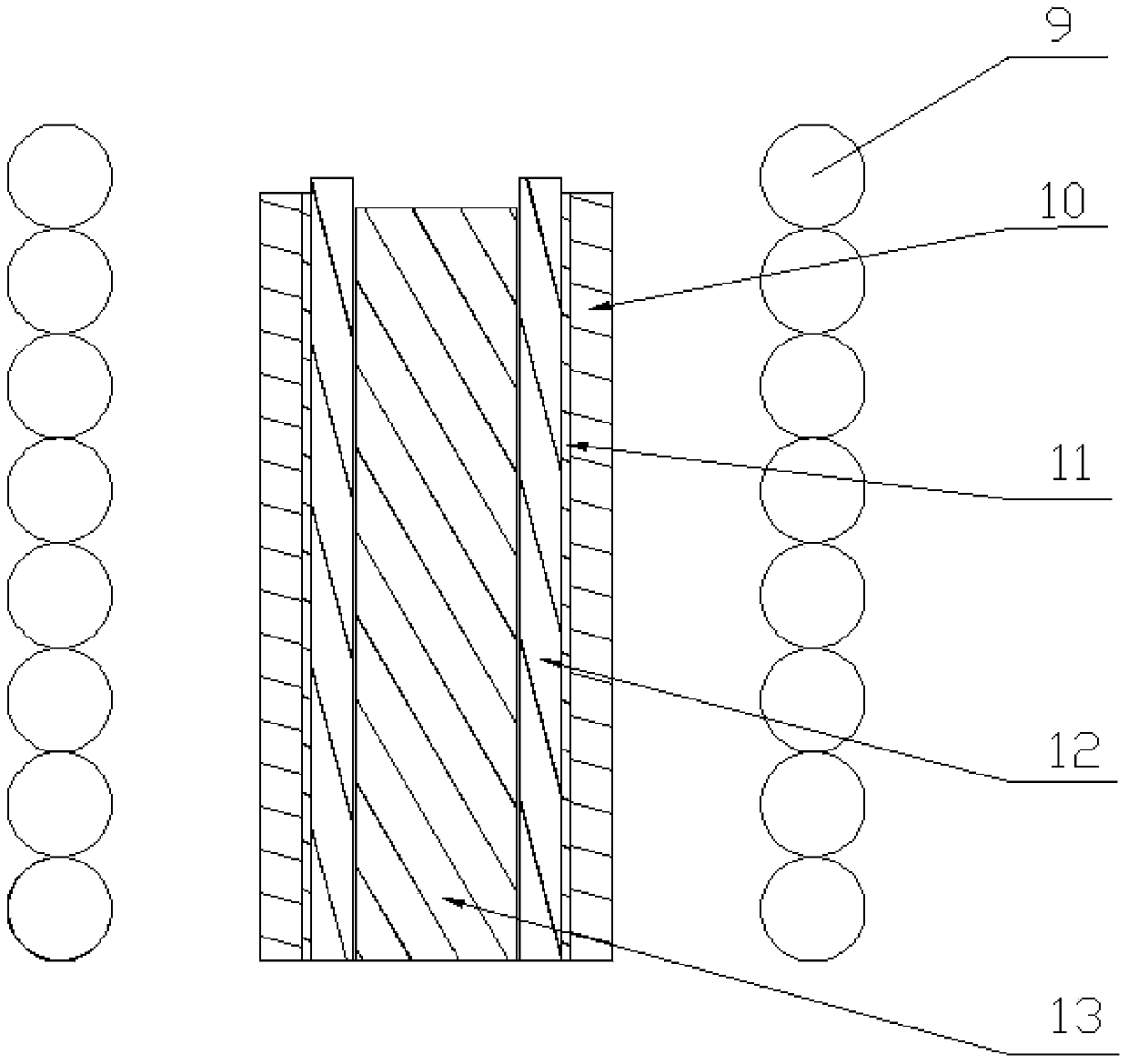

Contamination-free and high-efficient device for thinning titanium aluminum alloy

InactiveCN104190906ASolve the problem of ultrasonic introductionTroubleshooting Damaged Ultrasonic EquipmentTransformerMullite

The invention relates to a contamination-free and high-efficient device for thinning titanium aluminum alloy, particularly to a device for thinning the titanium aluminum alloy. The invention aims to solve the problems that the conventional ultrasonic wave equipment cannot be used in the casting process of the titanium aluminum alloy, the reaction between the titanium aluminum melt and the molded case is serious when ultrasonic vibration is conducted, and the ultrasonography equipment cannot be used for treating the titanium aluminum alloy melt in the electromagnetic induction casting. The device comprises a tank body, a vacuum pump, an ultrasonic generator, ultrasonic wave oscillation equipment and titanium aluminum alloy melt smelting equipment, wherein the ultrasonic wave oscillation equipment comprises an upper feed transmission device, a connecting rod, an insulation washer, an energy converter, a fixing rack, an aluminum alloy amplitude transformer and a T8 steel tool head, and the titanium aluminum alloy melt smelting equipment comprises coils, an adamantine spar pipe, a mullite fibre layer, a molded case, a bar stock layer, a graphite felt and a lower fixing rod. The device can be used in the field of titanium aluminum alloy thinning with the characteristics of contamination-free and high-efficient.

