Patents

Literature

95results about How to "No inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

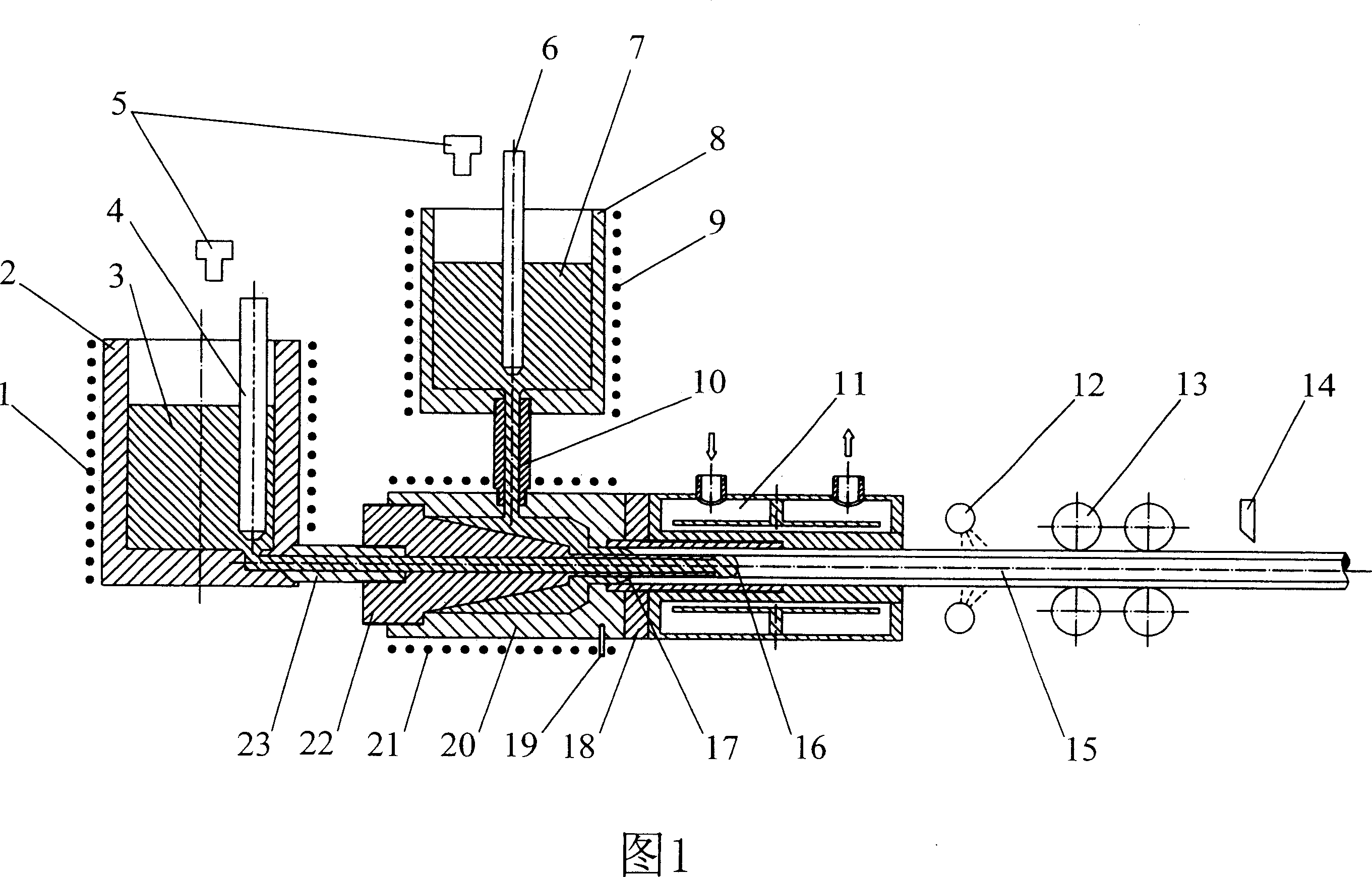

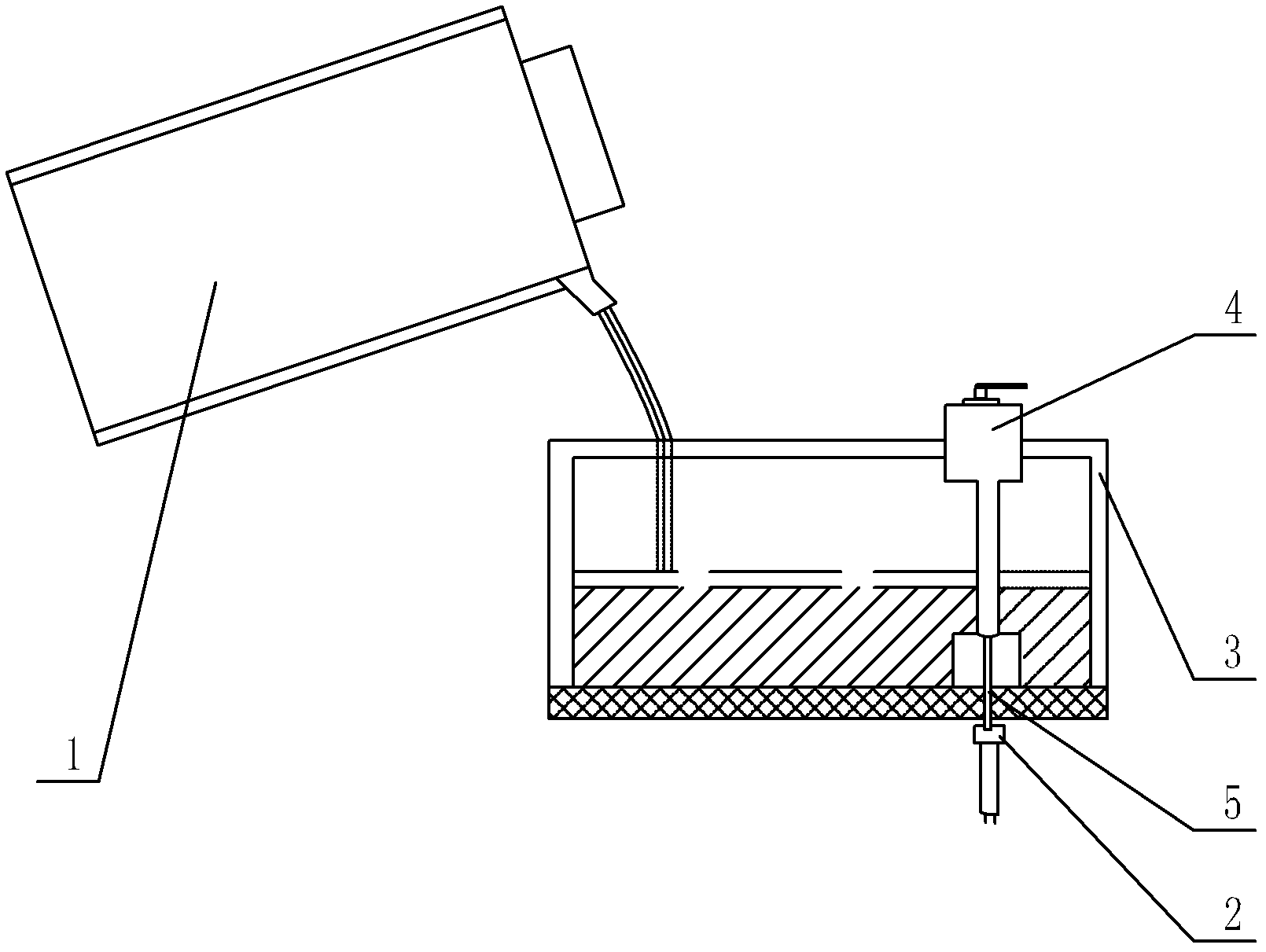

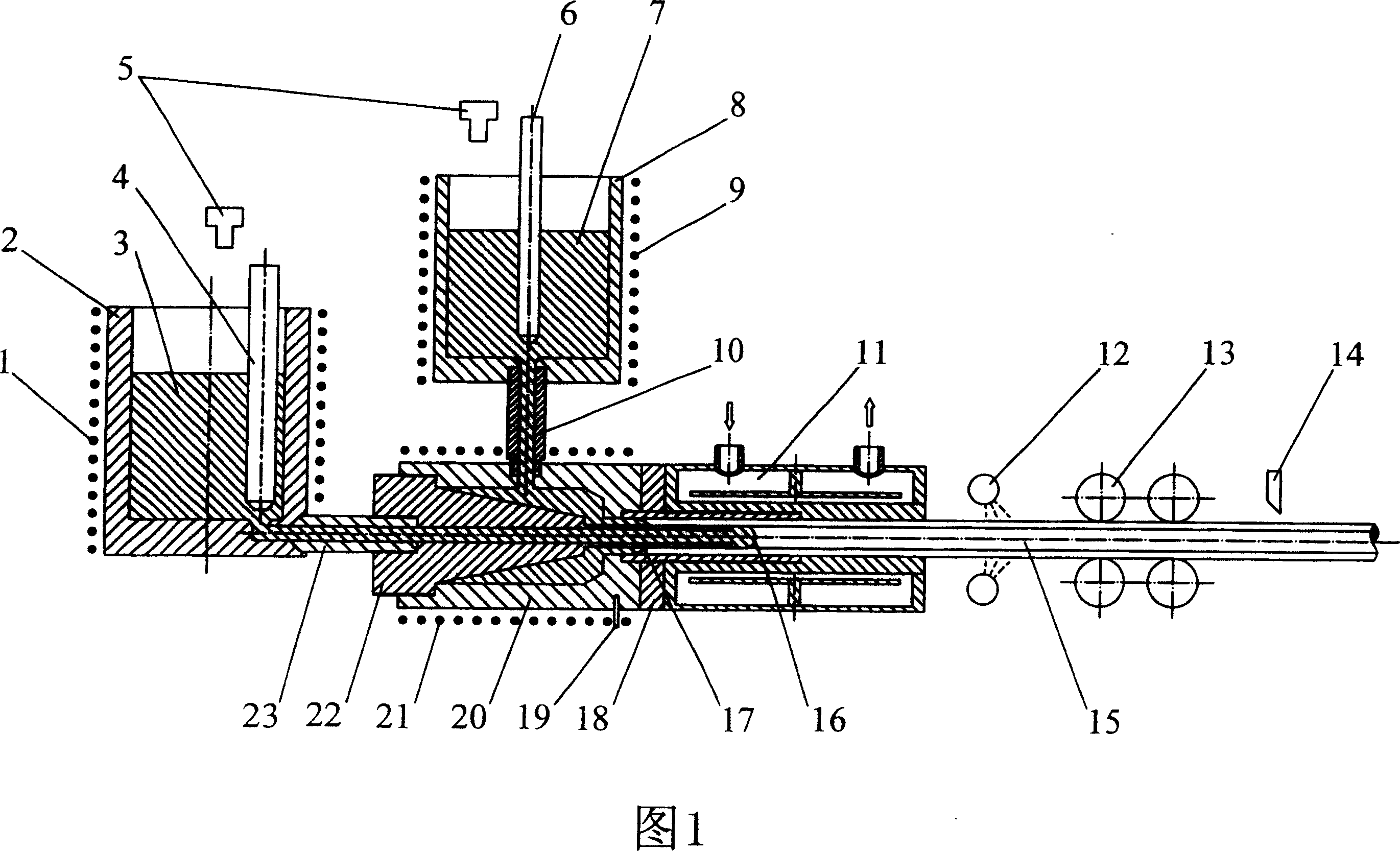

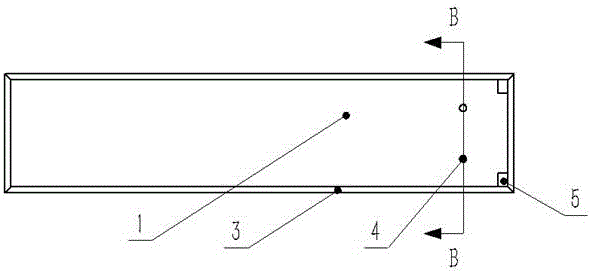

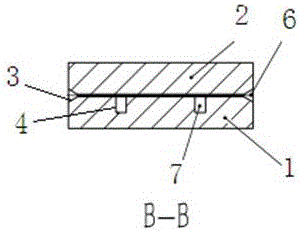

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN1927504AAchieve energy saving and consumption reductionContinuous pullHeating elementCrucible

