Patents

Literature

236 results about "Assurance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality assurance (QA) is a process-centered approach to ensuring that a company or organization is providing the best possible products or services. It is related to quality control, which focuses on the end result, such as testing a sample of items from a batch after production.

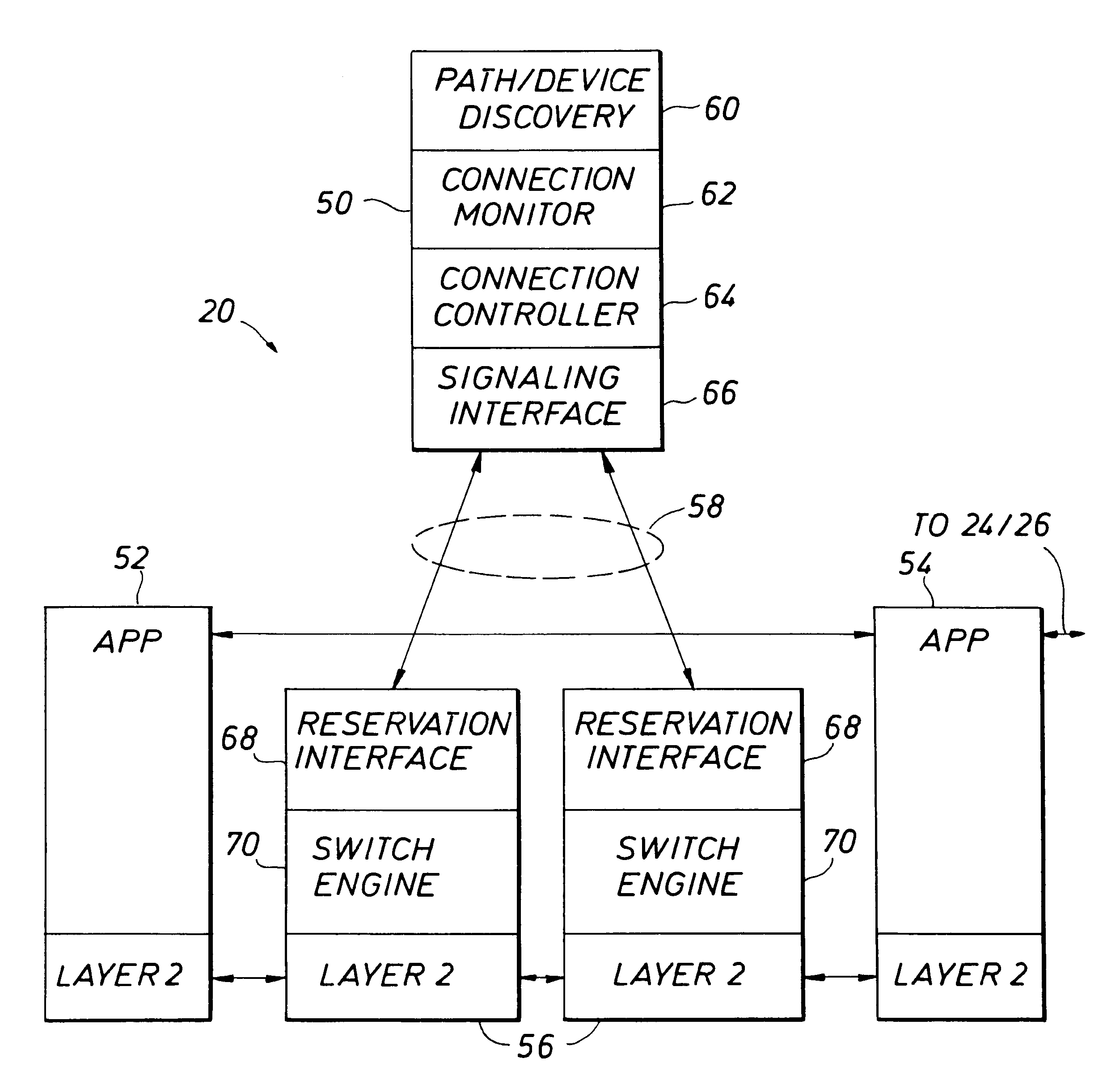

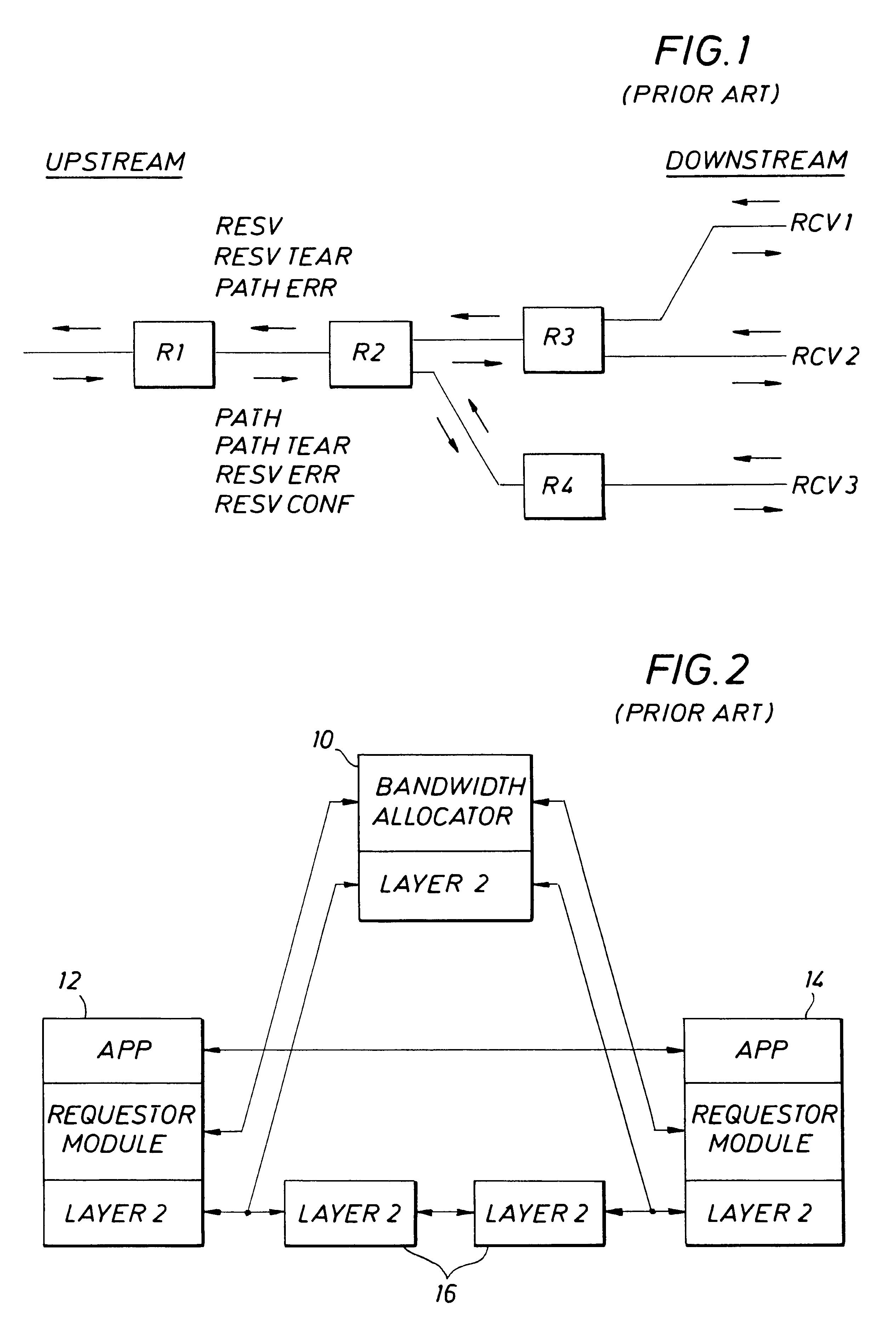

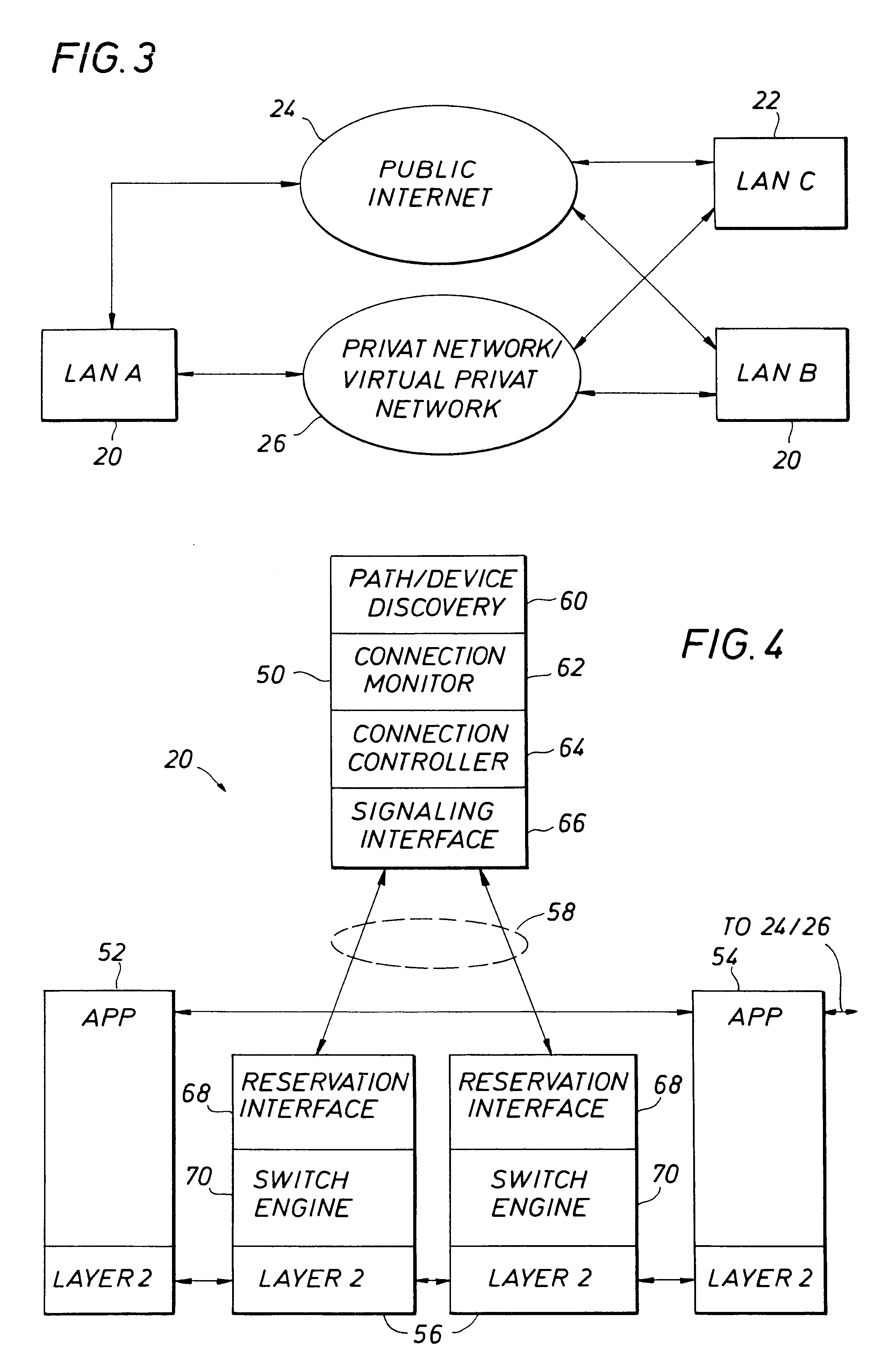

Method and apparatus for providing guaranteed quality/class of service within and across networks using existing reservation protocols and frame formats

InactiveUS6563793B1Error preventionFrequency-division multiplex detailsAssurance qualityClass of service

A method and apparatus provide reserved bandwidth and QOS / COS virtual circuit connections in a network using both conventional and novel reservation protocols and frame formats. An apparatus according to the invention includes an enterprise control point that communicates with switches via a reserved signaling channel. The switches have been upgraded or replaced to include enhanced functionality. The enhanced switches detect packets that include requests for reserved connections according to existing reservation protocols such as RSVP and IEEE 802.1P / Q. Such detected packets are forwarded to the enterprise control point for processing via a reserved signaling channel. The enterprise control point identifies a path within the network that can satisfy the requested QOS / COS and reserves the requested resources all along the path from beginning to end. A method according to the invention includes detecting packets that include requests for reserved connections according to existing reservation protocols such as RSVP and IEEE 802.1P / Q, forwarding detected packets to an enterprise control point for processing via a reserved signaling channel, identifying a path within the network that can satisfy the requested QOS / COS and reserving the requested resources all along the path from beginning to end.