Owner:HARBIN INST OF TECH

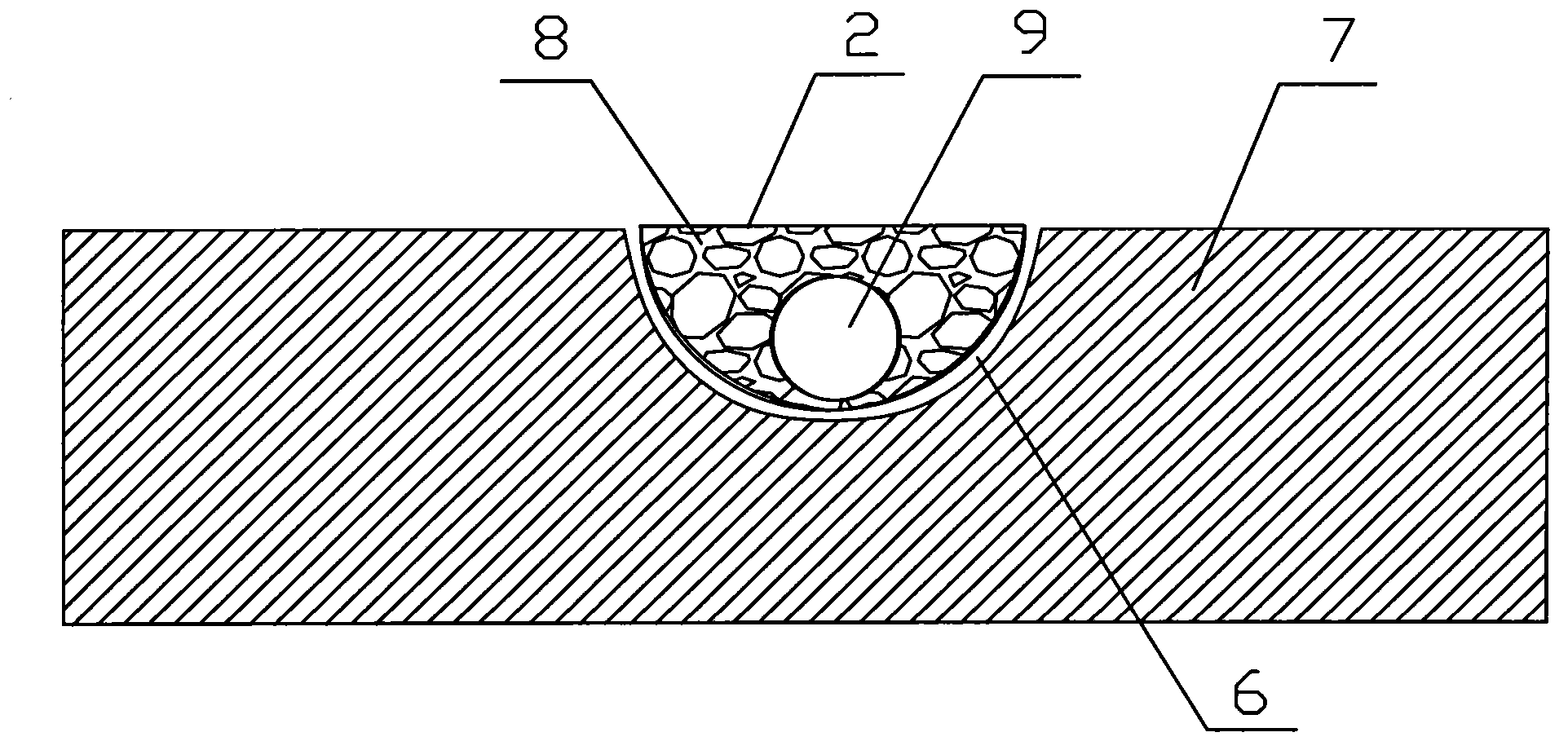

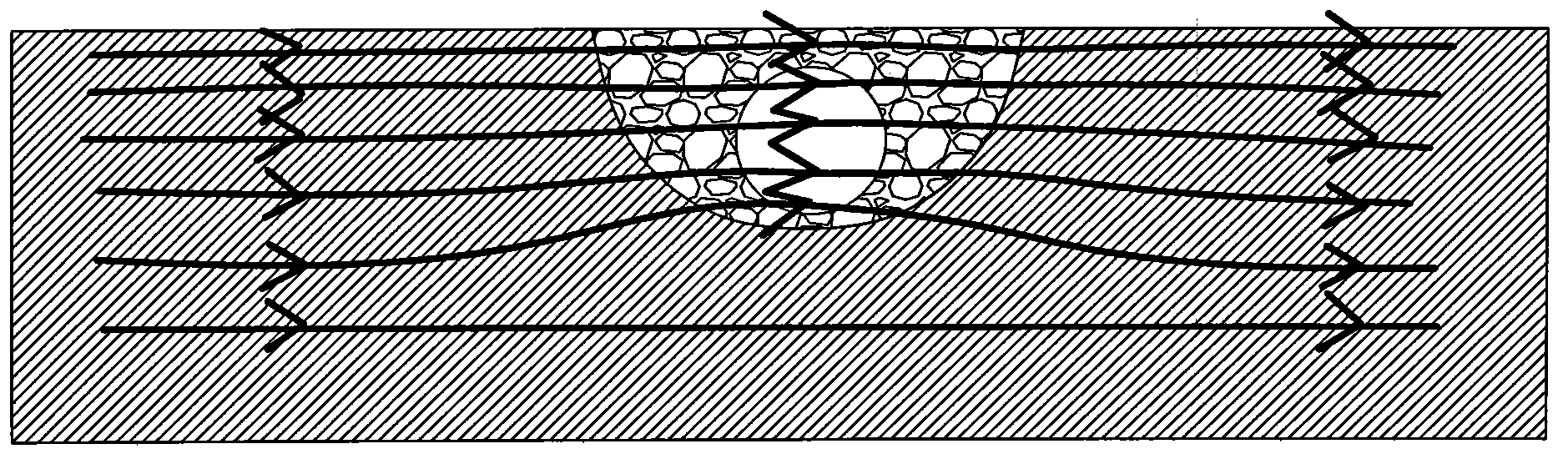

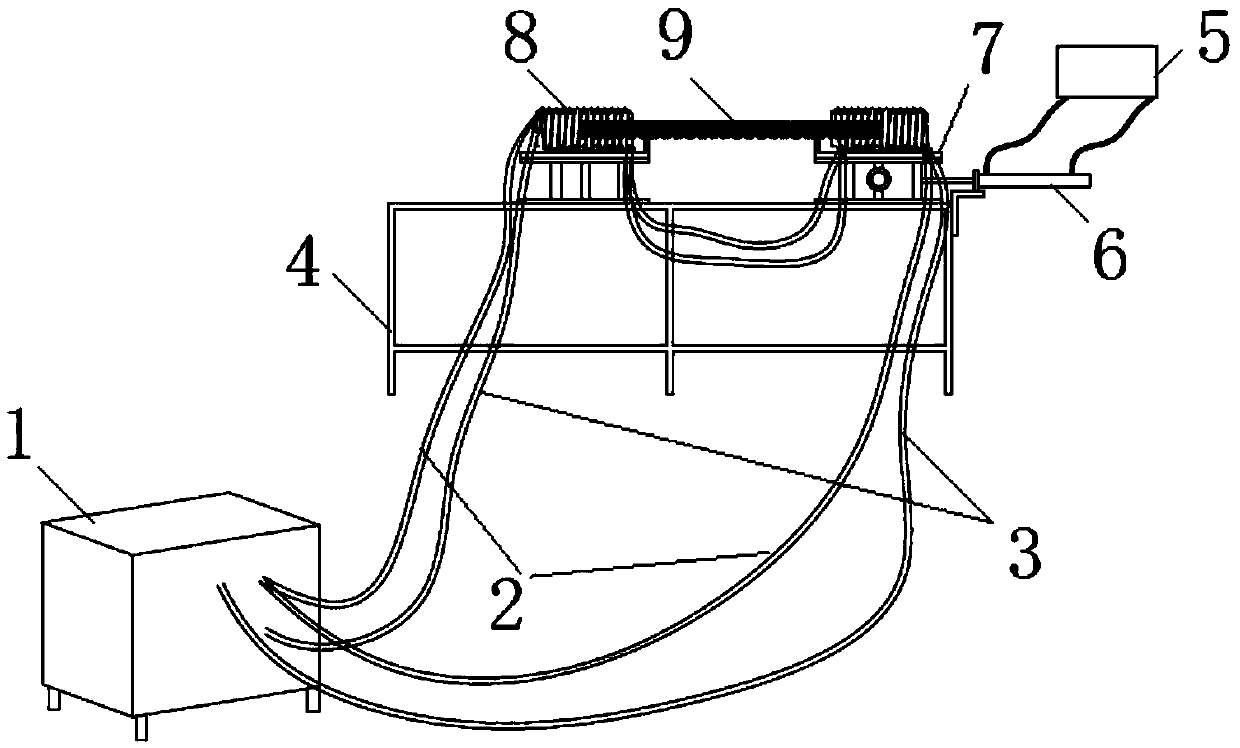

Torsion bar pier head heating device

InactiveCN105537497AReduce energy consumptionImprove induction heating efficiencyHeating/cooling devicesEnergy consumptionElectrical and Electronics engineering

The invention discloses a torsion bar pier head heating device which comprises a power cabinet, a rack and a pair of coil induction heating mechanisms used for heating the ends of a torsion bar. The coil induction heating mechanisms are arranged on the rack. The power cabinet and the coil induction heating mechanisms are connected through cables. The rack is provided with a pair of supports. The coil induction heating mechanisms are arranged on the supports respectively. One support is fixed to the rack, and the other support is movably arranged on the rack. The two ends of the torsion bar are heated through induction coils at the same time, and therefore energy consumption is low; the induction heating efficiency is high, time and labor are saved, and the production efficiency is greatly improved; the two heads are heated at the same time, the temperature of the two ends is consistent, and the machining quality is ensured; torsion bars of different specifications can be heated.

