High-strength magnesium alloy extruded profile and manufacturing method thereof

A technology for extruded profiles and manufacturing methods, applied in the field of magnesium alloy extruded profiles and their manufacturing, can solve the problem that the uniformity of profile temperature and microstructure properties does not necessarily bring benefits, the influence of temperature requirements lacks targeted guidance, and the temperature field Changes and other problems, to achieve good uniformity of tissue properties, improve the purpose of temperature control, and good uniformity of tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1

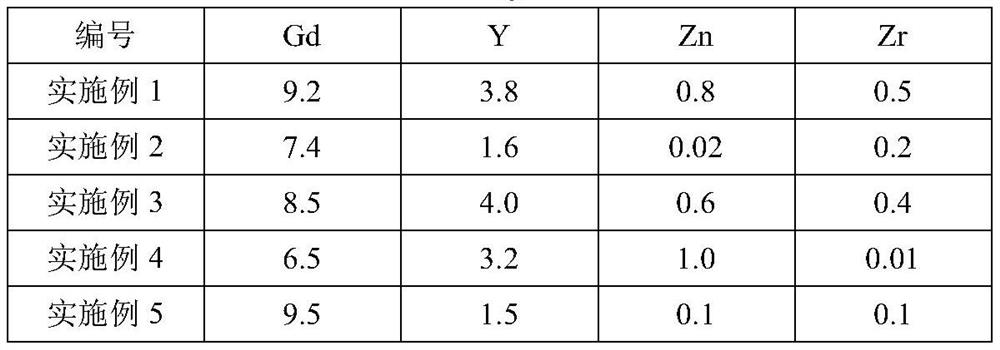

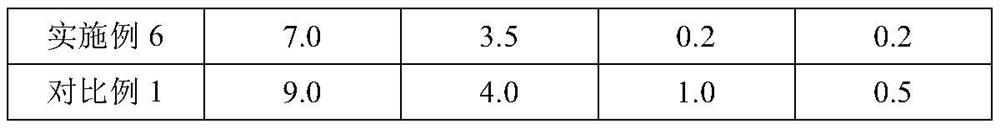

[0080] Table 1 lists the mass percentages of each chemical element in the high-strength magnesium alloy extruded profiles of Examples 1-6 and the magnesium alloy extruded profile of Comparative Example 1.

[0081] Table 1. (wt%, the balance is Mg and other unavoidable impurities)

[0082]

[0083]

[0084] In the present invention, the high-strength magnesium alloy extruded profiles of Examples 1-6 are all prepared by the following steps:

[0085] Step 1: Extruded ingots are prepared according to the chemical element composition shown in Table 1;

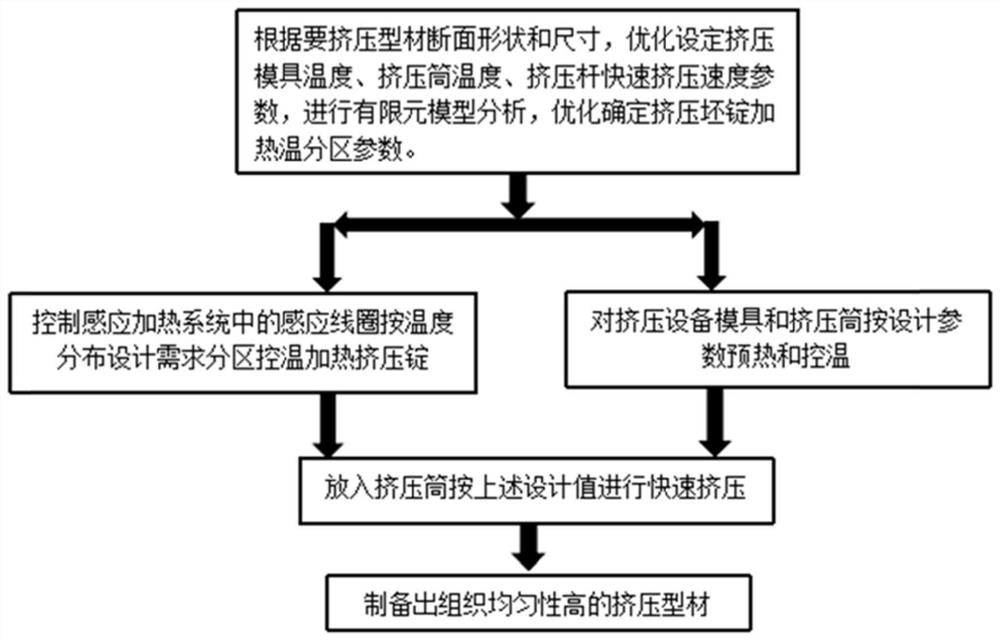

[0086] Step 2: According to the section shape and size of the profile to be extruded, optimize and set the temperature of the extrusion die, the temperature of the extrusion barrel and the rapid extrusion speed parameters of the extrusion rod, and determine the temperature of the extrusion ingot in all directions based on the finite element simulation software distributed;

[0087] Step 3: According to the temperature distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com