Patents

Literature

57results about How to "Reasonable system design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

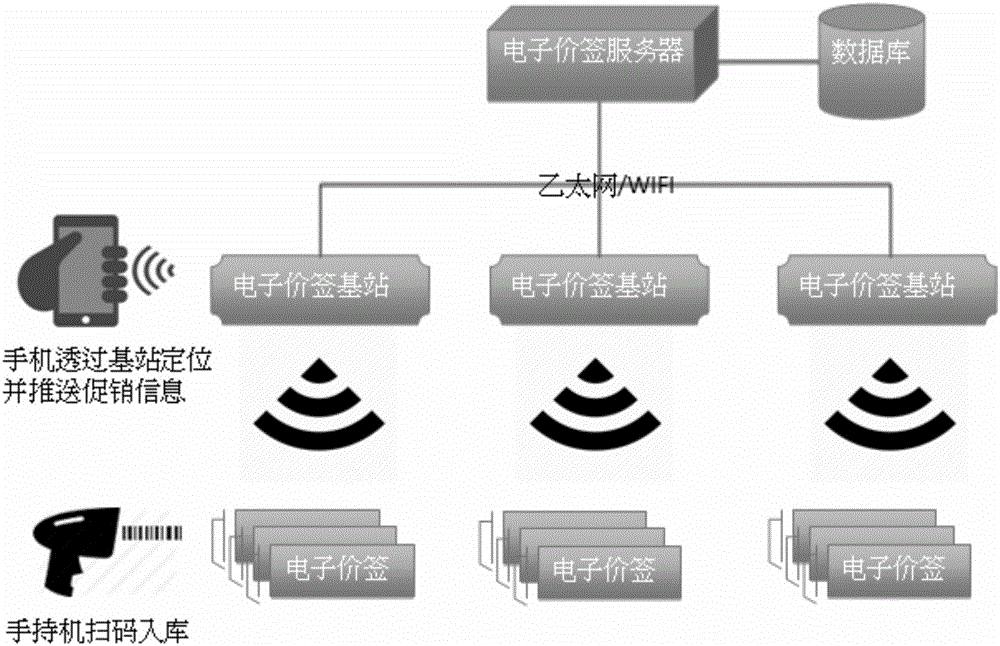

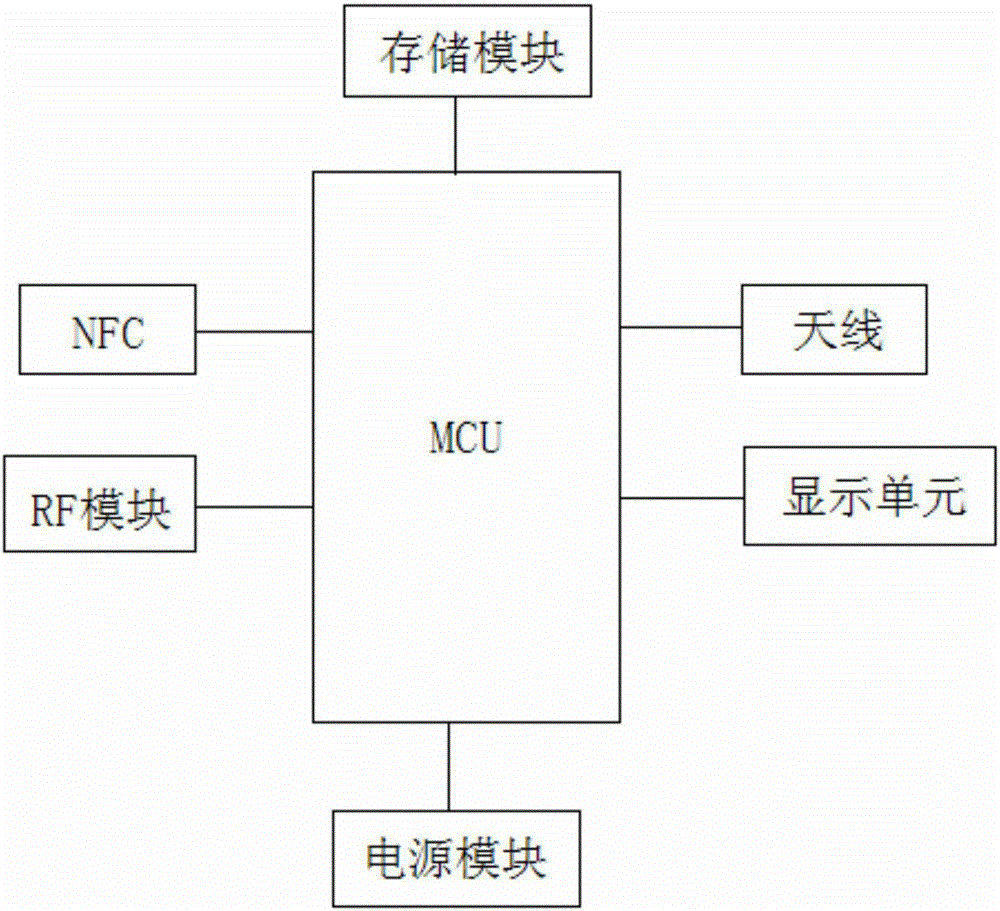

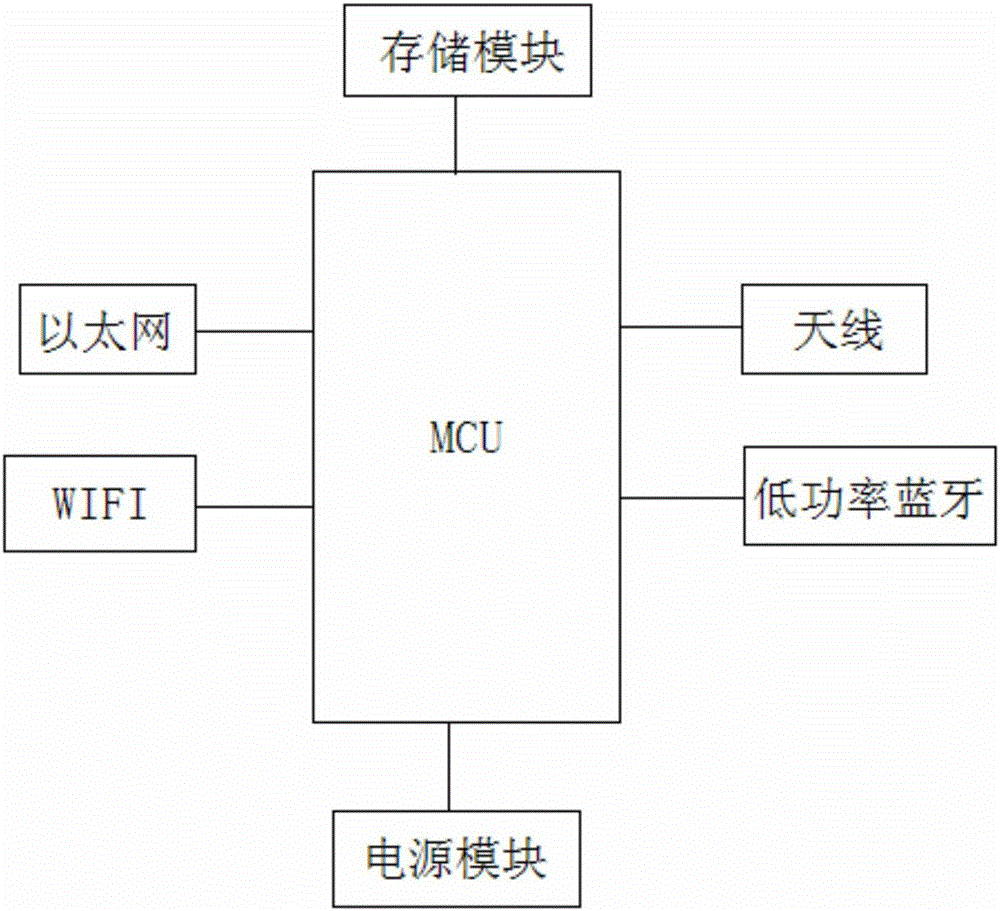

Interactive electronic price tag control system and control method thereof

InactiveCN105809218AReasonable system designLow costCo-operative working arrangementsSystems designFault rate

The invention discloses an interactive electronic price tag control system and a control method thereof. The system comprises an electronic price tag server, an electronic price tag base station, electronic price tags and a hand-held machine. The hand-held machine is used for inputting the electronic price tags and mutually communicating with the base station and the server for the input data. The electronic price tag base station is a base station having an indoor positioning function and is used as a mediator for the electronic price tag server, the electronic price tags and client mobile phones. Each electronic price tag has a group of unique identification codes for identification and has NFC and Bluetooth functions. The system is reasonable in design and is capable of lowering the cost of manual conventional paper tag pasting and reducing the fault rate of price changes; when the system is connected with an ERP system, the goods turnover ratio is improved, and the stock is reduced; and rapid price changing promotions are realized, and the system has the advantages of high working efficiency, compact structure and the like.

Owner:嘉兴瀚腾物联网科技有限公司

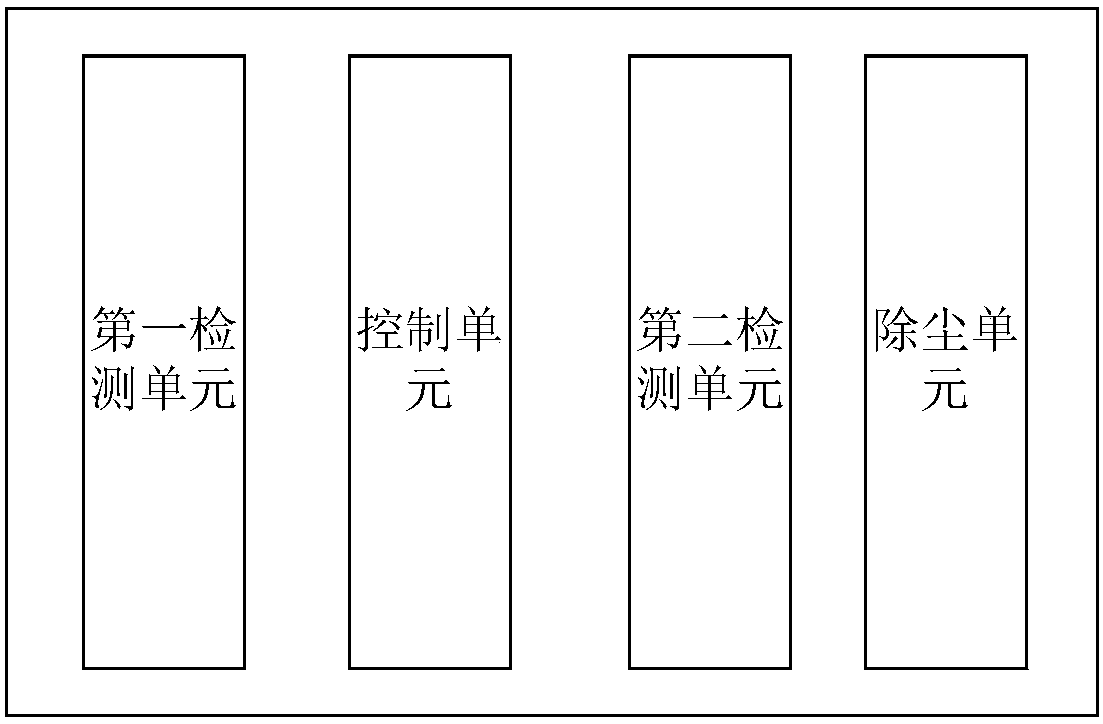

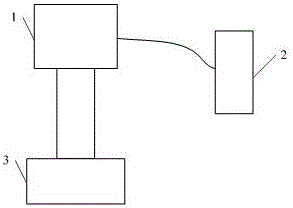

Intelligent detection and automatic dedusting system for computer case

InactiveCN107783884AReasonable system designAuto clearHardware monitoringCleaning using gasesComputer basedComputer case

The invention discloses an intelligent detection and automatic dust removal system for a computer case. The system includes: a first detection unit for detecting the dust content in the computer case; a control unit for turning on the second The detection unit and the dust removal unit; the second detection unit is used to detect the dust distribution in the computer case; the dust removal unit is used to remove the dust in the computer case based on the dust distribution in the computer case; There are technical problems such as low dust removal efficiency, troublesome disassembly, and easy damage to equipment. The technical effect of reasonable system design, automatic dust removal without disassembly is realized.