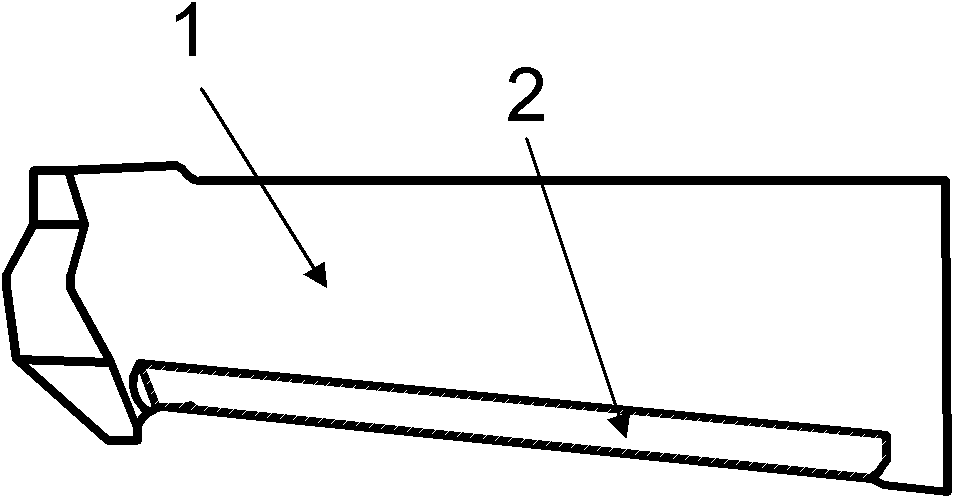

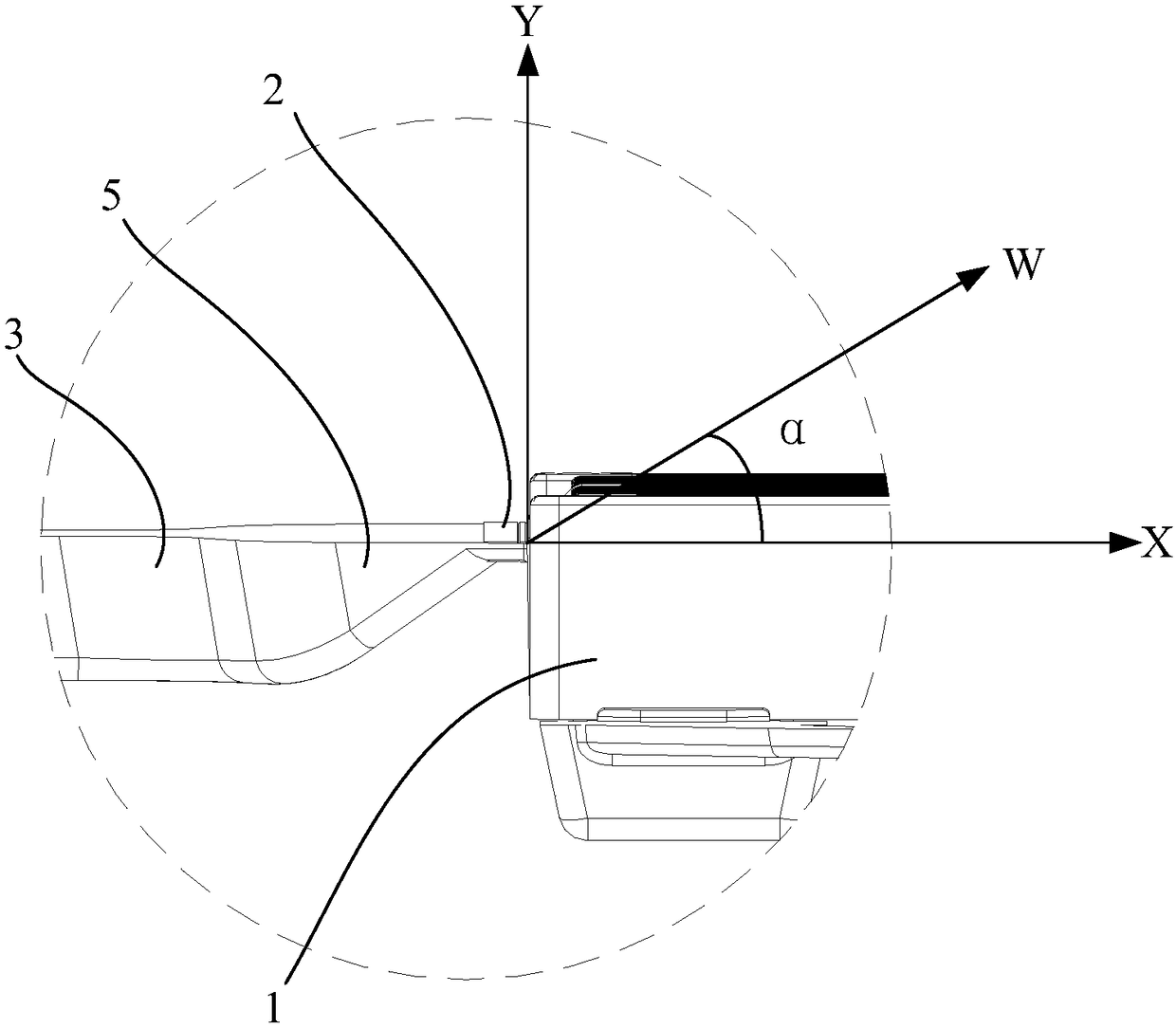

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

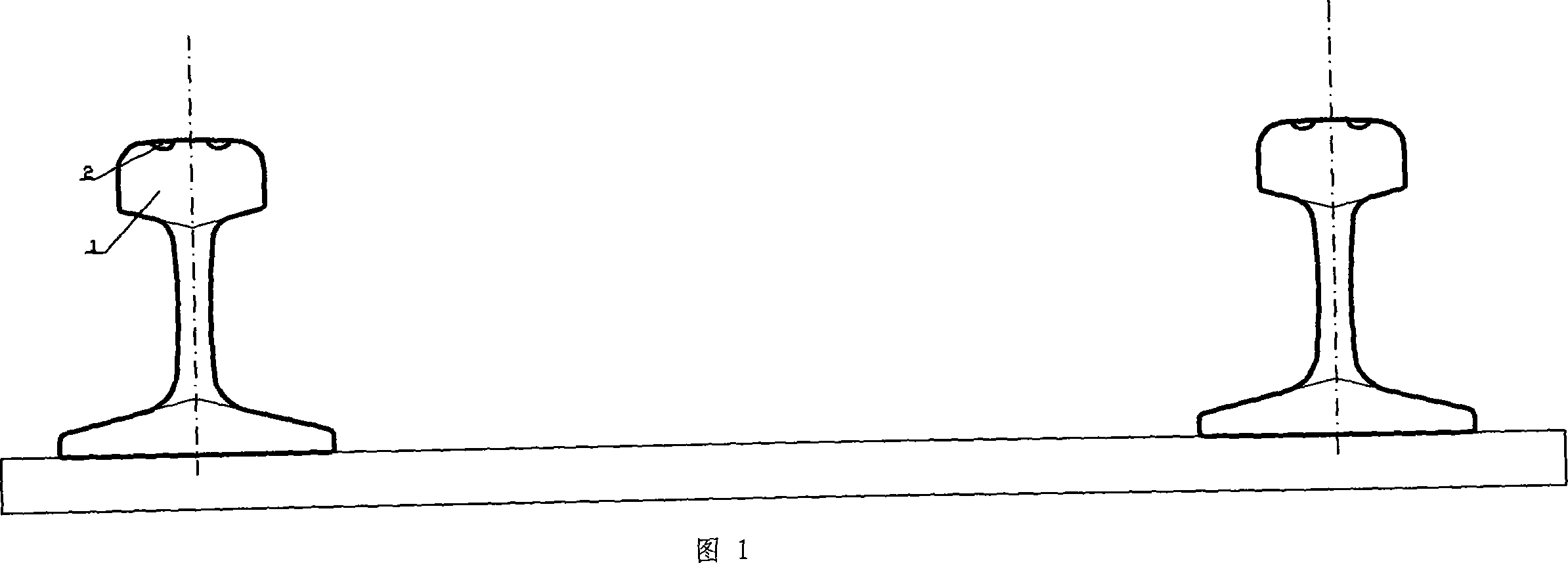

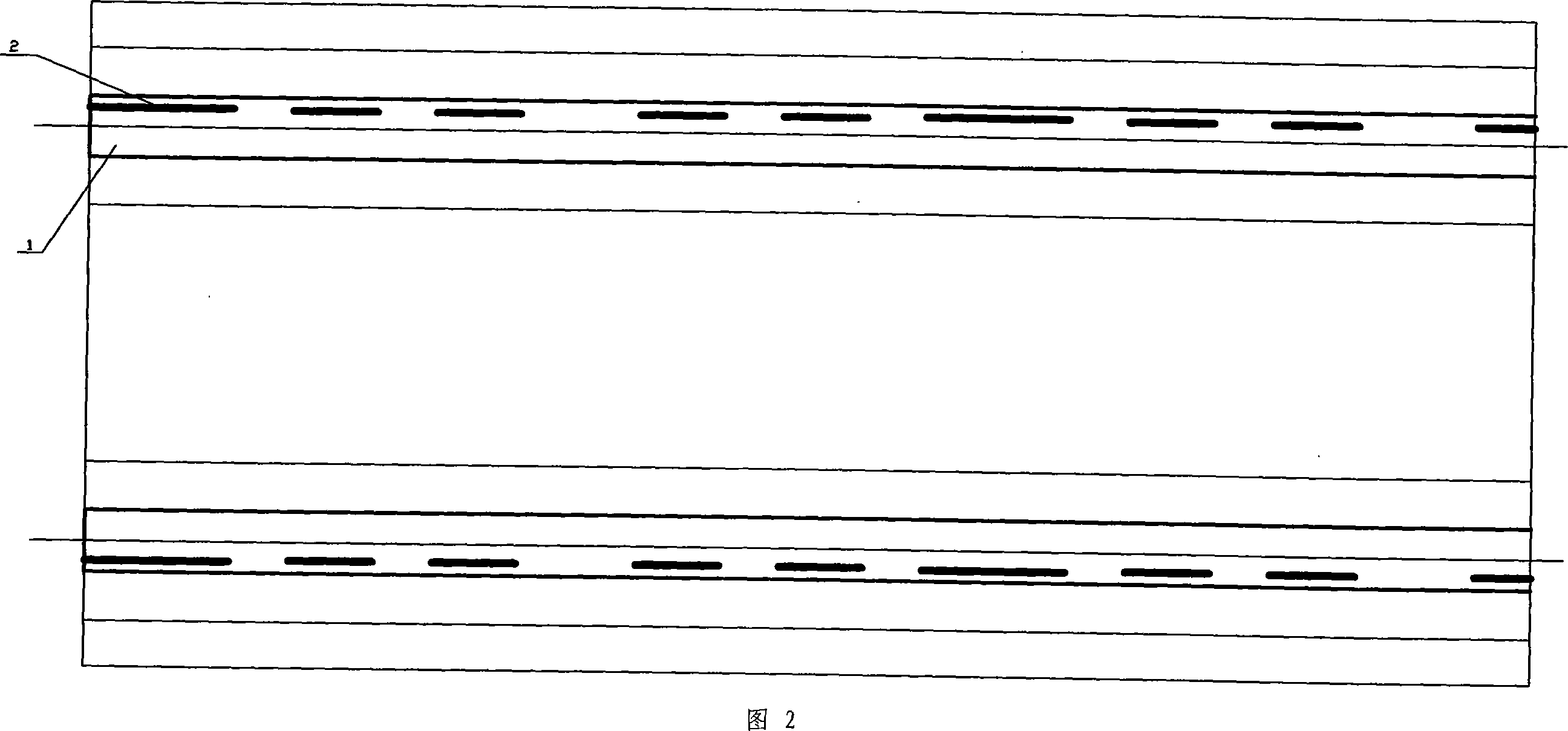

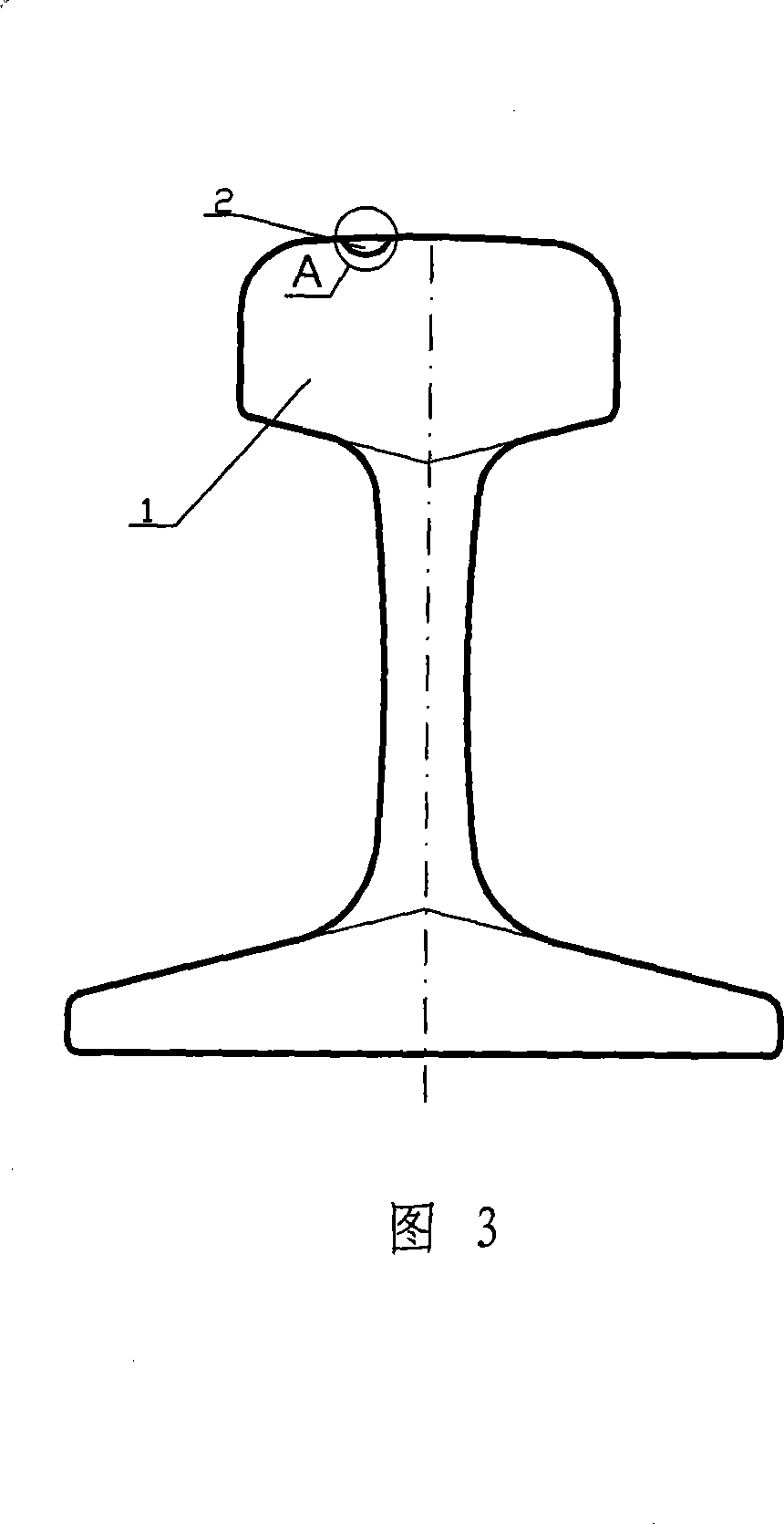

Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

ActiveCN101144160AImprove efficiencyEasy to operateArc welding apparatusMetallic material coating processesBonding strengthWhite light

The present invention discloses a method for smelting rust preventing and wear resistant alloy on the surface of a steel rail. The position needing alloy smelting on the surface of the steel rail head is heated by supersonic frequency or medium frequency induction-heating equipment, the induction heater is arranged above the position needing alloy smelting on the surface of the steel rail head, and the preheating temperature is 290-450 DEG C; the alloy is smelted on the surface of the steel rail head by using plasma smelting or arc welding smelting, when the preheating temperature is 290-450 DEG C, and the welding gun of plasma build up welding or arc welding equipment is moved to the position needing alloy smelting, the alloy powder, the alloy electrode or the alloy welding wire are automatically smelted; the railroad steel rail adopting the present invention can ensure that the train wheels and the rust preventing and wear resistant alloy layer are always in a contacting and compacting state, thereby the rail circuit works normally, and the white light zone phenomenon is completely eliminated; the cracking and breaking phenomena of the steel rail do not occur, the smelted alloy has good rust preventing and wear resistant properties, high bonding strength with the steel rail, and long service life.

Owner:CHENGDU ZHONGGUI TECH CO LTD

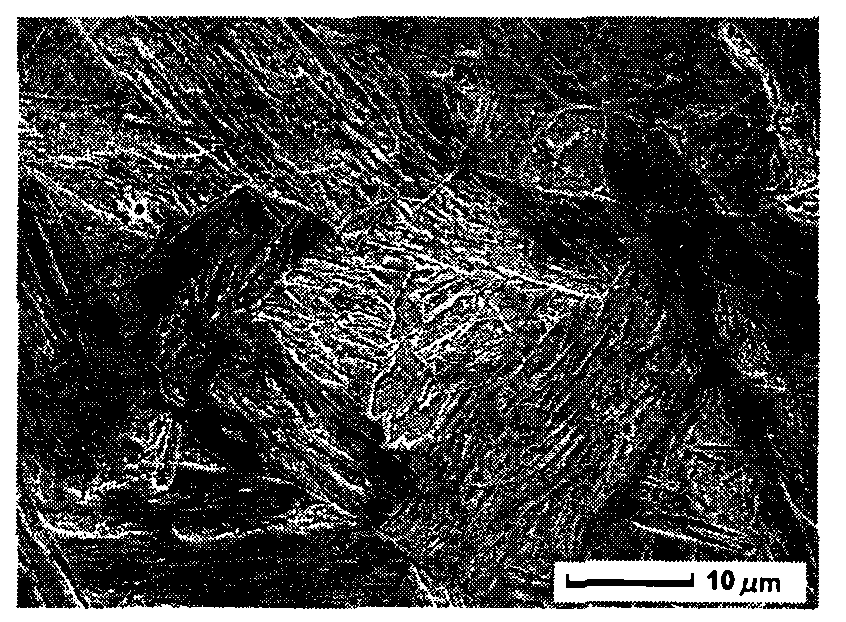

Laser cladding technological method and alloy material for laser cladding

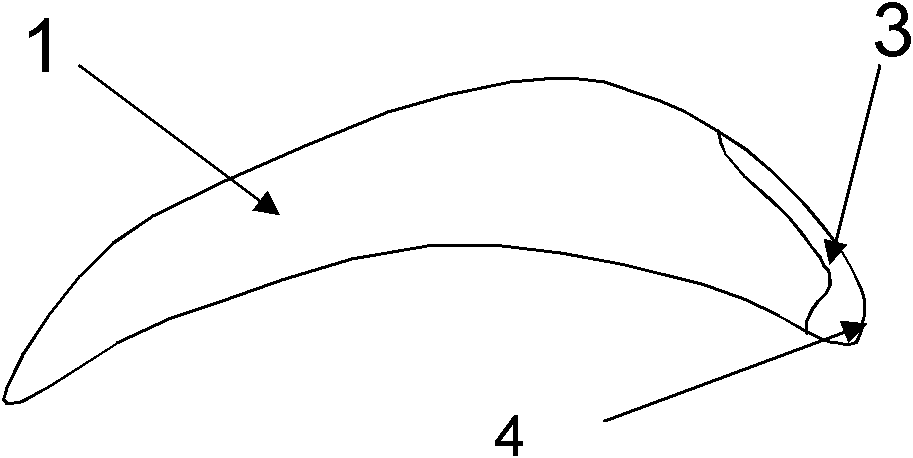

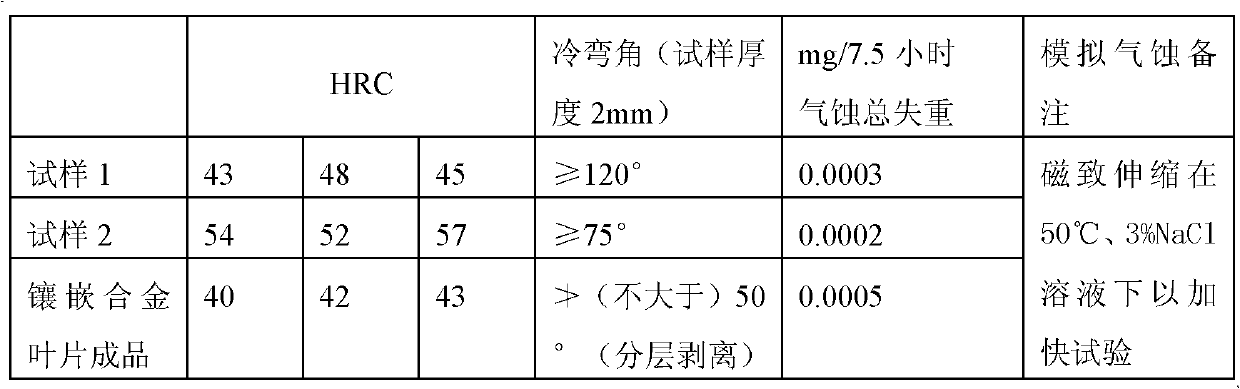

ActiveCN102168210AUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusCavitationSlag

The invention discloses an alloy material for laser cladding. The alloy material is alloy powder and contains the following components in percent by weight: C: 0.85-0.98%, Cr: 35-45%, Fe: 3-5%, Si: 0.5-1.0%, W: 3.5-5.5%, Mo: 1 .0-1.5%, Ni: 6-8%, V: 1.5-2.0%, Ti: 1.0-2.0%, B: 0.5-1.5%, Nb: 0.10-0.50%, Re: 0.5-1.5%, and Co: the balance. The invention also discloses a laser cladding technological method adopting the alloy material. In the technical scheme, under the combined action of the added alloy elements, cladding layer tissue is uniform and tiny and has no pore, no inclusion and no included slag; and preheating is not needed when a blade is cladded and crack does not emerge. The alloy material has high rigidity and excellent cavitation resistance; without follow-up heating treatment, a cladded part can be directly fine machined to use; and the laser treatment technology has good adaptivity and is simple and feasible in operation.

Owner:HANGZHOU BOHUA LASER TECH

High-strength steel high-ductility gas shielded welding wire

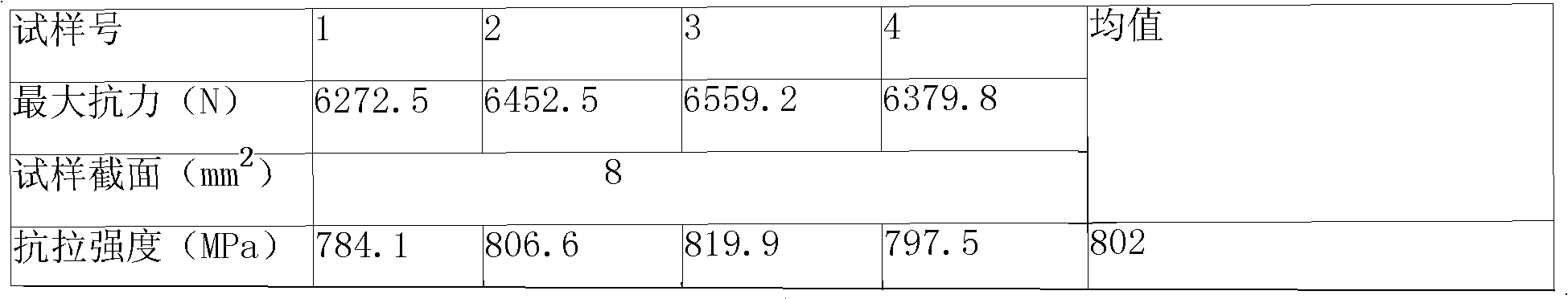

InactiveCN101439446AProcess performance is stableStable welding arcWelding/cutting media/materialsSoldering mediaDuctilityArc welding

The invention relates to a high-tenacity gas-shielded welding wire for high-tensile steel. The welding wire solves problems of 780-850MPa-level low-alloy high-tensile steel welding material, including lack of matching performance and especially poor toughness and high cost. The technical proposal of the invention comprises that the chemical component consists of (counted by weight percentage) 0.05-0.13 percent of C, 1.4-1.9 percent of Mn, 0.4-0.8 percent of Si, 0.4-0.8 percent of Cr, 1.5-1.8 percent of Ni, 0.3-0.8 percent of Mo, 0.06-0.25 percent of Ti, 0-0.60 percent of Cu, not more than 0.025 percent of S, not more than 0.025 percent of P and the balance of Fe and unavoidable impurity elements. When gas-shielded welding is carried out on the welding wire, the welding line has the metal tensile strength of 780-850MPa; the ballistic work AkV at -20 DEG C is not less than 70J, thereby applying to gas-shielded arc welding of 780-850MPa-level low-alloy high-tensile steel.

