Intelligent full-process manufacture brand-new mode for tyre

An intelligent manufacturing and whole-process technology, applied in tires, other household appliances, household appliances, etc., can solve problems such as unstable product quality, unstable process, and low degree of automation, so as to optimize the intelligent manufacturing process, reduce intermediate links, Reduce the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

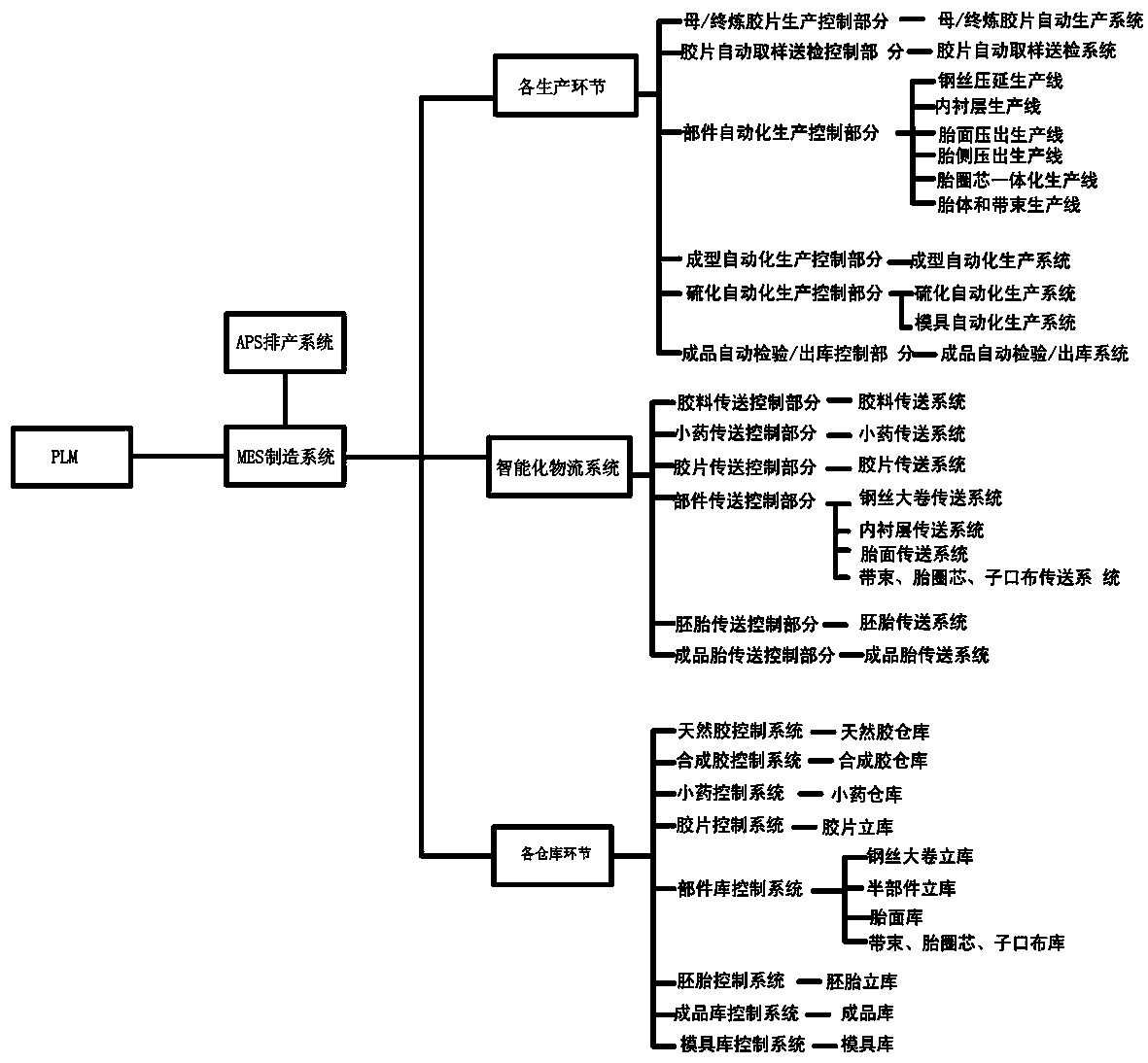

[0045] The whole-process intelligent manufacturing mode of tires of the present invention is a brand-new mode of intelligent manufacturing of tires in the whole process, which is a method of intelligent manufacturing of tires in the whole process which is jointly completed by APS production scheduling system, MES manufacturing execution system, various production links, various warehouse links and intelligent logistics system; The method of intelligent manufacturing of tires in the whole process is as follows:

[0046] (1) Define the scheduling method to the APS scheduling system to generate the production plan, and at the same time give it the parameters to start working;

[0047] (2) Define the total production method of tires to the MES manufacturing execution system, and at the same time give it the parameters to start work, where the total production method is associated with each production link in tire production; the MES manufacturing execution system receives the produ...

Embodiment 2

[0120]This embodiment is an improvement made on the basis of Embodiment 1. In this embodiment, an automatic film sampling and inspection production system is provided on the rubber cooling line, and the film automatic sampling and inspection production system controls the production through automatic film sampling and inspection. Partial control, film automatic sampling and inspection system includes sampling equipment, automatic coding equipment, automatic bottling equipment and inspection room, in which sampling equipment, automatic coding equipment, automatic bottling equipment are connected in sequence, and the automatic bottling equipment and inspection room The room is connected by pneumatic conveying, in which the sampling equipment, automatic coding equipment, and automatic bottling equipment are all connected with the film automatic sampling inspection control part.

[0121] When the automatic production system of master / final rubber is working, the MES manufacturing e...

Embodiment 3

[0123] This embodiment is an improvement made on the basis of embodiment 1 or implementation 2. This embodiment is provided with a mold automatic production system, a mold library and a mold library control system, wherein the mold automatic production system accepts the control of the vulcanization automatic production control part, The mold library control system accepts the tasks of the MES manufacturing execution system, and the mold library control system controls the mold library to complete the output and storage work.

[0124] When performing vulcanization production, the MES manufacturing execution system sends production tasks to the vulcanization automation production control part, and generates a mold assembly construction task list. When the vulcanization automation production control part controls the vulcanization automation production system, it also sends the task to the mold automation production system. The mold automation production system selects the molds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com