Owner:WUHU LIFENG PRECISION TECH

Method for manufacturing steel plate with high strength and high toughness by using hot-rolling coiled plate

Owner:武汉钢实机电设备有限公司

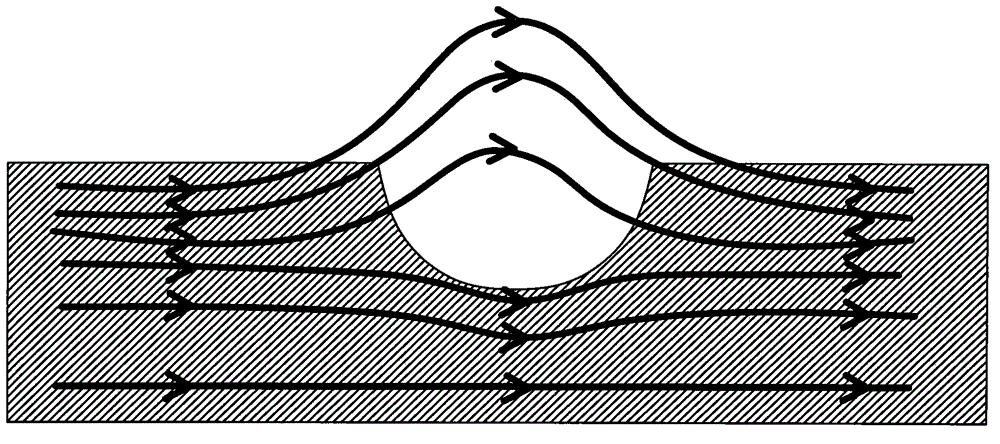

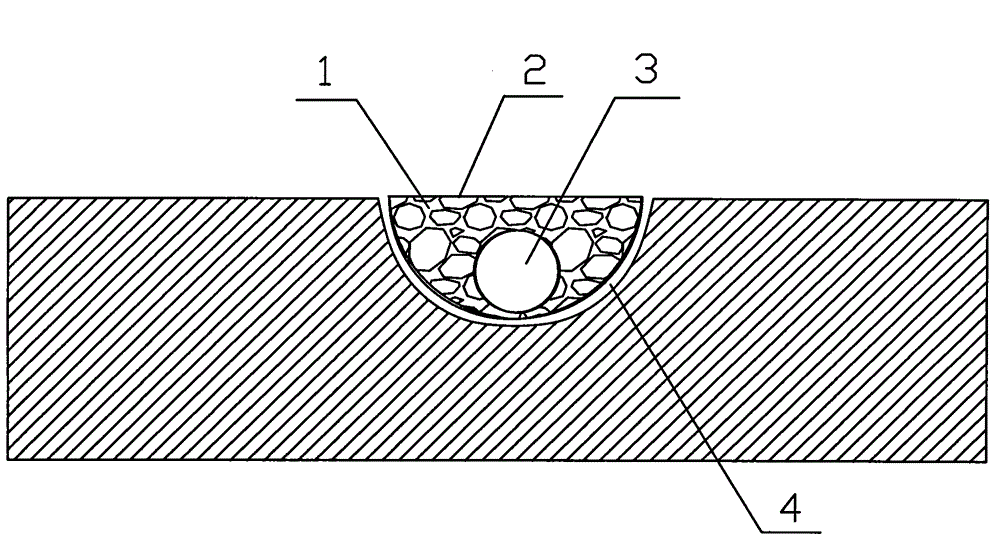

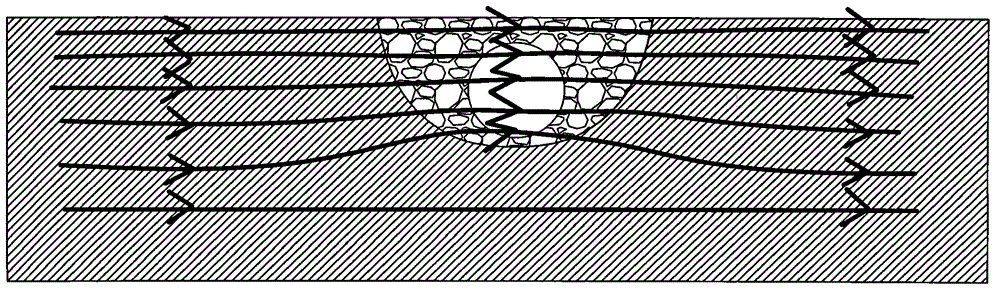

Quenching device for controlling induction hardening flux leakage of workpiece groove and quenching method for quenching device

InactiveCN102796856AHigh flux densityAdd depthIncreasing energy efficiencyHeat treatment process controlForce linesInduction hardening

The invention provides a quenching device for controlling the induction hardening flux leakage of a workpiece groove. The quenching device comprises a quenching machine tool chuck, a workpiece, a quenching coil, a spraying coil and a flux leakage controller coupled with the workpiece groove, wherein the workpiece is arranged on the quenching machine tool chuck, the quenching coil and the spraying coil are arranged on a quenching machine tool slide carriage box, the flux leakage controller is fixed on the quenching machine tool slide carriage box, and the flux leakage controller comprises a quartz glass pipe and a magnetism guide device packed at the outer layer of the quartz glass pipe. A quenching method for controlling the induction hardening flux leakage of the workpiece groove comprises the following steps of: (1) filling the flux leakage controller at the workpiece groove, and charging cooling circulating water into the quartz glass pipe to carry out induction heating; (2) removing the flux leakage controller in the workpiece groove; and (3) spraying the workpiece groove, so that the workpiece groove can be evenly cooled. The quenching device and the quenching method have the benefit effects that the quenching device comprises the flux leakage controller coupled with the workpiece groove, so that the problem of a lead screw groove such as the flux leakage and the magnetic force line loss can be solved.

Owner:SHANDONG UNIV OF SCI & TECH

Synchronous heating equipment of pier heads at two end parts of torsion bar

InactiveCN105567919AReduce energy consumptionImprove induction heating efficiencyIncreasing energy efficiencyFurnace typesBobbinEngineering

The invention discloses synchronous heating equipment of pier heads at two end parts of a torsion bar. The equipment comprises a power supply cabinet, a rack, and a pair of coil inductive heating mechanisms for heating the end parts of the torsion bar; the pair of coil inductive heating mechanisms is arranged on the rack; the power supply cabin is connected with the coil inductive heating mechanisms through cables; a pair of brackets is arranged on the rack; the pair of coil inductive heating mechanisms is respectively arranged on the pair of brackets; one bracket is fixed on the rack, and the other bracket is movably arranged on the rack; the coil inductive heating mechanisms include inductive coils and bobbins; and the inductive coils are wound on the bobbins. The two ends of the torsion bar are synchronously heated through the inductive coils, so that the energy consumption is low, the inductive heating efficiency is high, both time and labors are saved, and the production efficiency is greatly improved; the two ends are synchronously heated, and are the same in temperature, so that the processing quality is guaranteed; and the torsion bars with different specifications can be heated.

Owner:WUHU LIFENG PRECISION TECH

Metal organic compound chemical vapor deposition equipment

ActiveCN102560434BImprove induction heating efficiencyExtend your lifeChemical vapor deposition coatingGas phaseChemical compound

A cavity component comprises: a cavity outer sleeve, forming an outer sleeve cavity by encircling the cavity; induction coils, enclosing the outside of the cavity outer sleeve; and a graphite sleeve, sleeved inside the outer sleeve cavity of the cavity outer sleeve. Also disclosed is a metal-organic chemical vapor deposition (MOCVD) device provided with the cavity component.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Electromagnetic induction heating press-roller

InactiveCN102137523BImprove induction heating efficiencyAvoid crossingInduction heating apparatusMachine partsExcitation current

The invention discloses an electromagnetic induction heating press-roller, which has an integral double-end supporting structure and comprises a rotating device and a fixing device, wherein the rotating device consists of an action roller and a rotating shaft which are connected; the rotating shaft inputs a rotating torque to drive the action roller to rotate; the fixing device consists of a fixed shaft, a sleeve arranged on the outer side of the fixed shaft, magnetizers and excitation coils; through the magnetizers and excitation coils segmentedly installed outside the sleeve, a magnetic airgap is formed between the outside end face of the fixed magnetizer and the inner circular face of the rotating action roller; the alternating magnetic field forms a circuit through the magnetizer, the air gap and the action roller metal; the magnetic field in the action roller forms an eddy current so as to uniformly heat the working face of the rotating action roller. Since a structure of axially segmented magnetizers and excitation coils is adopted, a magnetic circuit is formed on the working face metal of the heating roller only to avoid the magnetic circuit penetration of the non-heating working part and reduce the excitation current, and simultaneously prevent the machine parts from overheating; besides, the induction heating efficiency can be improved so as to control the axial temperature gratitude of the heating roller continently.