Owner:WARPSPEED COMM

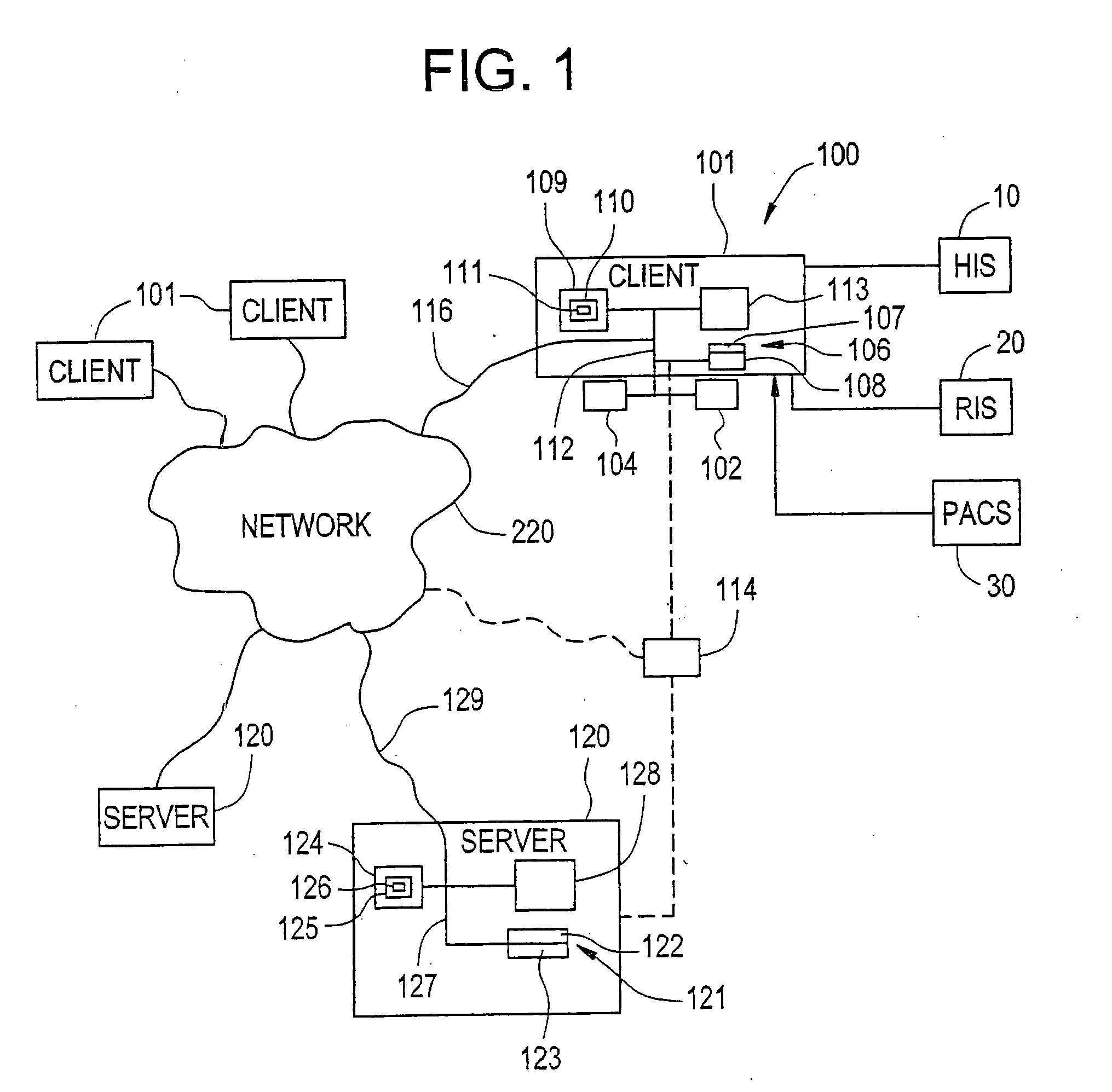

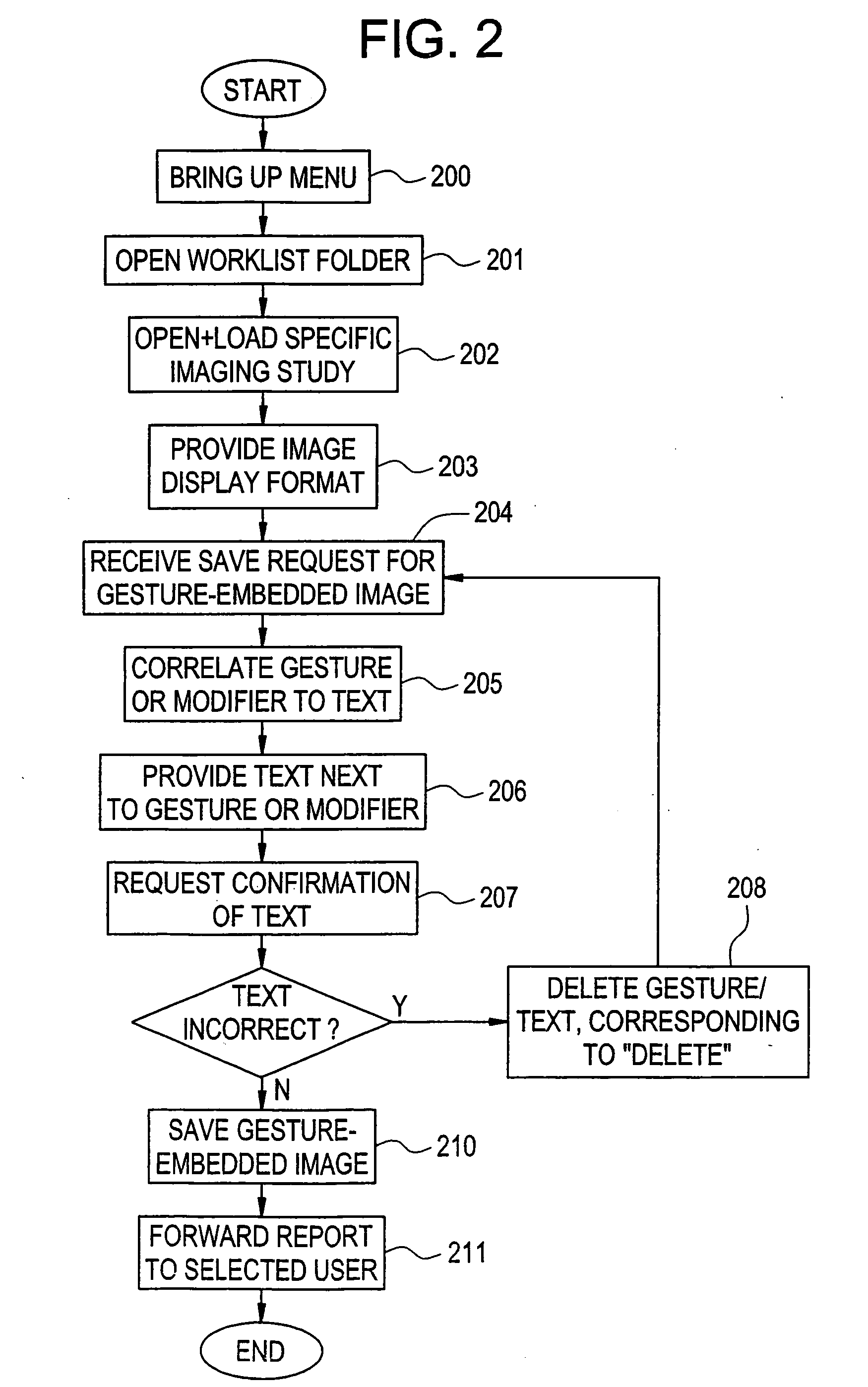

Gesture-based communication and reporting system

ActiveUS20090018867A1Avoid mistakesFacilitate communicationData processing applicationsMechanical/radiation/invasive therapiesData dredgingImaging quality