Owner:SHOUGANG CORPORATION

Method for producing aluminum-magnesium alloy by utilizing liquid aluminum cathode method

The invention discloses a method for producing an aluminum-magnesium alloy by utilizing a liquid aluminum cathode method. The method is used for high-efficiently producing the high-quality aluminum-magnesium alloy. The method comprises the following steps of dissolving the high-purity magnesium oxide (MgO) in an electrolyte system consisting of Na3PO3-MgF2-NaCl in an electrolytic cell under the electrolytic temperature of 850DEG C to 900DEG C, wherein the aluminum liquid which is formed by melting a high-purity aluminum ingot is used as a liquid cathode; and applying a coil magnetic field with the intensity of 30mT to 40mT outside the electrolytic cell so as to enable the aluminum liquid to rotate under the electrolytic conditions that the anode current density is 0.47 to 0.52A / cm<2> and the high-purity graphite is adopted as an anode, reducing the magnesium ions on the rotating aluminum liquid cathode into elemental magnesium under the electromagnetic stirring effect to be uniformly dispersed into the aluminum liquid so as to form the aluminum-magnesium alloy product, and producing CO2 gas on the anode. The alloy prepared through the method is uniform in components and contains no impurity. The production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

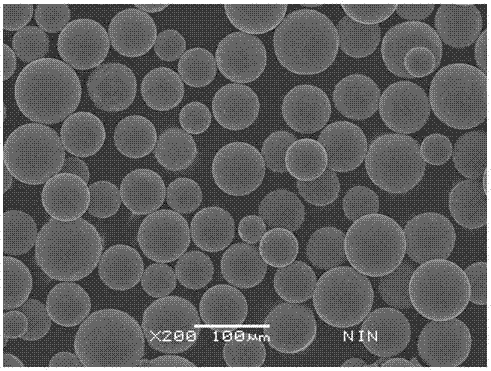

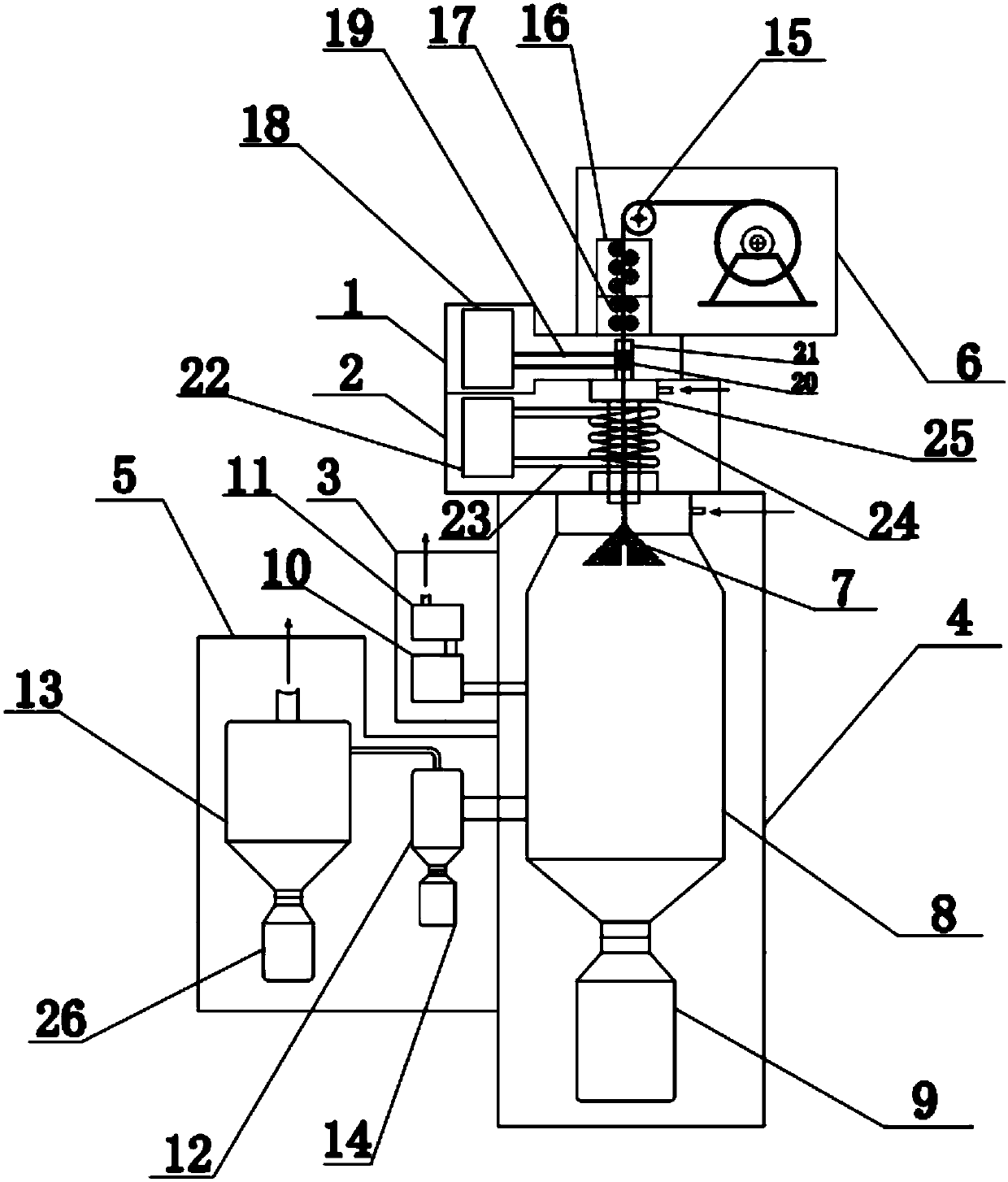

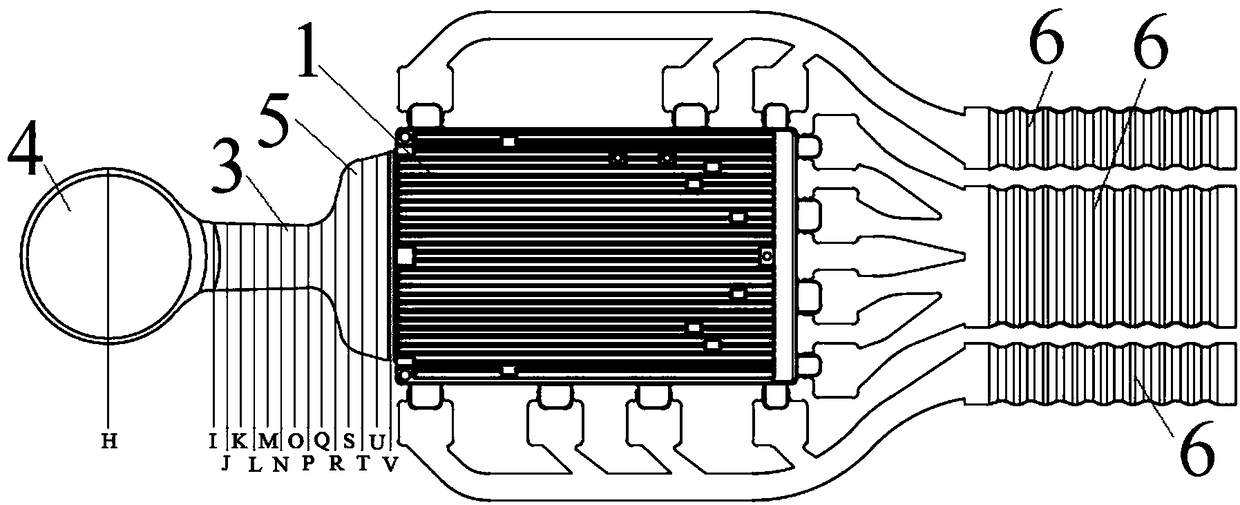

Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

ActiveCN108161019AHigh purityPrevent purityAdditive manufacturing apparatusHigh pressureRadio frequency

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

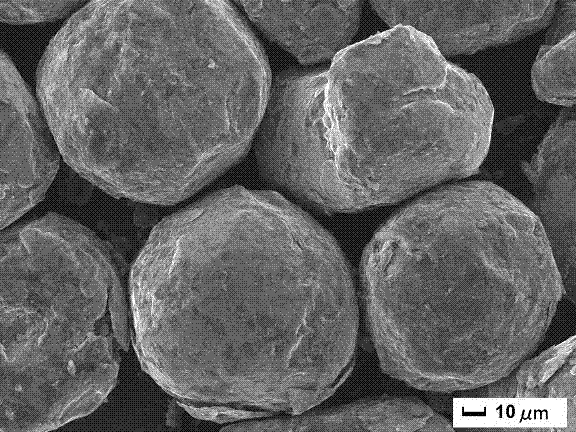

Preparation method of high-quality gamma-TiAl spherical powder

A preparation method of high-quality gamma-TiAl spherical powder comprises the following steps that (1) a gamma-TiAl alloy bar is smelted according to ingredient compounding of a gamma-TiAl base alloy; (2) the smelted gamma-TiAl alloy bar is subjected to forging so as to remove internal defects, and stress relief annealing is performed; (3) annealed gamma-TiAl alloy bar is subjected to finish turning processing to obtain a high-precision alloy bar; (4) the gamma-TiAl alloy bar is loaded to a reaction chamber, and the reaction chamber is vacuumized and filled with inert gas; (5) the end part of the high-precision alloy bar is heated by PREP powder making equipment, atomized drops are thrown away from the end part of the alloy bar, the drops are cooled rapidly into spherical particles in the inert gas environment, and the spherical particles fall into a collector; (6) prepared gamma-TiAl alloy powder is screened and packaged in the inert gas protection environment; (7) the gamma-TiAl alloy powder prepared with the method has the advantages that the degree of sphericity is high, the oxygen increase is low, no mixing exists, and the particle distribution is controllable.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

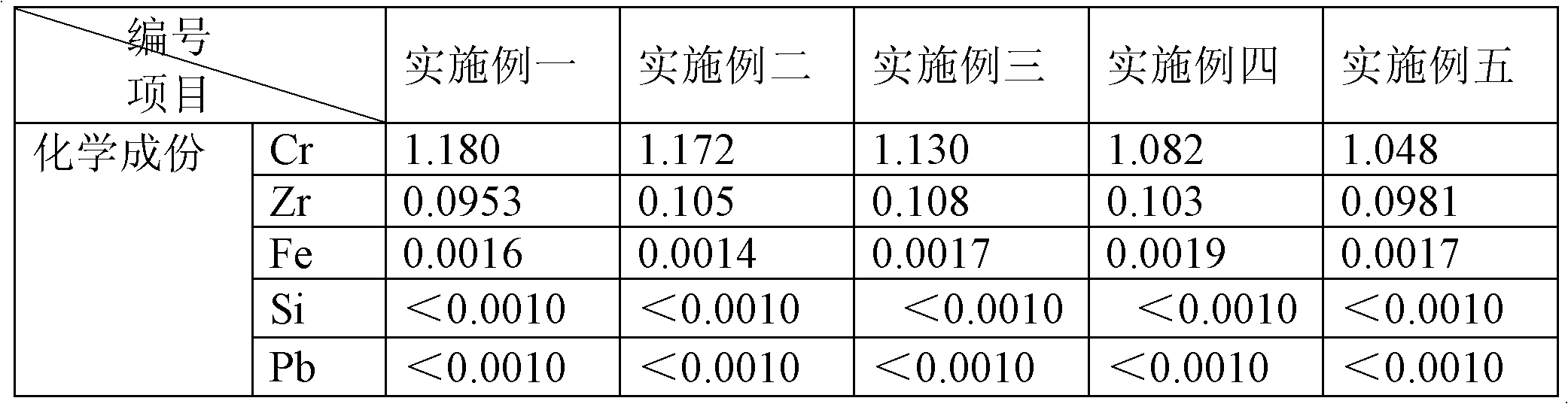

Vacuum semi-continuous method for casting copper chromium zirconium alloy

The invention relates to a vacuum semi-continuous method for casting copper chromium zirconium alloy, which is characterized by following steps of (1) smelting copper zirconium intermediate alloy, (2) sending cathode copper into an intermediate frequency furnace to be smelted, adding deoxidant to deaerate and deoxidize and adding metal chromium into the intermediate frequency furnace after deaeration and deoxidization, (3) heating and drying runner in casting equipment and using gas flame to seal an opening of the runner at the position of the opening above the runner, (4) pouring liquid copper in the intermediate frequency furnace in the heated and dried runner through a furnace opening of the intermediate frequency furnace, (5) pouring the liquid copper in the runner, simultaneously throwing the copper zirconium intermediate alloy into the runner at the position identical with a falling point of the liquid copper, and (6) opening a plug rod switch on the runner to enable the liquid copper to be guided into a water cooling crystallizer through a graphite leakage pipe to be casted ingots. The vacuum semi-continuous method smelts to cast the copper chromium zirconium alloy in the air, thereby being small in investment, simple in operation, stable in ingredient control, safe and reliable.

Owner:江苏隆达超合金股份有限公司

High-precision ultrathin cold-rolled steel strip for electronic component and production method thereof

The invention discloses a high-precision ultrathin cold-rolled steel strip for an electronic component and a production method thereof. The thickness of the high-precision ultrathin cold-rolled steelstrip is 0.14 to 0.16mm; the high-precision ultrathin cold-rolled steel strip is prepared by carrying out acid washing of a hydrochloric acid acid-washing machine set, one-rolling-path rolling of a single-rack and six-roller HC rolling machine, unwinding and edge cutting of a slitting machine set, primary annealing of a bright cover type annealing furnace, flattening of a single-rack and four-roller flattening machine, and plate-shaped defect elimination of a bending and straightening machine set on a hot-rolled steel strip in sequence. The high-precision ultrathin cold-rolled steel strip disclosed by the invention has the advantages of short flow and high product rate, secondary rolling and secondary annealing procedures are omitted and the production cost is reduced; meanwhile, the high-precision ultrathin cold-rolled steel strip for the electronic component has the characteristics of low impurity content, ultrathin thickness, high size precision, flat and straight plate shape, highsurface reflection rate, high roughness uniformity, low yield ratio, uniform performance and good stamping performance, and is applicable to electronic basic components including a battery shell, a communication cable, a television color tube, a carbon membrane resistor and the like.