Owner:WUHAN UNIV OF TECH

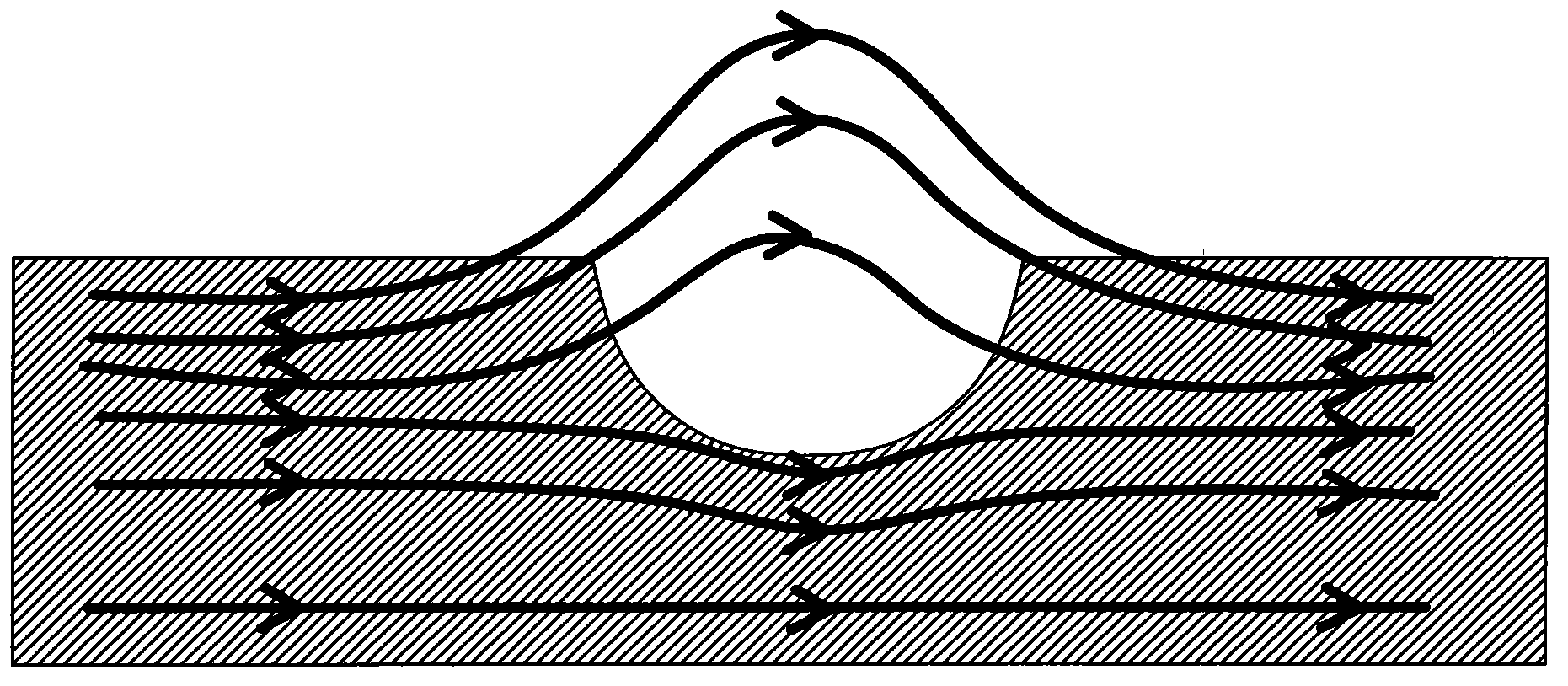

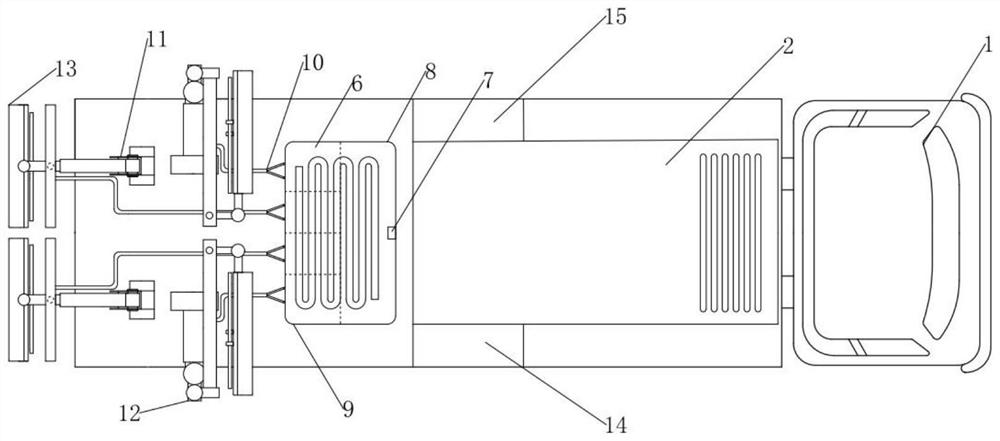

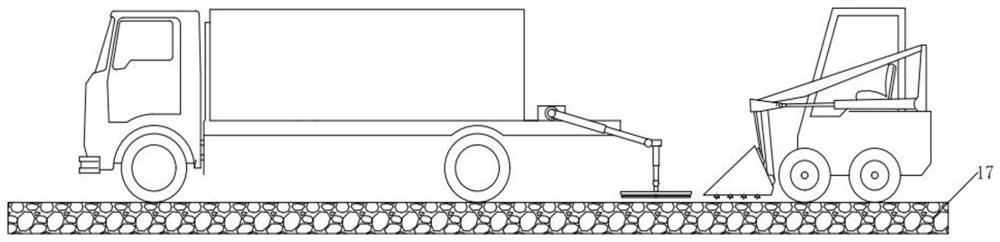

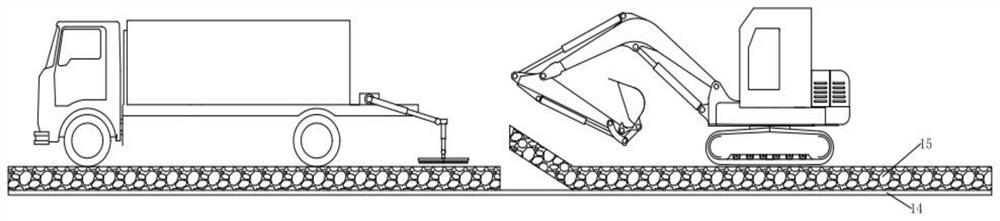

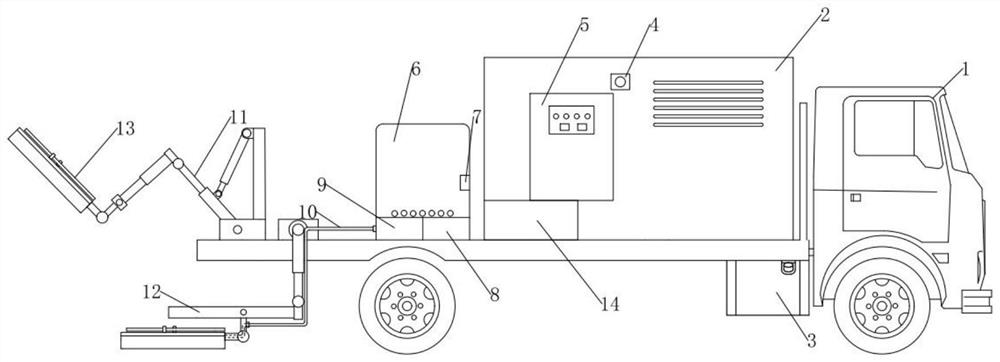

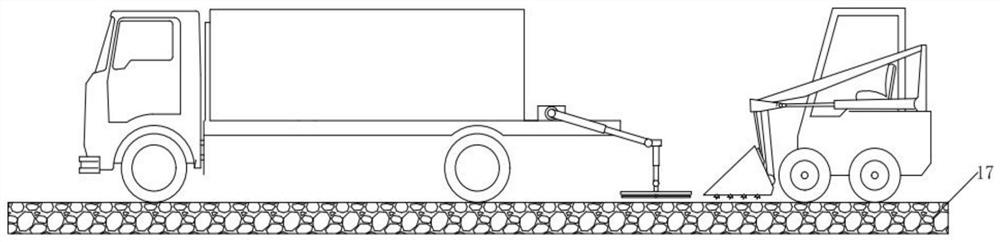

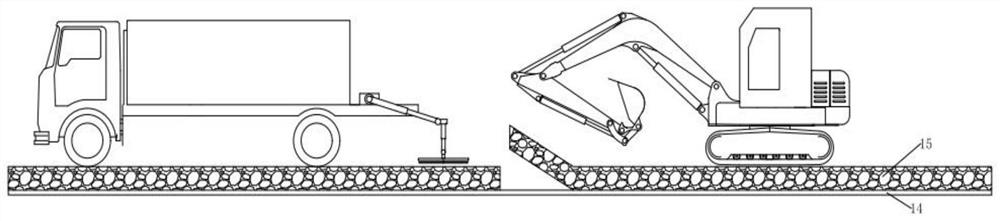

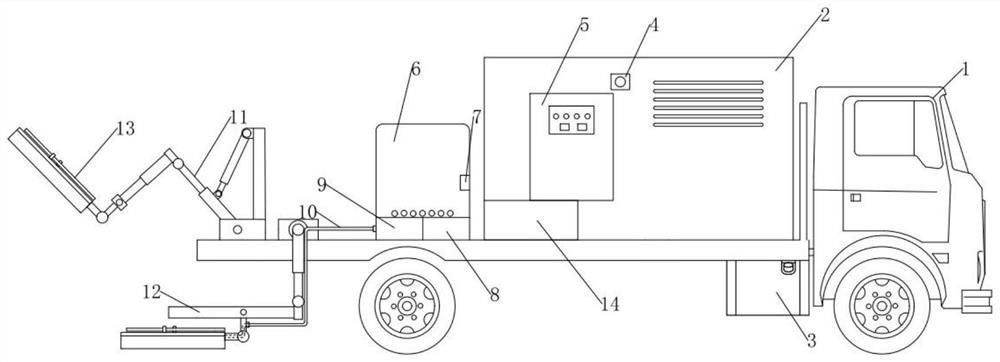

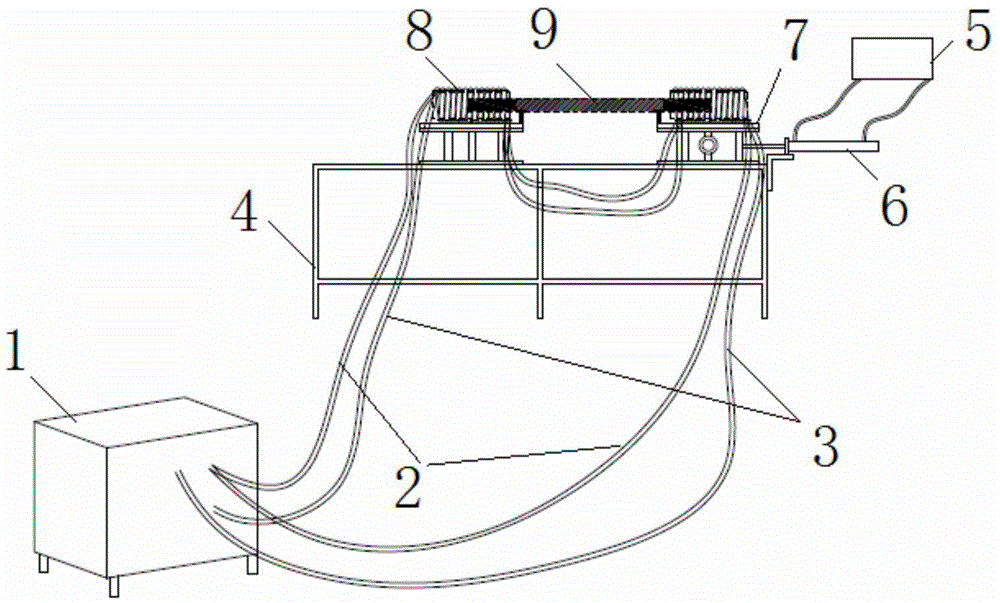

Asphalt pavement multifunctional heating vehicle based on induction heating and microwave heating

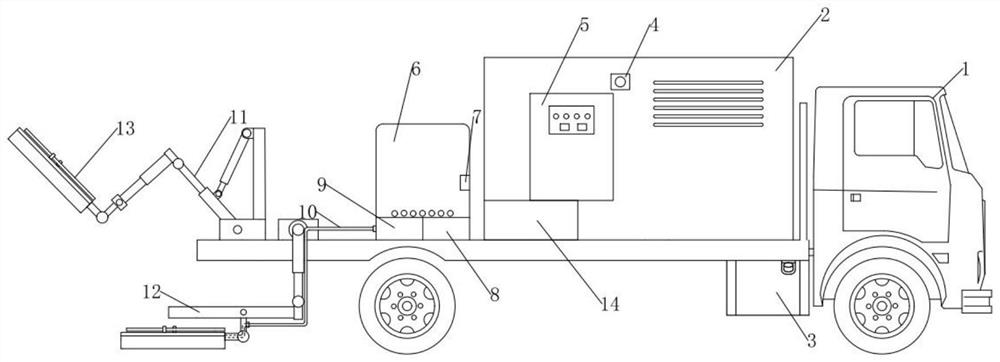

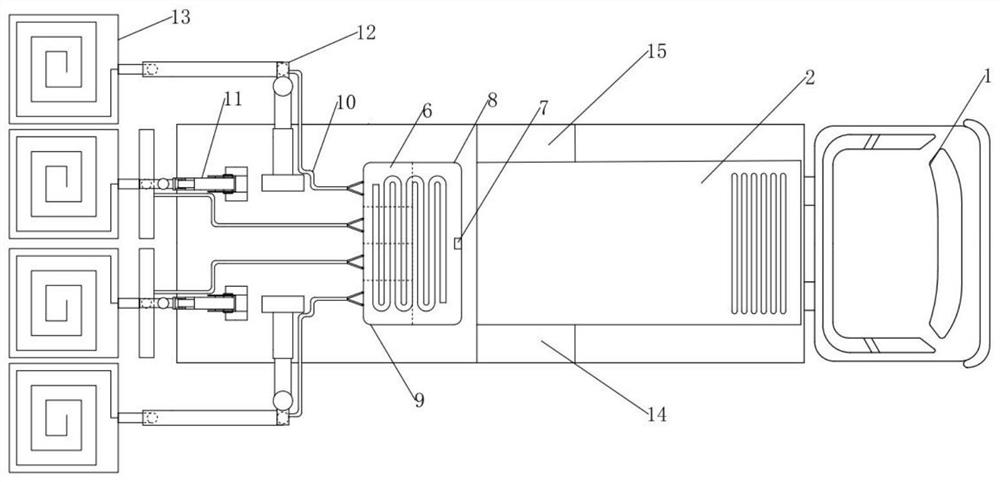

PendingCN112376381AEfficient heatingHeating fastRoads maintainenceThermodynamicsDiesel engine generator

The invention discloses an asphalt pavement multifunctional heating vehicle based on induction heating and microwave heating. The vehicle comprises a heating mechanism used for heating a bituminous pavement, a vehicle body used for moving the heating mechanism on the bituminous pavement, a high-power diesel generator used for supplying power to the heating mechanism, a water cooling mechanism usedfor cooling the heating mechanism, a first mechanical arm and a second mechanical arm, and the first mechanical arm and the second mechanical arm are used for adjusting the posture of the heating mechanism at the tail of the vehicle body. The free end of the first mechanical arm is connected with the heating mechanism, the fixed end of the first mechanical arm is connected with the tail of the vehicle body, the free end of the second mechanical arm is connected with the heating mechanism, and the fixed end of the second mechanical arm is connected with the tail of the vehicle body. The high-power diesel generator is fixed to the vehicle body and is electrically connected to the heating mechanism. The water cooling mechanism is fixed to the vehicle body and connected with the heating mechanism through a water pipe. According to the invention, an induction heating or microwave heating mode is flexibly applied, and the pavement is efficiently heated by utilizing the effects of magnetismgathering and microwave reflection.