Owner:王宁

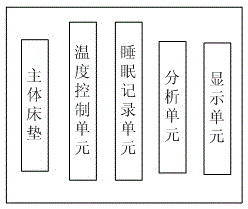

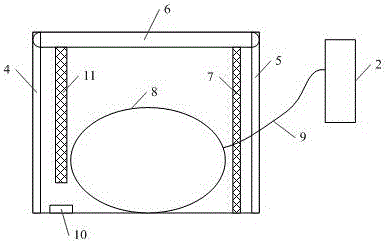

Intelligent mattress system

InactiveCN105146963AReasonable system designGood and efficient monitoringStuffed mattressesSpring mattressesSystems designSleep recording

The invention discloses an intelligent mattress system. The intelligent mattress system comprises a main body mattress laid on a bed of a user, a temperature control unit used for controlling the surface temperature of the main body mattress to be within a preset range, a sleep recording unit used for recording sleep information of the user, an analysis unit used for analyzing the sleep information of the user to obtain a sleep quality report and a display unit used for displaying the sleep quality report. The intelligent mattress system realizes reasonable design, can favorably and efficiently monitor the sleep quality of the user and analyze to generate the report to be checked by the user, and therefore, has the technical effect of guaranteeing the sleep quality of the user.

Owner:成都玩者天下网络技术有限公司

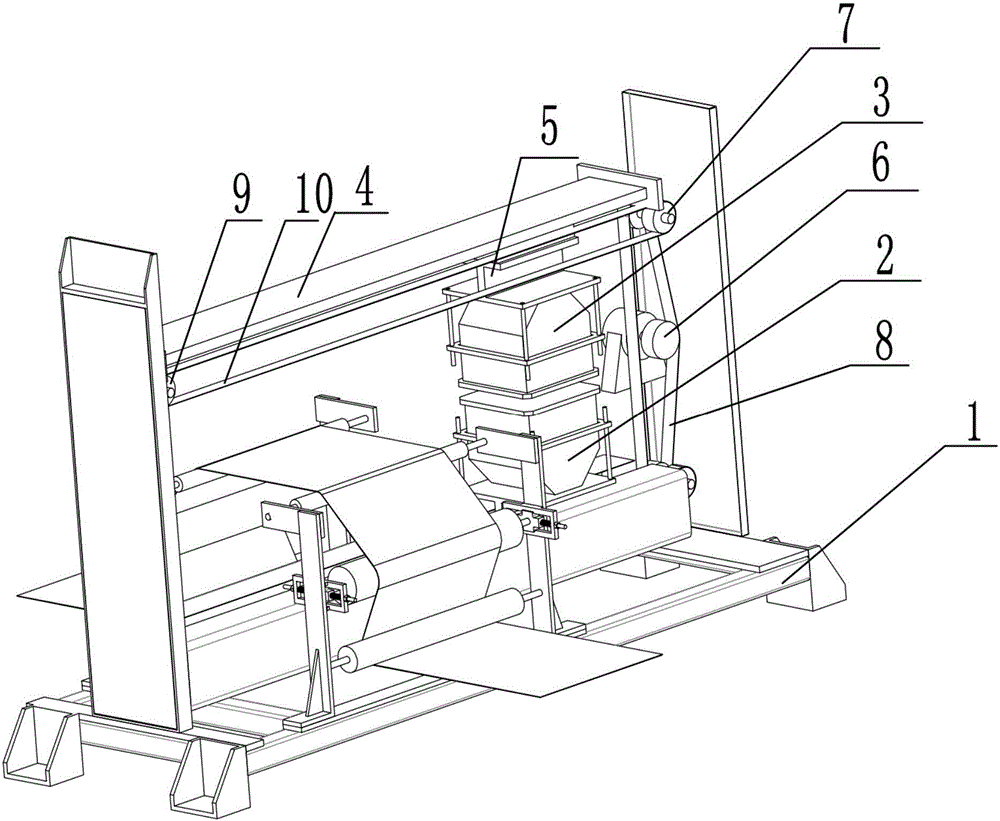

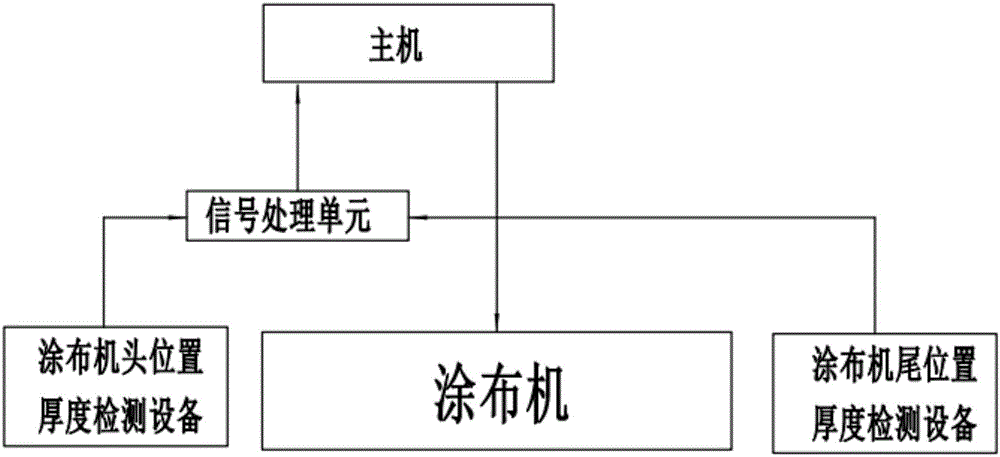

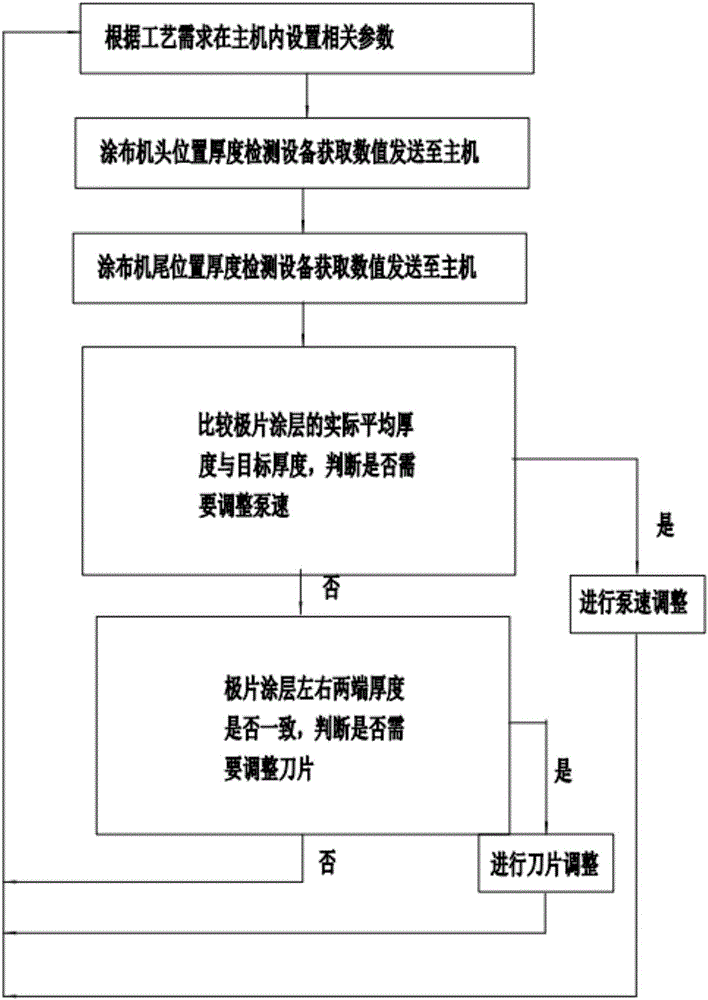

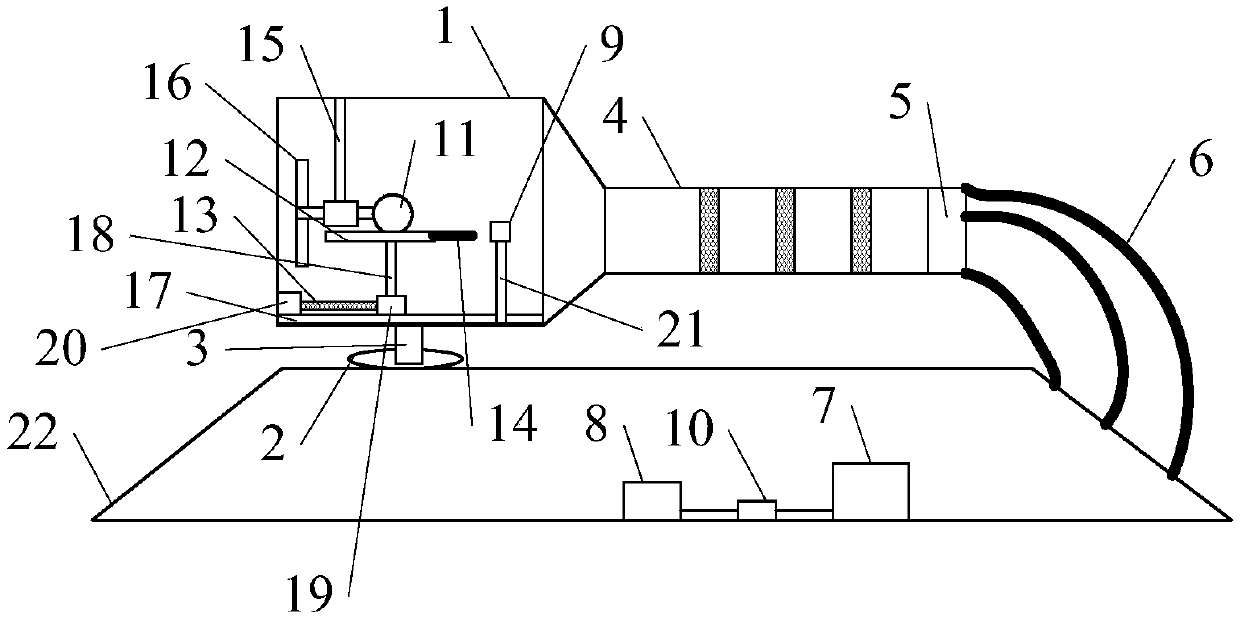

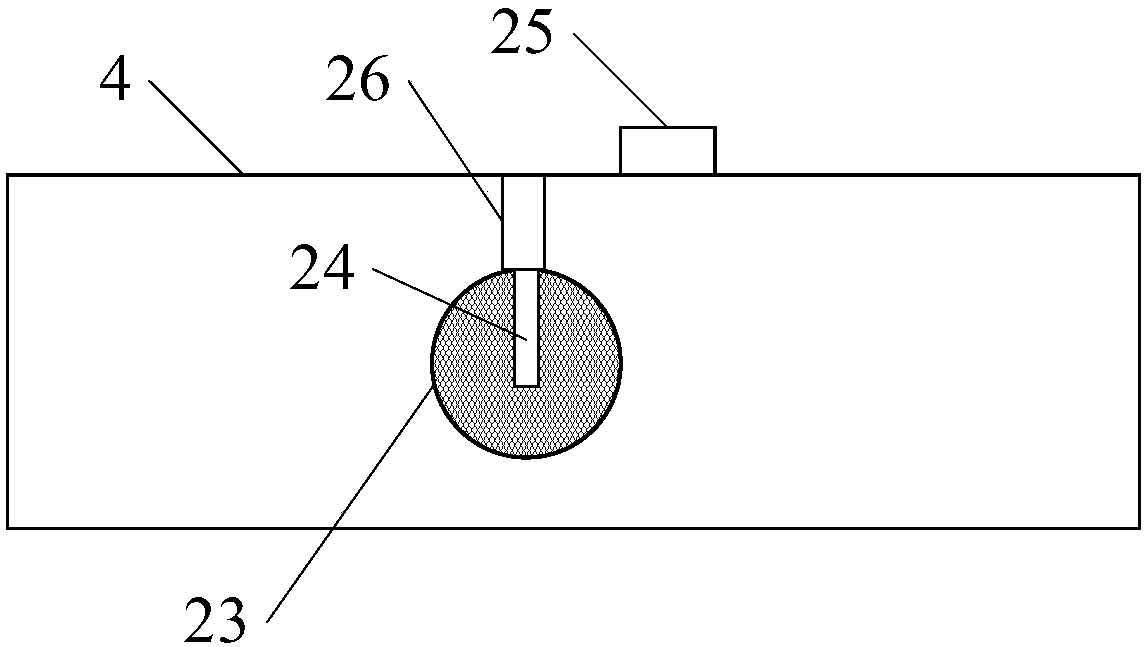

Pole piece coating thickness online detecting system and detecting method

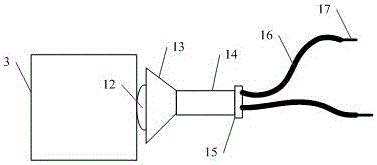

InactiveCN106840052AReasonable system designHigh degree of automationUsing wave/particle radiation meansMaterial dimension controlTesting equipmentEngineering