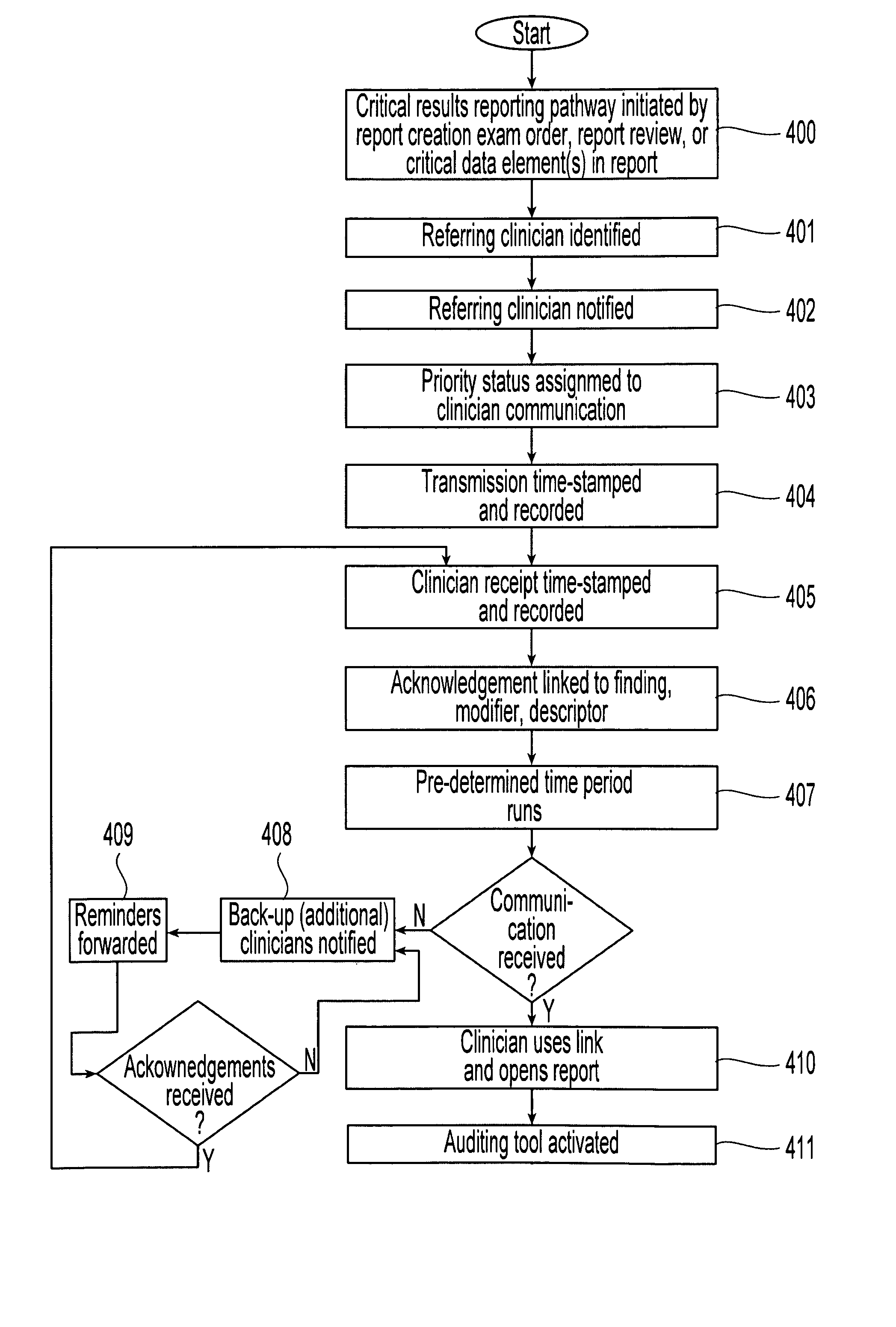

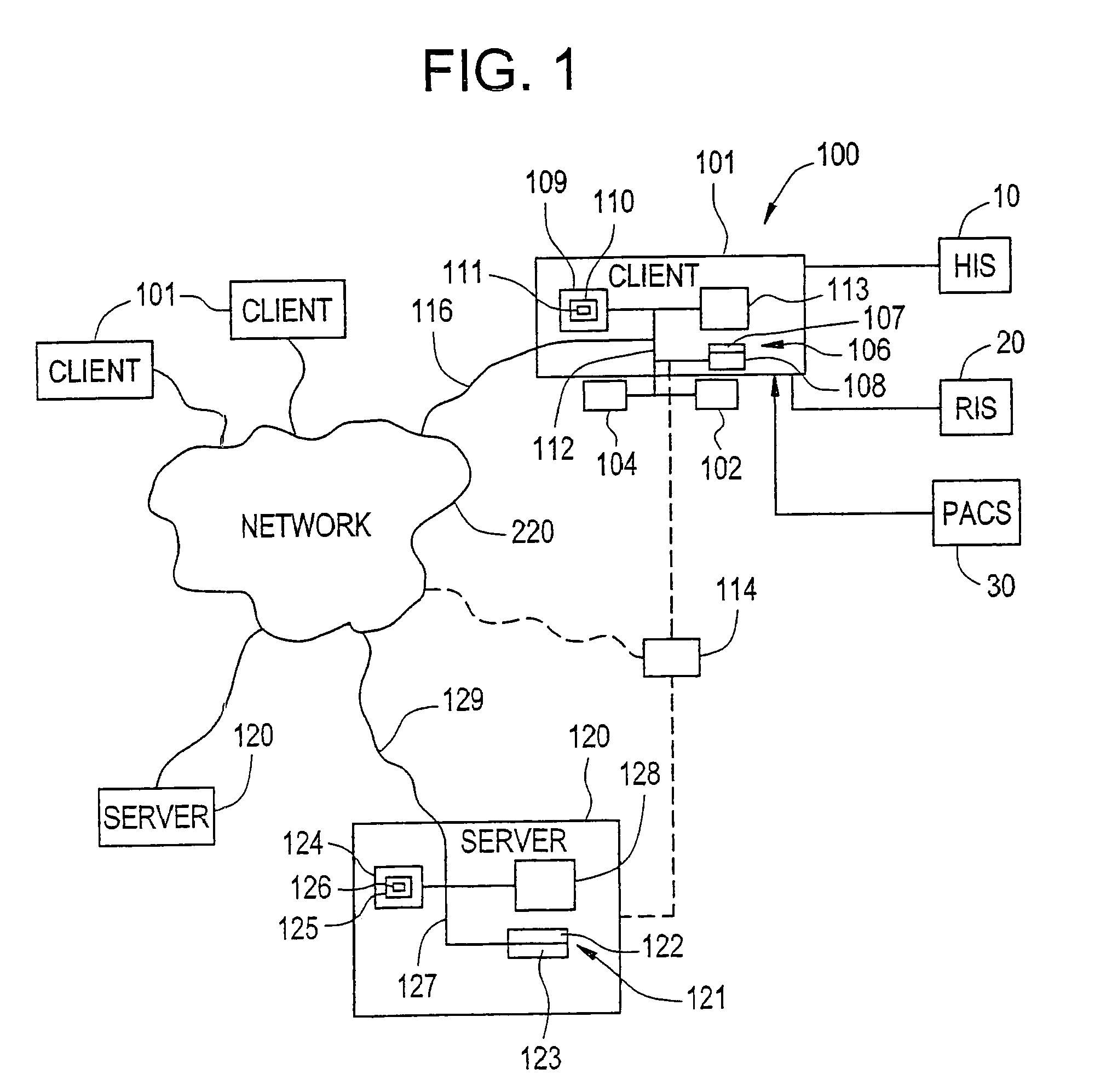

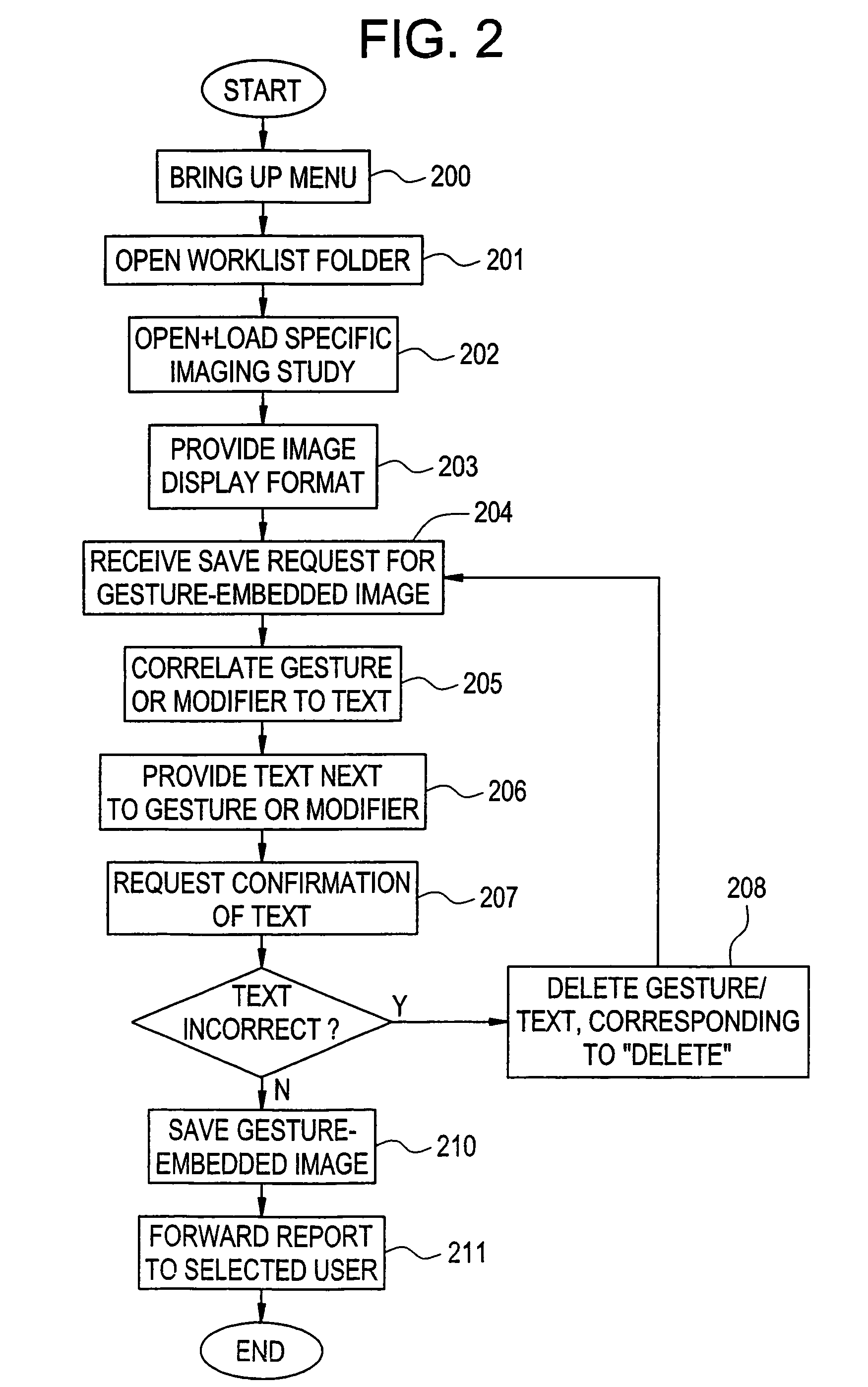

The present invention relates to a gesture-based reporting method and system, including a critical results reporting pathway, which is used to communicate critical findings to users according to predetermined methods (i.e., e-mail, facsimile, etc.), and create an electronic auditing trail to document receipt, understanding, bi-directional queries, and track clinical outcomes. Based on a predetermined rule set, predetermined data elements within the structured database could trigger the critical results reporting pathway. There is a quality assurance component to the invention, such that technical deficiencies in an imaging quality can be noted, analyzed, and tracked. There is a workflow and data analysis portion to the invention, wherein workflow is enhanced, and structured data is mapped to a standardized lexicon, such that data mining can be performed. Thus, the present invention extends beyond reporting alone and is a tool to facilitate electronic communication, consultation, education / training, and data mining for quality assurance.