Owner:HEFEI UNIV OF TECH

Flux leakage controller used for controlling workpiece groove induction quenching flux leakage and preparation process thereof

ActiveCN102787218BHigh precisionExtended service lifeIncreasing energy efficiencyQuenching devicesMaterials scienceInduction heating

Owner:SHANDONG UNIV OF SCI & TECH

An Amorphous Alloy Magnetic Yoke Applied to High Frequency Induction Heating Furnace

InactiveCN107548176BAvoid heatingImprove induction heating efficiencyCoil arrangementsEddy current effectAlloy

The invention relates to a functional device of an induction heating furnace for plate blanks, in particular to an amorphous alloy magnet yoke applied to a high-frequency induction heating furnace. The amorphous alloy magnet yoke applied to the high-frequency induction heating furnace comprises an upper amorphous alloy magnet yoke, an injection coil and a lower amorphous alloy magnet yoke, whereinthe induction coil is an annular coil arranged transversely and vertically; the upper amorphous alloy magnet yoke and the lower amorphous alloy magnet yoke are arranged at the upper end and the lowerend of the induction coil respectively. The amorphous alloy magnet yoke has the advantages that the amorphous alloy magnet yoke is simple in structure and reasonable in design, excellent restrictionand shielding effects can be achieved for external radiation of the induction heating furnace, the coil is prevented from heating an external transmission component, and the heat efficiency generatedby an eddy current effect can be reduced, so that the temperature is reduced, and then the induction heating efficiency of the furnace can be improved.

Owner:武汉蓝点科技发展有限公司

Manufacture method for manufacturing cantilever steel pipe with high strength and high toughness by using hot-rolling coiled plate

ActiveCN101603156BAccurate heating temperature controlLess investmentIncreasing energy efficiencySmall footprintQuenching

The invention relates to a manufacture method for manufacturing a cantilever steel pipe with high strength and high toughness by using a hot-rolling coiled plate. The method comprises the following steps that: firstly, a hot-rolling coiled plate is rolled into an ERW welding pipe by using an ERW pipe welding machine set, the ERW welding pipe is heated by induction in induction heating equipment, the heating time is within 60-140s, the ERW welding pipe is heated to 910DEG C to 960DEG C, and austenitizing is carried out; then, the ERW welding pipe enters a water-cooling or steam-cooling quenching machine set to carry out quenching, the quenching and cooling speed of the ERW welding pipe is greater than or equal to 5DEG C / s, and a quenched martensite organization is obtained after quenching;tempering is carried out after quenching, induction heating is carried out by adopting the induction heating equipment in the tempering, the heating temperature of the quenched martensite organization is 220DEG C to 440DEG C, the tempering time is 80 to 180s, and a tempered martensite organization is obtained; and finally, straightening, flaw detection, surface inspection and sampling inspection are carried out to finally obtain the cantilever steel pipe with excellent performance, high strength and high toughness. The invention has the advantages that the invention adopts a heat treatment method of induction heating to cause the heated cantilever steel pipe to be evenly heated, decomposes the residual austenite when obtaining the tempered martensite after induction tempering and has low equipment investment, little maintenance cost of the equipment, small occupation area and small environmental pollution.

