Supporting substrate for preparing semiconductor light-emitting device and semiconductor light-emitting device using supporting substrates

a technology for supporting substrates and semiconductor light-emitting devices, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical devices, etc., can solve the problems of reducing the reliability of devices, unable to apply a large current to leds, and a lot of constraints in packaging processes, so as to improve the production yield of led chips, reduce the risk of micro-cracks or breaks, and reduce the effect of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

PREPARATION OF A SUPPORTING SUBSTRATE FOR PREPARING A SEMICONDUCTOR LIGHT-EMITTING DEVICE

Preparation Example 1

Preparation of a Supporting Substrate for Preparing a Semiconductor Light-Emitting Device

[0071]Hereinafter, the structure of a supporting substrate for preparing a semiconductor light-emitting device and its sequential manufacturing method according to an embodiment of the present invention will be described.

[0072]FIG. 4(a) is a sectional view illustrating a supporting substrate for preparing a semiconductor light-emitting device according to an embodiment of the invention.

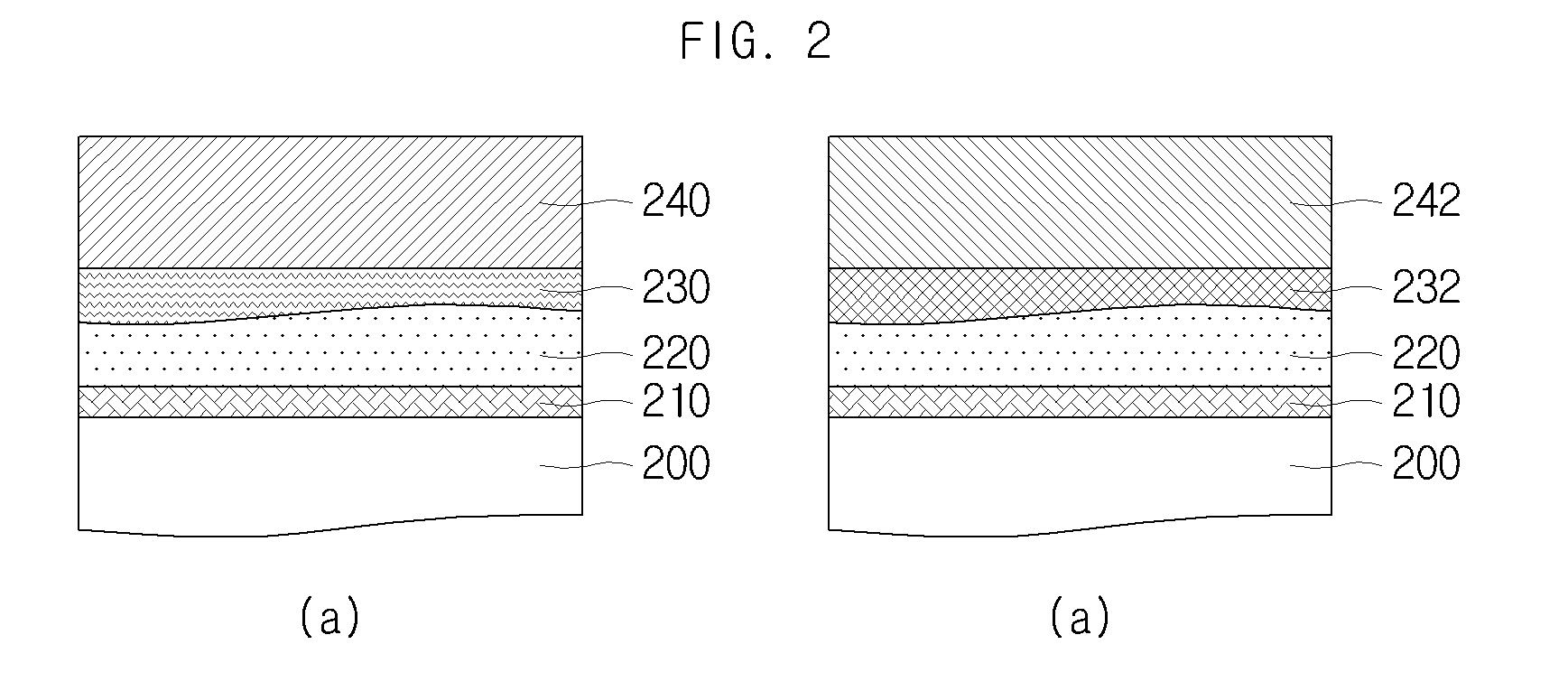

[0073]Referring to FIG. 4(a), a supporting substrate for preparing a semiconductor light-emitting device 40 includes a selected supporting substrate 400, a sacrificial layer 410, a heat-sink layer 420, and a bonding layer 430.