The invention discloses a pole piece coating thickness online detecting system, which is applied to a coating machine. The pole piece coating thickness online detecting system comprises thickness detecting equipment and a control system; the control system comprises a host computer, a signal processing unit, an operating interface and a control box; two sets of the thickness detecting equipment are respectively arranged in front of and behind the coating machine; the thickness detecting equipment comprises a beta-ray emitting device, a beta-ray receiving device and driving devices; the driving devices are in vertical symmetrical arrangement and respectively drive the beta-ray emitting device and the beta-ray receiving device; the signal processing unit acquires data of the thickness detecting equipment and transmits the data to the host computer for performing analysis processing, judging whether to regulate a pump speed and a blade, and performing pole piece coating thickness cycle control. According to the pole piece coating thickness online detecting system, online measurement of pole piece coating thickness is realized; process parameters can be regulated in time; the stability and the consistency of the coating thickness during a coating process are effectively ensured; the production efficiency and the continuity of a production line are improved.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

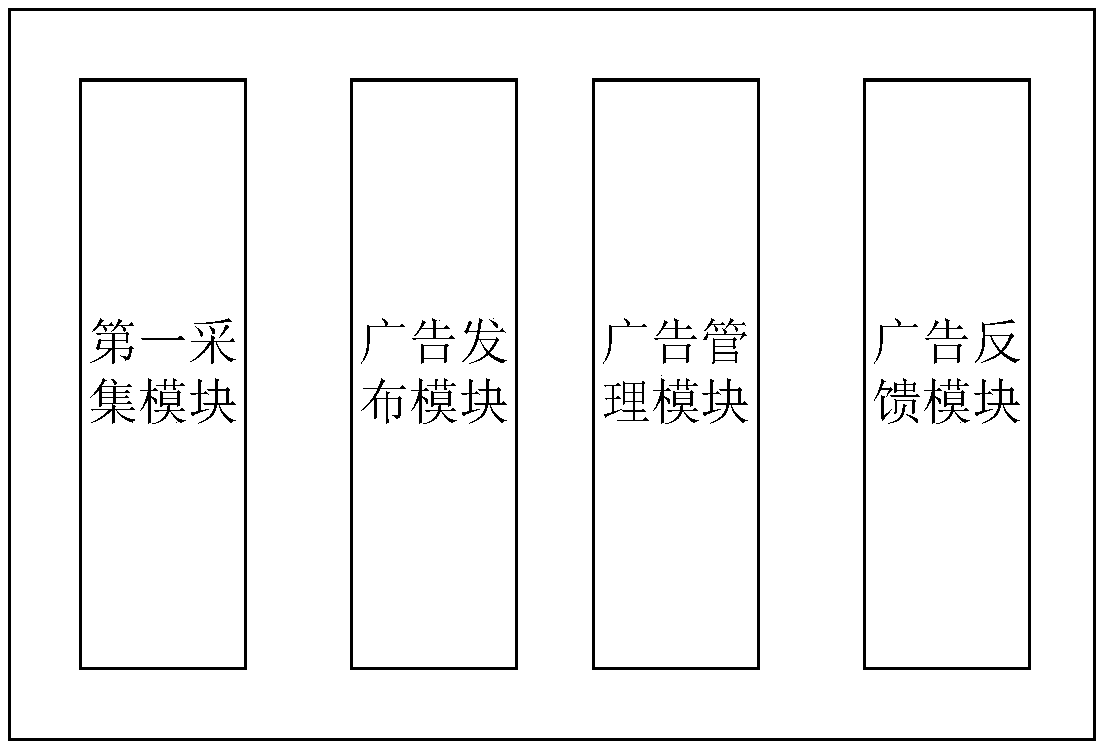

Advertisement operation system based on blockchain

The invention discloses an advertisement operation system based on blockchain. The advertisement operation system comprises a first collecting module used for collecting public data stored by all users in the blockchain, analyzing the collected data, and obtaining advertisement-related data, an advertisement releasing module used for analyzing advertisement content, extracting advertisement keyword data, and sending the advertisements to the users in the blockchain, an advertisement managing module used for managing the advertisements received by the users in the blockchain based on an advertisement intelligence contract in the blockchain, an advertisement feedback module used for users in the blockchain to evaluate and rate relevant advertisements based on actual products. The technical problems of inaccurate advertising operation and delivery, advertising revenue or advertising contracts needing to be discussed offline, and low efficiency in an existing blockchain are solved. The technical effects of reasonable system design, accurate advertisement delivery in the blockchain, intelligent contract generation, and high efficiency of advertising management are achieved.

Owner:GUANGZHOU TIANGAO SOFTWARE TECH CO LTD

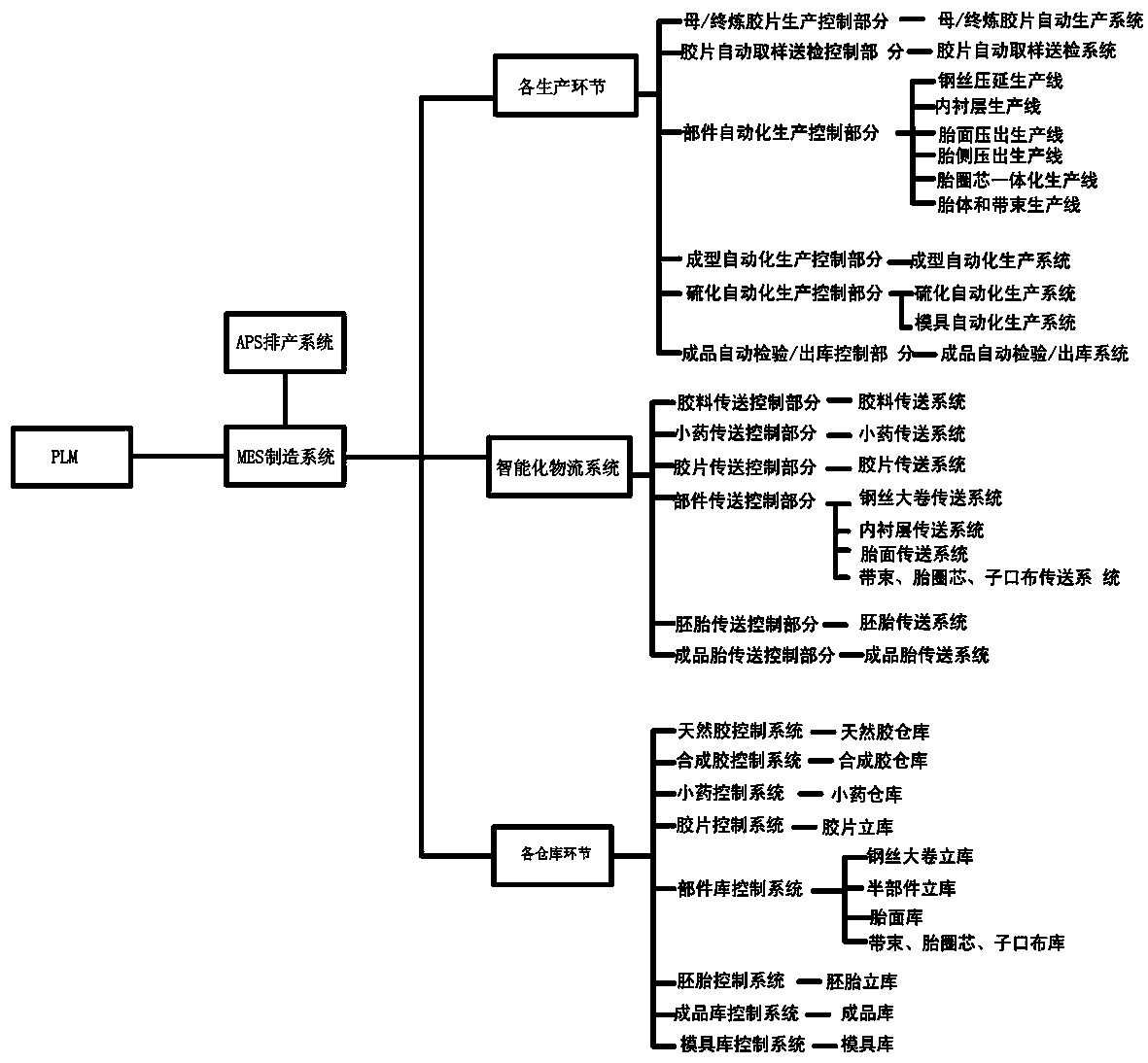

Intelligent full-process manufacture brand-new mode for tyre

PendingCN108501419AImprove labor productivityIncrease productivityTyresManufacturing cost reductionLogistics management

The invention discloses an intelligent full-process manufacture brand-new mode for a tyre, and relates to a tyre production and manufacture mode, in particular to an intelligent full-process manufacture brand-new mode for the tyre. The intelligent full-process manufacture brand-new mode for the tyre comprises a tyre full process intelligent manufacture method which is jointly finished by an APS (Automatic Purchase System) production scheduling system, an MES (Manufacturing Execution System), each production link, each warehouse link and an intelligent logistics system. According to the intelligent manufacture brand-new mode for the tyre full process, through the MES, each production system is controlled to finish a production task, the automation and the intelligence of a full process of raw material convey to finished product delivery can be realized, and the intelligent manufacture brand-new mode has an outstanding meaning on the aspects of labor productivity improvement, product quality stability guaranteeing, manufacture cost reduction and the like.

Owner:HEFEI WANLI TIRE CO LTD

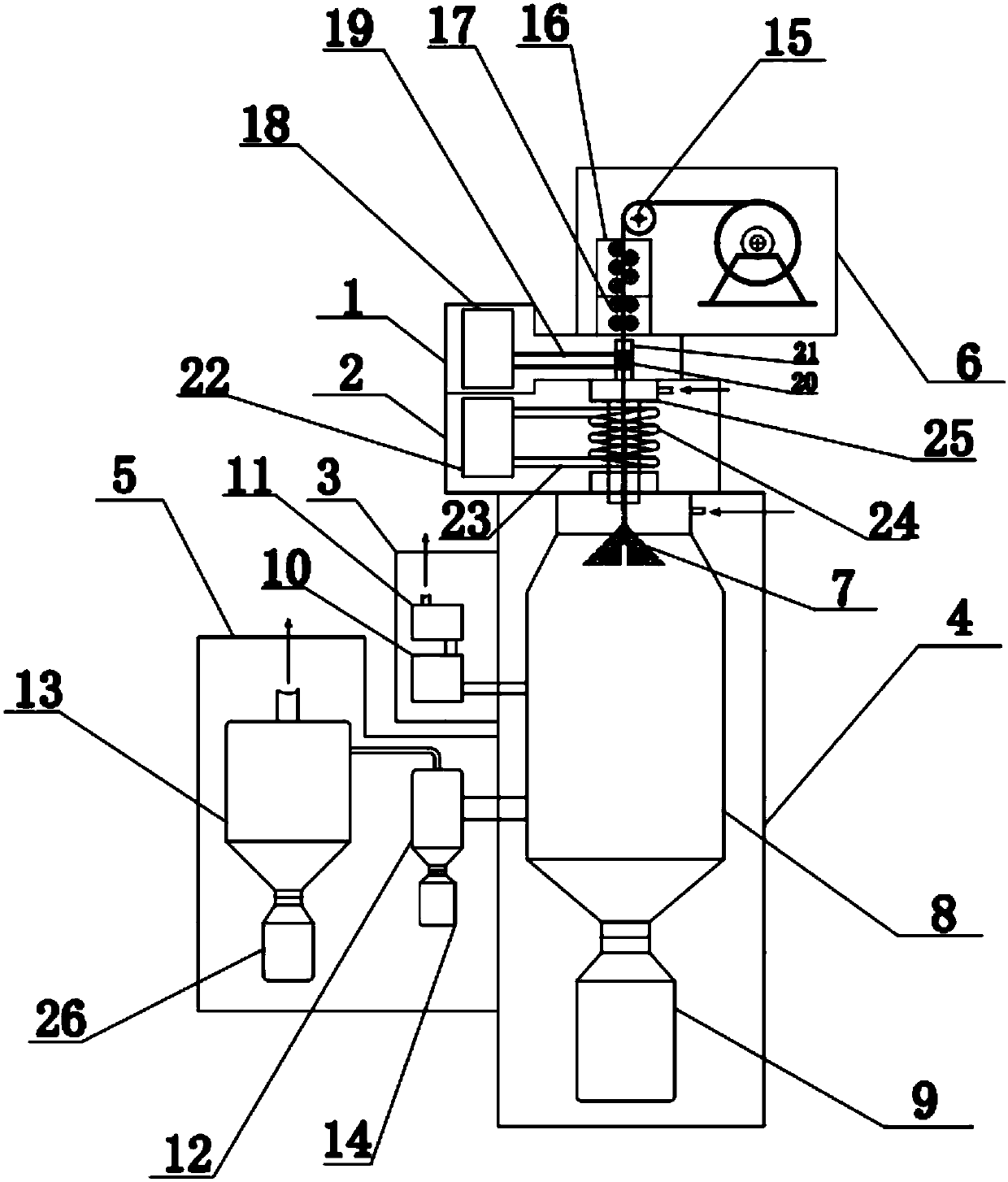

Atomizing pulverization system combined with induction heating and radio frequency plasma

