Diesel engine DPF active regeneration control method

A control method and active regeneration technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of low regeneration temperature control accuracy, poor control consistency, and large number of parameters, so as to reduce errors, reduce parameters, and calculate formula simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

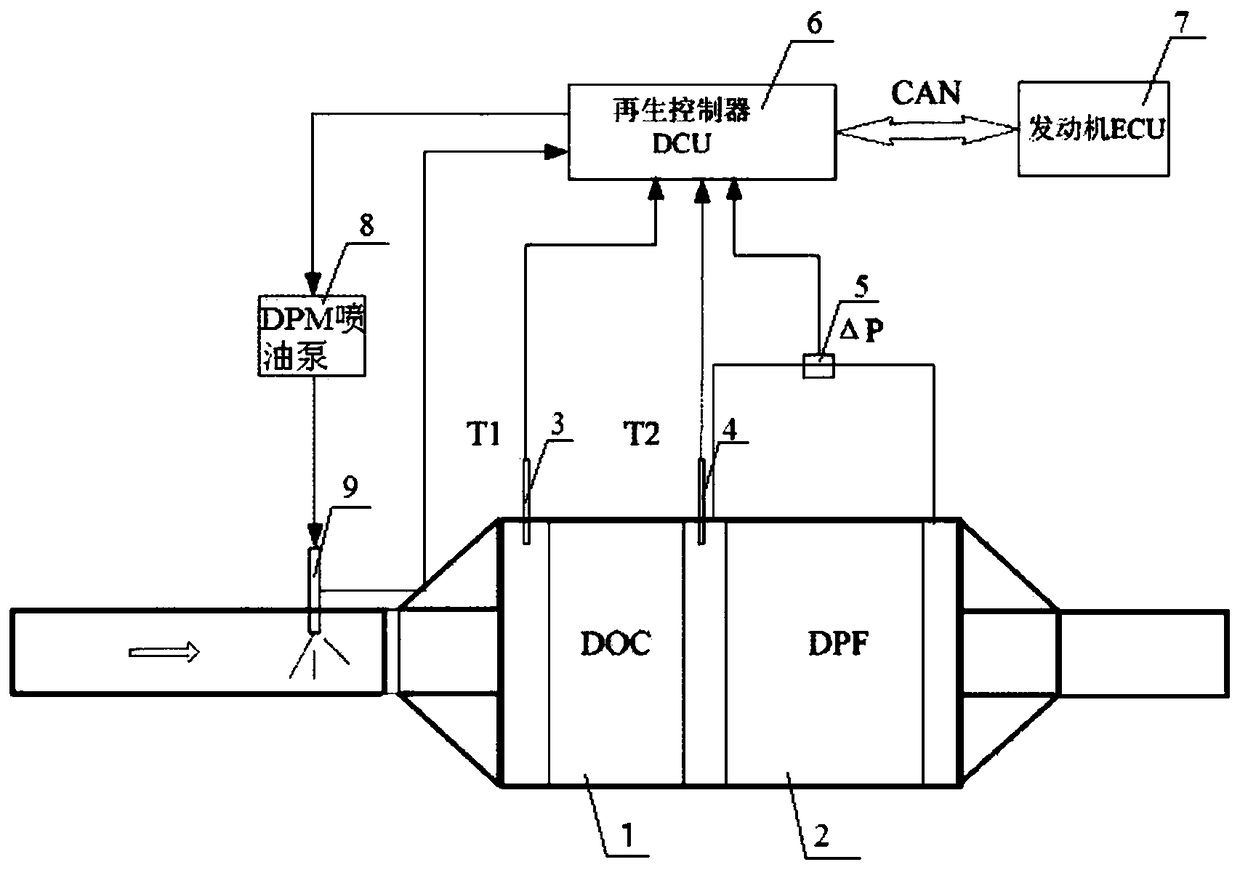

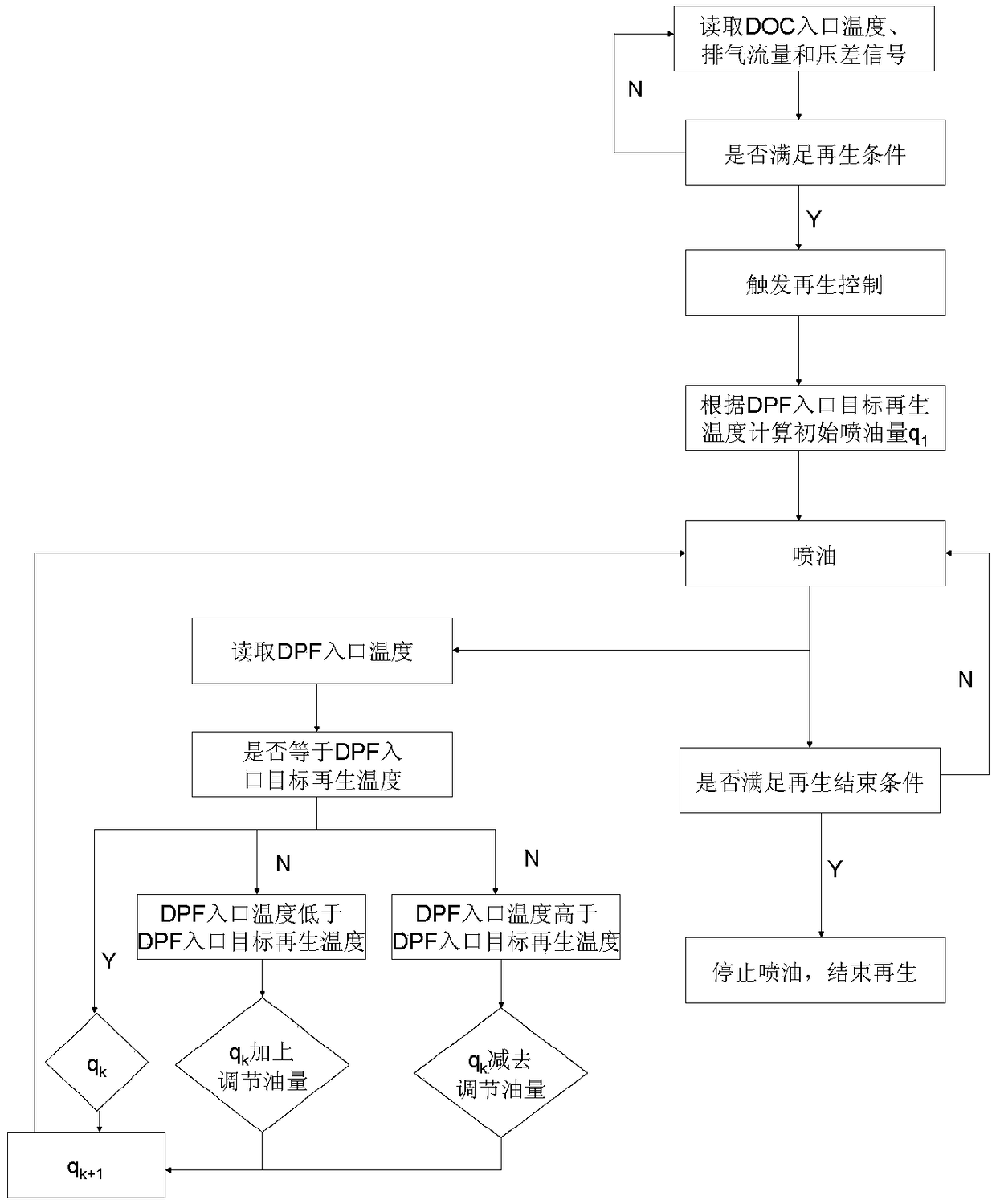

[0054] see figure 1 and figure 2 , a kind of diesel engine DPF active regeneration control method, heats DPF2 by injecting fuel oxidation to DOC1 to release heat, comprises the following steps:

[0055] (1) The regenerative controller DCU6 reads the operating conditions of the engine, collects the exhaust gas mass flow rate of the engine fed back by the engine ECU7, the DOC inlet temperature sensor 3 obtains the DOC inlet temperature, and the DPF outlet and inlet differential pressure sensor 5 obtains the DPF outlet and inlet air pressure difference, T1=270°C, ΔP=15kPa, engine exhaust mass flow rate 200kg / h, which meets the regeneration trigger value and triggers regeneration control;

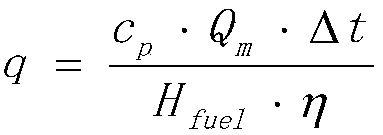

