Manufacture method for manufacturing cantilever steel pipe with high strength and high toughness by using hot-rolling coiled plate

A technology with high strength and toughness and a manufacturing method, which is applied in the direction of improving energy efficiency and process efficiency, and can solve the problems of poor shape accuracy of the boom, expensive welding wire, and low manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] When the mass percentage of each chemical element is: C: 0.10-0.18%, Si: 0.10-0.45%, Mn: 0.80-1.45%, Ni: 0.02-0.60%, Cr: 0.15-0.55%, Mo: 0.20-0.55% , Cu: 0-0.30%, Nb: 0.010-0.060%, V: 0.020-0.055%, Ti: 0.002-0.030%, Al: 0.010-0.065%, B: 0.0005-0.0040%, Zr: 0-0.0005%, When P<0.020%, S<0.010%, N<0.0080%, and the rest are iron boom steel pipes, the heat treatment process is as follows: rolling ERW steel pipes into the precise size and shape of boom steel pipes in the pass of the special-shaped steel pipe unit The tube billet is heated to 910-960°C in the induction heating equipment for austenitization, the heating time is 60-140s, the cooling rate of heating and quenching is ≥5°C / s, and it is tempered in the induction heating equipment at 370-420°C. The tempering time is 80-180s, and the tempered martensite structure is obtained. Obtain high-strength and tough boom steel pipes with mechanical properties: Reh≥900MPa, Rm≥950-1100MPa, A%≥14%, Akv-40°C≥47J.

Embodiment 2

[0073] When the mass percentage of each chemical element is: C: 0.12-0.20%, Si: 0.10-0.45%, Mn: 0.80-1.45%, Ni: 0.02-0.65%, Cr: 0.15-0.60%, Mo: 0.25-0.60% , Cu: Cu: 0-0.30%, Nb: 0.010-0.060%, V: 0.025-0.055%, Ti: 0.002-0.030%, Al: 0.010-0.065%, B: 0.0005-0.0040%, Zr: 0-0.0005 %, P<0.020%, S<0.010%, N<0.0080%, and the rest are iron hot-rolled coils. Solidification, the heating time is 60-140s, the heating and quenching cooling rate is ≥5°C / s, and the induction heating equipment is heated to 340-390°C for tempering, and the tempering time is 80-180s to obtain a tempered martensite structure. Obtain high-strength and tough boom steel pipes with mechanical properties: Reh≥960MPa, Rm≥980-1150MPa, A%≥14%, Akv-40°C≥47J.

Embodiment 3

[0075] When the mass percentage of each chemical element is: C: 0.17%, Si: 0.25%, Mn: 1.25%, Ni: 0.05%, Cr: 0.21%, Mo: 0.61%, Cu: 0.01%, Nb: 0.015%, V : 0.038%, Ti: 0.025%, Al: 0.035%, B: 0.0015%, P: 0.018%, S: 0.004%, N: 0.0035%, the rest is made of iron 12mm thick hot-rolled coil manufacturing yield strength Reh ≥ 1030MPa For high-strength and high-toughness steel plates, the heat treatment process is as follows: heating to 940°C in induction heating equipment for austenitization, heating time is 100s, quenching cooling rate is 20°C / s, and heating to 290°C in induction heating equipment Tempering, tempering time 120s. The mechanical properties are: Reh: 1080MPa, Rm: 1280MPa, A%: 13%, Akv-40°C: 98J high strength and toughness boom steel pipe.

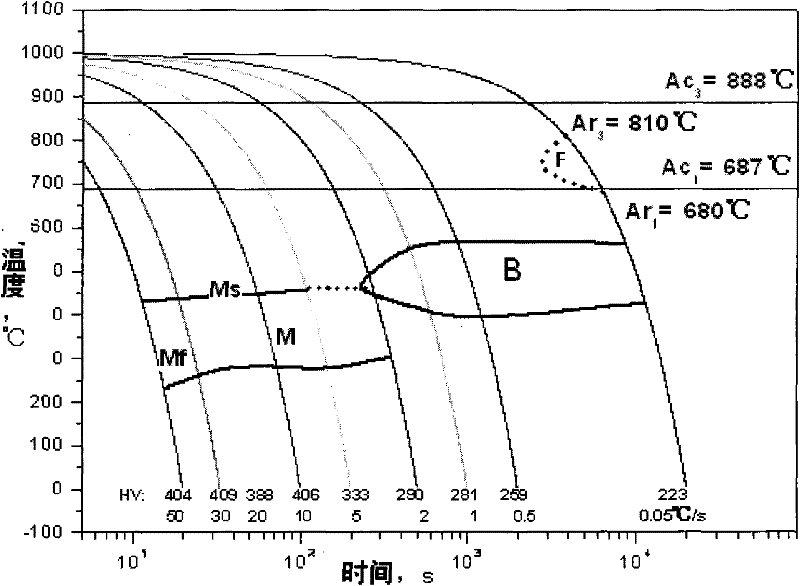

[0076] figure 1 It shows the CCT curve of the Reh 1030MPa high-strength and toughness boom steel pipe manufactured by hot-rolled coils using a Formastor-F thermal dilatometer, combined with metallographic structure observation and ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com