PendingCN108031855AReasonable system designEasy to operateAdditive manufacturing apparatusRadio frequency plasmaHigh frequency

The invention relates to an atomizing pulverization system combined with induction heating and radio frequency plasma. The atomizing pulverization system comprises a high frequency induction heating device, a radio frequency induction plasma device, a vacuum device, an atomizing collection device, a separation and dust removal device and a wire conveyor device. The atomizing pulverization system is rational in design and easy in operation; by adopting the technology that high the frequency induction heating is combined with the radio frequency plasma melting and gas atomization, the whole heating, melting and gas atomization process is subjected to vacuum pumping by the system, and then inert gas is filled for protection; no pollution or inclusions are generated; by combining the high frequency induction heating device used for preheating wires with the radio frequency induction plasma device used for melting the wires, the heat absorption rate in the preheating and melting process isimproved, and the superheat degree of liquid flow or drop is improved, so that high-quality spherical powder, with high sphericity degree and spheroidization rate and small particle size and without hollow spheres, can be obtained after gas atomization; and a high-pressure atomizing nozzle is adopted in the atomization process, and the output rate of metal powder within unit time is improved.

Owner:北京金物科技发展有限公司

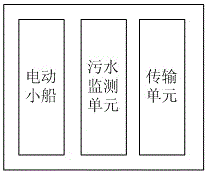

Sewage monitoring system

InactiveCN105842413AReasonable system designHigh efficiency of sewage monitoringNavigational calculation instrumentsTesting waterMonitoring dataSystems design

The invention discloses a sewage monitoring system which includes an electric boat moving in a monitored river according to preset track; a sewage monitoring unit being installed on the bottom of the electric boat and used for collecting and monitoring sewage; and a transmission unit sending monitoring data collected from the sewage monitoring unit to a monitoring server through a wireless network. The sewage monitoring system has reasonable design, has high monitoring efficiency, is low in monitoring cost and has high monitoring accuracy.

Owner:CHENGDU ZHENZHONG ELECTRIC

Photovoltaic power station dust blocking loss analysis method

ActiveCN107229817AReasonable system designAccurate calculationPhotovoltaic monitoringPhotovoltaic energy generationPhotovoltaic power stationEngineering

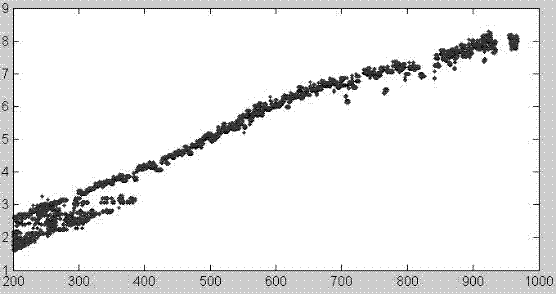

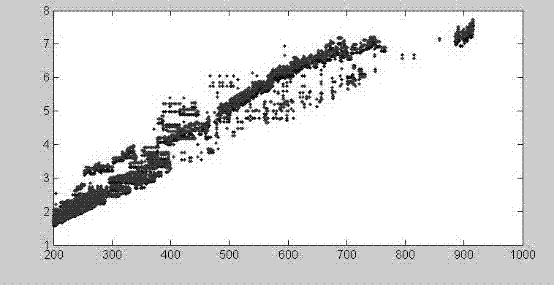

The invention relates to a photovoltaic power station dust blocking loss analysis method. The method sequentially comprises the steps that a plurality of days are selected to serve as dust accumulation days, dust accumulation is performed on a common string and a cleaning string in the dust accumulation days, and current data of the common string and current data of the cleaning string at the same moment in the dust accumulation days are recorded; a plurality of days are selected to serve as cleaning days, dust accumulation continues to be performed on the common string in the cleaning days, a cleaning robot cleans the cleaning string in the cleaning days, and current data of the common string and current data of the cleaning string at the same moment in the cleaning days are recorded; dust accumulation day moment deviations at all moments in the dust accumulation days are calculated; cleaning day moment deviations at all moments in the cleaning days are calculated; a dust accumulation day mean variation and a cleaning day mean variation are calculated respectively; and the cleaning day mean variation and the dust accumulation day mean variation are subtracted to obtain a dust blocking loss rate.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Wire harness process aided design system

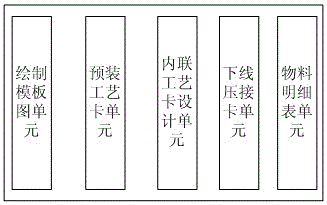

InactiveCN105808841AReasonable system designImprove efficiencyGeometric CADSpecial data processing applicationsDesign systemsEngineering

The invention discloses a wire harness process aided design system. The system comprises a template graph drawing unit, a pre-assembly process card unit, an inline process card design unit, a wire disassembly crimping card unit and a material list unit, wherein the template graph drawing unit provides a template drawing function and is used for a user to finish wire harness flow template drawing work; the pre-assembly process card unit is used for assisting the user in designing a pre-assembly process card and automatically extracting each sub-assembly body capable of performing pre-assembly according to a standard template graph drawn by the user; the inline process card design unit is used for assisting the user in designing an inline process card and can automatically extract each connected conducting loop from the standard template graph drawn by the user according to a given rule and generate an inline design interaction environment; the wire disassembly crimping card unit is used for automatically generating a wire disassembly crimping process card; and the material list unit is used for automatically making statistics on materials required to be used in wire harness production. Therefore, the technical effects of reasonable system design, relatively high automobile wire harness process design efficiency and relatively low cost are achieved.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

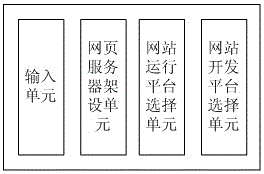

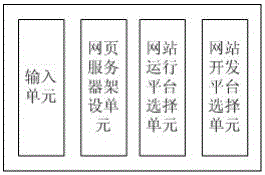

Website construction assistance design system

InactiveCN105739997ALow efficiencyReasonable system designProgramming languages/paradigmsSpecific program execution arrangementsWeb serverDesign systems

The invention discloses a website construction assistance design system which comprises an input unit, a webpage server erecting unit, a website running platform selecting unit and a website developing platform selecting unit.The input unit is used for allowing a user to input website design data; the webpage server erecting unit is used for automatically generating a webpage server erecting scheme on the basis of the website design data input by the user; the website running platform selecting unit is used for automatically selecting a website running platform on the basis of the website design data input by the user; the website developing platform selecting unit is used for automatically selecting a website developing platform on the basis of the website design data input by the user.Accordingly, the technical effects that the system design is reasonable, and developers are assisted in website design, so that the website construction efficiency is high are achieved.

Owner:CHENGDU ETC CERTIFICATION GRP CO LTD

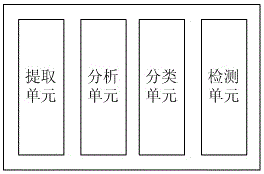

Automatic food additive detecting system

InactiveCN106018712AReasonable system designImprove detection efficiencyTesting foodSystems designFood additive

The invention discloses an automatic detection system for food additives, which includes: an extraction unit, which is used to extract samples from the food to be tested; an analysis unit, which is used to analyze the types of food additives in the samples; a classification unit, the The classification unit is used to divide the sample into a corresponding number of sub-samples based on the number of types of food additives in the sample; the detection unit is used to perform corresponding food additive detection based on the type of food additives in the sub-samples, realizing a reasonable system design, automatic The detection of food additives in food, the technical effect of high detection efficiency.