Owner:IMPRIVATA

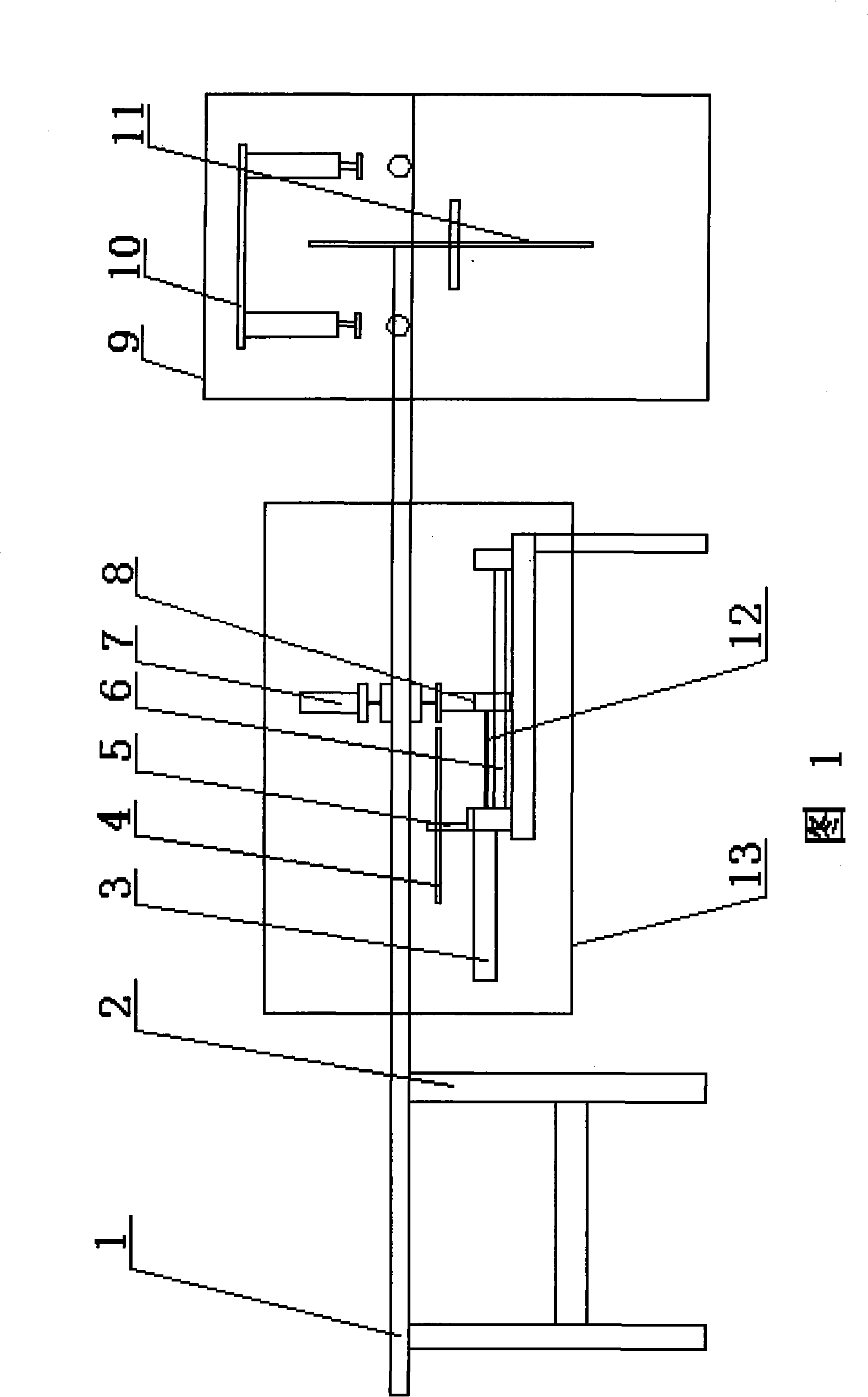

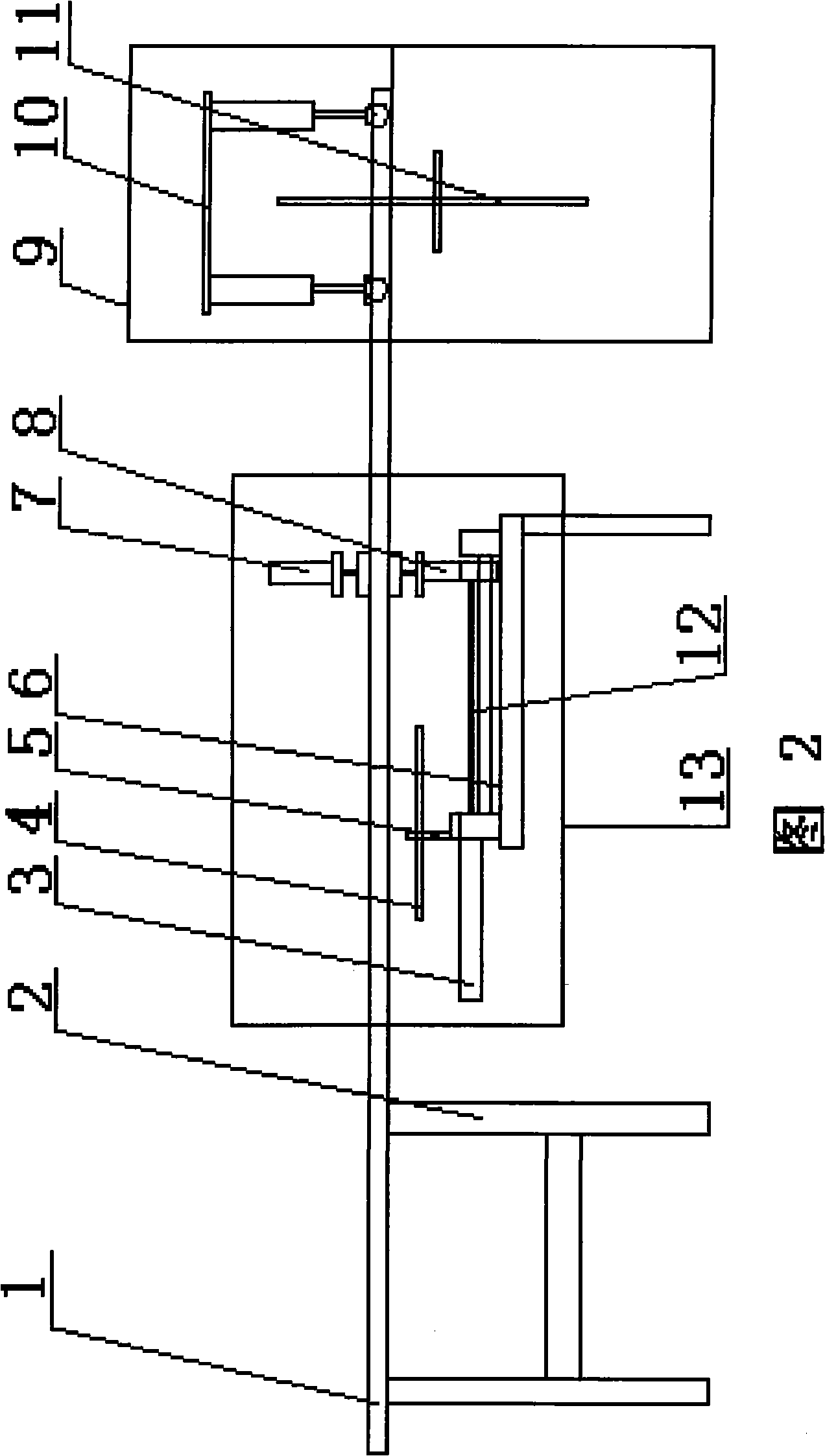

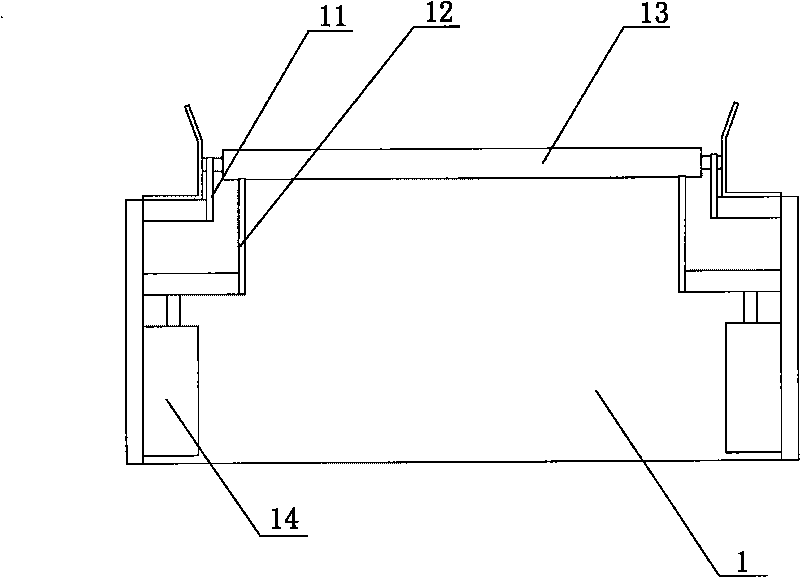

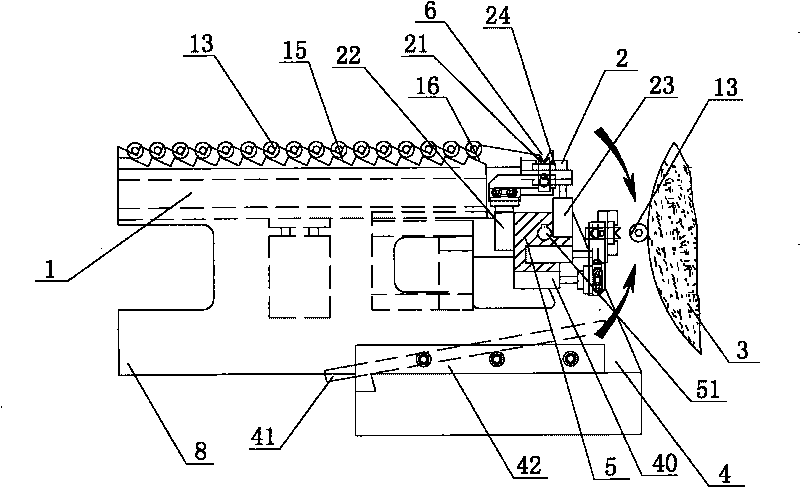

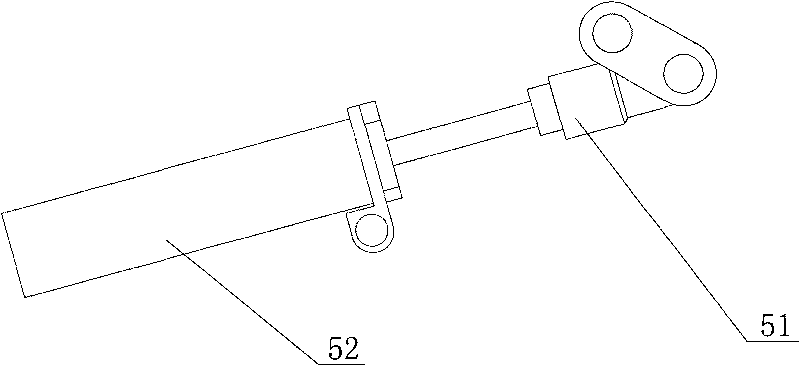

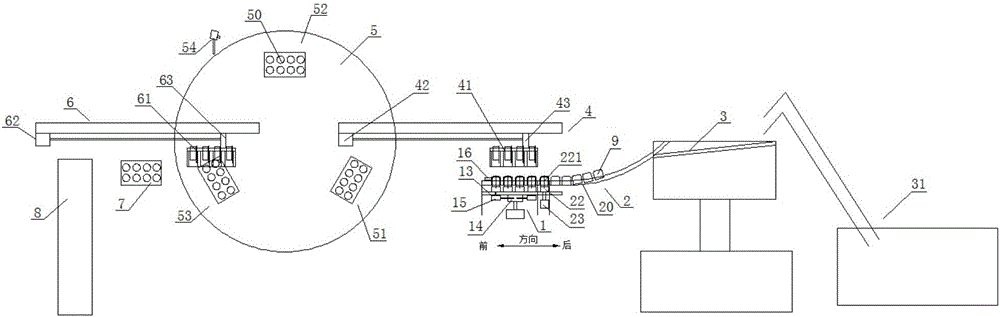

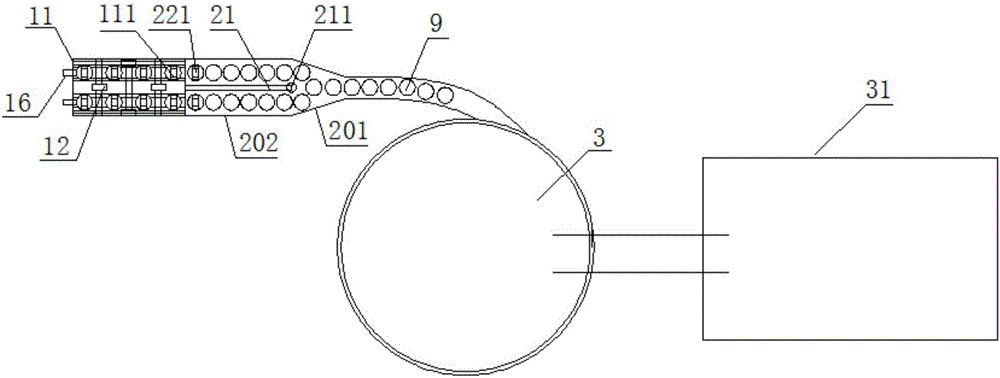

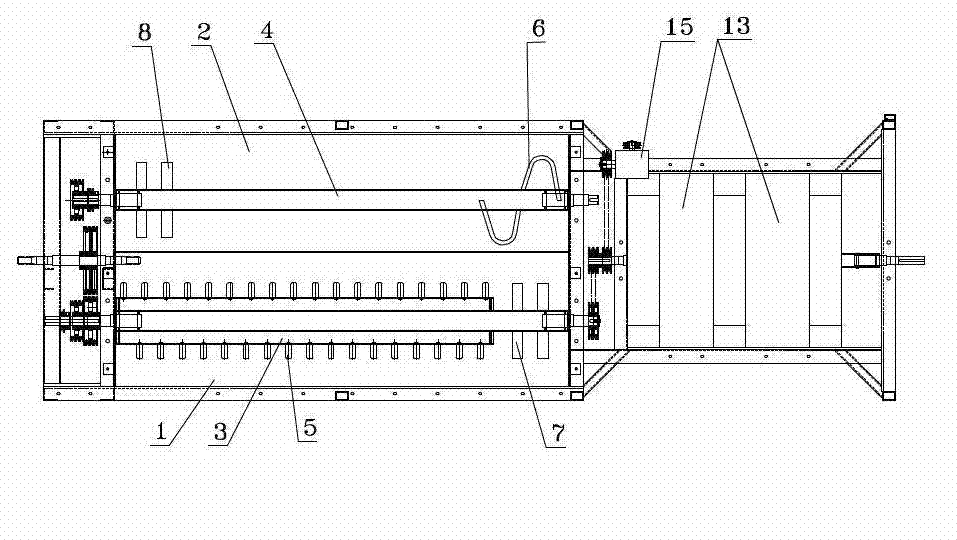

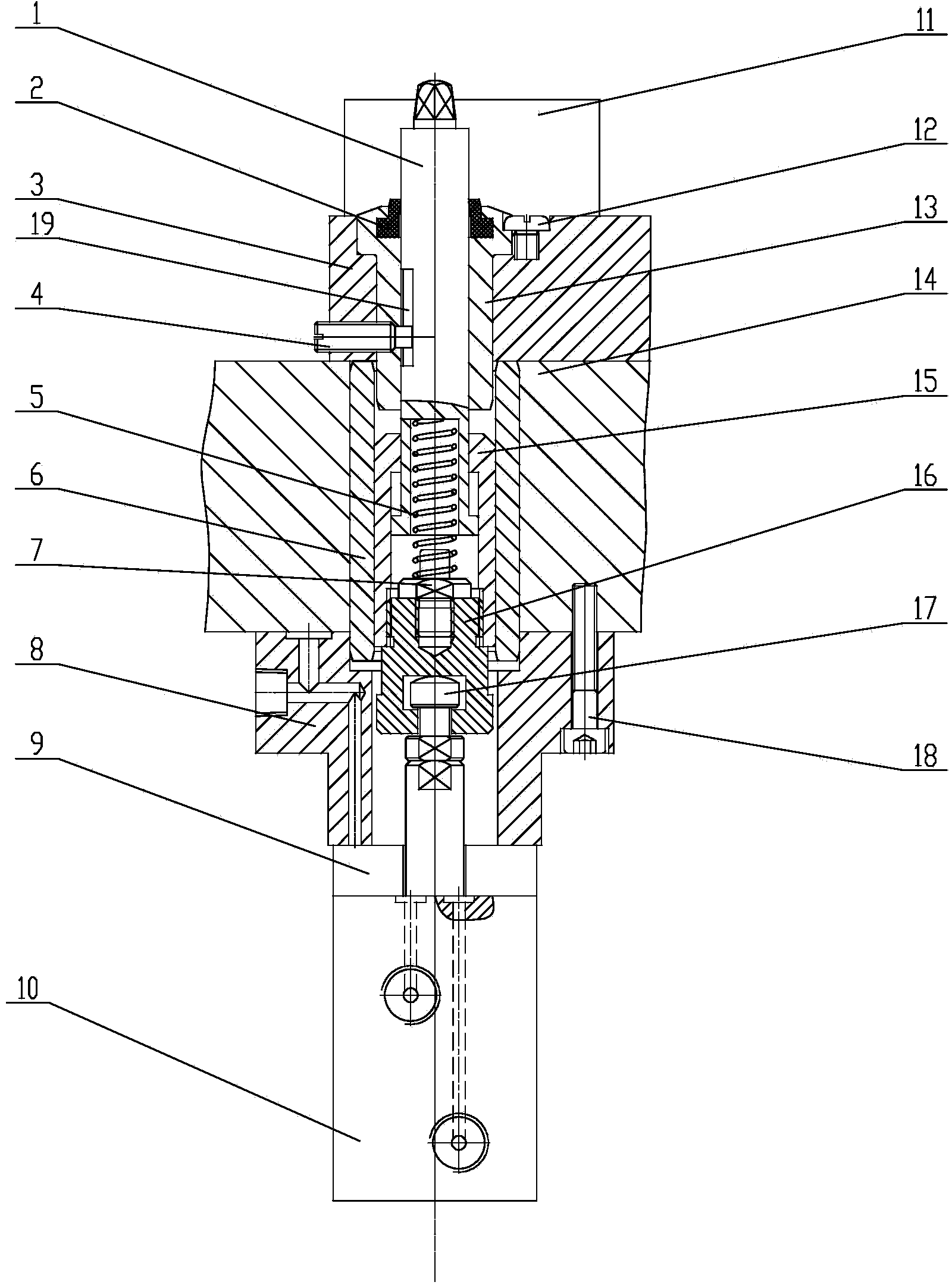

Full automatic aluminium section bar cutter device

InactiveCN101352770AImprove accuracyReduce randomnessMetal sawing devicesMetal-working feeding devicesAssurance qualityEngineering