[0074]A method for manufacturing the above-mentioned supporting substrate for preparing a semiconductor light-emitting device 40 includes: (a) preparing a selected supporting substrat...

example 2

PREPARATION OF A SEMICONDUCTOR LIGHT-EMITTING DEVICE USING A SUPPORTING SUBSTRATE FOR PREPARING A SEMICODUCTOR LIGHT-EMITTING DEVICE

preparation example 1

Preparation of a Semiconductor Light-Emitting Device

[0104]Hereinafter, the structure of a semiconductor light-emitting device using a supporting substrate for preparing a semiconductor light-emitting device and its manufacturing method according to an embodiment of the present invention will be described.

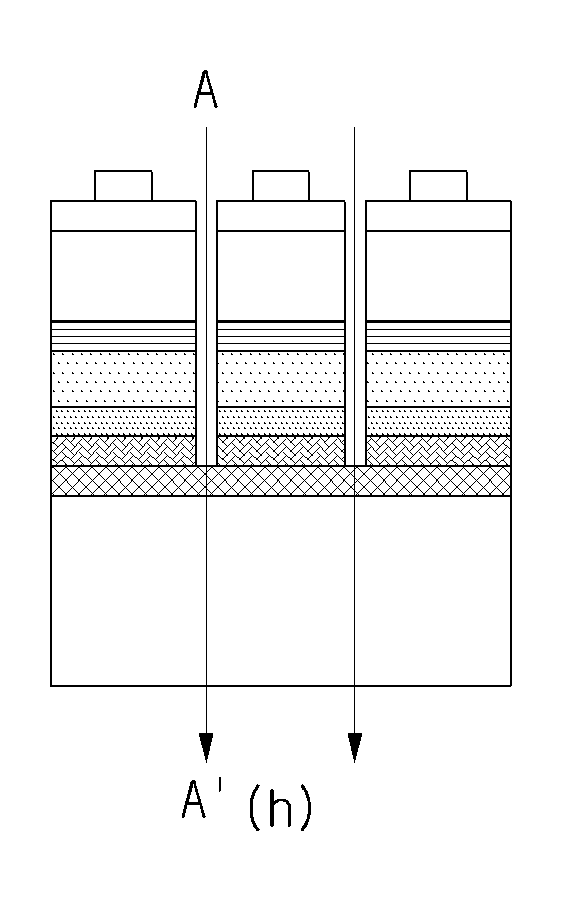

[0105]FIG. 7 is a sectional view illustrating a semiconductor light-emitting device manufactured by using the supporting substrate for preparing a semiconductor light-emitting device according to Example 1 of the present invention. A semiconductor light-emitting device 70 in FIG. 7 is a light-emitting device manufactured by using a supporting substrate for preparing a semiconductor light-emitting device including a heat-sink layer 780 having the thin thickness of 80 μm or less.

[0106]The semiconductor light-emitting device 70 is formed by laminating a first ohmic contact electrode 780, a buffering layer 710, an n-type semiconductor cladding layer 720, a light-emitting active layer 73...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com