Owner:CHENGDU ETC CERTIFICATION GRP CO LTD

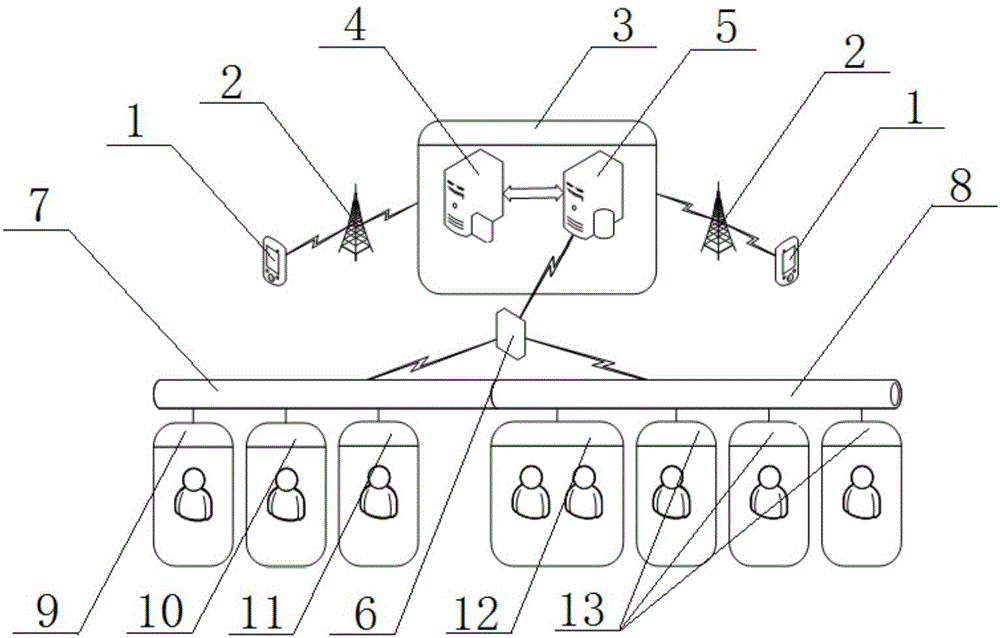

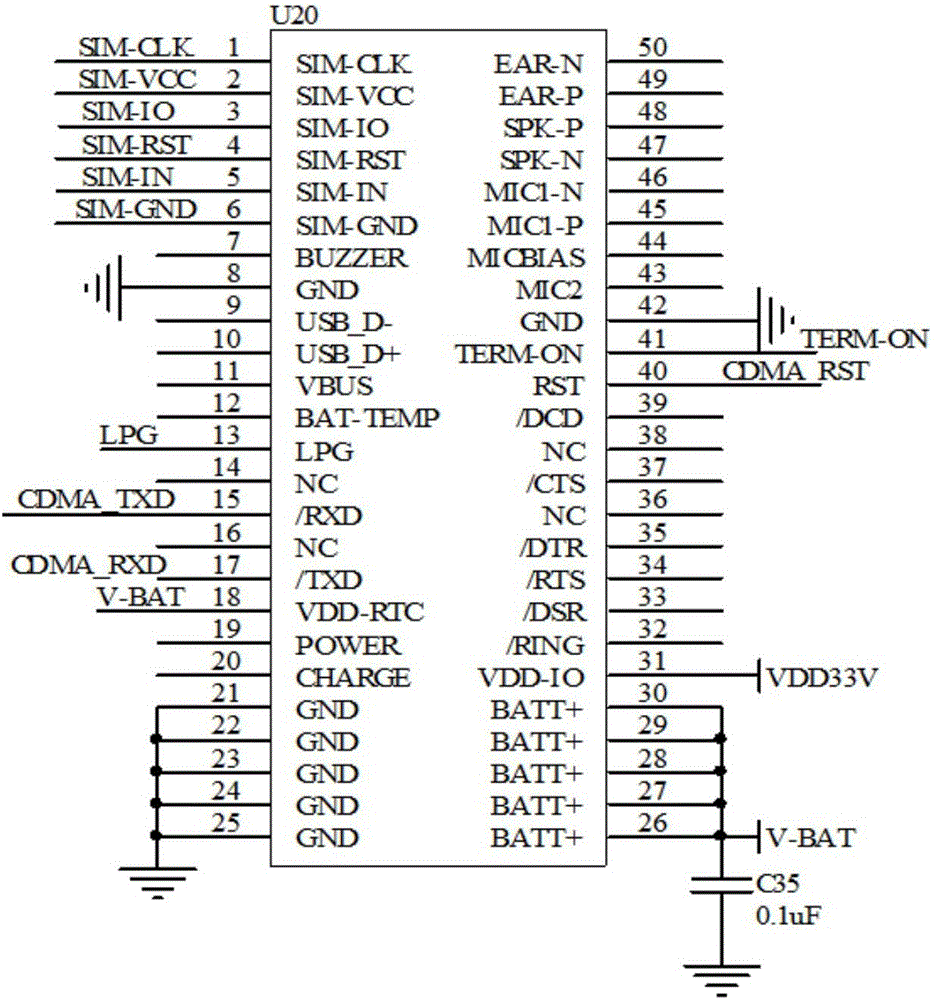

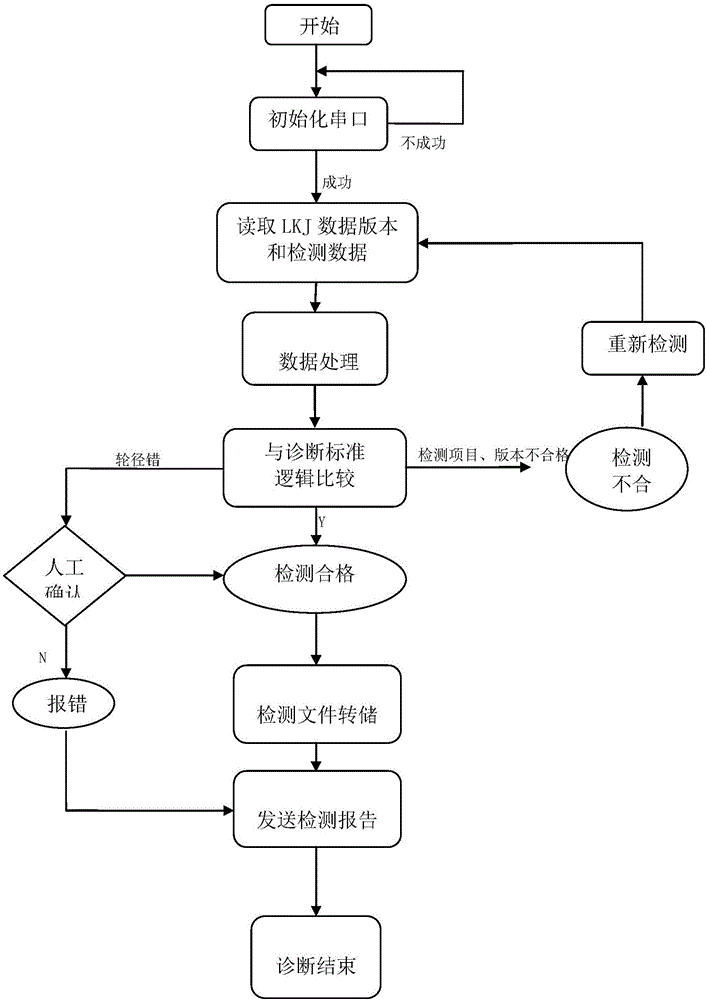

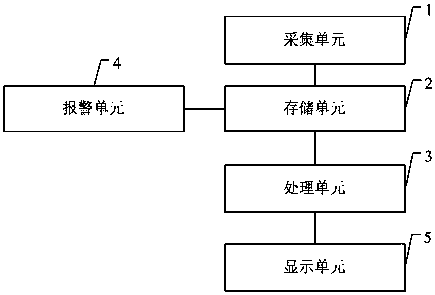

Detection diagnosis system and diagnosis method for railway intranet based on LKJ

InactiveCN106610613AReasonable system designImprove real-time performanceProgramme controlComputer controlCdma networksMachine control

The invention relates to a detection diagnosis system and diagnosis method for a railway intranet based on LKJ, and belongs to the technical field of diagnosis devices and methods. The system comprises a ground operation end and a client. The system can achieve the real-time alarm and display of various types of hidden quality problem information of equipment through the retrieval analysis of an LKJ operation file, and can timely guide a detector to carry out the inspection and processing timely, thereby improving the detection efficiency, and solving an equipment quality problem caused by delayed analysis. A system transmits the edition information to a ground data server through a CDMA network, employs a mode that a diagnostic apparatus is provided with an LKJ data exchange plane in advance, achieves the redundancy diagnosis function of the LKJ data edition of a hand-held diagnostic apparatus and the ground server, and guarantees the accuracy of the LKJ edition. The system achieves the change of detection operation process control from manual control to machine control, and fundamentally guarantees the warehousing quality of equipment.

Owner:中国铁路济南局集团有限公司青岛电务段

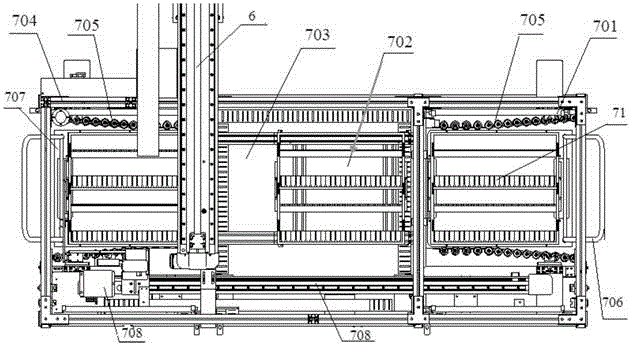

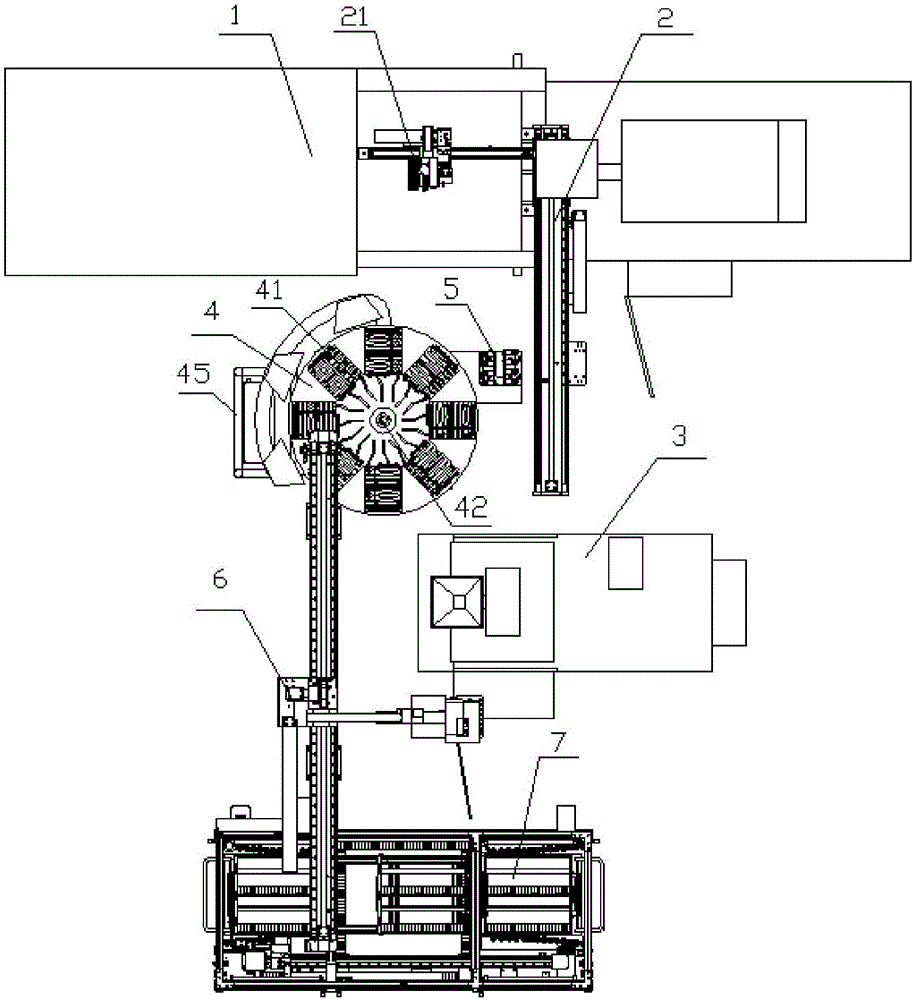

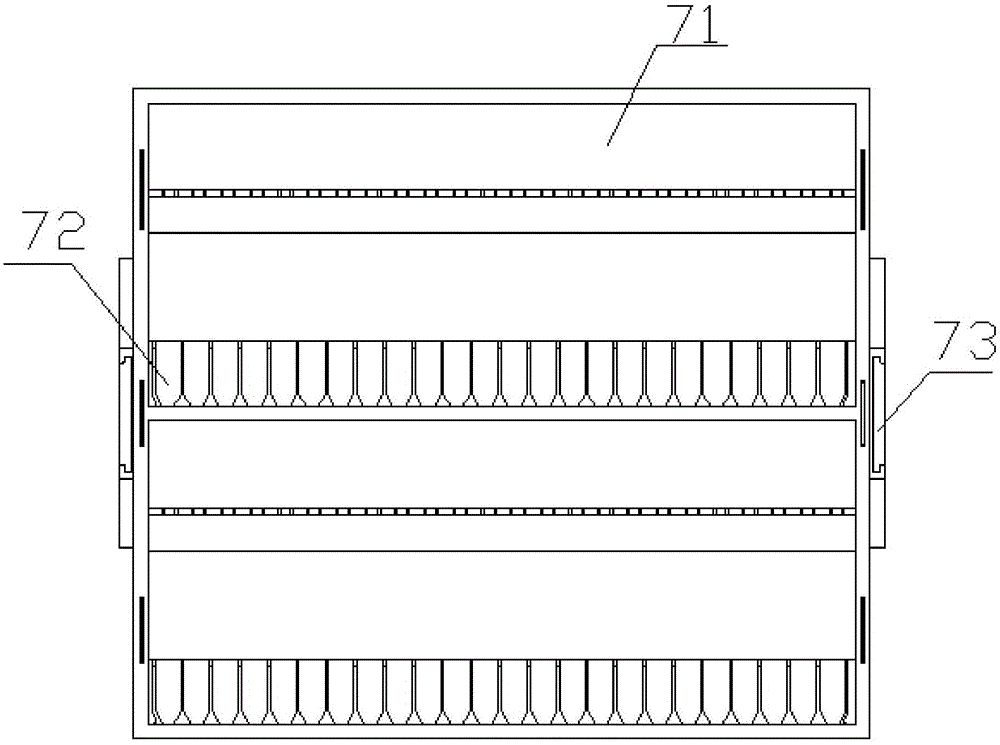

System for taking toothbrush handles from horizontal machine, shearing toothbrush handles, placing toothbrush handles into vertical machine for secondary glue injection, and conducting casing

The invention relates to system for taking toothbrush handles from a horizontal machine, shearing the toothbrush handles, placing the toothbrush handles into a vertical machine for secondary glue injection, and conducting casing. The system comprises a three-axis full-servo mechanical arm, an air shear jig, a rotating conveyer, a vertical injection molding machine, a three-axis full-servo truss robot and an automatic stacker. A plurality of toothbrush handles are grabbed through the three-axis full-servo mechanical arm from the interior of a mold opening die and then moved onto the air shear jig, stub bars of the toothbrush handles are sheared off through an air shear, and then the sheared toothbrush handles are placed on the rotating conveyer, cooled on the rotating conveyer and conveyed to an automatic feeding standby position of the vertical injection molding machine in the rotating process of the rotating conveyer; then, the toothbrush handles are grabbed and sent into a cavity of the vertical injection molding machine through the three-axis full-servo truss robot, and after injection molding is completed, the toothbrush handles are taken out and sent into a tray of the automatic stacker through the three-axis full-servo truss robot; automatic tray exchange is achieved through the automatic stacker, and then automatic casing is achieved. The system is high in automation degree, the usage rate of manpower is reduced, production efficiency is improved, and production cost is reduced relatively.

Owner:SUZHOU IND PARK CHAOQUN AUTOMATION EQUIP

Transaction processing system based on big data

InactiveCN106251184AReasonable system designEasy to handleMarket predictionsPreference dataSystems design

The invention discloses a transaction processing system based on big data. The system comprises an acquisition unit used for acquiring historical transaction data of a user; an analysis unit used for analyzing the historical transaction data of the user; a generation unit used for generating user purchase preference data on the basis of an analysis result of the analysis unit; and a push unit used for, based on the user purchase preference data, pushing service correlation products to the users. The system realizes the technical effects of reasonable design, convenient processing of the transaction data of the users, quite high processing efficiency and accuracy and convenient prediction and analysis of the transactions of the users.