Owner:山东泰山轧钢有限公司

Application of laser weld in ultra-high tensile steel welding and welding method

InactiveCN101284334ASimple security protectionImprove polarization performanceLaser beam welding apparatusEngineeringSand-paper

The invention discloses the application of laser welding on Unimach and a welding method thereof, which comprises the steps of cutting a Unimach welded sample cut by adopting a molybdenum wire; polishing the welding joint of the sample with metallographical sand paper before welding; removing rust and chips; cleaning with acetone; and adopting a CO2 laser for laser welding. Compared with prior art, the method adopts the laser for welding the Unimach without the need of gas shielding, and penetration welding with welding thickness of 1mm results in good welding effect. The welding joint is smooth and fine macroscopically, without cracks or holes generated. The microstructure analysis and the stretching fracture analysis show that the welding joint is free of welding defects, impurities and pores, and has good fusion, thus greatly improving the anti-cracking performance of the Unimach welding joint.

Owner:GUIZHOU UNIV

High antiwear concrete conveying pipe and production method thereof

InactiveCN101323934AImprove anti-wear performanceImproves wall thickness uniformityMaterials scienceCasting

The invention discloses a concrete delivery pipe with high-wearing feature. According to mass percentage, the following materials are adopted: 0.15 to 0.4 percent of C, 0.1 to 2.0 percent of Si, 1.6 to 3.0 percent of Mn, 0.3 to 2.0 percent of Cr, 0 to 0.5 percent of Mo, 0.02 to 0.1percent of V, 0.01 to 0.06 percent of Ti, 0 to 0.03 percent of Ni, 0 to 0.5 percent of Cu, 0.02 to 0.06 percent of Nb, 0.01 to 0.05 percent of Al, 0.0005 to 0.005 percent of B, 0.02 to 0.06 percent of Re, 0 to 0.02 percent of N, 0 to 0.035 percent of S, 0 to 0.035 percent of P and the rest being Fe, and then the steps of smelting, centrifugal casting, hot rolling, controlled cooling, etc. are carried out to the materials. The production process of the invention is simple and short; the produced delivery pipe has martensite and bainite metallographic structure with high-wearing feature and a service life 4 to 20 times higher than No.20 seamless pipe.

Owner:CHENGDU TIANYUAN XINTAI COMPOSITE MATERIAL

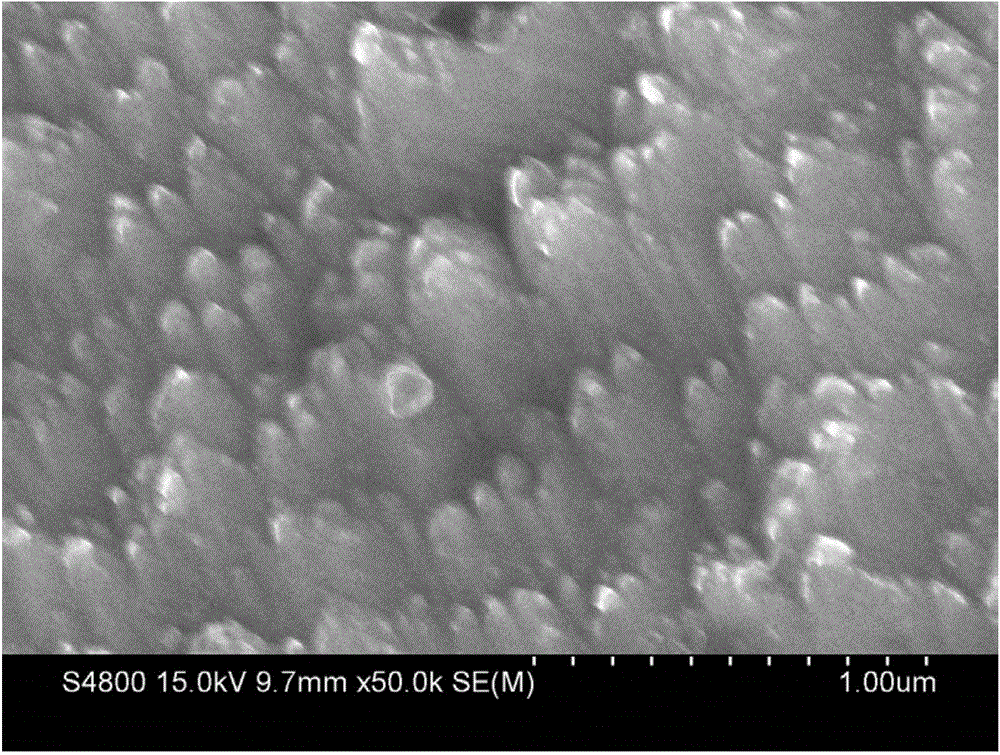

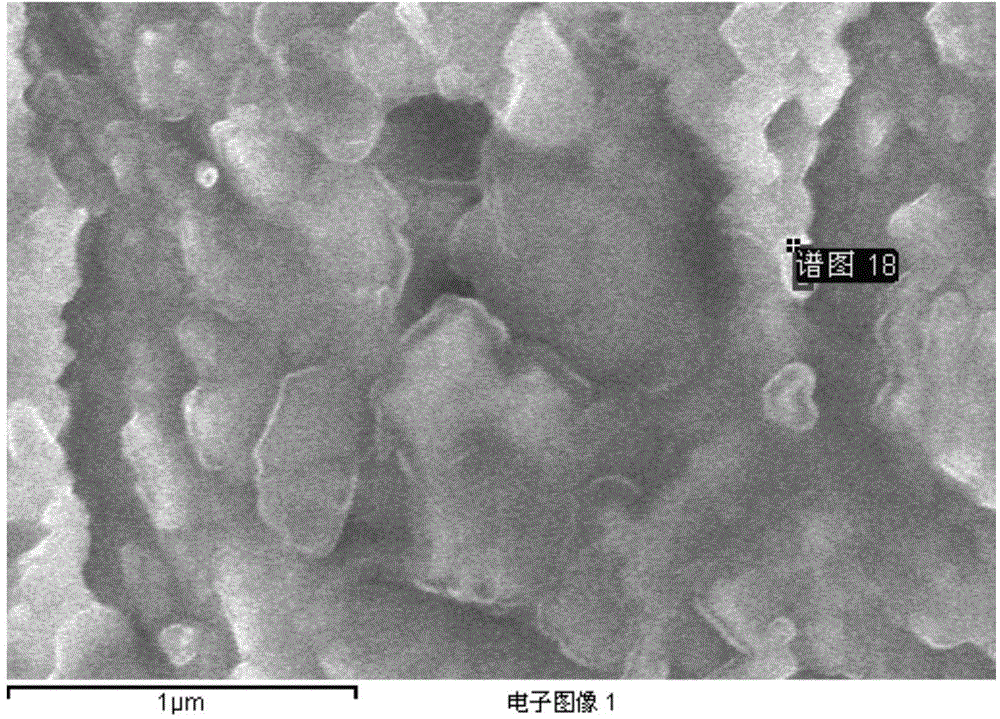

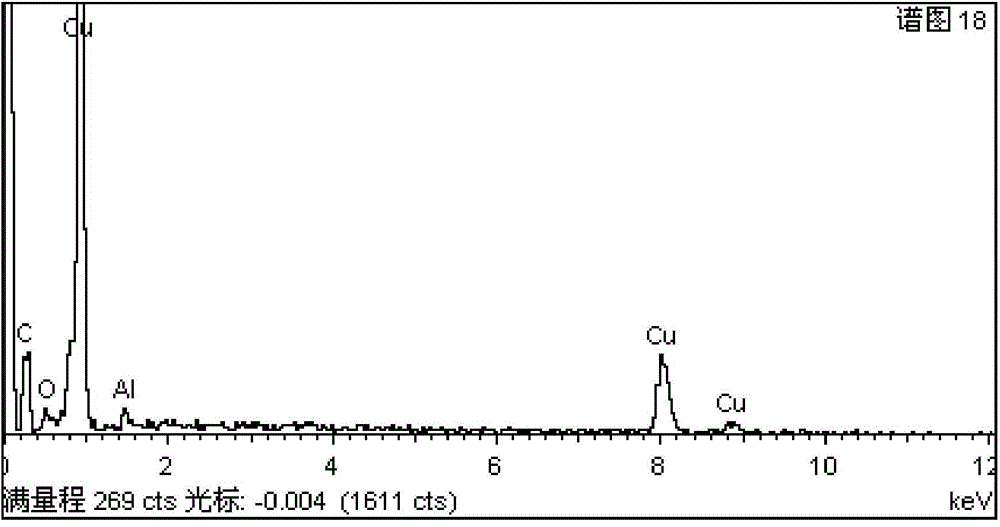

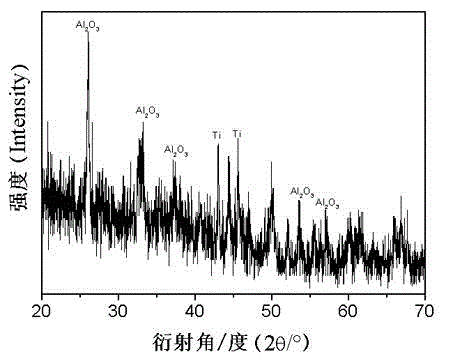

Diffusion-strengthened copper prepared by nano particle stirring method and preparation method thereof

ActiveCN104532051AImprove mechanical propertiesHigh temperature hardness unchangedNano al2o3Surface modification

Diffusion-strengthened copper prepared by a nano particle stirring method is provided; a nano component is Al2O3, after surface modification, the Al2O3 is directly added into a copper matrix under a stirring action and can be uniformly distributed. A preparation method comprises the steps: modifying the surface of nano Al2O3, and then packaging the nano Al2O3 in a copper tube; preparing according to the components, firstly, adding a copper plate into smelting to 1180-1200 DEG C, covering the surface with a layer of charcoal powder with the thickness of more than 2 mm, then adding the packaged nano Al2O3 in a smelting furnace in a dispersion feeding mode, after stirring, allowing to standing for 30 minutes, pouring into a horizontal continuous casting heat-preserving furnace, and at the temperature of 1150 DEG C, casting into a casting blank; carrying out cold-hot deformation, to obtain a finished tube rod profile having the characteristics of a high-strength and high-conductivity copper alloy material. The diffused strengthened copper is characterized in that the nano Al2O3 having the surface modified can be directly added to the copper melt, a technology of stirring coupling surface modification of the nano Al2O3 is adopted, nanoparticles are uniform in distribution, and the casting blank is stable in properties, has no inclusion and is low in cost and suitable for industrialized continuous production. The finished product has the characteristics of high strength and high conductivity.