The invention discloses a full-automatic aluminum cutting device which aims at solving the problem of low manual feeding efficiency of the existing aluminum cutting device and provides a safe and convenient full-automatic aluminum cutting device which can ensure the quality. The device of the invention includes: a feed device, a bracket and a cutting saw arranged on the bracket; the feed device includes an upper clamping part, a lower clamping part, a horizontal feed part and a locating part. The device fully uses machines to replace manual operation, thus not only enhancing the accuracy, increasing the efficiency, reducing the cost, but also saving the human labor and materials as well as enhancing the safety performance.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

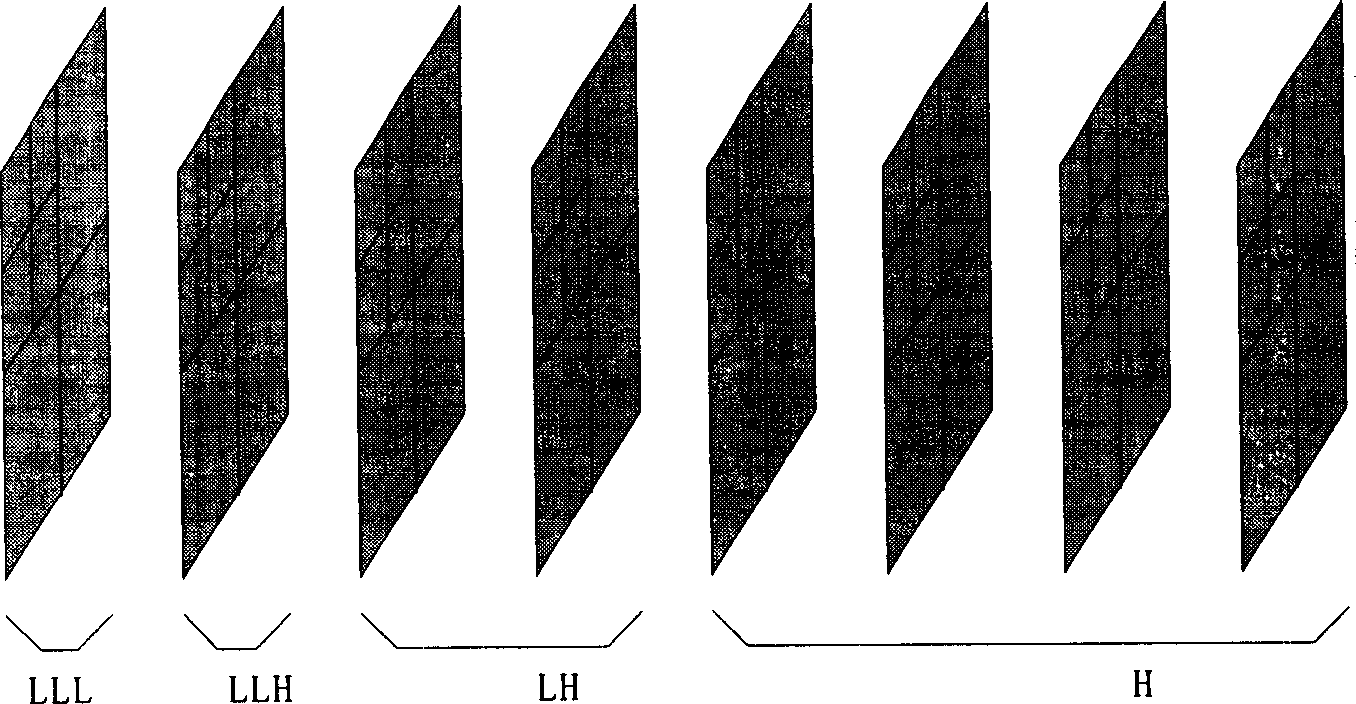

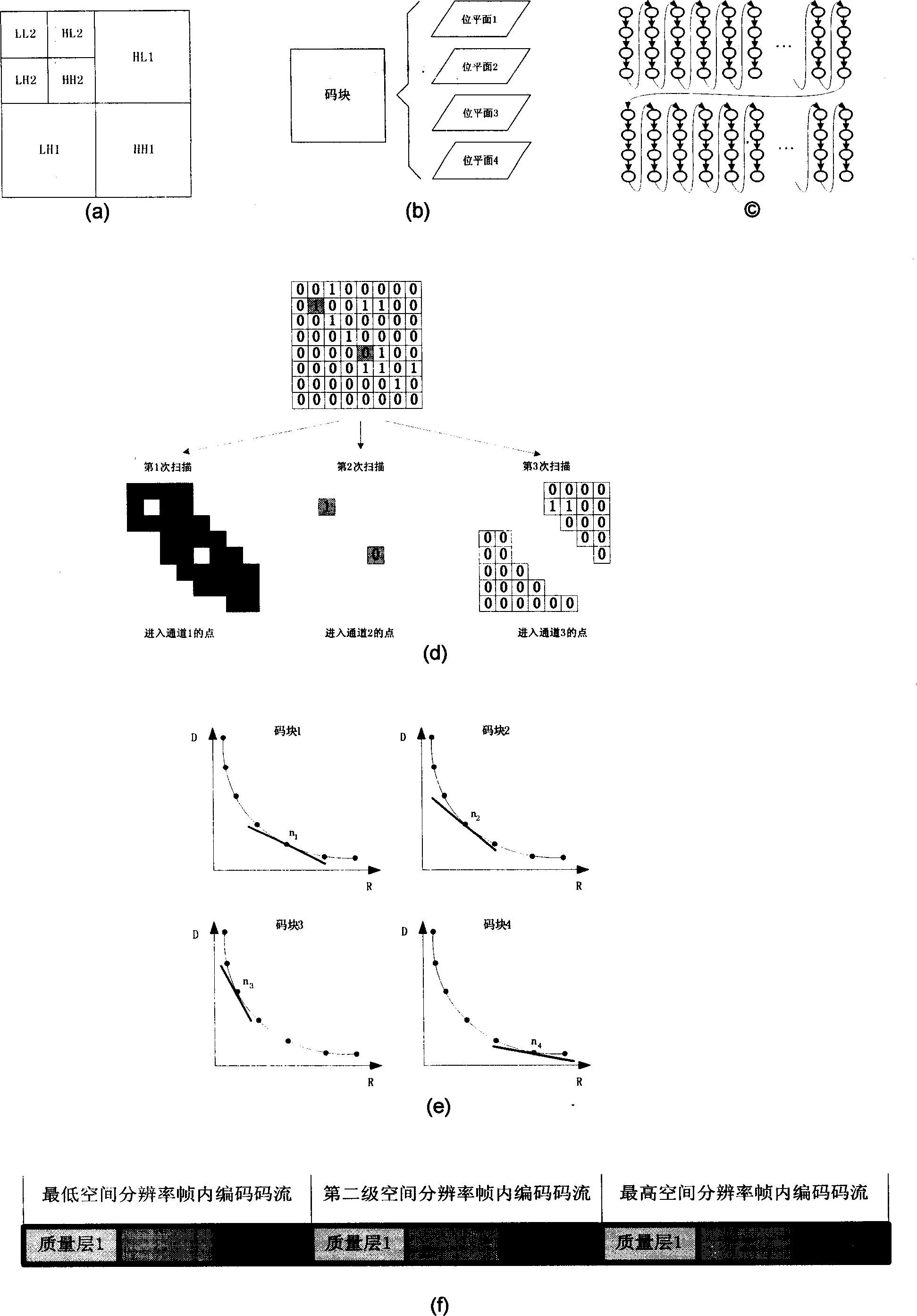

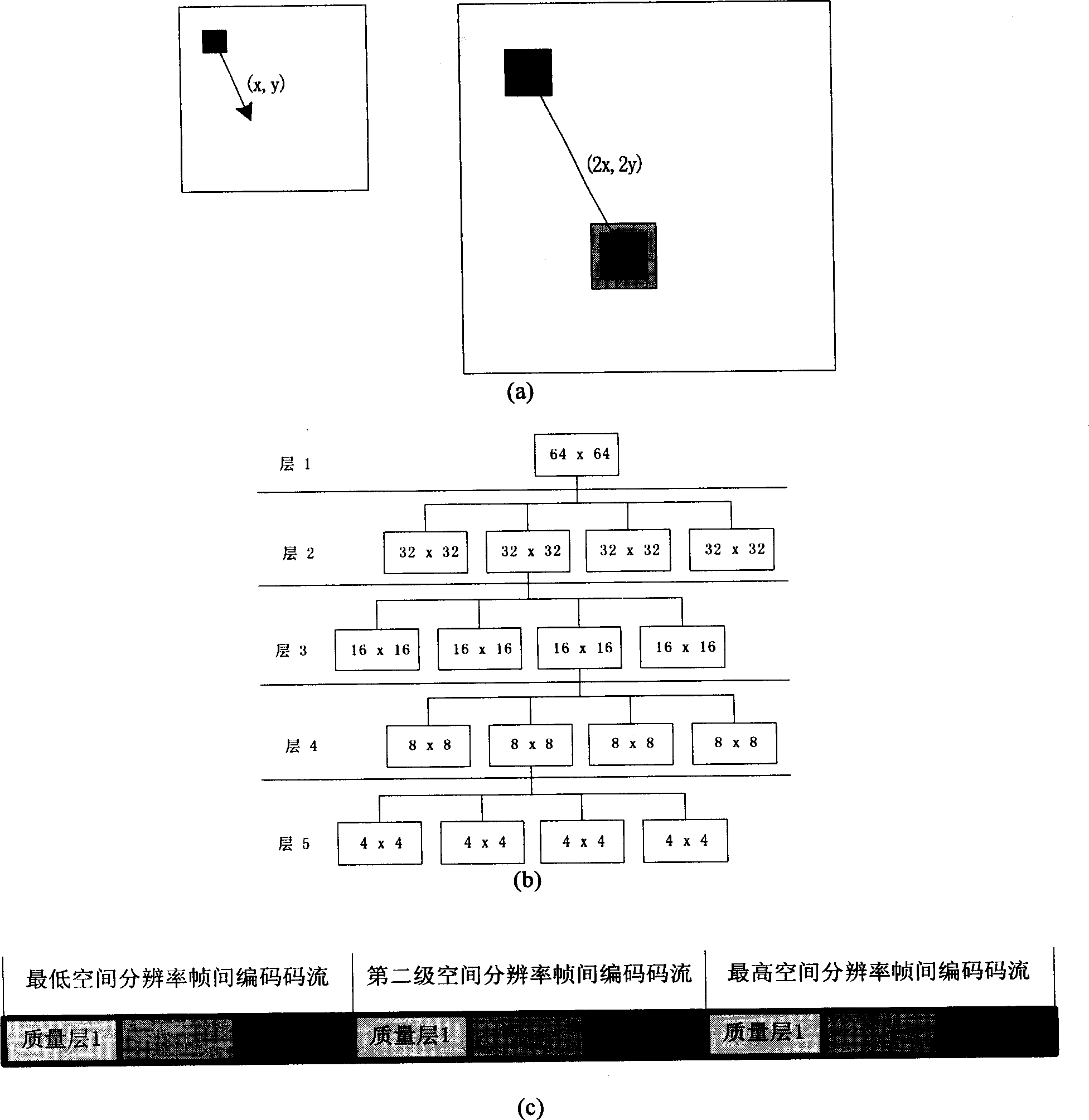

Control method of high performance three-dimensional code rate in flexible video coding

InactiveCN1794818AImprove scalabilityMeet needsDigital video signal modificationTime domainVideo transmission

This invention discloses a high performance 3-D code rate control method in scalable video coding, which takes the 3-D rate control technology as the core to provide an embedded video code stream of high performance time domain, space domain and quality scalability adapting the heterogeneousness of the video transmission network, waveness of the network bandwidth and user receiving ends to be scalable on time, space and quality and is intercepted based on the variety and network bandwidth of user video receiving ends.

