Atomizing pulverization system combined with induction heating and radio frequency plasma

A radio frequency plasma and atomization powder making technology, applied in the field of powder metallurgy, can solve the problems of difficult to obtain high-quality spherical powder, achieve the effect of small particle size, increase heat absorption rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

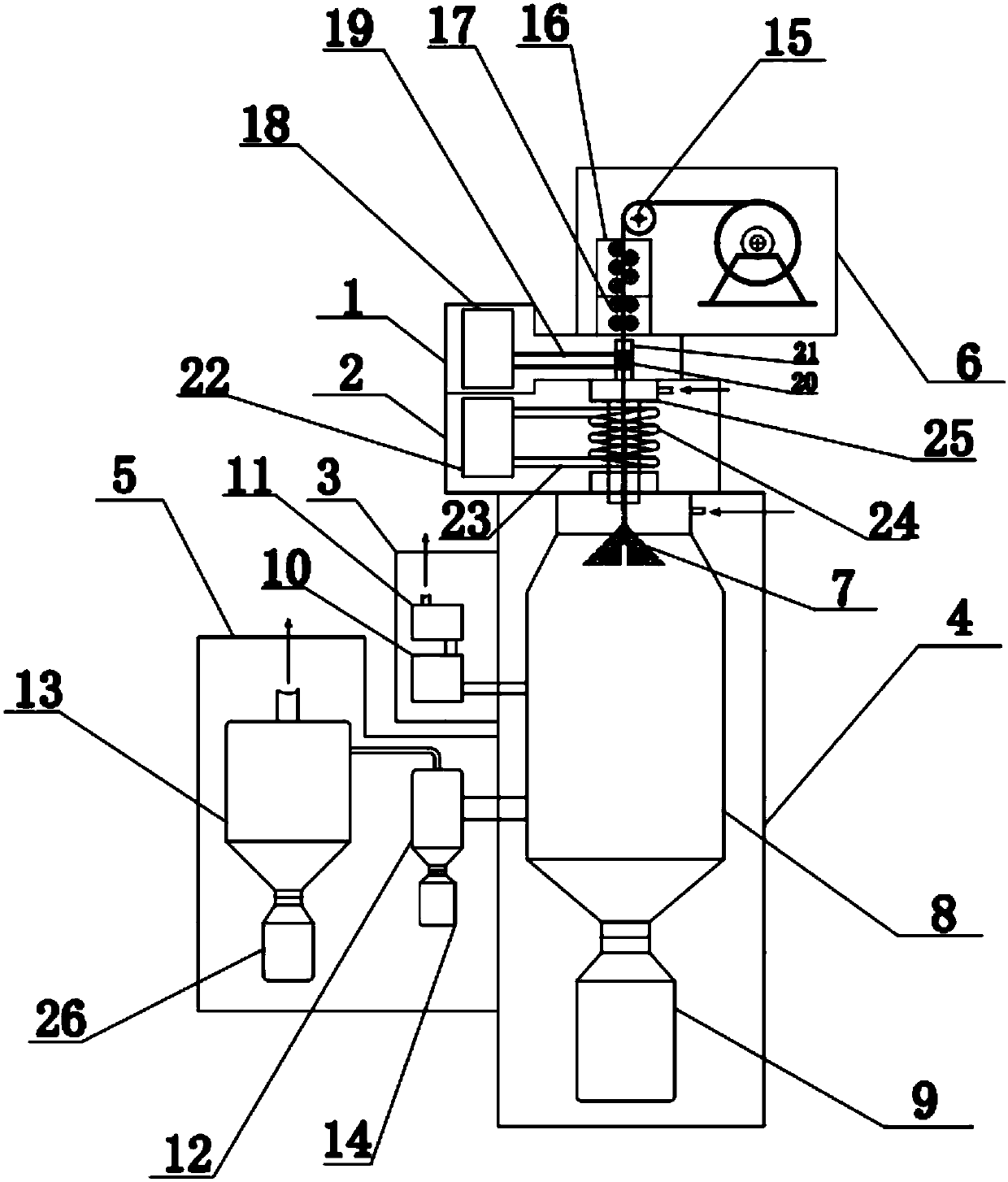

[0027] Such as figure 1 As shown, an induction heating and radio frequency plasma combined atomization pulverization system includes a high frequency induction heating device 1, a radio frequency induction plasma device 2, a vacuum device 3, an atomization collection device 4, a separation and dust removal device 5 and a wire conveying Device 6, the high-frequency induction heating device 1 includes a high-frequency induction heating power supply 18, a high-frequency induction coil 19, an insulating packaging tube 20 and a packaging structure 21, the power of the high-frequency induction heating power supply 18 is 30KW, and the oscillation frequency is 100~300KHz, the high-frequency induction coil 19 has 6 turns and a diameter of 10mm. Made of hollow copper tube, the high-frequency induction coil 19 is inserted into the insulating packaging tube 20, the insulating packaging tube 20 is made of quartz glass material, and the packaging structure 21 combines the high-frequency he...

Embodiment 2

[0030] Such as figure 1 As shown, an induction heating and radio frequency plasma combined atomization pulverization system includes a high frequency induction heating device 1, a radio frequency induction plasma device 2, a vacuum device 3, an atomization collection device 4, a separation and dust removal device 5 and a wire conveying Device 6, the high-frequency induction heating device 1 includes a high-frequency induction heating power supply 18, a high-frequency induction coil 19, an insulating packaging tube 20 and a packaging structure 21, the power of the high-frequency induction heating power supply 18 is 60KW, and the oscillation frequency is 200~400KHz, the high frequency induction coil 19 is 8 turns, the diameter is 12mm, adopts Made of hollow copper tube, the high-frequency induction coil 19 is inserted into the insulating packaging tube 20, the insulating packaging tube 20 is made of quartz glass material, and the packaging structure 21 combines the high-frequen...

Embodiment 3

[0033] Such as figure 1 As shown, an induction heating and radio frequency plasma combined atomization pulverization system includes a high frequency induction heating device 1, a radio frequency induction plasma device 2, a vacuum device 3, an atomization collection device 4, a separation and dust removal device 5 and a wire conveying Device 6, the high-frequency induction heating device 1 includes a high-frequency induction heating power supply 18, a high-frequency induction coil 19, an insulating packaging tube 20 and a packaging structure 21, the power of the high-frequency induction heating power supply 18 is 40Kw, and the oscillation frequency is 100~300KHz, the high-frequency induction coil 19 is 8 turns, the diameter is 10mm, adopts Made of hollow copper tube, the high-frequency induction coil 19 is inserted into the insulating packaging tube 20, the insulating packaging tube 20 is made of quartz glass material, and the packaging structure 21 combines the high-frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com