Pole piece coating thickness online detecting system and detecting method

A technology of coating thickness and detection system, which is applied in the direction of control/adjustment system, measuring device, instrument, etc., can solve the problems affecting the efficiency and continuity of production, backward detection methods, low efficiency, etc., and achieve simple and fast detection process, High degree of automation and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

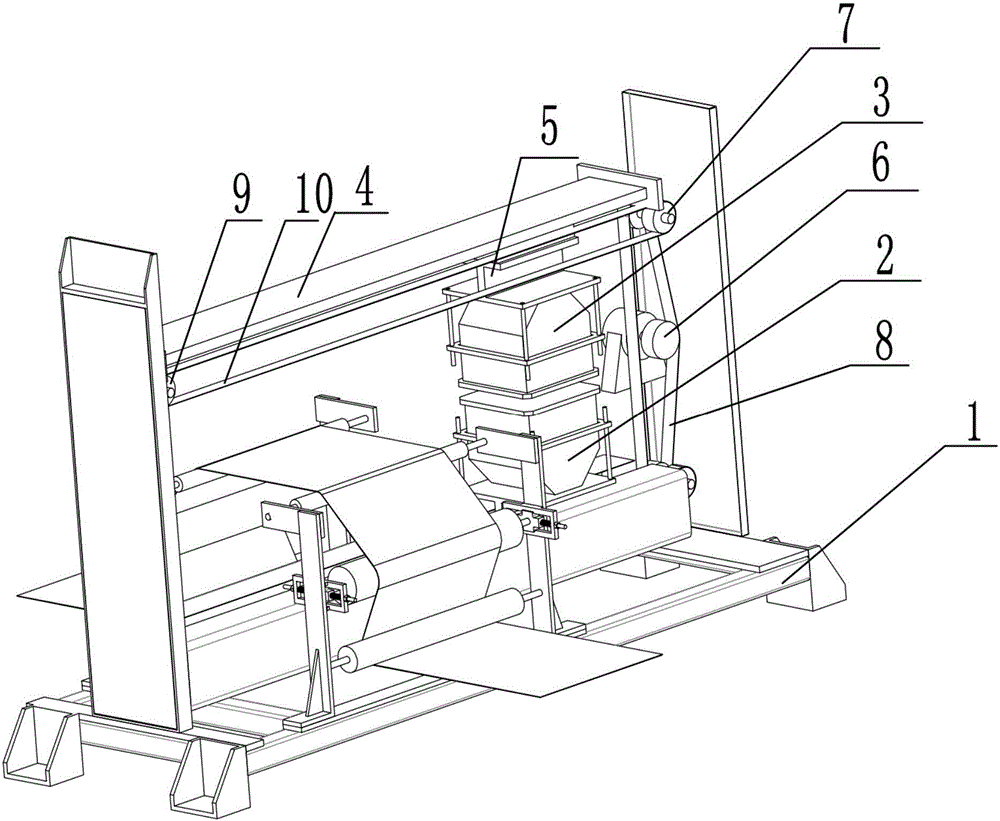

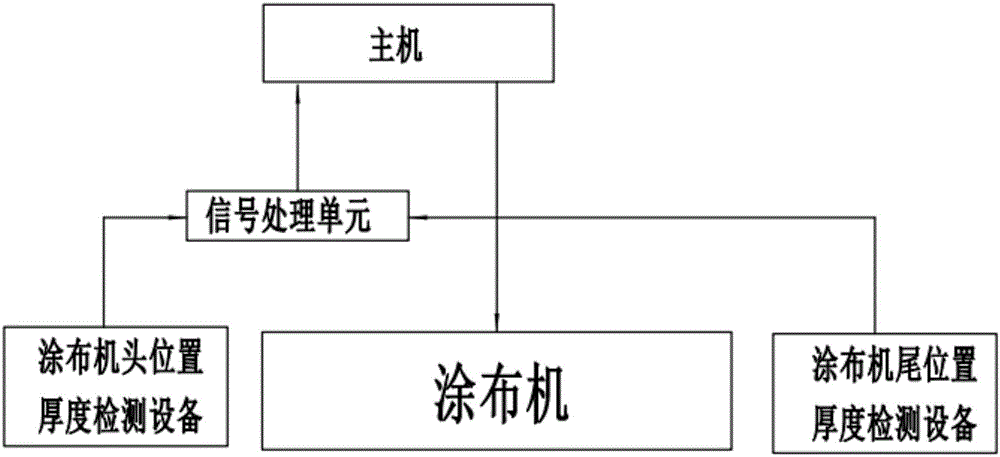

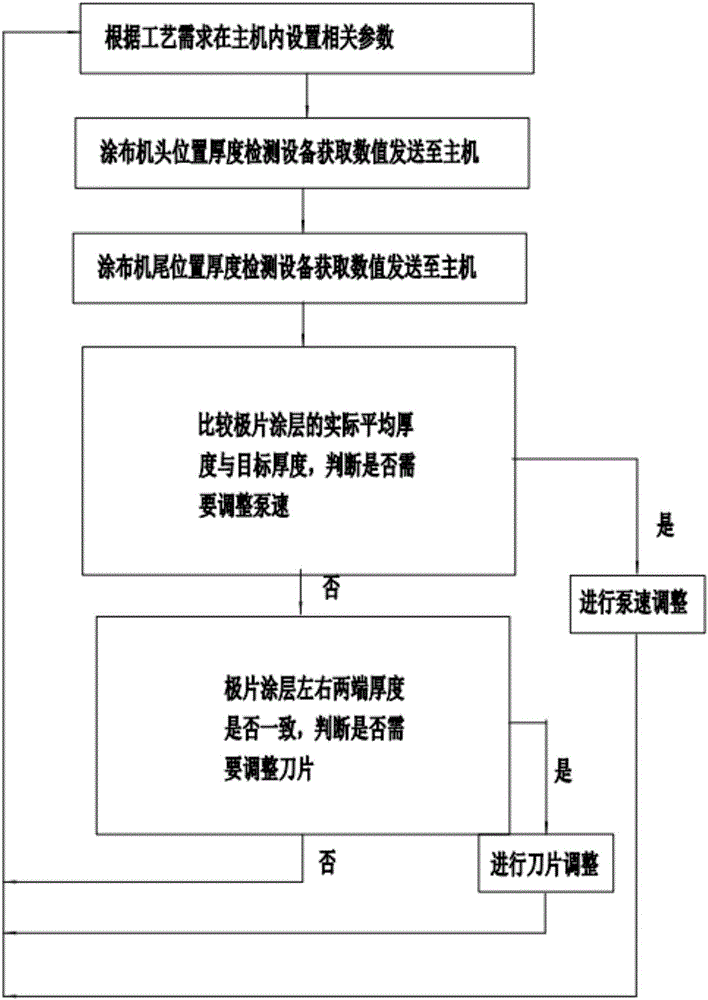

[0025] This embodiment provides a pole piece coating thickness online detection system, the pole piece coating thickness online detection system is mainly composed of thickness detection equipment and a control system, wherein the control system consists of a host computer, a signal processing unit, an operation interface, and a control box It consists of two sets of thickness detection equipment, which are respectively arranged in front of the coating machine and behind the coating machine. The thickness detection equipment includes a β-ray emitting device, a β-ray receiving device, and a driving device. The β-ray emitting device and the β-ray receiving device are composed of a driving device including a motor, a driving wheel, a driven wheel, a synchronous belt, and a belt. The driving device drives the β-ray emitting device and the β-ray receiving device to realize synchronous movement.

[0026] In this embodiment, the structural diagram of the thickness detection equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com