Owner:东营市东凯新材料技术研发有限责任公司

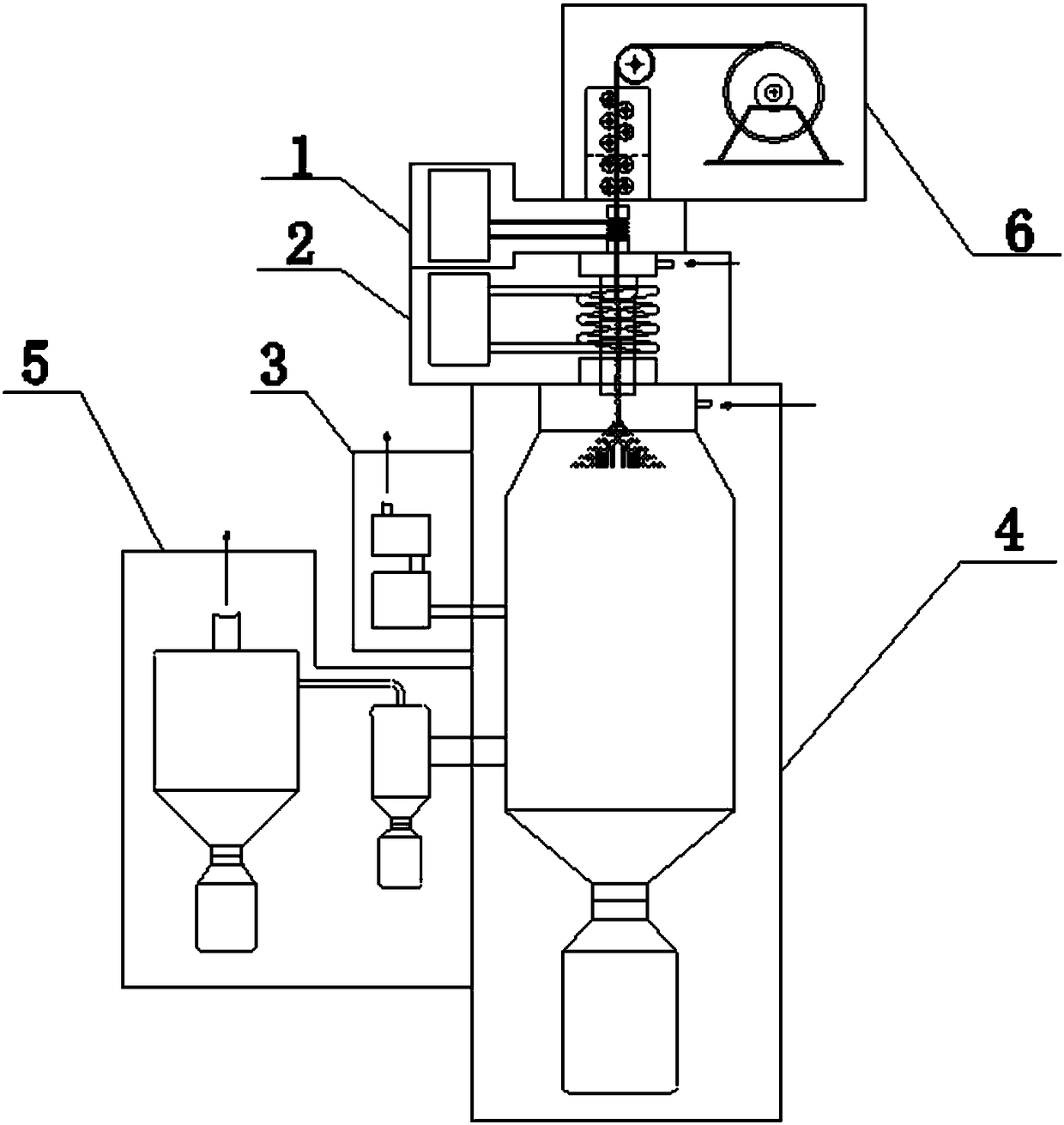

Atomizing pulverization system combined with induction heating and radio frequency plasma

PendingCN108031855AReasonable system designEasy to operateAdditive manufacturing apparatusRadio frequency plasmaHigh frequency

The invention relates to an atomizing pulverization system combined with induction heating and radio frequency plasma. The atomizing pulverization system comprises a high frequency induction heating device, a radio frequency induction plasma device, a vacuum device, an atomizing collection device, a separation and dust removal device and a wire conveyor device. The atomizing pulverization system is rational in design and easy in operation; by adopting the technology that high the frequency induction heating is combined with the radio frequency plasma melting and gas atomization, the whole heating, melting and gas atomization process is subjected to vacuum pumping by the system, and then inert gas is filled for protection; no pollution or inclusions are generated; by combining the high frequency induction heating device used for preheating wires with the radio frequency induction plasma device used for melting the wires, the heat absorption rate in the preheating and melting process isimproved, and the superheat degree of liquid flow or drop is improved, so that high-quality spherical powder, with high sphericity degree and spheroidization rate and small particle size and without hollow spheres, can be obtained after gas atomization; and a high-pressure atomizing nozzle is adopted in the atomization process, and the output rate of metal powder within unit time is improved.

Owner:北京金物科技发展有限公司

Application of laser in low activation martensitic steel welding and welding method

InactiveCN101559540AImprove power densityLow heat inputWelding/soldering/cutting articlesLaser beam welding apparatusSand-paperEngineering

The invention relates to the technical field of welding, disclosing an application of laser welding in low activation martensitic (CLAM) steel welding and a welding method. Linear cutting is carried out on CLAM steel, welding joint is polished by metallographical sand paper before welding and is washed by acetone, and then laser welding is carried out by an Nd: YAG laser. Compared with the prior art, the invention first adopts laser to weld CLAM steel; the welding is penetration welding, the welding thickness is 4-6mm, and the welding effect is excellent. The welding joint after being welded is neat and aesthetic with no crack and cavity generated macroscopically, microstructure analysis shows that the welding joint has no welding defect, no inclusion and no pore-free being with excellent fusion, thereby greatly improving the comprehensive property of the welding joint of CLAM steel.

Owner:JIANGSU UNIV

Lithium recovery process of waste lithium ion batteries

InactiveCN110396600ASimple processHigh purityWaste accumulators reclaimingProcess efficiency improvementCalcium hydroxideLithium electrode

The invention provides a lithium recovery process of waste lithium ion batteries. The process comprises the following steps of firstly crushing the waste lithium ion batteries and then sorting out toobtain positive and negative electrode active material powder and diaphragms; placing the sorted positive and negative electrode active material powder and diaphragms in a roasting furnace for roasting for a certain period of time based on a certain mass ratio at the temperature of 600 DEG C-650 DEG C; leaching roasting product through using oxalic acid solution and then filtering to obtain nickel-cobalt-manganese slag and lithium oxalate solution; adding calcium hydroxide into the lithium oxalate solution for reaction, and filtering to obtain lithium hydroxide solution and calcium oxalate; and finally, adding sulfuric acid into the obtained calcium oxalate for acidifying treatment, and then filtering to obtain oxalic acid solution. The method has the advantages of being simple and novel in process and high in the purity of the obtained lithium hydroxide solution and the recovery rate.

Owner:先进储能材料国家工程研究中心有限责任公司

Coating powder for submerged arc surfacing of low-carbon steel and application method thereof

ActiveCN102152020AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsHigh resistanceHardness

The invention particularly relates to coating powder for submerged arc surfacing of low-carbon steel and an application method thereof. The coating powder contains C 7 wt% to 14 wt%, Cr 30 wt% to 65 wt%, Si 0.15 wt% to 3 wt%, Mn 1 wt% to 2 wt%, P 0.01 wt% to 0.04 wt%, S 0.01 wt% to 0.04 wt%, B 2 wt% to 6 wt%, and the balance of Fe. During the application, the coating powder is applied on the surface of a workpiece by 4 to 6 mm, and then the workpiece is subjected to submerged arc surfacing. The surfacing layer of the coating powder has high hardness, high resistance to abrasion and impact, and no cracks, impurities and pores, and filament-like stress releasing cracks generated on the surface of the surfacing layer can be prevented from dropping or stripping during the processing or application. Additionally, the process design of the coating powder is reasonable, and the parameters are easily controlled and the labor intensity is lower.

Owner:BIRTLEY TIANJIN IND EQUIP

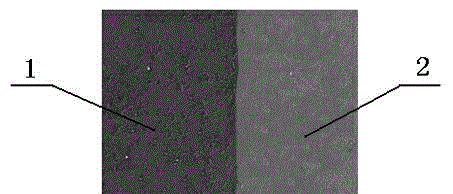

Method for laser cladding of metal ceramic powder on surface of austenitic stainless steel

The invention discloses a method for laser cladding of metal ceramic powder on the surface of austenitic stainless steel: A) carrying out oil removal and texturing treatment on the surface of an austenitic stainless steel base material to be cladded; B) mixing and grinding Al2O3 powder, Ti powder, Mo powder and B powder in accordance with weight percentage; C) coating the mixed powder after grinding on the surface of the austenitic stainless steel base material; and D) performing laser cladding on a surface coating layer of the austenitic stainless steel base material. The corrosion-resistant metal ceramic layer subjected to treatment by the method is highly combined with the austenitic stainless steel base material and has the advantageous of high liquid zinc corrosion resistance, high hardness, no environmental pollution and no generation of defects such as crack, air bubble and inclusion.

Owner:JIANGSU ZHAOLONG ELECTRIC

Preparation method of zinc selenide with high optical quality

ActiveCN101759161AHigh infrared transmittanceSmall absorption coefficientBinary selenium/tellurium compoundsAbsorption factorZinc selenide

The invention discloses a preparation method of zinc selenide with high optical quality, which belongs to the technical field of inorganic block body material preparation. The method comprises the following steps: putting zinc into a deposition furnace; pumping the vacuum; raising the temperature in a deposition chamber; using argon as carrying gas of reaction raw material gas; introducing H2Se gas and the argon into the deposition chamber through a mass flowmeter (the mol ratio of zinc to H2Se is between 0.8 and 1.2, the deposition reaction is carried out on the inner wall of the deposition chamber, and the zinc selenide begins to grow); maintaining the unchanged mol ratio of zinc to H2Se and the constant pressure in the furnace; carrying out deposition for 15 to 25 days; and then, lowering the temperature to the room temperature to obtain the zinc selenide with high optical quality. The invention effectively solves the problem of powder generation in the process of preparing the zinc selenide through chemical vapor deposition, the impurities mixed in products are eliminated, the materials have high infrared transmission rate and low absorption factor, and the optical quality is greatly improved.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD +1

Pouring system for vacuum die casting of profiled optical fiber module and die casting process of pouring system

The invention discloses a pouring system for vacuum die casting of a profiled optical fiber module and a die casting process of the pouring system. The pouring system and the die casting process comprise (1) calculation and simulation of the pouring system; (2), design of a vacuum-pumping system; (3), selection of an aluminum alloy material; (4), alloy smelting; (5), design of a mold heating system; (6), design of the die casting process. The process steps are simple, operability is high, and the service life of a mold is prolonged; by means of the process, the uniformity of poured molten metal is further improved through improvement of a pouring mouth, the situation that the molten metal cannot enter a cavity smoothly for die casting due to accumulation of the metal liquid is prevented, the die casting efficiency is improved, and a casting generated through die casting in a vacuum state is high in quality; and the direction that the molten metal enters the mold cavity is controlled, the flowing process that the molten metal enters the mold cavity through the pouring system is effectively controlled, the mixed degree between the molten metal and the air is lowered, the overall filling of the molten metal in the mold is good, the proportions of surface bubbling, surface flow liner, loose structure, low intensity and decrease of electric conductivity of an aluminum alloy thin-walled workpiece product are lowered, and the qualified rate of the product is increased.

Owner:深圳市奥力压铸五金制品有限公司

Brazing connection method for W/CuCrZr poling module

The invention belongs to the technical field of metal materials and relates to a brazing connection method for a W / CuCrZr poling module. The method is implemented through the following steps that firstly, oil stains, impurities and oxide films on the to-be-welded surface of a tungsten block with a drilled hole are removed; secondly, a layer of oxygen-free copper is cast onto the inner hole of the tungsten block by using a graphite casting die; a CuCrZr alloy pipe, solder and a tungsten block composite block are assembled, the solder is placed between pure copper liners of the CuCrZr alloy pipe and the tungsten block composite block, and then an assembly is put into a vacuum brazing furnace for welding; after completion of brazing, the assembly is quickly cooled to 470-480 DEG C and then is subjected to heat preservation at the temperature for 2-3h, and the W / CuCrZr poling module is formed, wherein the W / CuCrZr poling module comprises the CuCrZr alloy pipe, a brazing layer, a pure copper layer and the tungsten block in sequence from inside to outside. By means of the method, the efficiency is high, and a weld joint is combined well. The method has the advantages that the process is simple, and the preparation cost is low, and is suitable for large-scale industrial production.

Owner:SOUTHWESTERN INST OF PHYSICS

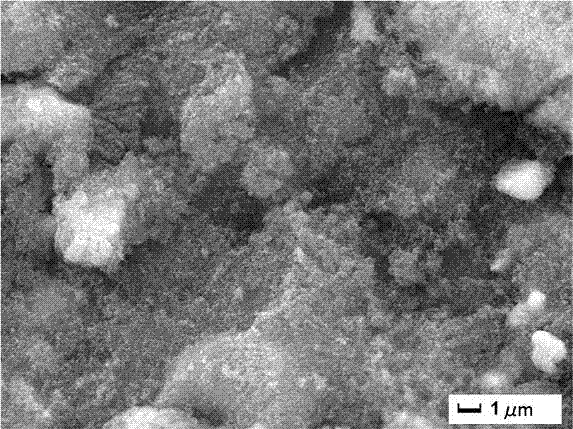

Method for preparing high-silicon steel sheet by powder compression sintering

The invention discloses a method for preparing a high-silicon steel sheet by powder compression sintering, and belongs to the technical field of powder metallurgy. According to the method, gas atomized Fe-6.5 wt.% Si powder is used as a raw material, the powder is in a compact state through powder presetting, the powder is placed in a vacuum sintering furnace to be metallurgically bonded through high-temperature sintering, multi-passes hot rolling are carried out to a certain thickness and then 1-4 times of cold rolling are carried out, and finally annealing is carried out at high temperatureto obtain the high-silicon steel sheet with excellent performance. Compared with adopting water atomized powder, gas atomized high-silicon steel powder is adopted and oxide inclusions of an alloy system are greatly reduced, meanwhile, the problem that spherical gas atomized powder is difficult to form is solved by adopting a direct compression sintering method, so that the process complexity and the subsequent problems of degumming and carbon residue caused by adding a forming agent are avoided, and the method has the advantages of being simple to operate, high in production efficiency, high in product precision, short in process flow, free of pollution and inclusions, excellent in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing high-purity spherical niobium oxide by peroxidizing precipitation

The invention discloses a method for preparing high-purity spherical niobium oxide by peroxidizing precipitation, which comprises the steps of: adding hydrogen peroxide H2O2 and liquid ammonia into a fluooxycolumbic acid solution H2NbOF5 to obtain (NH4)3NbO8 crystals; and roasting the crystals at a controlled temperature to obtain niobium oxide having a corresponding phase state and a granularity of 0.3-1 mum. According to the method disclosed by the invention, ammonium niobate crystals which are obtained from precipitation process are free from package, adsorption, and impurities and filtered easily. Consequently, high product purity is obtained in a case of the same raw materials and technological conditions; the ammonium niobate is then roasted at 150-1300 DEG C to obtain fluorine-free niobium oxide which is obviously spherical, uniform in particle and has the granularity of 0.3-1 mum; and niobium oxide at alpha, beta and gamma phase states can be obtained by controlling the roasting temperature according to application requirements. The method disclosed by the invention leaves out washing, drying as well as grinding and sieving procedures, saves plenty of manpower, material resources and energy sources.