Owner:XI AN JIAOTONG UNIV

Intelligent tissue mimicking ultrasonic phantom and method of preparing the same

InactiveUS20100330545A1Resists deteriorationEnsure consistency of qualityUltrasound therapySurgeryThermal denaturationLower critical solution temperature

Owner:CHONGQING HAIFU MEDICAL TECH CO LTD

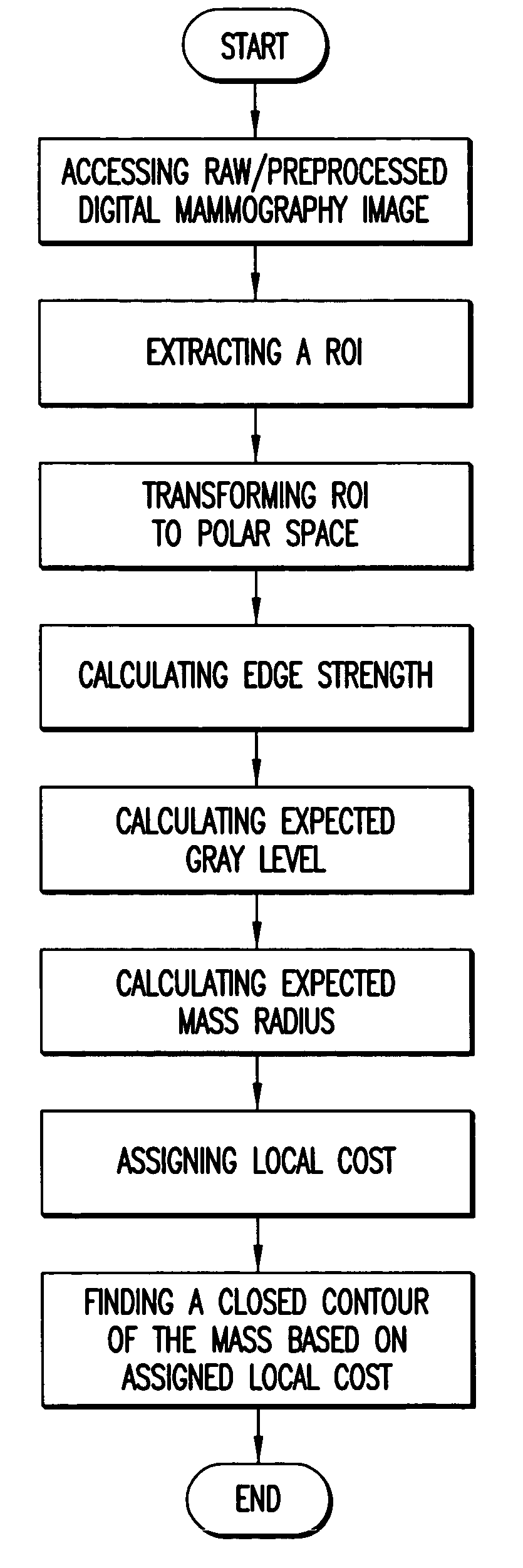

Mass segmentation using mirror image of region of interest

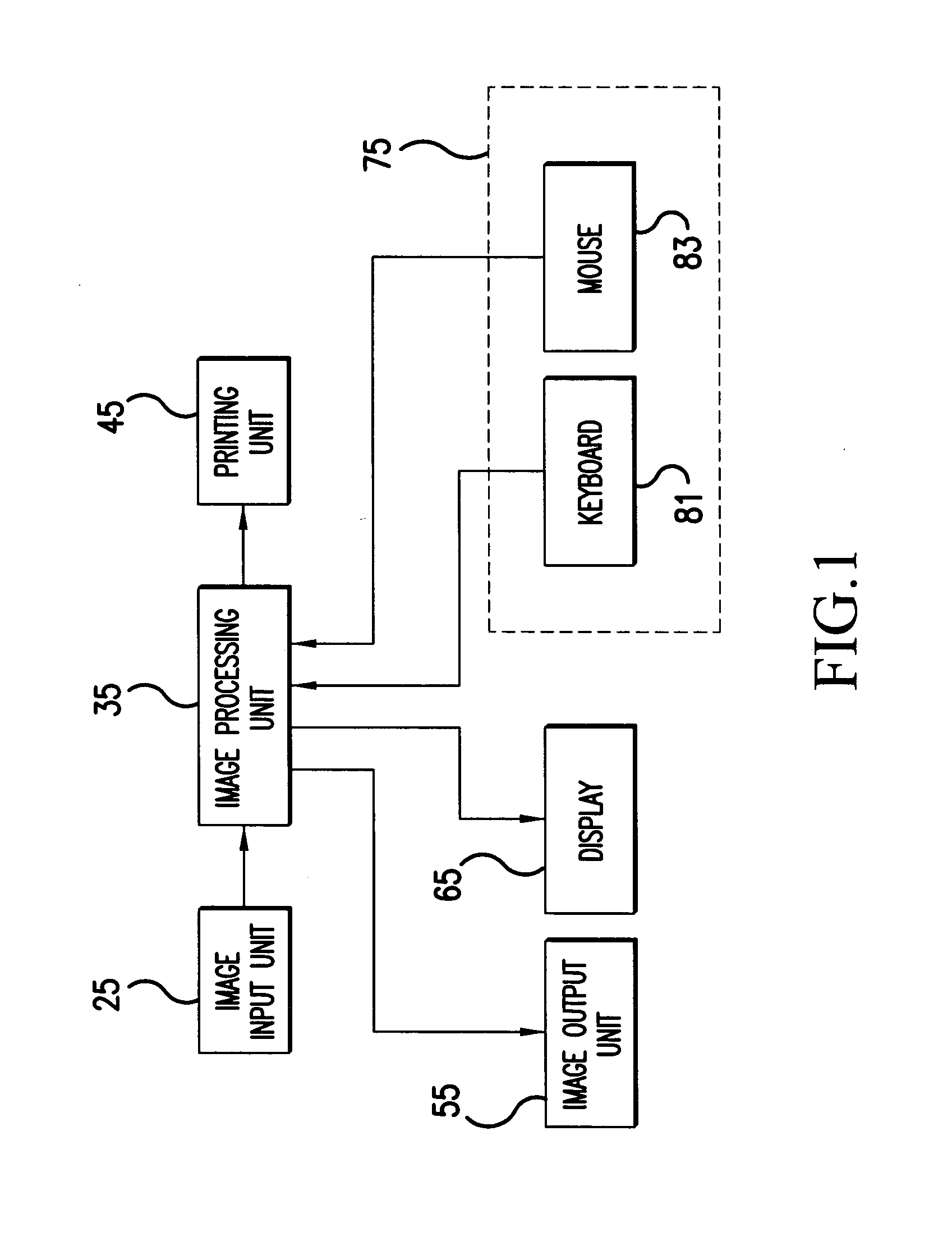

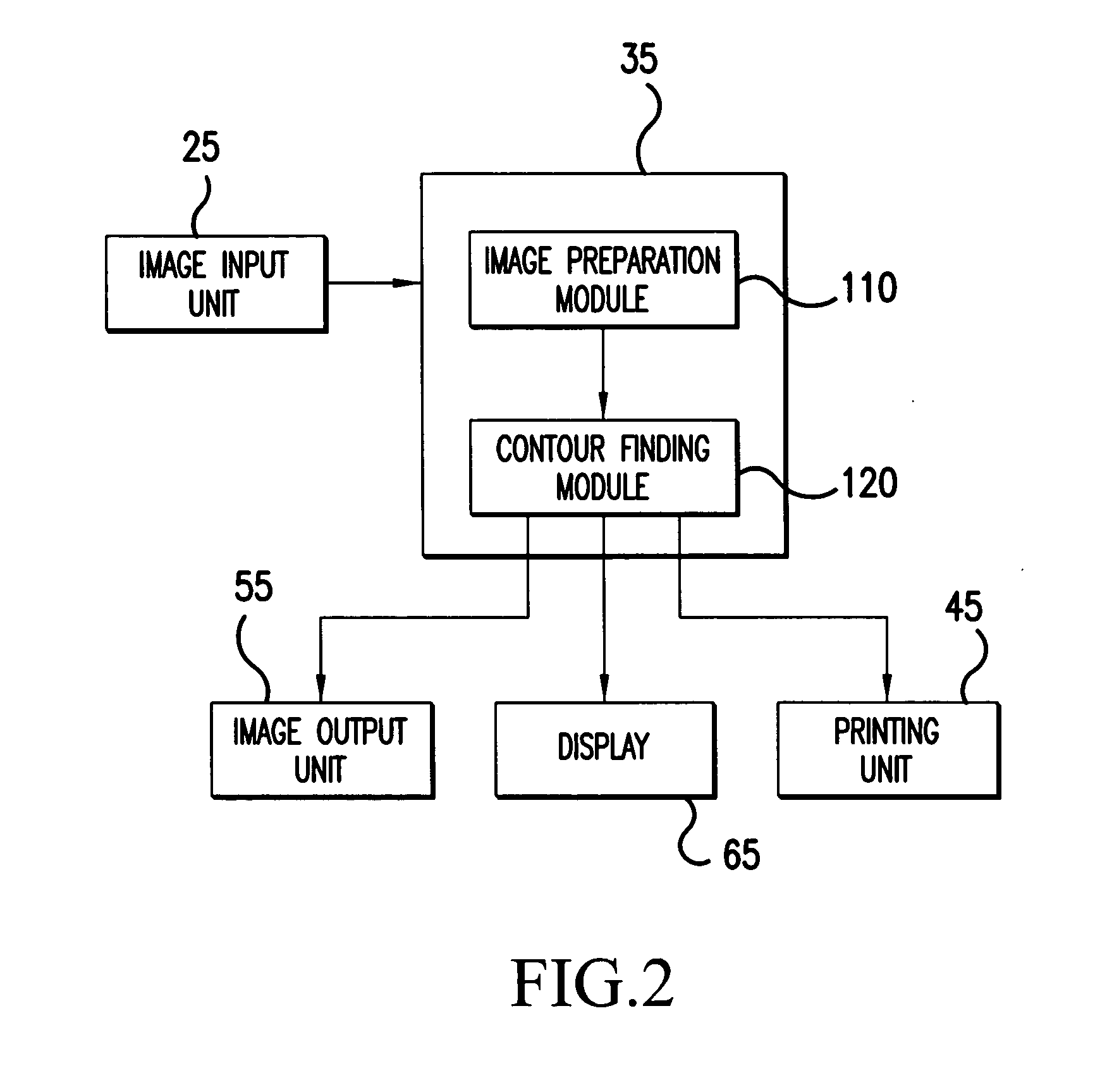

InactiveUS20080152220A1Recognition of medical/anatomical patternsAutomatic segmentationAssurance quality

A method and an apparatus for automatic segmentation of an image representing a mass of a tissue region based on dynamic programming that guarantees an accurate and closed contour of the mass is disclosed. The method according to one embodiment accesses digital image data representing an image including the mass of the tissue region, creates a mirror image of the digital image data, extracts a Region of Interest (ROI) which includes a portion of the mirror image containing the mass, transforms the ROI to polar space for obtaining a polar image of the ROI, assigns local cost to sub portions of the polar image, and finds a contour of the mass based on the assigned local cost.