[0056] (2) After the regeneration control is triggered, according to the DOC inlet temperature T1 = 270°C before fuel injection and the DPF inlet regeneration target temperature of 600°C, c p =1.004J / (kg·℃), Q m =200kg / h, H fuel =42760J / kg, η=90%, the calculated initial fuel injection quan...

Embodiment 2

[0064] see figure 1 and figure 2 , a kind of diesel engine DPF active regeneration control method, heats DPF2 by injecting fuel oxidation to DOC1 to release heat, comprises the following steps:

[0065] (1) The regenerative controller DCU6 reads the operating conditions of the engine, collects the exhaust gas mass flow rate of the engine fed back by the engine ECU7, the DOC inlet temperature sensor 3 obtains the DOC inlet temperature, and the DPF outlet and inlet differential pressure sensor 5 obtains the DPF outlet and inlet Air pressure difference, T1 = 280°C, ΔP = 17kPa, engine exhaust mass flow rate 200kg / h, which meets the regeneration trigger value and triggers regeneration control;

[0066] (2) After the regeneration control is triggered, according to the DOC inlet temperature T1 = 280°C before fuel injection and the DPF inlet regeneration target temperature of 580°C, c p =1.004J / (kg·℃), Q m =200kg / h, H fuel=42760J / kg, η=90%, the calculated initial fuel injection q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com