An Amorphous Alloy Magnetic Yoke Applied to High Frequency Induction Heating Furnace

A high-frequency induction heating and amorphous alloy technology, applied in induction heating, coil devices, etc., can solve the problems of high-frequency induction heating environment, low coil heating efficiency, and insufficient iron loss, so as to improve induction heating Efficiency, simple structure, effect of reducing thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

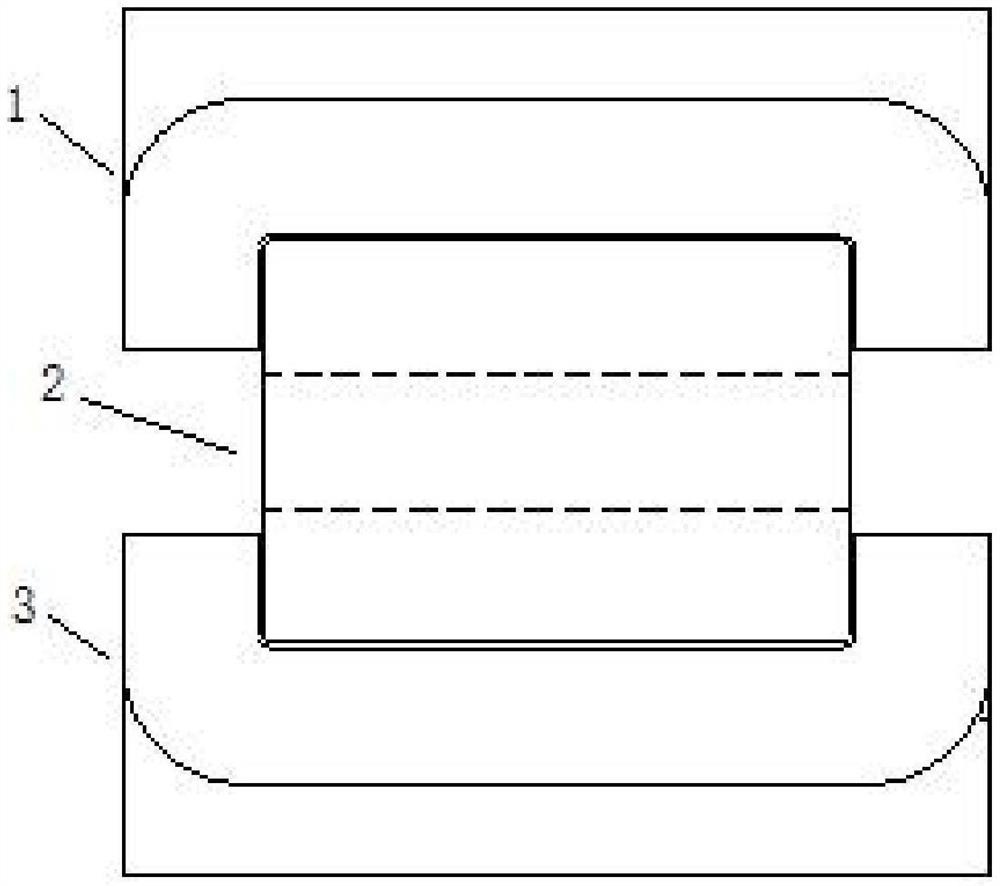

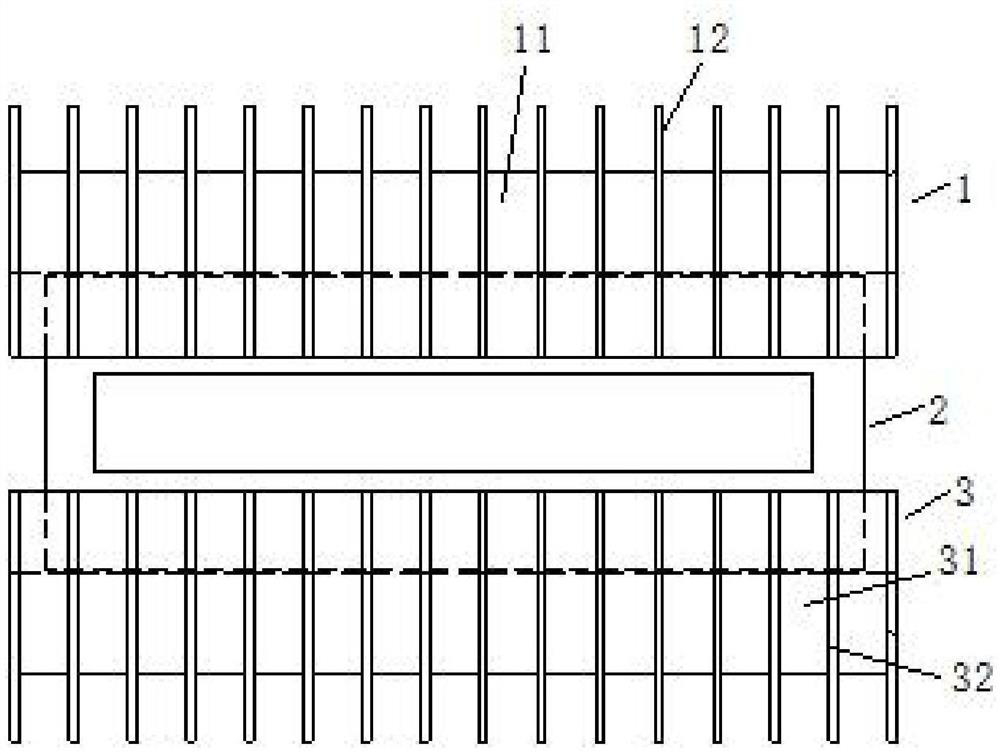

[0037] Example: such as figure 1 and 2 As shown, the amorphous alloy yoke applied to a high-frequency induction heating furnace in this embodiment includes an upper amorphous alloy yoke 1, an induction coil 2 and a lower amorphous alloy yoke 3;

[0038] The above-mentioned induction coil 2 is a ring-shaped coil vertically arranged horizontally;

[0039] The above-mentioned upper amorphous alloy yoke 1 and the lower amorphous alloy yoke 3 are respectively arranged at the upper and lower ends of the above-mentioned induction coil 2 .

[0040] During use, the upper amorphous alloy yoke 1 and the lower amorphous alloy yoke 3 with high magnetic permeability can constrain and shield the magnetic force lines outside the induction coil 2, so as to prevent the external transmission parts from being heated. At the same time, The upper amorphous alloy yoke 1 and the lower amorphous alloy yoke 3 have low iron loss, which can reduce their own thermal efficiency due to the eddy current ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com