Owner:FUJIFILM CORP

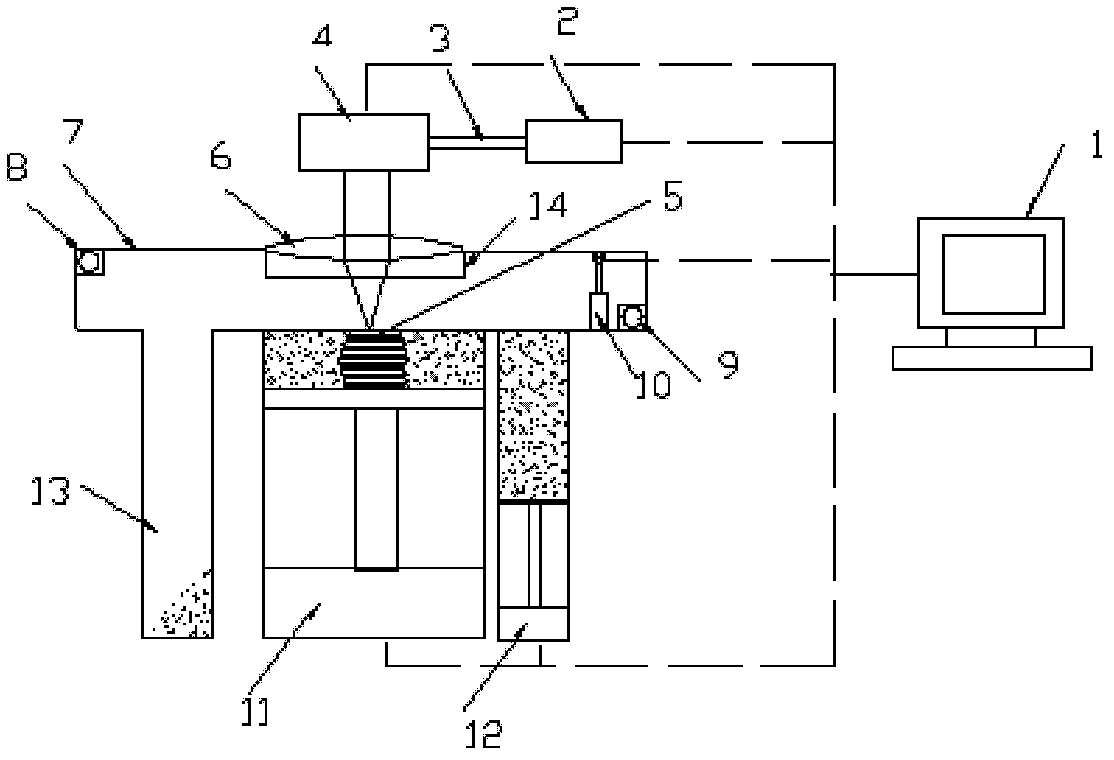

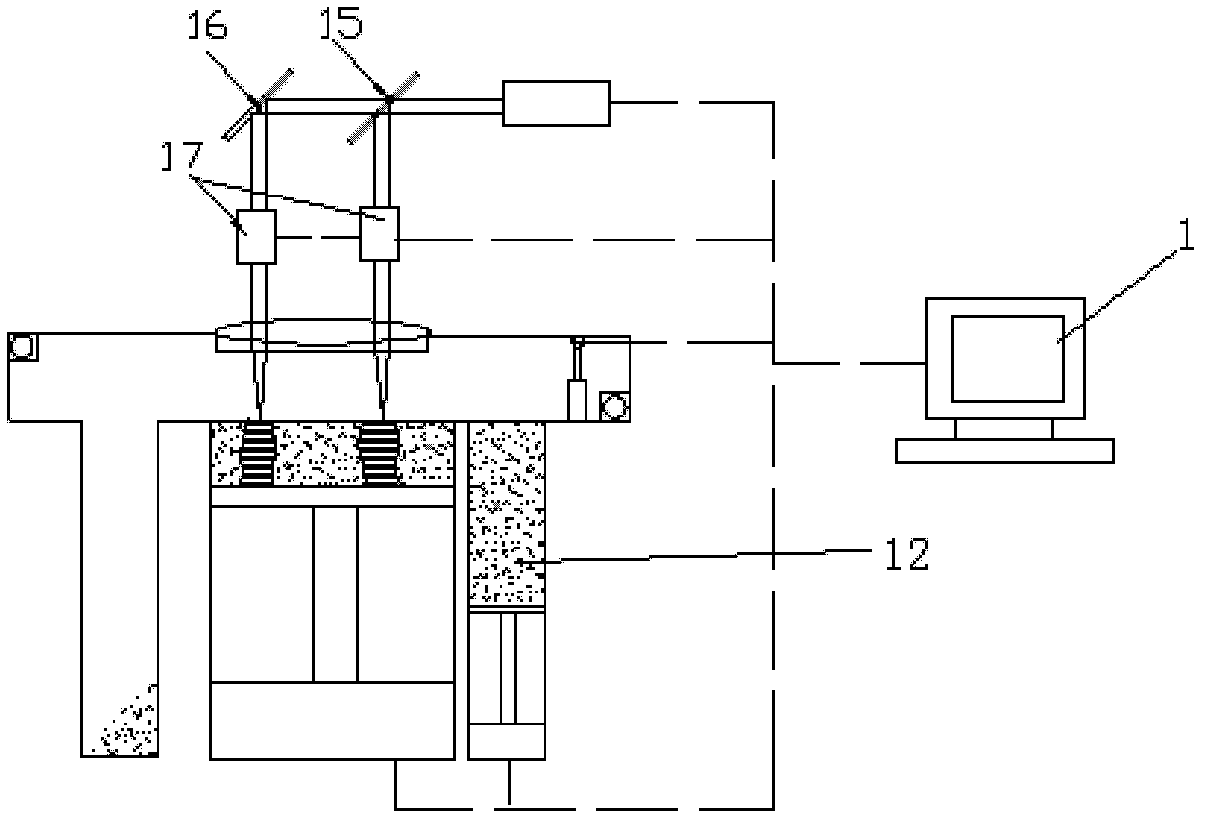

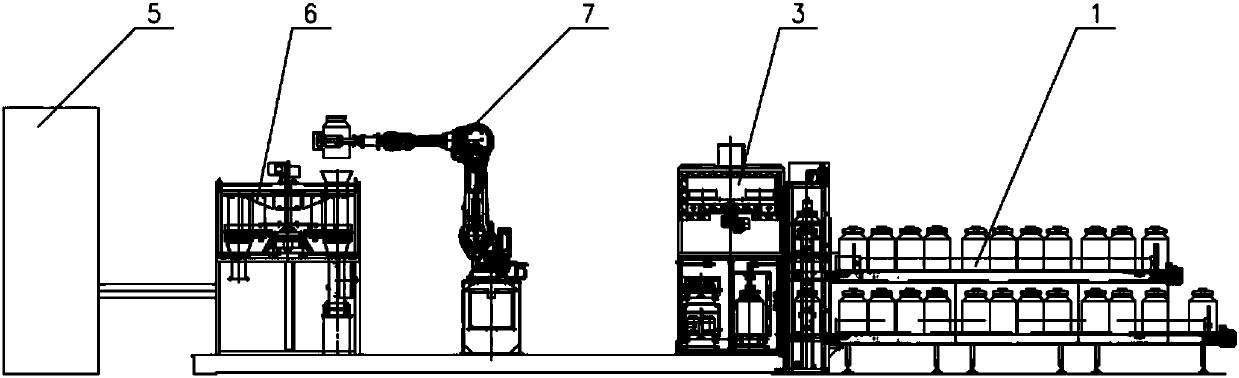

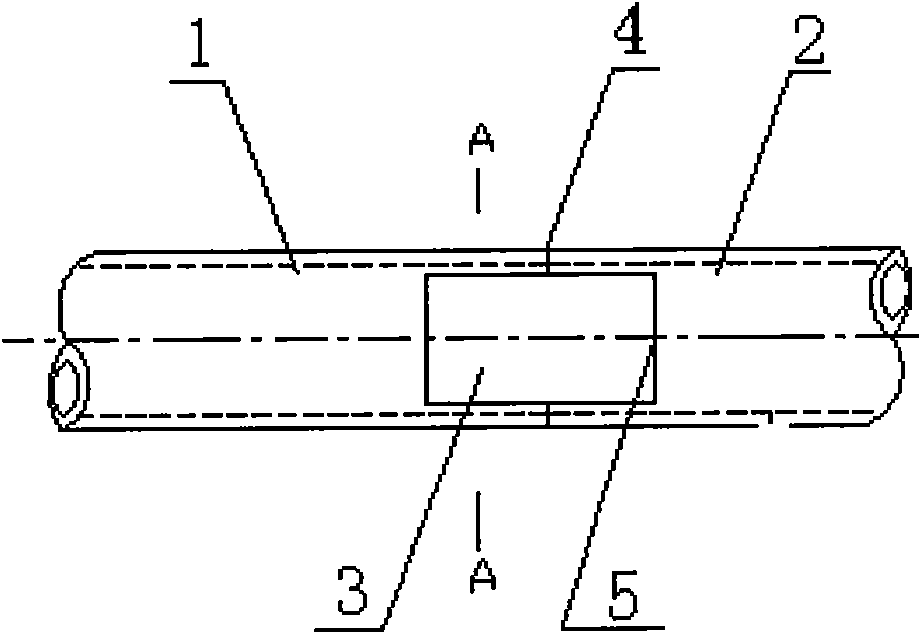

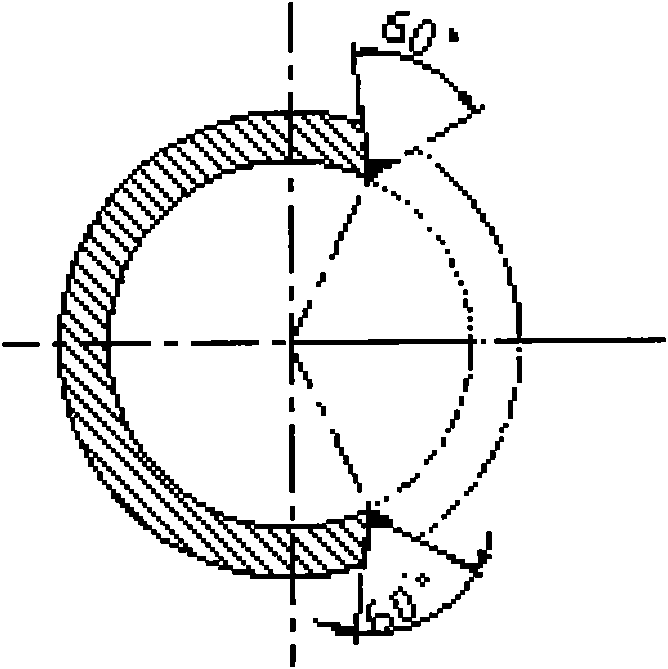

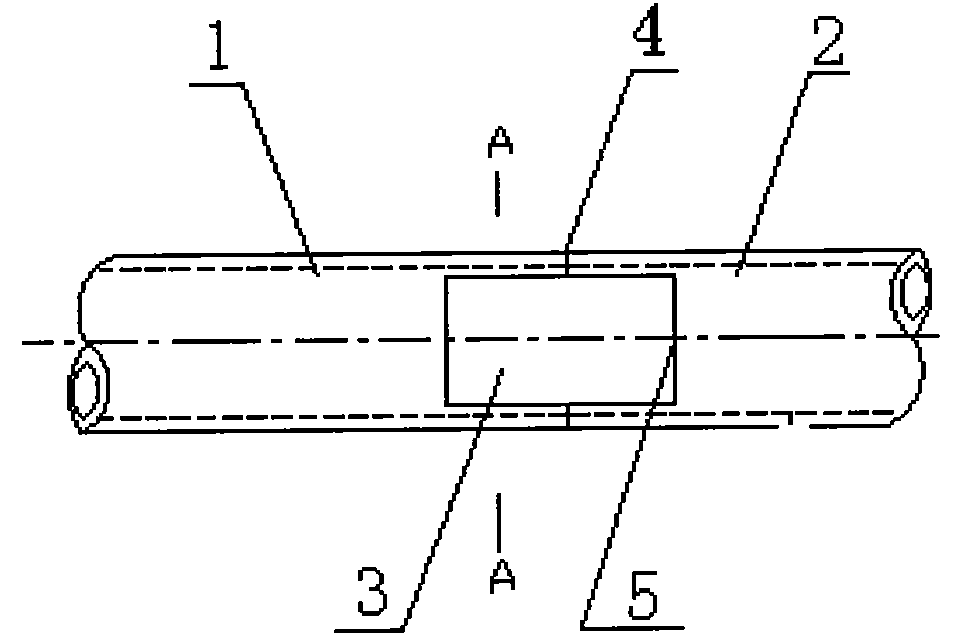

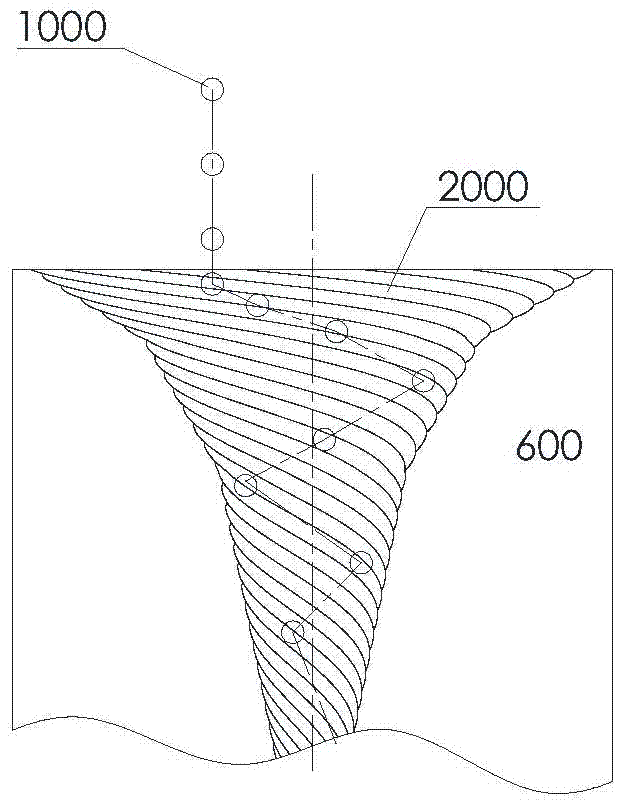

A device for preparing nonlinear dendritic wicks by selective laser melting

InactiveCN102274968AReasonable structureFast preparationIncreasing energy efficiencySelective laser meltingAssurance quality