Owner:武汉钢实机电设备有限公司

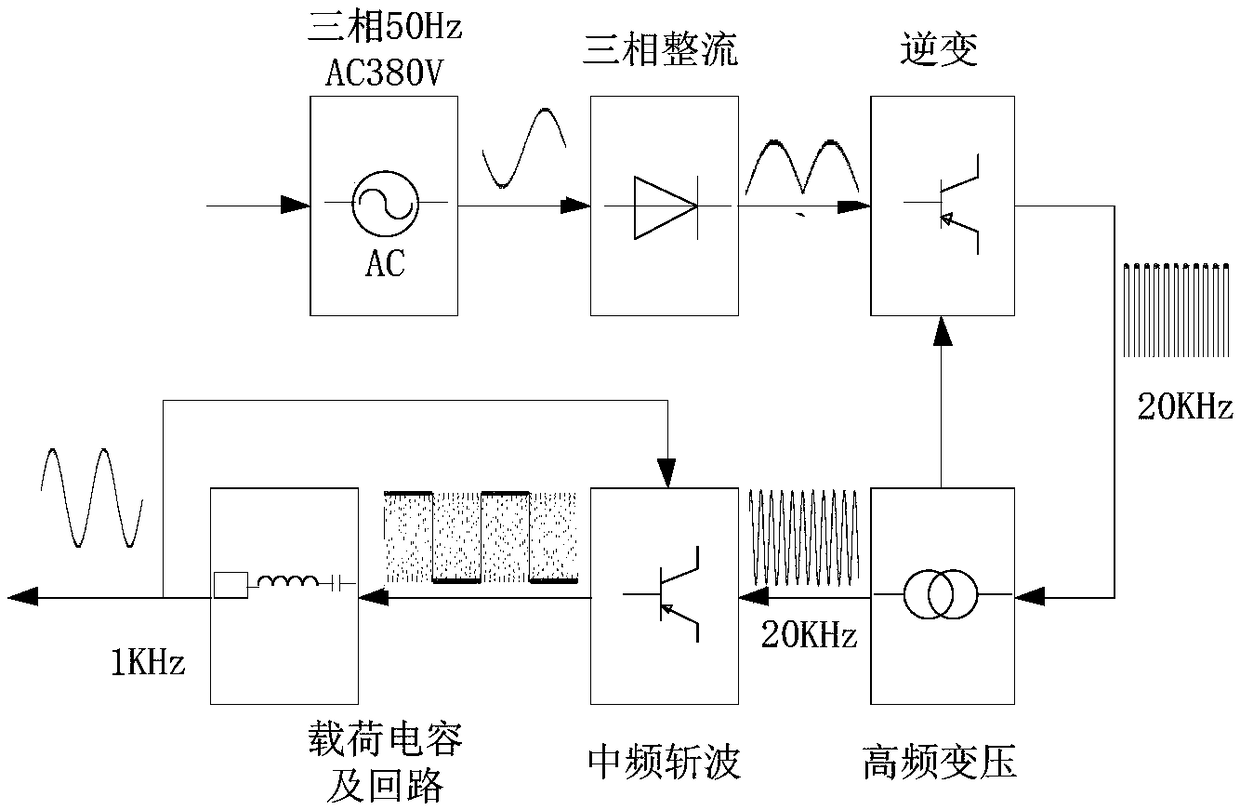

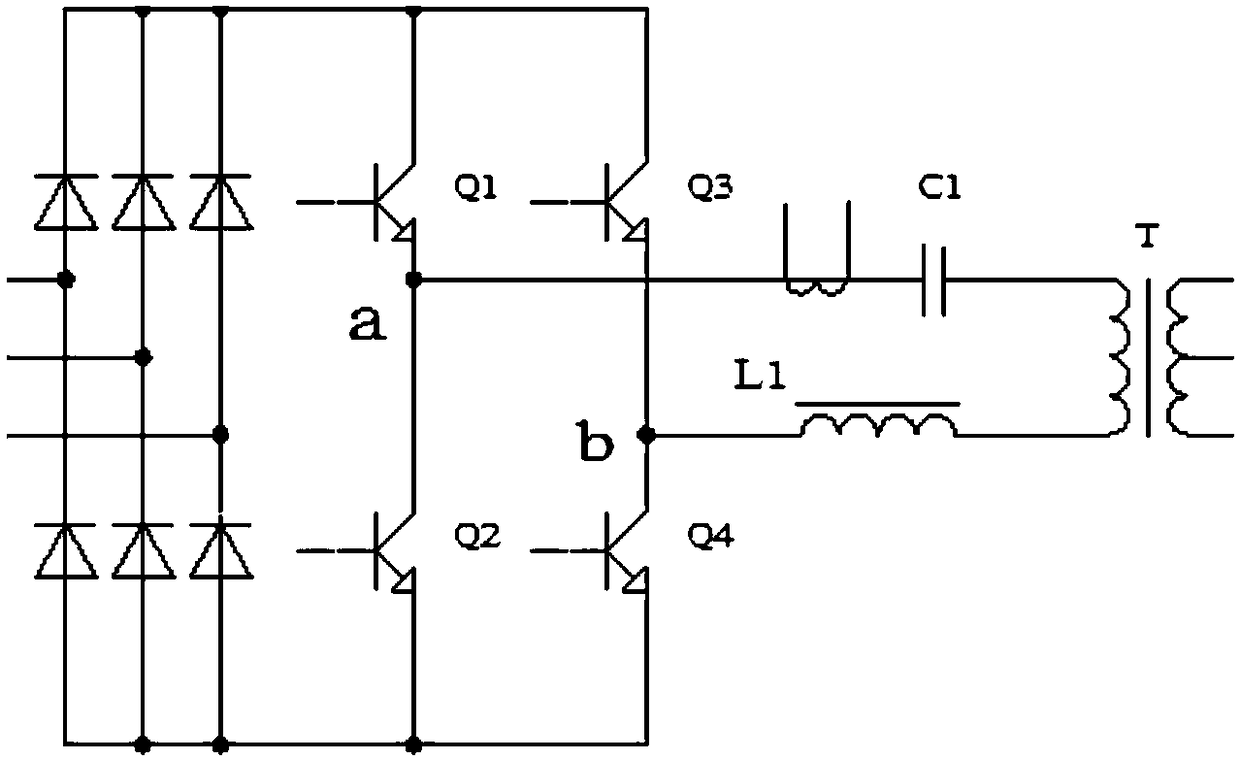

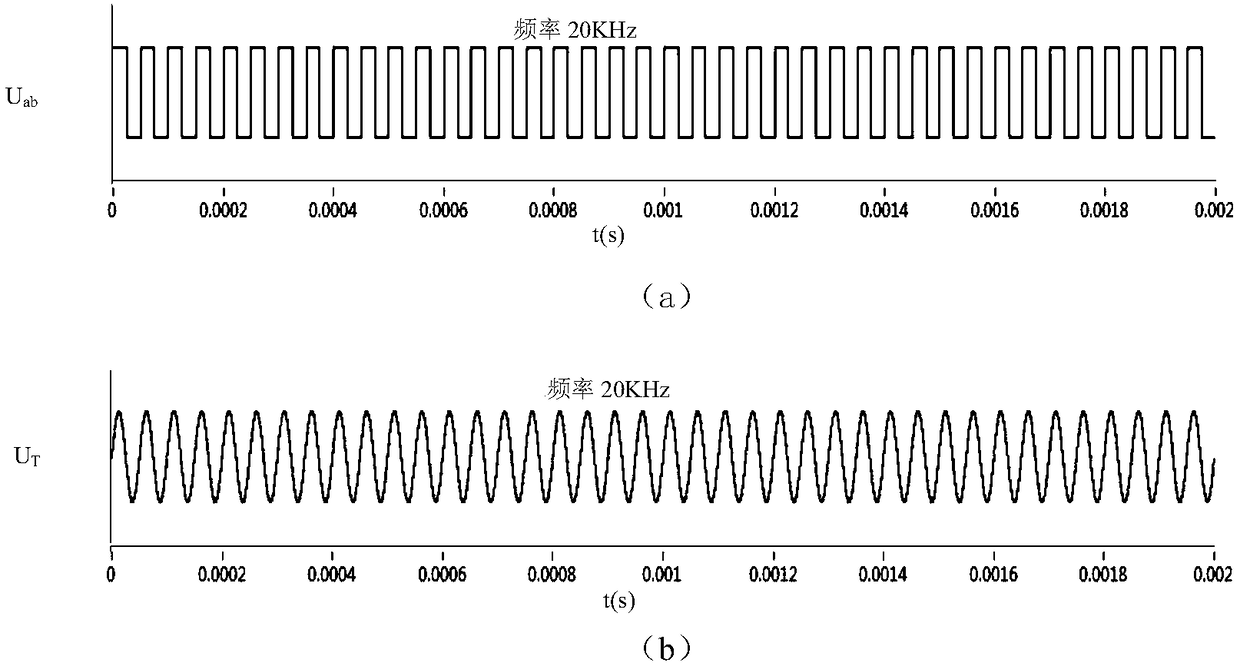

A light intermediate frequency heating power supply and design method based on high frequency rectification and inverter

ActiveCN106655797BReduce volumeReduce weightEfficient power electronics conversionInduction heatingCapacitanceSoft switching

The invention discloses a light intermediate frequency heating power supply based on high-frequency rectification and inverter and a design method thereof. Through the high-frequency IGBT rectification and inverter circuit, and using soft switching technology, the three-phase power frequency AC voltage signal is converted into a high frequency of 20KHz. Square wave voltage output; on the output side of the IGBT rectifier inverter circuit, an external high-frequency step-up transformer is connected, in which the primary winding of the high-frequency step-up transformer is an inductive load, and a capacitor is connected in series to make the output circuit of the secondary winding of the transformer resonate at 20KHz; as a high-frequency AC The power supply, through a group of IGBT switch modules, realizes medium-frequency chopping of the input high-frequency high voltage. 1KHz series resonance occurs in the capacitor, at this time, the intermediate frequency sinusoidal AC current flows through the load to meet the demand of the load heating current. The invention not only greatly reduces manufacturing and application costs, but also uses simple modules and is easy to implement.

Owner:XIAN PENGRUI PETROLEUM TECH

A pollution-free and high-efficiency refining titanium-aluminum alloy device

InactiveCN104190906BSolve the problem of ultrasonic introductionTroubleshooting Damaged Ultrasonic EquipmentTransformerMullite

The invention relates to a contamination-free and high-efficient device for thinning titanium aluminum alloy, particularly to a device for thinning the titanium aluminum alloy. The invention aims to solve the problems that the conventional ultrasonic wave equipment cannot be used in the casting process of the titanium aluminum alloy, the reaction between the titanium aluminum melt and the molded case is serious when ultrasonic vibration is conducted, and the ultrasonography equipment cannot be used for treating the titanium aluminum alloy melt in the electromagnetic induction casting. The device comprises a tank body, a vacuum pump, an ultrasonic generator, ultrasonic wave oscillation equipment and titanium aluminum alloy melt smelting equipment, wherein the ultrasonic wave oscillation equipment comprises an upper feed transmission device, a connecting rod, an insulation washer, an energy converter, a fixing rack, an aluminum alloy amplitude transformer and a T8 steel tool head, and the titanium aluminum alloy melt smelting equipment comprises coils, an adamantine spar pipe, a mullite fibre layer, a molded case, a bar stock layer, a graphite felt and a lower fixing rod. The device can be used in the field of titanium aluminum alloy thinning with the characteristics of contamination-free and high-efficient.