Owner:成都天地网络科技有限公司

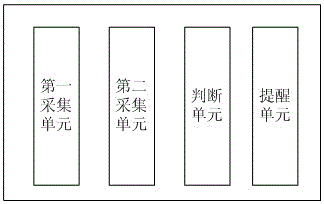

Automatic car violation reminding system

InactiveCN105809966AReasonable system designThe system prompts real-time performanceDetection of traffic movementReal time acquisitionEngineering

The invention discloses an automatic reminder system for vehicle violations. The system includes: a first collection unit used for real-time collection of vehicle driving information; a second collection unit for real-time collection Road violation regulation information; a judging unit, configured to determine whether a vehicle violates regulations based on the driving information and the violation regulation information, and the type and reason of the violation; a reminder unit, configured to judge The judgment result of the unit is displayed on the monitor, and the judgment result is transmitted to the vehicle owner in real time, which realizes a reasonable system design, good real-time reminder of the system, and real-time monitoring of the technical effect of the vehicle.

Owner:CHENGDU LIANZHONGZHI TECH CO LTD

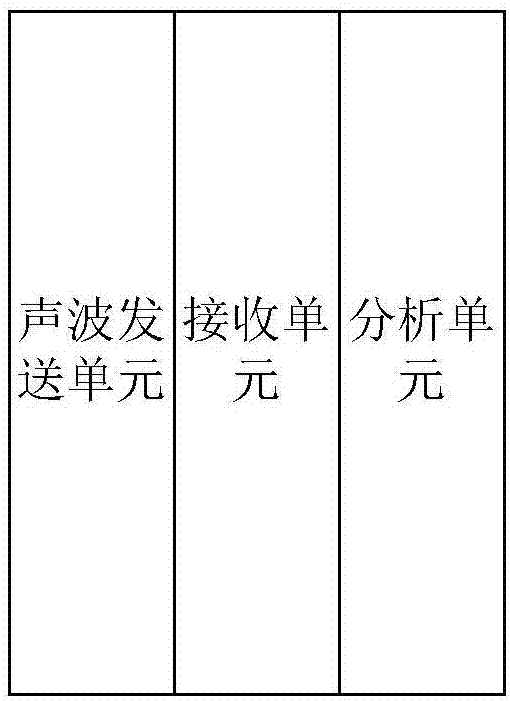

Long-distance pipeline ultrasonic guided wave focusing detection system

InactiveCN107218519AReasonable system designReasonable designPipeline systemsDistance detectionCorrosion

The invention discloses a long-distance pipeline ultrasonic guided wave focusing detection system. The long-distance pipeline ultrasonic guided wave focusing detection system comprises a sound wave sending unit, a receiving unit and an analysis unit, wherein the sound wave sending unit is used for sending a detection sound wave to a to-be-detected pipeline; the receiving unit is used for receiving a sound wave feedback signal of the pipeline; and the analysis unit is used for conducting analysis based on the sound wave feedback signal and obtaining the corrosion detection result of the pipeline. The technical effects that the system design is reasonable, and long-distance detection can be conducted are achieved.

Owner:成都润泰茂成科技有限公司

Touch inquiry system convenient to use

InactiveCN106155208AReasonable system designEasy to dissipate heatCleaning using toolsHousing of computer displaysSystems designTouchscreen

The invention discloses a touch inquiry system convenient to use. The system comprises a touch inquiry machine, a server and a base, wherein the touch inquiry machine is connected with the server; a pedal capable of moving is arranged on the base; a first switch is arranged below the pedal; a heat dissipation structure and a cleaning structure are connected with a power supply by the first switch. The touch inquiry system has the effect of effectively solving the technical problem that the using effects are reduced as existing touch inquiry machines are poorer in heat dissipation and impurities and dirt easily appear on touch screens of the touch inquiry machines and then achieves the technical effects that the system is reasonable in design; the heat of the touch inquiry machines is convenient to dissipate, and the surfaces of the touch screens can be automatically cleaned, thus guaranteeing normal use.

Owner:成都润泰茂成科技有限公司

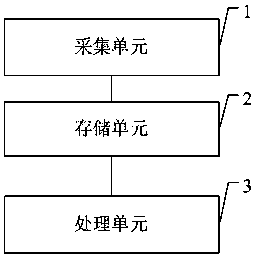

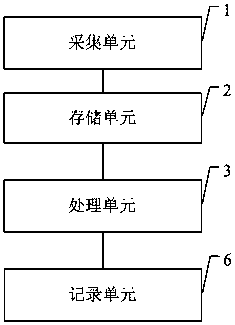

Big data processing system

InactiveCN107562823AReasonable system designImprove processing efficiency and accuracySpecial data processing applicationsData memoryStorage cell

The present invention provides a big data processing system, the system includes: a collection unit, a customer unit and a processing unit, the collection unit is connected to the storage unit, and the processing unit is connected to the storage unit for processing The data to be processed in the storage unit; the collection unit is used to collect business data from the business management system connected to the data processing system, and send the collected data to the storage unit; the storage unit is used for the storage unit for storing the collected business data; the processing unit is used for analyzing and processing the data in the storage unit. The system provided by the invention realizes reasonable system design, can automatically analyze and process business operation data, and has high processing efficiency and accuracy.

