Wire harness process aided design system

A technology of auxiliary design and wire harness, applied in the field of wire harness process auxiliary design system, can solve the problems of low efficiency, high cost and low cost, and achieve the effect of high efficiency, low cost and reasonable system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

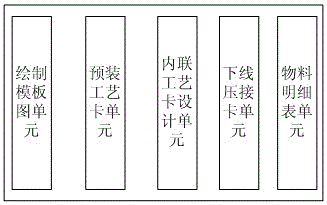

[0025] In the first embodiment, a wiring harness process aided design system is provided, please refer to figure 1 , the system includes:

[0026] drawing template diagram unit, the drawing template diagram unit provides a board drawing function for the user to complete the drawing work of wiring harness flow board diagram;

[0027] A pre-installed process card unit, the pre-installed process card unit is used to assist the user in designing a pre-installed process card, and automatically extract each sub-assembly that can be pre-installed according to the standard template diagram drawn by the user;

[0028] An inline process card design unit, the inline process card design unit is used to assist users in designing inline process cards, and can automatically extract the conduction loops of each connection from the standard template diagram drawn by the user according to a given rule, and Generate an inline design interaction environment;

[0029] An off-line crimping card u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com