Owner:HARBIN INST OF TECH

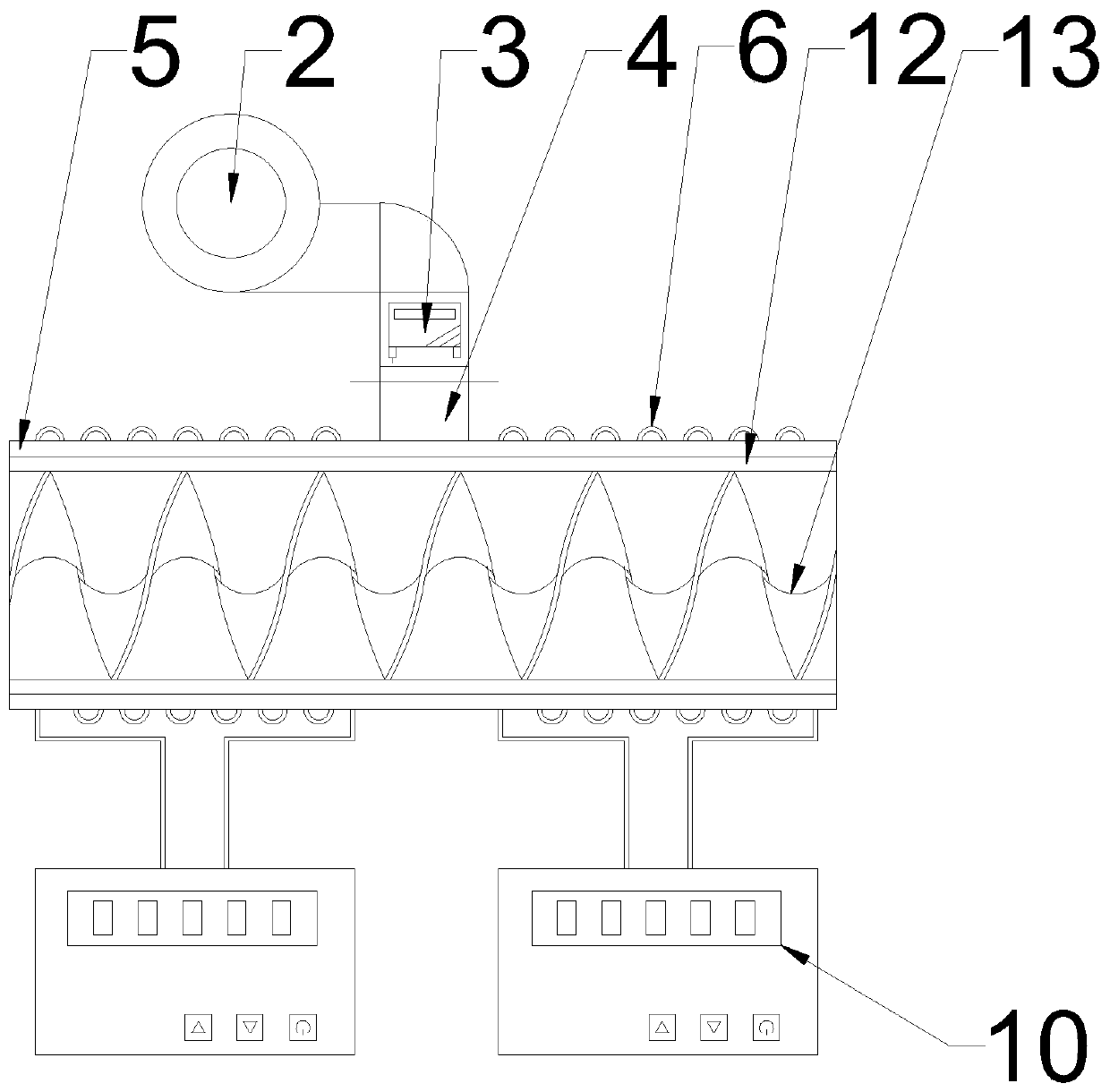

Biomass particle drying device in electromagnetic induction heating and drying method of biomass particle drying device

InactiveCN109945628AReduce lossImprove induction heating efficiencyDrying solid materials with heatDrying chambers/containersThermal energyProcess engineering

The invention discloses a biomass particle drying device in electromagnetic induction heating and a drying method of the biomass particle drying device. A biomass particle inlet, a biomass particle outlet, a conveying portion and a drying heating portion are included; the conveying portion comprises a variable frequency speed controlling motor and an Archimedes screw; and the drying heating portion comprises an electromagnetic coil, heat preserving cotton, heating pipes, a steam discharging port, an induced draught fan, a humidity sensor and an electromagnetic controller. According to the biomass particle drying device in electromagnetic induction heating, the electric energy is converted into heat energy to heat materials through the electromagnetic induction heating principle, the rotating speed of the variable frequency speed controlling motor is adjusted through the humidity sensor, and then the staying time of biomass particles in the heating pipes is controlled; and the electromagnetic controller is adjusted through the humidity sensor, and then the temperature of the various heating pipes is changed. The biomass particle drying device in electromagnetic induction heating issimple in structure, convenient to operate, high in drying efficiency, capable of accurately controlling the heating temperature, safe and reliable in heating manner, efficient, capable of saving energy, and clean and environment-friendly.

Owner:YANSHAN UNIV

Construction method of induction heating and microwave heating for asphalt pavement multi-functional thermal milling

Owner:HEFEI UNIV OF TECH

Induction heating and microwave heating asphalt pavement multifunctional hot milling construction method

The invention discloses an induction heating and microwave heating asphalt pavement multifunctional hot milling construction method. The method comprises the steps that a pavement material is judged;a heating mode is determined; according to the area size and position of the part needing to be milled, a mechanical arm controls a heating mechanism to move, permutate and combine to correspond to aheating position; a power supply is started, heating is started, a water pump is started to cool the heating device, and a heating vehicle slowly moves at a certain speed; and the heated part is milled. The problems that the milling effect is poor due to the poor heating effect on different pavements, and a traditional milling mode of steel bridge deck asphalt is not suitable can be solved.

Owner:HEFEI UNIV OF TECH

Efficient heating device for ends of torsion bar

InactiveCN105603163AReduce energy consumptionImprove induction heating efficiencyFurnace typesIncreasing energy efficiencyHydraulic cylinderProtection mechanism

The invention discloses an efficient heating device for the ends of a torsion bar. The device comprises a power cabinet, a rack, a hydraulic pump, a hydraulic cylinder, a cooling protection mechanism and a pair of coil induction heating mechanisms for heating the ends of the torsion bar. The coil induction heating mechanisms are arranged on the rack. The power cabinet is connected with the coil induction heating mechanisms through cables. The rack is provided with a pair of supports, the coil induction heating mechanisms are arranged on the supports respectively, one support is fixed to the rack, and the other support is movably arranged on the rack. The coil induction heating mechanisms comprise induction coils and pipe barrels, and the induction coils are wound around the pipe barrels. The cooling protection mechanism comprises cooling water pipes, and the cooling water pipes and the induction coils are wound around the interiors of the pipe barrels side by side. The induction coils are hollow pipes, and the cooling water pipes are communicated with the hollow pipes. Induction heating efficiency is high, time and labor are saved, and production efficiency is greatly improved.

Owner:WUHU LIFENG PRECISION TECH

A pulverization method of induction heating and radio frequency plasma combined atomization pulverization system

ActiveCN108161019BHigh purityPrevent purityAdditive manufacturing apparatusDusting powdersMetal filament

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

Induction heating system with external combined induction heating coil phased arrays and application for induction heating system

The invention discloses an induction heating system which is provided with external combined induction heating coil phased arrays and used for an injection molding process and an application for the induction heating system, and belongs to the field of methods for manufacturing injection molding products. According to the technical scheme, a singlechip, a relay, inverters, coils and a keyboard are provided, wherein a program for controlling each heating mode states is pre-set in the singlechip; and switching among the heating mode states is realized by the keyboard; induction coils is powered on or powered off according to the preset program sequence or other ways, so that mutual influence of magnetic fields among the coils is eliminated, and the heating efficiency is improved; and meanwhile, the coils also can be separately or synchronously powered on or powered off according to the specific sequence, so that local temperature of a mould cavity can be controlled, and the heating flexibility is increased; and therefore, the system is particularly suitable for performing injection molding on parts which are made of thermoplastic or thermosetting composite materials or heating complicated mould cavities of injection moulds and locally heating the mould cavities of the injection moulds during compression molding production.

Owner:芜湖精益达模塑股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com