Owner:稀美资源(广东)有限公司

Preparation technique of high-purity nickel ingot for semiconductor target

InactiveCN106399721ALow purityControlled Evaporation RemovalTemperature controlMaterials preparation

The invention provides a preparation technique of a high-purity nickel ingot low in impurity element content, namely a preparation technique of a high-purity nickel ingot for a semiconductor target. The preparation technique comprises the main steps that material preparation, charging and repeated smelting are conducted, specifically, an electron beam furnace is used for smelting, warming smelting starts to be conducted when the vacuum degree of a hearth is maintained to 1.0*10<2> Pa or below in the smelting process, the smelting temperature is controlled to 2130 DEG C or over, the smelting speed is controlled to 20.1 kg / h or below, and an electrolysis nickel board is fully molten; and the nickel ingot formed after smelting is cooled in the hearth for 6-12 h and then discharged out of the furnace. According to the preparation technique of the high-purity nickel ingot for the semiconductor target, parameters including the smelting speed, the smelting temperature, the smelting time and the like are selected according to the quantity of materials, electron beams are controlled to be distributed accurately in the smelting process, and thus the purity of metal and volatilizing removal of impurities can be controlled to the maximum extent; and high-purity metallic nickel is free of pores and inclusions and suitable for subsequent processing and using of the target.

Owner:宝鸡一众有色金属材料有限公司

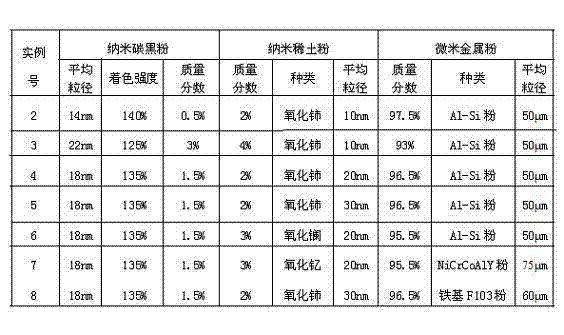

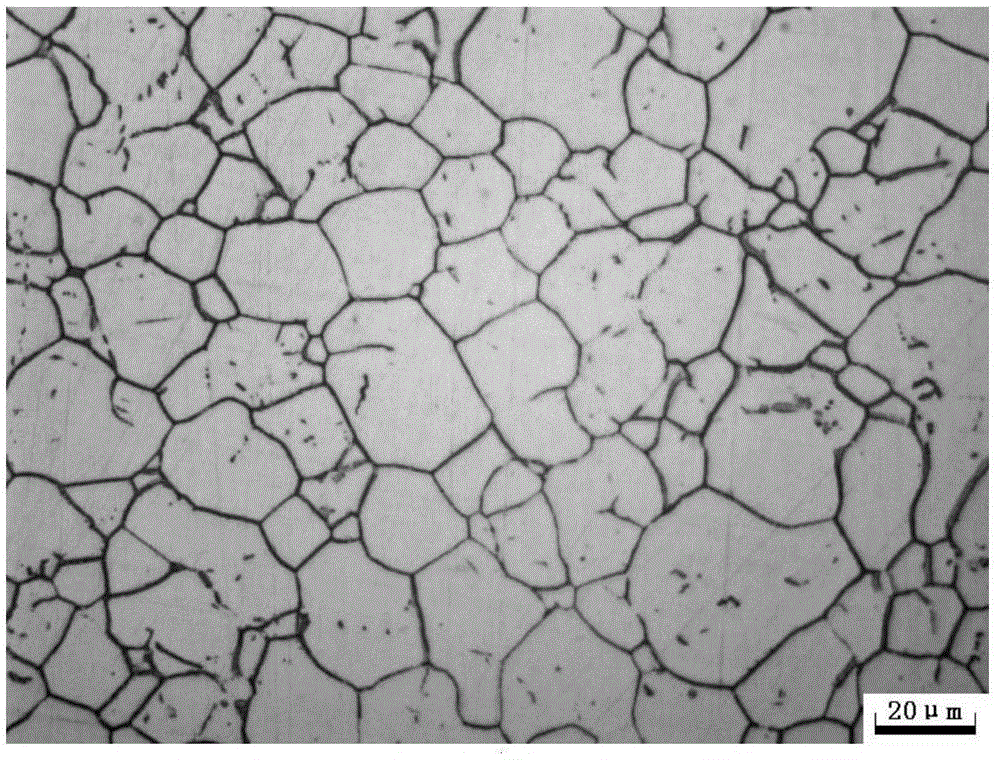

Nano carbon black and nano rare earth synergistic-enhanced metal matrix micro-nano powder and preparation method thereof

The invention discloses nano carbon black and nano rare earth synergistic-enhanced metal matrix micro-nano powder and a preparation method thereof. The powder is characterized by comprising the following components in percentage by mass: 0.5-3% of nano carbon black powder, 2-4% of nano rare earth powder and 93-97.5% micron metal powder, wherein the percentage sum of the components is 100%; and core-shell structure micro-nano powder with the micron metal powder as core and with the nano carbon black powder and the nano rare earth powder as shell is formed. The preparation method comprises the following steps: single-phase nano carbon black suspension and single-phase nano rare earth suspension are prepared firstly, and are mixed to form double-phase nano suspension; then the double-phase nano suspension and spherically preprocessed micron metal powder are mixed, milled with balls, and are dried to prepare the metal matrix micro-nano powder. As the nano carbon black and the nano rare earth are synchronously guided in, the adding quantity of the nano carbon black can be further increased, so that better absorptivity for laser is achieved; produced thin-walled pieces have less deformation, narrow heat influence areas and good wear resistance, and can satisfy the requirements of powder conveying through the present laser forming mainstream technology, that is direct powder conveying type laser forming technology; and the powder has stronger engineering practicability and excellent application prospect.

Owner:JIANGSU UNIV

Preparation method of Ti-25Nb alloy sheet

The invention provides a preparation method of a Ti-25Nb alloy sheet, which comprises the following steps: 1. carrying out vacuum consumable arc-melting on raw materials sponge titanium and Ti-47Nb interalloy to obtain a Ti-25Nb alloy cast ingot; 2. carrying out cogging and forging; 3. forging a sheet blank; 4. carrying out hot rolling; 5. sequentially carrying out quenching, shot blasting and pickling treatment; and 6. carrying out cold rolling to obtain the Ti-25Nb alloy sheet of which the thickness is 0.3-1mm. The Ti-25Nb alloy sheet prepared by the method provided by the invention has the advantages of no inclusion, no composition segregation, more uniform structural composition, high flatness, smooth surface and no defects, such as cracking, peeling, stratifying, folding and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Ni-W-added Al alloy target material and manufacturing method thereof

ActiveCN105420678AHigh puritySuitable for magnetron sputteringVacuum evaporation coatingSputtering coatingIngot castingMicrometer

The invention discloses an Ni-W-added Al alloy target material and a manufacturing method thereof. The target material includes, by atom percentage, 0.5-10% of Al, 3.5-15% of W and 75-96% of Ni. The manufacturing method sequentially includes the steps of burdening, intermediate alloy smelting, secondary smelting, ingot casting, forging, primary heat treatment, rolling, secondary heat treatment and machining for finished product production. The Ni-W-added Al alloy target material has the advantages that the components of finished products are controlled accurately, uniform in distribution and free of segregation, no inclusion exists, grains are uniform, and the finished products are high in purity. Specifically, the components are controlled accurately to be smaller than or equal to 0.2 at%, the mean grain size is not larger than 80 micrometers, and the purity is up to 99.95%.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

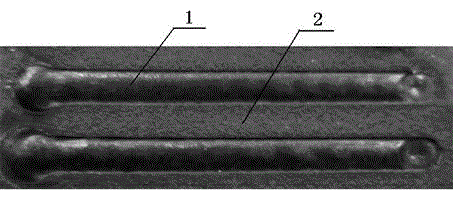

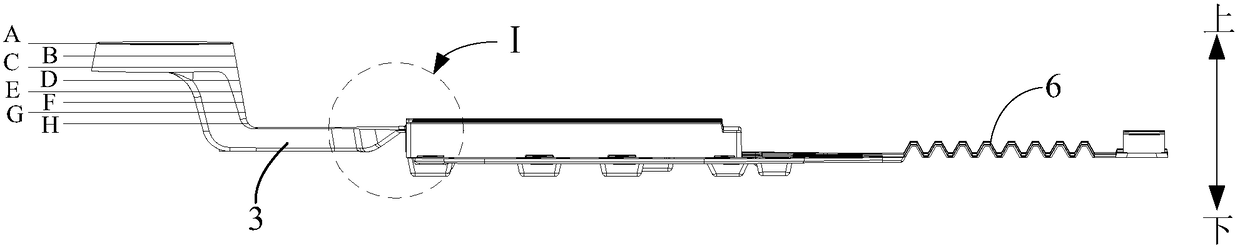

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN100377814CAchieve energy saving and consumption reductionContinuous pullTemperature controlCrucible