Owner:佛山市高研信息技术有限公司

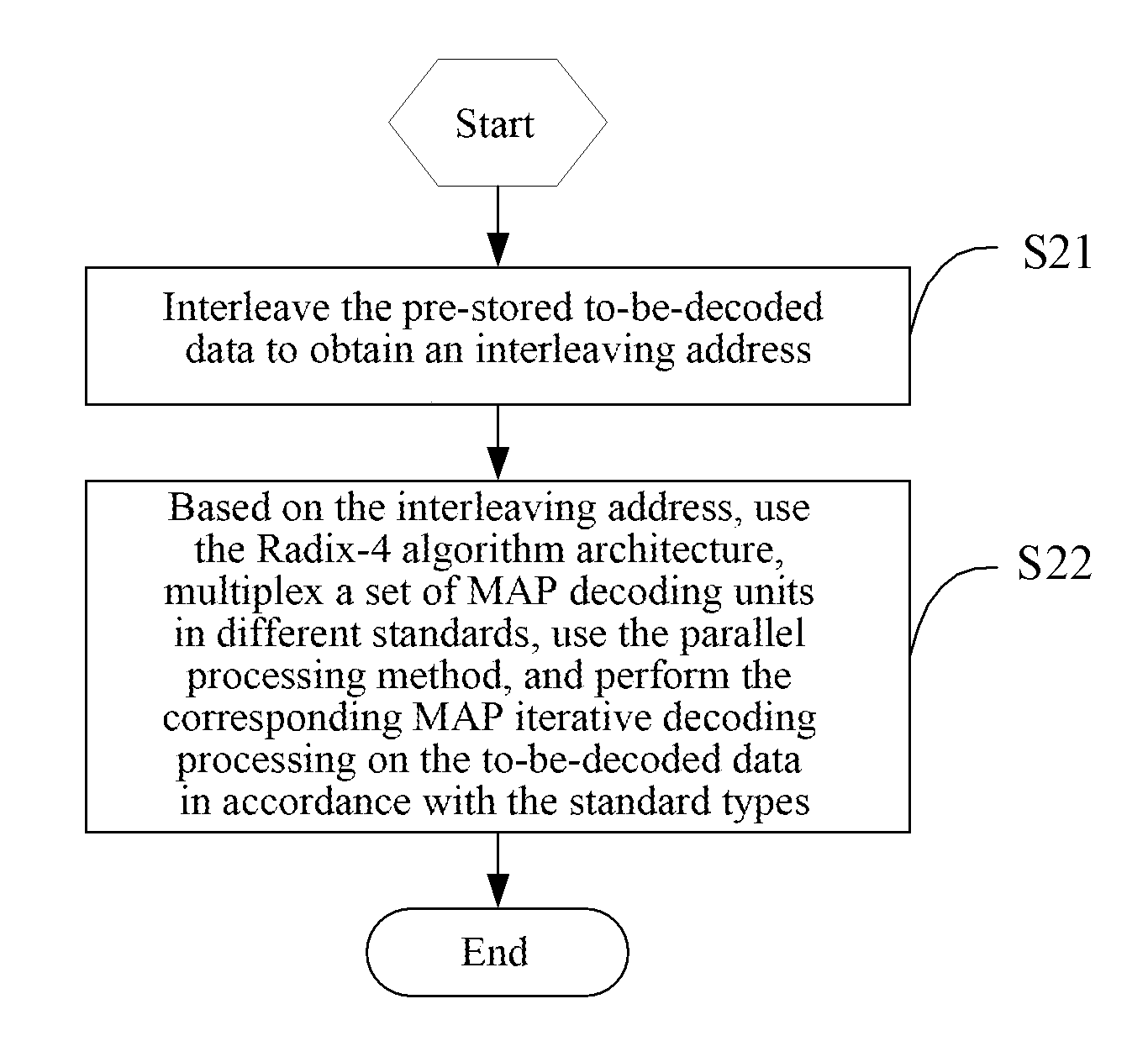

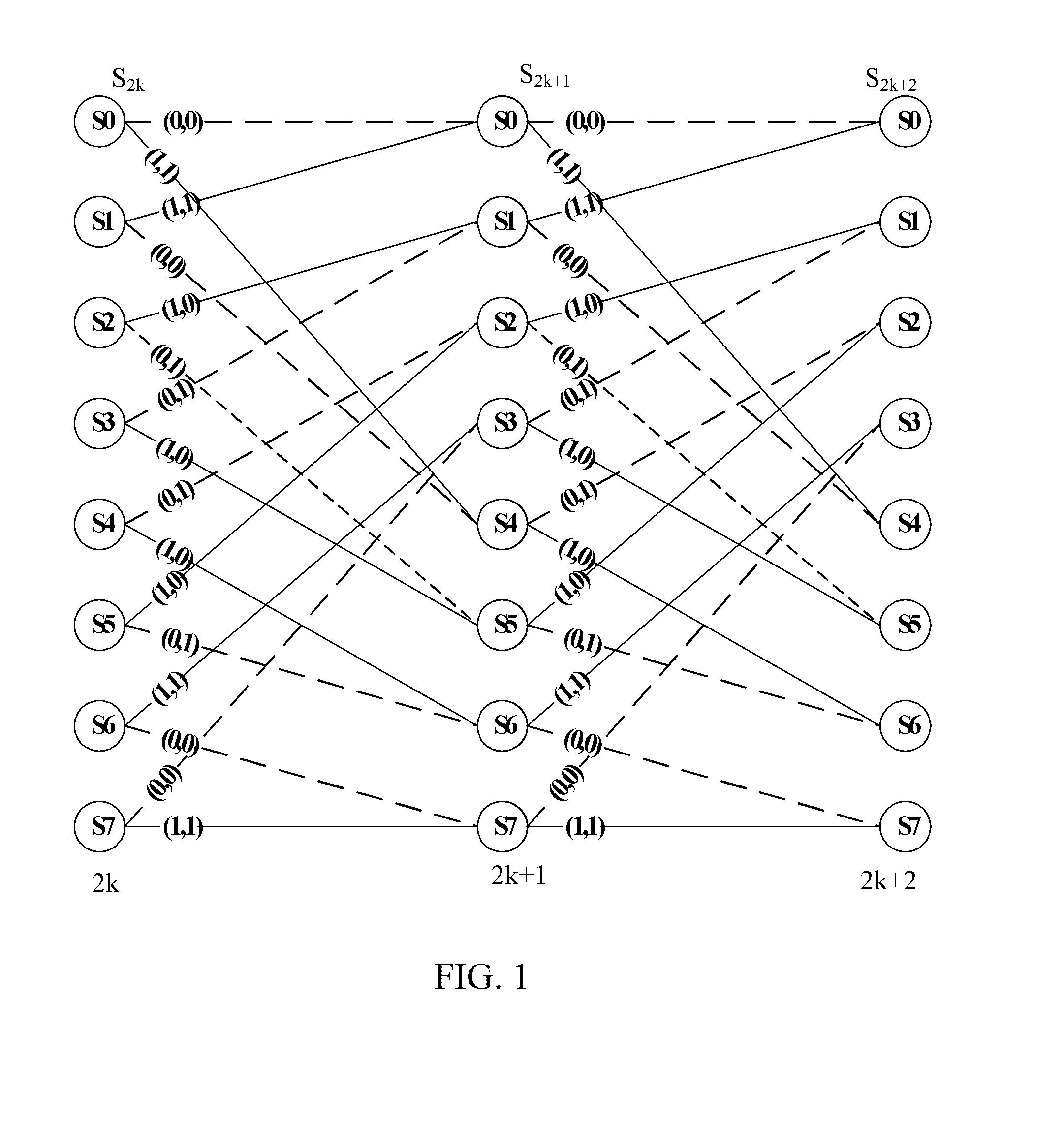

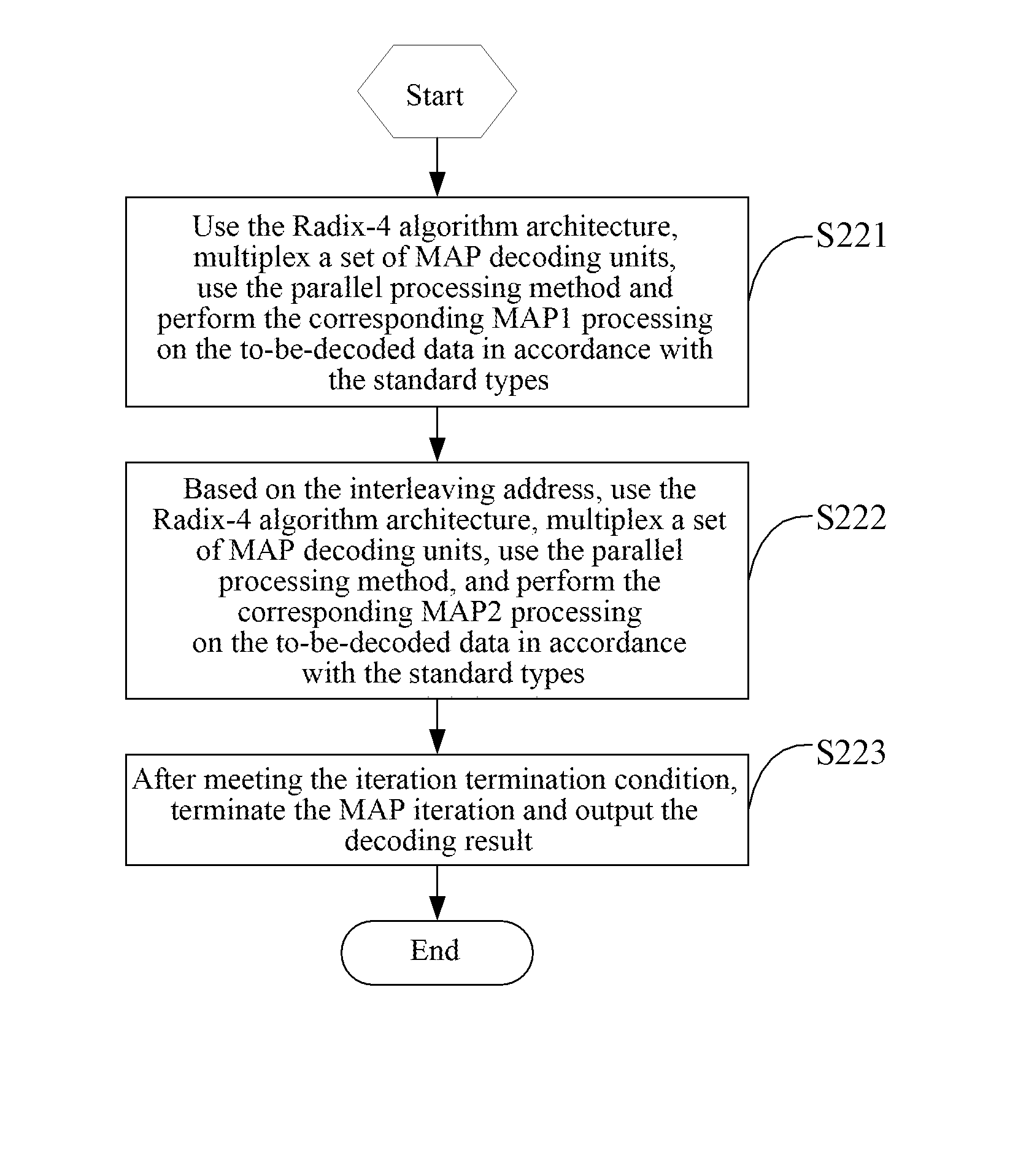

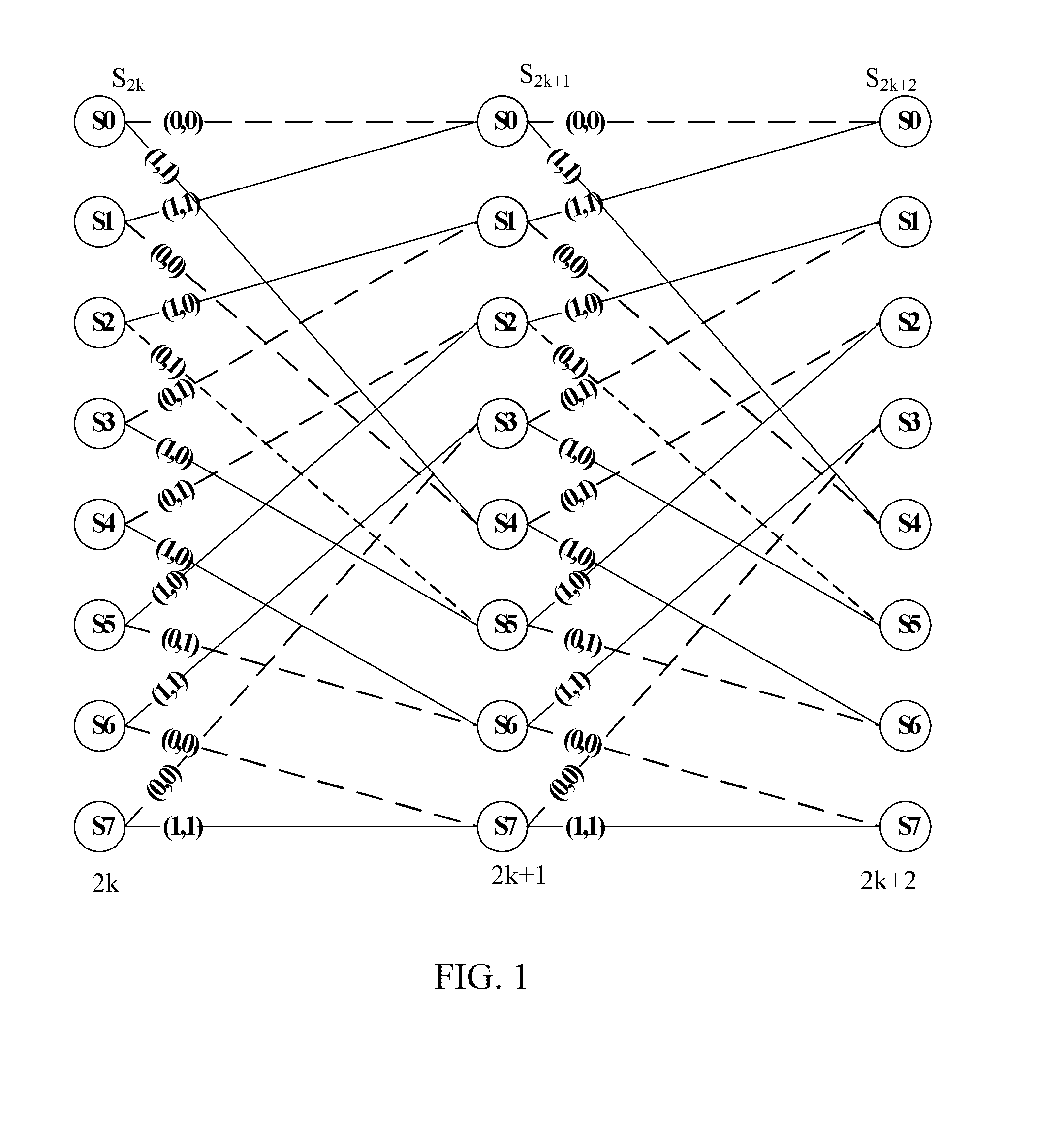

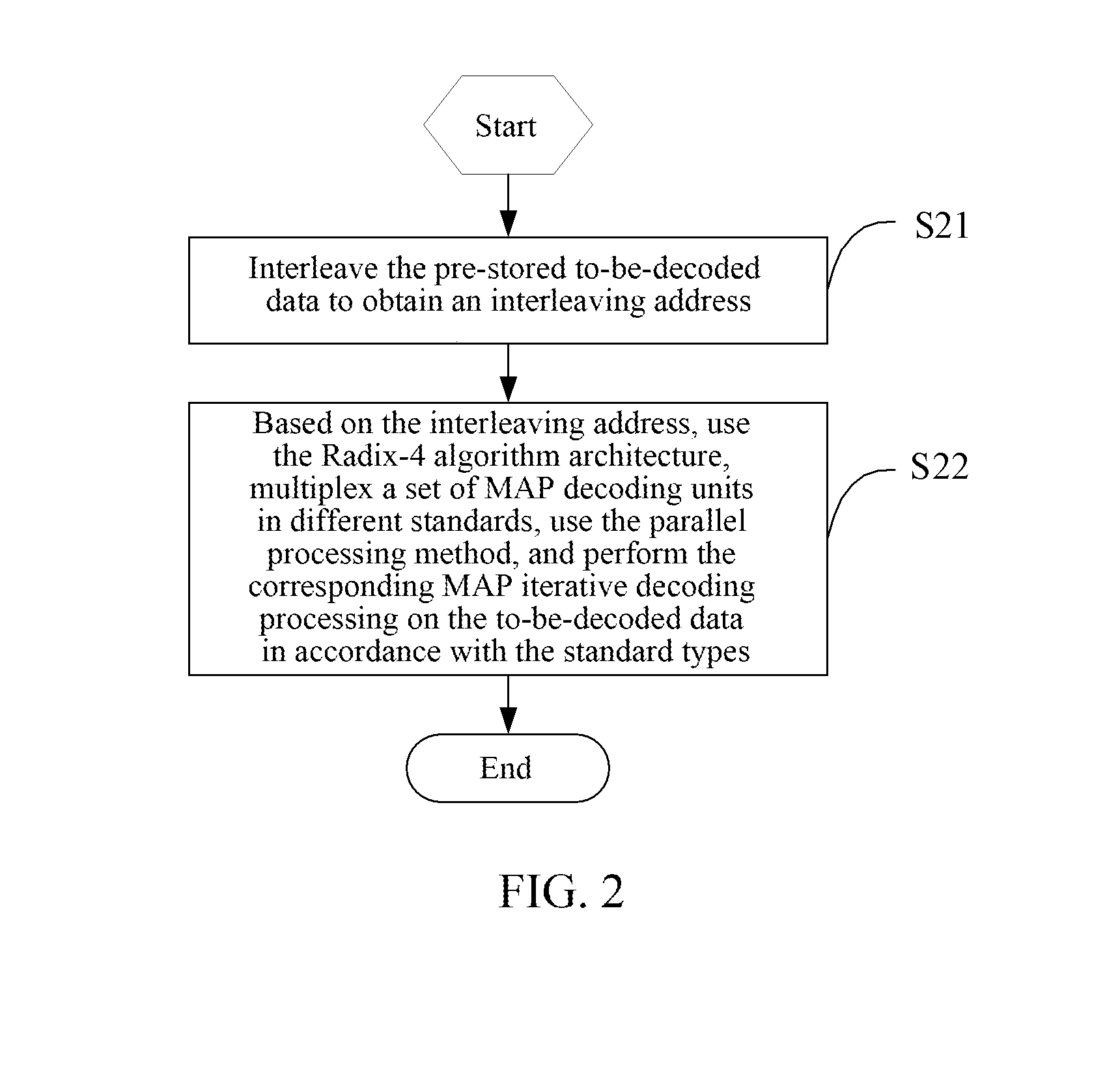

Multimode Decoder Implementation Method and Device

ActiveUS20150381211A1Efficient integrationReasonable system designOther decoding techniquesCode conversionAlgorithmParallel processing

Disclosed are a multimode decoder method and device. The method includes: interleaving pre-stored to-be-decoded data to obtain an interleaving address; and based on the interleaving address, using a Radix-4 algorithm architecture, multiplexing a set of MAP decoding units under different standards, and in a parallel processing method, performing MAP iterative decoding processing on the to-be-decoded data according to standard types.

