Insulation cover for crucible, and fabricating method

A technology for insulation sleeves and crucibles, which is applied to crucible furnaces, chemical instruments and methods, furnaces, etc., and can solve problems such as troublesome production and installation of insulation sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

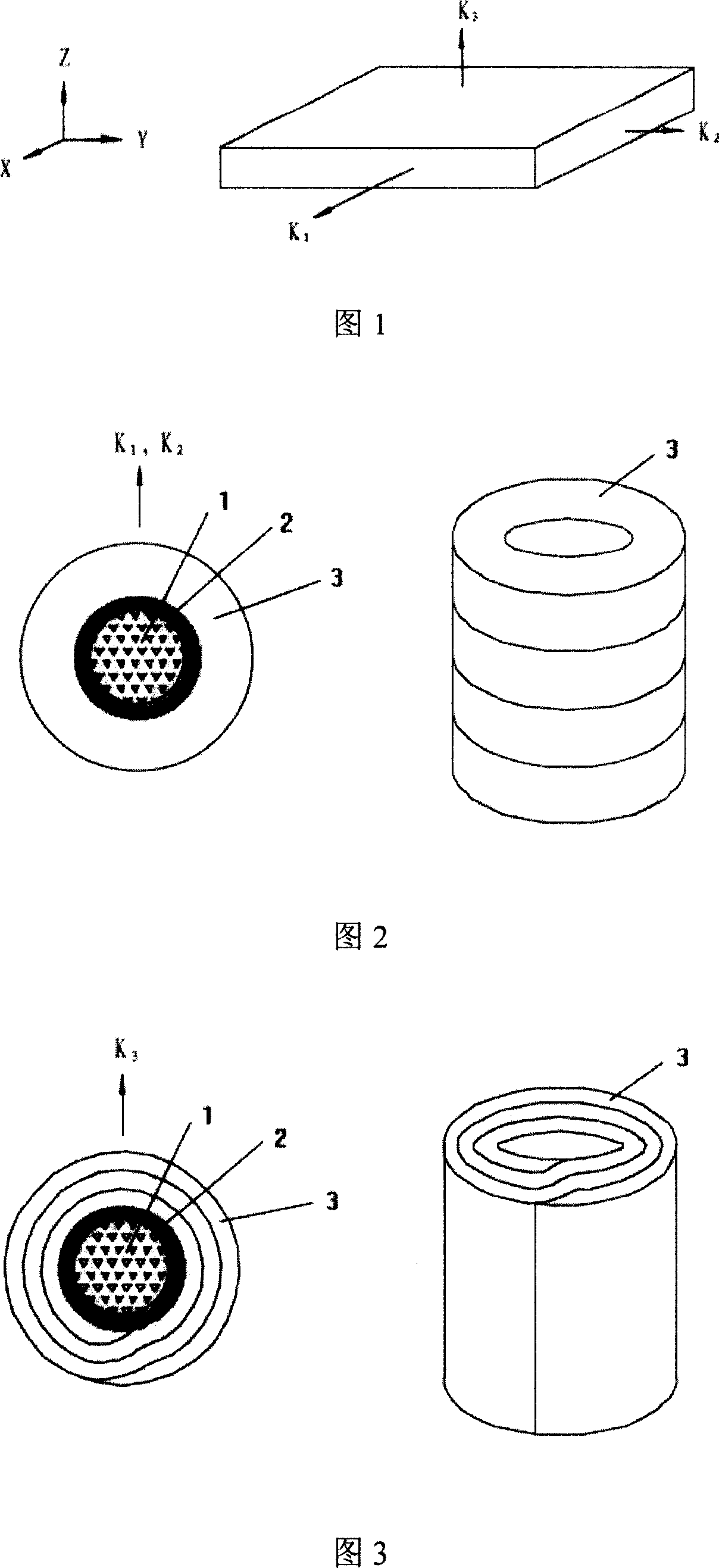

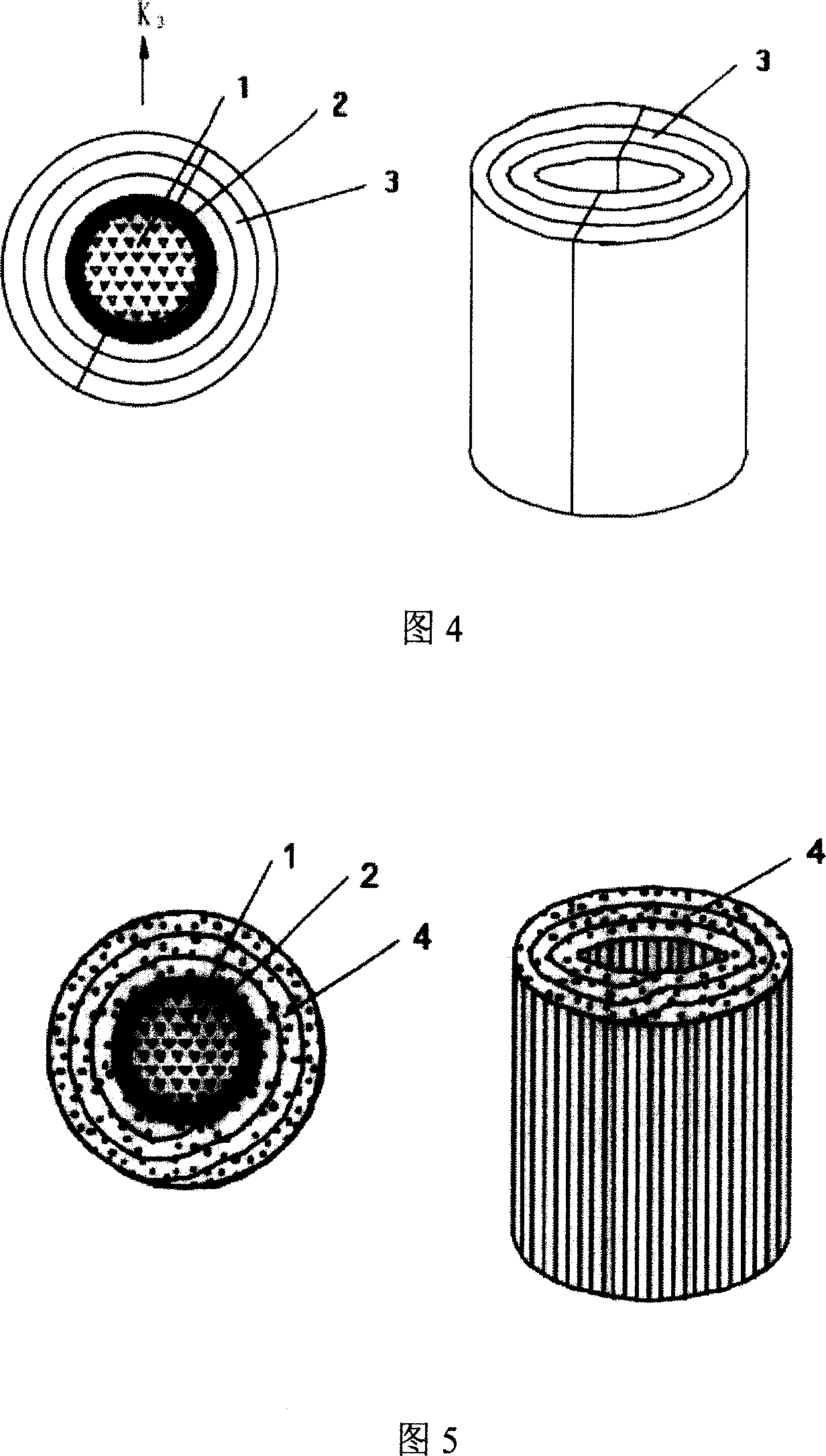

[0015] The long-fiber graphite insulation felt with concentrated fiber arrangement and orientation is selected as the material for making the crucible insulation cover. In this graphite insulation felt, the fibers are arranged along a certain fixed direction or most of the fibers are distributed along a certain fixed direction. In this way, the thermal conductivity along this direction is much greater than that of other directions, that is, the thermal insulation performance along other directions is much better than that of the main arrangement direction of the long fibers.

[0016] Using the design scheme in Figure 5, the long-fiber graphite felt with concentrated fiber orientation is wrapped layer by layer outside the crucible, and the main arrangement direction of the fibers in the insulation felt is required to be parallel to the crucible axis. The crucible is a tungsten crucible with an outer diameter of 50 mm, and the thickness of the graphite felt insulation sleeve aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com