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

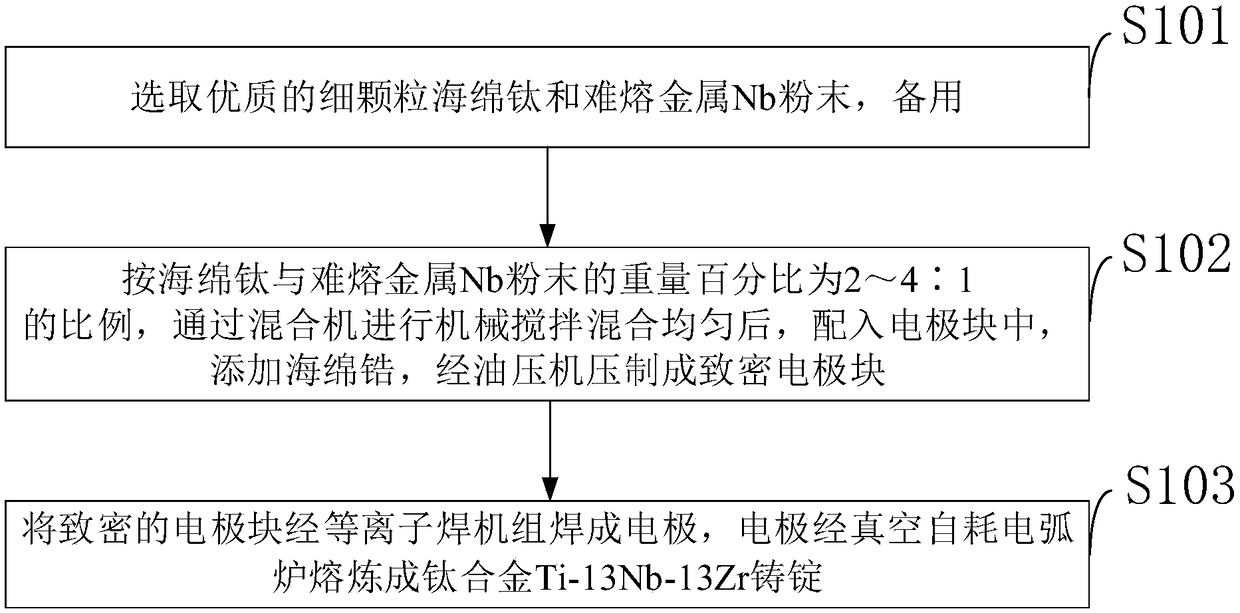

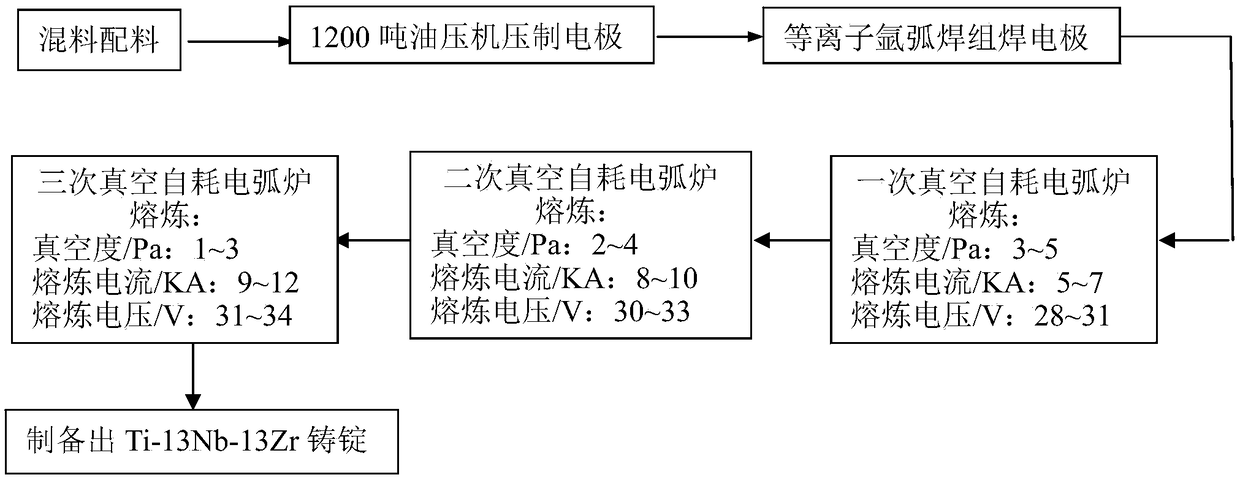

Medical titanium alloy Ti-13Nb-13Zr ingot and preparation method thereof

The invention belongs to the technical field of titanium alloy, and discloses a preparation method of a medical titanium alloy Ti-13Nb-13Zr ingot. The preparation method comprises the following steps:selecting high-quality fine particle sponge titanium and refractory metal Nb powder; according to the ratio of weight percentage of sponge titanium to refractory metal Nb powder of (2 to 4) to 1, mechanically stirring and uniformly mixing by a mixer, and then mixing into an electrode block, and adding sponge zirconium, and pressing into a compact electrode block by an oil press; assembling and welding the compact electrode block into an electrode by a plasma welding unit, and smelting the electrode into the titanium alloy Ti-13Nb-13Zr ingot by a vacuum consumable electro-arc furnace. The preparation method disclosed by the invention has the advantages that the production cost of the titanium alloy Ti-13Nb-13Zr ingot is greatly reduced, the chemical components of the produced titanium alloy Ti-13Nb-13Zr ingot meet the requirements of GB / T3620.1-2016 standard, no refractory metal Nb element is segregated and entrained, and the metallurgical quality is good.

Owner:西安圣泰金属材料有限公司

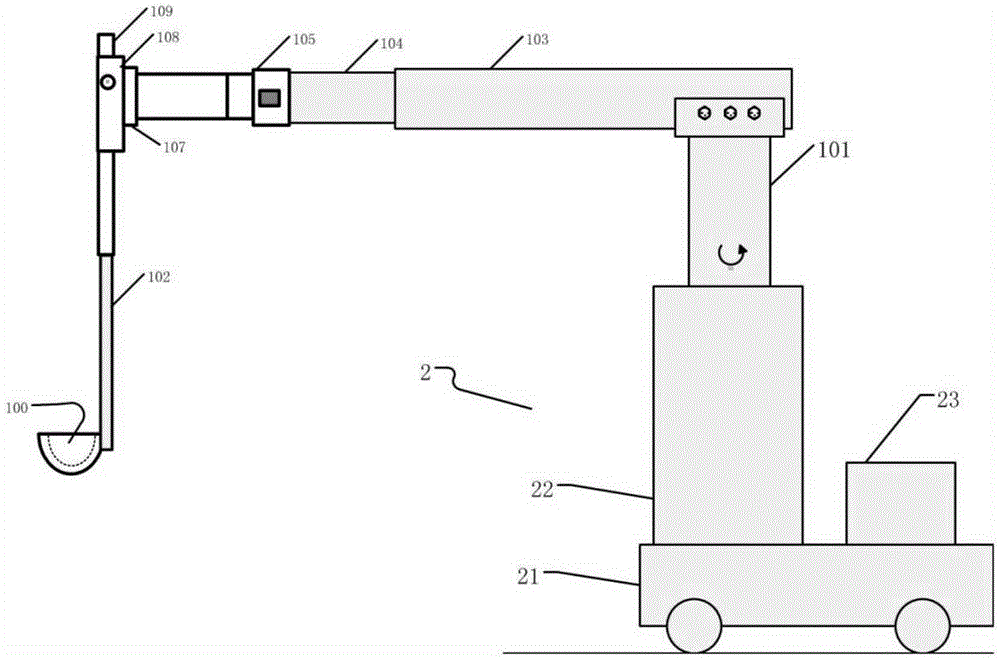

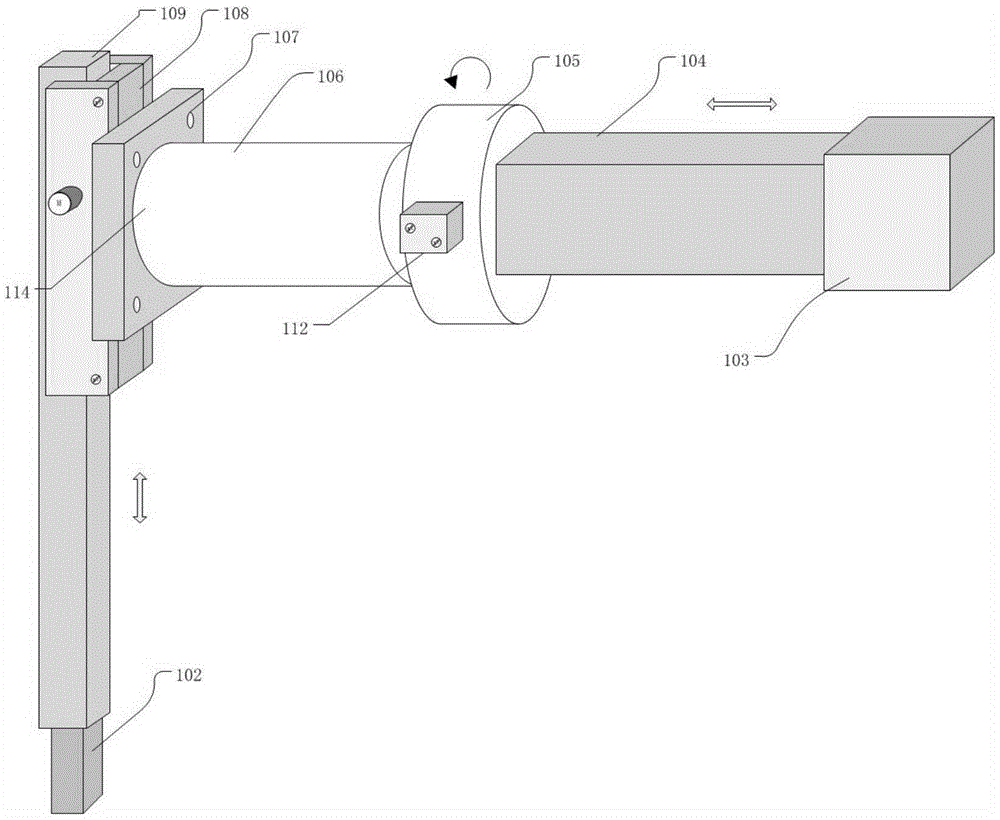

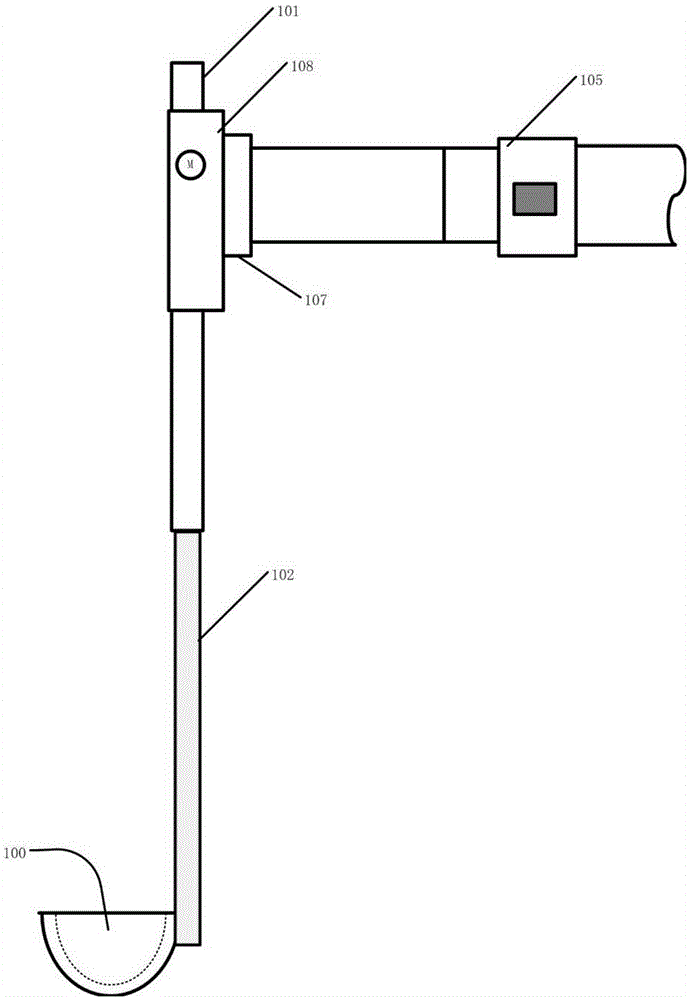

Rare earth electrolysis cell tapping device and method

The invention relates to a rare earth electrolysis cell tapping device and method. The rare earth electrolysis cell tapping device comprises a metal scoop, a scoop handle, a multi-freedom-degree mechanical arm and a control system. The multi-freedom-degree mechanical arm comprises a longitudinal movement mechanism, a turning-over mechanism, a transverse moving mechanism and a rotating mechanism. The control system is electrically connected with the multi-freedom-degree mechanical arm and used for controlling the multi-freedom-degree mechanical arm to move so as to enable the metal scoop to complete the scooping-out motion. The method for achieving tapping through the device comprises the steps that the multi-freedom-degree mechanical arm moves to the position over an electrolysis cell, descends to a molten salt electrolyte layer to be preheated, descends to a rare earth metal layer, and ascends to scoop out metal and cast ingots. The device and method have the advantages of being free of electrolyzing temperature influence, small in weight and high in efficiency. Through a second longitudinal moving mechanism fixed to a first lifting rod and a size block inserted into the metal scoop, oxidation of the surface of rare earth metal can be effectively prevented, and the surface quality of the rare earth metal is endured.

Owner:BAOTOU XIJUN RARE EARTH

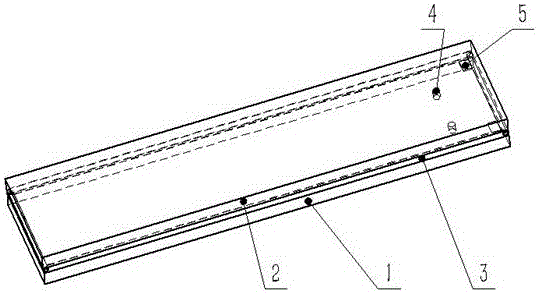

Preparation method of rolled laminar metal composite board blank

The invention provides a preparation method of a rolled laminar metal composite board blank and belongs to the technical field of a preparation method of a metal composite board blank. The preparation method is used for preparing the rolled laminar metal composite board blank in a low-cost and high-efficiency manner. According to the technical scheme, the preparation method comprises: punching a non-through round hole in a base material plate blank, and storing a reducing vacuum treatment agent in the hole; after aligning a surface to be compounded of a base material (1) with a surface to be compounded of a coating material (2), welding along a peripheral groove; after conveying the blank into a heating furnace, enabling the reducing vacuum treatment agent and a main component of air in a compounding cavity to react at high temperature, wherein a reaction product is solid particles, the compounding cavity reaches a near-vacuum state, a surface to be compounded of a steel plate is not oxidized, oxidization-free metallurgical bonding of the surface to be compounded in a post-period rolling process is guaranteed and a metal composite board with good performance is obtained. The invention provides innovation of the preparation method of the rolled laminar metal composite board blank, and the preparation method is greatly better than an existing explosion method and a vacuum welding method; the preparation method is simple in process, low in cost and high in production efficiency, and has remarkable economic benefits.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com