Owner:SANECHIPS TECH CO LTD

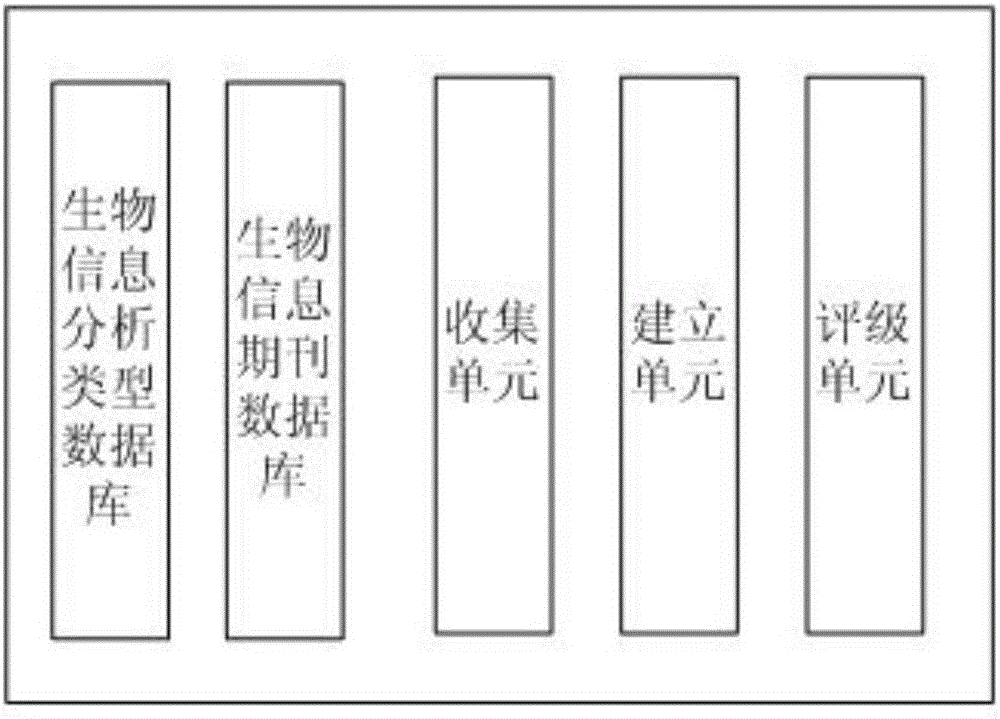

Biological information engineer skill rating system

InactiveCN106651167AReasonable system designAccurate calculationRelational databasesResourcesRating systemInformation analysis

The invention discloses a biological information engineer skill rating system, which comprises a biological information analysis type database, a biological information periodical database, a collecting unit, an establishing unit and a rating unit, wherein the collecting unit is used for collecting basic information of a biological information engineer and user project evaluation registration information; the establishing unit is used for establishing a classifier based on the biological information analysis type database and the biological information periodical database by taking the information collected by the collecting unit as a training sample; and the rating unit is used for performing rating on the skill of the biological information engineer based on the established classifier, thereby realizing the technical effects that the system design is reasonable and that rating is performed on the skill of the biological information engineer accurately, efficiently and reliably.

Owner:成都生命基线科技有限公司

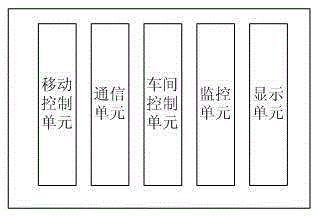

Remote workshop control system based on internet

InactiveCN105388874AReasonable system designConvenience and efficiencyTotal factory controlProgramme total factory controlReal-time computingControl system

The invention discloses a remote workshop control system based on an internet. The system comprises a mobile control unit, which is used for sending a control instruction based on input of a user; a communication unit, which is used for carrying out communication between the mobile control unit and a workshop control unit; the workshop control unit, which is used for controlling a workshop according to the control instruction sent by the communication unit; a monitoring unit, which is used for obtaining monitoring information of the workshop; and a display unit, which is used for carrying out corresponding display in the mobile control unit based on the monitoring information sent by the communication unit. Therefore, the technical effects of reasonable design of the system and convenient and efficient and labor-saving and time-saving remote workshop control are realized.

Owner:SICHUAN XUNJI TECH CO LTD

An auxiliary design system for website construction

InactiveCN106406893AImprove construction efficiencySolve technical problems with low efficiencySoftware designWebsite content managementSystems designUser input

The invention provides an auxiliary design system for website construction. The system comprises: an input unit through which a user inputs website design data; a web page server set-up unit which generates a web page server set-up scheme automatically based on the website design data input by the user; a website operation platform selection unit which selects a website operation platform automatically based on the website design data input by the user; a website development platform selection unit which selects a website development platform automatically based on the website design data input by the user. The system is reasonable in design, can assist developers in designing websites and enables the website construction efficiency to be high.

Owner:武汉米企通网络科技有限公司

An engineering project management system and method

PendingCN109840748AReasonable system designEasy to operatePayment architectureOffice automationProgram planningProject management system

The invention discloses an engineering project management system and method. The system comprises a project investment plan maintenance and audit unit used for project maintenance and investment planaudit; a project information management unit which is used for inputting project information and auditing the project information; a contract information management unit which is used for registeringcontract information and auditing the contract information; and a payment information management unit which is used for contract payment application, contract payment auditing and project payment application. According to the invention, project maintenance and investment plan auditing can be carried out with a project investment plan maintenance and auditing unit; Project information input and project information audit are carried out through the project information management unit. Contract information registration and contract information auditing are carried out through the contract information management unit, contract payment application, contract payment auditing and project payment application are carried out through the payment information management unit, the system design is reasonable, the operation is simple and convenient, the project management is clear, the operation cost is reduced, and the management reliability is improved.

Owner:江苏数创智软科技有限公司

Multimode decoder implementation method and device

ActiveUS9374110B2Efficient integrationReasonable system designOther decoding techniquesCode conversionAlgorithmParallel processing

Disclosed are a multimode decoder method and device. The method includes: interleaving pre-stored to-be-decoded data to obtain an interleaving address; and based on the interleaving address, using a Radix-4 algorithm architecture, multiplexing a set of MAP decoding units under different standards, and in a parallel processing method, performing MAP iterative decoding processing on the to-be-decoded data according to standard types.

Owner:SANECHIPS TECH CO LTD

In-vehicle air purification system for purification through natural airflow

InactiveCN107715585AReasonable system designReduce system energy consumptionGas treatmentAir-treating devicesIn vehicleAirflow

The invention discloses an in-vehicle air purification system for purification through natural airflow. The in-vehicle air purification system comprises an air collection hood, a vacuum suction cup, afirst support, a main air pipe, a flow-dividing valve, multiple branch air pipes, an air purifier, a storage battery, a first switch, a second switch, a gear, a rack, a reset spring, a touch rod, a second support, a windmill, a guide rail, a third support, a slide block, a first fixed block and a fourth support; a heating structure is fixed inside the main air pipe and comprises a protection hood, a heating rod, a third switch and a fixed rod, the upper end of the fixed rod is connected with the inner wall of the main air pipe, the lower end of the fixed rod is connected with the upper end ofthe protection hood, the protection hood is of a net-shaped structure, the heating rod is installed in the protection hood and is connected with the storage battery through the third switch, the third switch is fixed to the outer wall of the main air pipe, and a drying layer is arranged on the inner wall of the main air pipe and is filled with desiccant. The in-vehicle air purification system forpurification through the natural airflow has the technical advantages of being reasonable in system design and low in system energy consumption, and reducing the in-vehicle air purification cost.

Owner:王媛玥

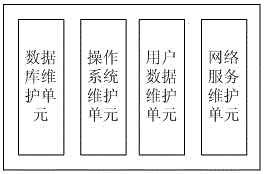

Website maintenance auxiliary system

InactiveCN105741125AReasonable system designImprove efficiencyCommerceSpecial data processing applicationsDatabase maintenanceSystems design

The invention discloses a website maintenance auxiliary system, comprising a database maintenance unit, an operation system maintenance unit, a user data maintenance unit, and a network service maintenance unit, wherein the database maintenance unit is used for maintaining the database at intervals according to the preset frequency; the operation system maintenance unit is used for performing maintenance on the operation system of the website; the user data maintenance unit is used for performing maintenance on the user data atregular intervals; and the network service maintenance unit is used for monitoring the network service in real time, and monitoring and regulating the parameters of the network service in real time. The website maintenance auxiliary system realizes reasonable design on the system, automatic maintenance on the website, high efficiency, and good maintenance effect.

Owner:CHENGDU ETC CERTIFICATION GRP CO LTD

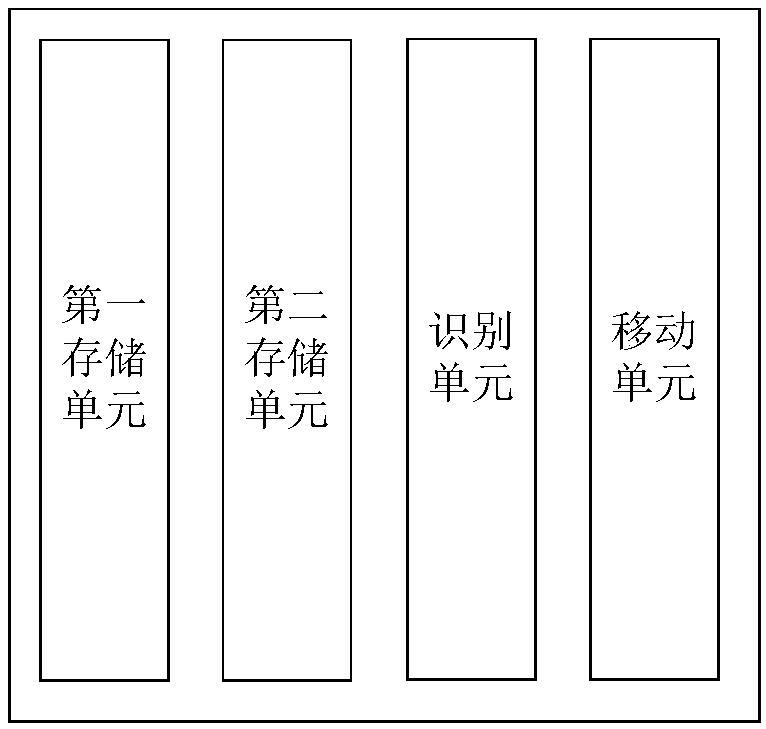

Distribution box intelligent management system

InactiveCN110503280AReasonable system designSecurityResourcesInformation technology support systemFingerprintEngineering

The invention discloses a power distribution box intelligent management system, comprising a first storage unit which is used for the protection storage of a power distribution box, and the power distribution box is stored in the first storage unit when the power distribution box is not operated, a second storage unit which is used for carrying out operation processing on the distribution box, a recognition unit which is used for carrying out face or fingerprint recognition on an operator of the distribution box, and a moving unit for moving the distribution box from the first storage unit tothe second storage unit, wherein when recognition fails, the distribution box is stored in the first recognition unit, and when recognition succeeds, the distribution box is moved to the second storage unit. The power distribution box intelligent management system solves the technical problem that an existing distribution box is poor in safety, achieves the technical effects that the system designis reasonable, and guarantees the safety of the distribution box.

Owner:黄琳

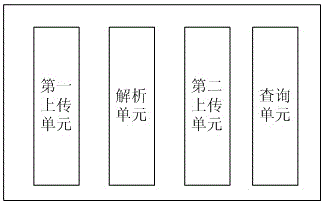

Traffic information record processing system

InactiveCN105913660AThe solution is limitedReasonable system designDetection of traffic movementSystems designReal-time computing

The invention discloses a traffic information record processing system, which comprises a first uploading unit, an analyzing unit, a second uploading unit and a querying unit, wherein the first uploading unit is used for transmitting traffic information acquired by a road monitoring system to a local server; the analyzing unit is used for analyzing the acquired traffic information and carrying out encrypted storage; the second uploading unit is used for uploading data in the local server to a national server; and the querying unit is used for querying data in the local server and the national server. The traffic information record processing system of the invention has the technical effects that the system is reasonably designed; the traffic information records in the national range can be processed; and the processing efficiency is high.

Owner:CHENGDU LIANZHONGZHI TECH CO LTD

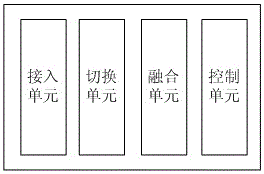

Multimedia video intelligent processing system

InactiveCN105847060AReasonable system designImprove video processing efficiencySelective content distributionData switching networksSystems designReal-time computing

The invention discloses a multimedia video intelligent processing system. The system includes an access unit capable of connecting multimedia data to the system through a network cable or optical fibers or in a wireless manner; a switching unit used for realizing seamless video switching; a fusion unit used for performing seamless fusion of different videos; a control unit used for performing real time control of the processing process of the system. Therefore, technical effects that the system design is reasonable, the video processing efficiency is comparatively high and the processing effect is comparatively good are achieved.

Owner:SICHUAN DIGITAL ARTISAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com