The invention discloses a non-linear tree-shaped liquid-absorbing core device prepared by selective laser melting. , formed parts lifting cylinder, powder lifting cylinder, powder recovery cylinder; the invention can quickly prepare "tree-like structure" liquid-absorbing cores with any pipe diameter ratio and bifurcation angle, which can be used for scientific research and meet high efficiency The needs of the cutting-edge field of heat pipes; the present invention also provides a solution that utilizes a spectroscopic system and a double-scanning galvanometer system to manufacture two liquid-absorbing cores with different structures at a time, which improves efficiency while ensuring quality; Some experimental studies on liquid-absorbing cores and the preparation of high-quality liquid-absorbing core structures are of great significance; the present invention has simple structure, convenient and quick operation, low production cost, and has the value of active popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

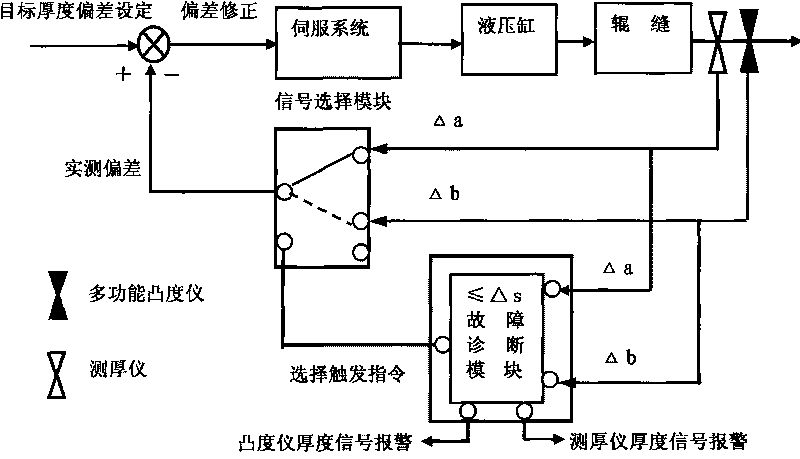

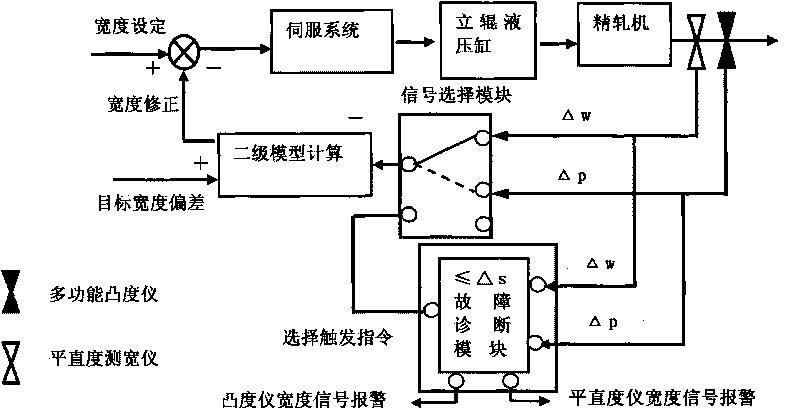

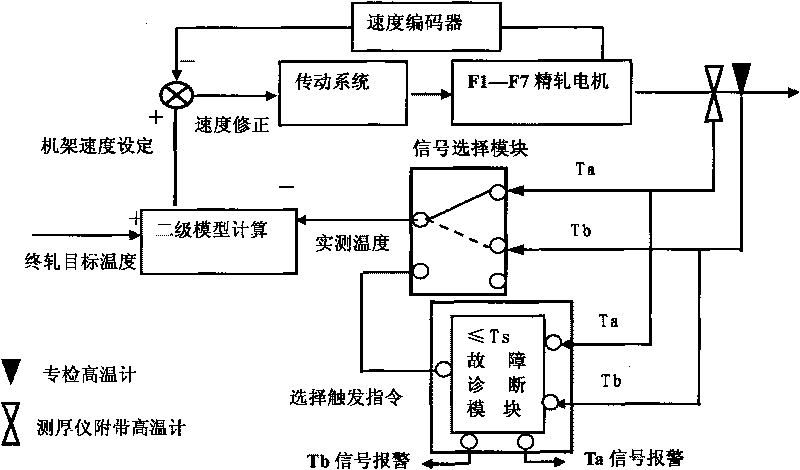

Method for realizing continuous feedback control by duality of hot finishing outlet instruments

InactiveCN101693257ATo meet the full load fast-paced high-quality rolling requirementsThe quantity configuration is reasonable and not complicatedTemperature control deviceMetal rolling stand detailsProduction lineAssurance quality

The invention discloses a method for realizing continuous feedback control by duality of hot finishing outlet instruments, which particularly includes steps that instruments used for detecting production target parameters are integrated into a hot continuous rolling production line, wherein each production target parameter is detected by at least two instruments simultaneously and utilizes identical data output modes to output, a parameter detected by one instrument of each production target parameter is utilized as a measured signal while a signal detected by the other instrument of each production target parameter is utilized as a redundant signal, the measured signal and the redundant signal are transmitted to a control system to form functions of redundantly outputting finished product key quality target detection data, mutually diagnosing the redundant signal basically and automatically and fast switching, thereby realizing closed loop control of instrument detected information continuous participating feedback, effectively guaranteeing four basic quality indexes of finished steel strips, and increasing operating rate of a rolling mill. The method plays a strong guarantee for increasing yield, guaranteeing quality and reducing waste steel rate and safety accident rate.

Owner:TANGSHAN GUOFENG IRON & STEEL

Gesture-based communication and reporting system

ActiveUS8335694B2Avoid mistakesFacilitate communicationData processing applicationsMechanical/radiation/invasive therapiesImaging qualityDocument preparation

Owner:IMPRIVATA

Abrasion-proof composite roller, board and manufacturing method thereof

ActiveCN101239382AReduce consumptionSolve the uneven distribution of hard phaseAssurance qualityAlloy

The invention discloses an abrasion-proof complex roller, plate and a producing method thereof. The device thereof comprises a metal base of the roller and the plate, a porous ceramal framework covers the working surface of the metal base. The metal on the working surface of the metal base and the porous ceramal framework are heated and melt to be a metallurgically combined integral. The invented abrasion-proof roller and plate greatly improve and increase integral abrasion-proof property and compression resistance of the complex working surface, the service life is improved by 3-5 times, metal cost is decreased by 2 times compared with parts produced by casting forge work heating processing or intensifying wearing resistance property by weld deposit. The optimal price performance can be obtained by reasonable allocation of prefabricated frameworks, and the problem that the uneven allocation of hard phase and the ratio is difficult to be controlled so that the quality is difficult to be guaranteed during particle direct permeation complex production is solved.

Owner:CHENGDU LEEJUN TECH CO LTD

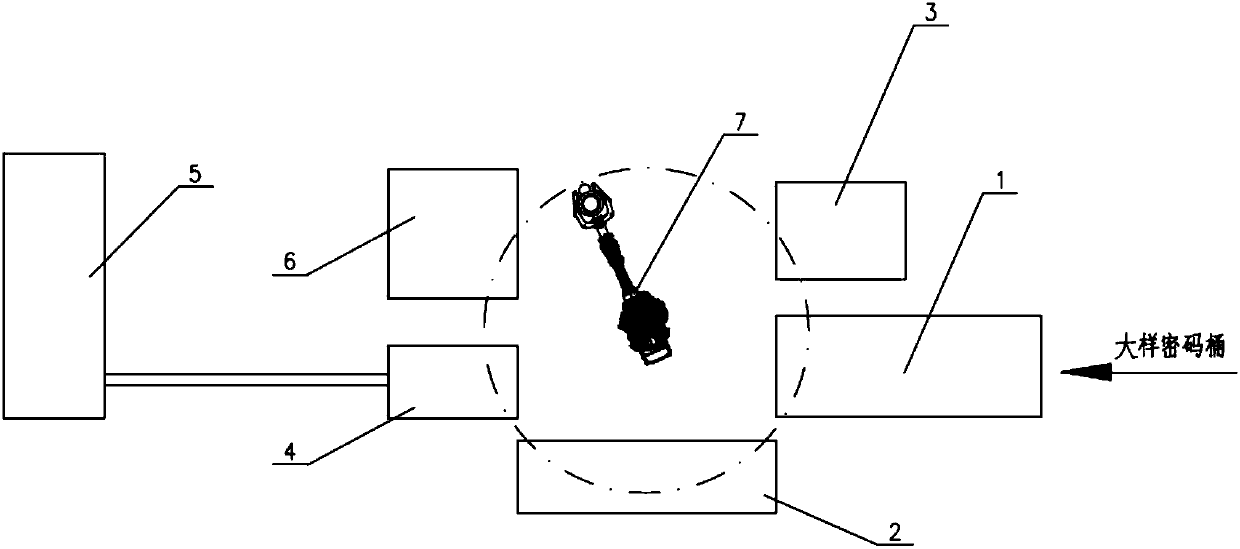

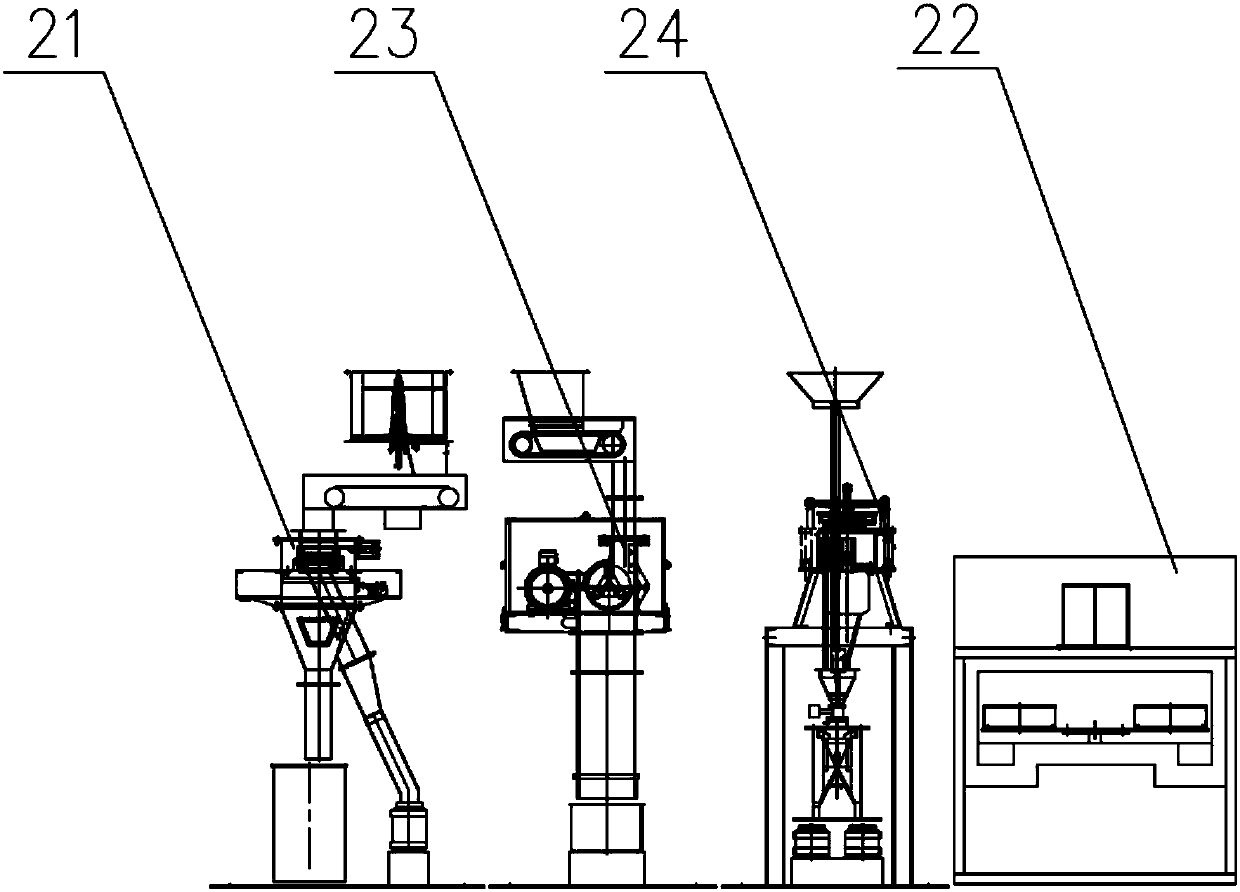

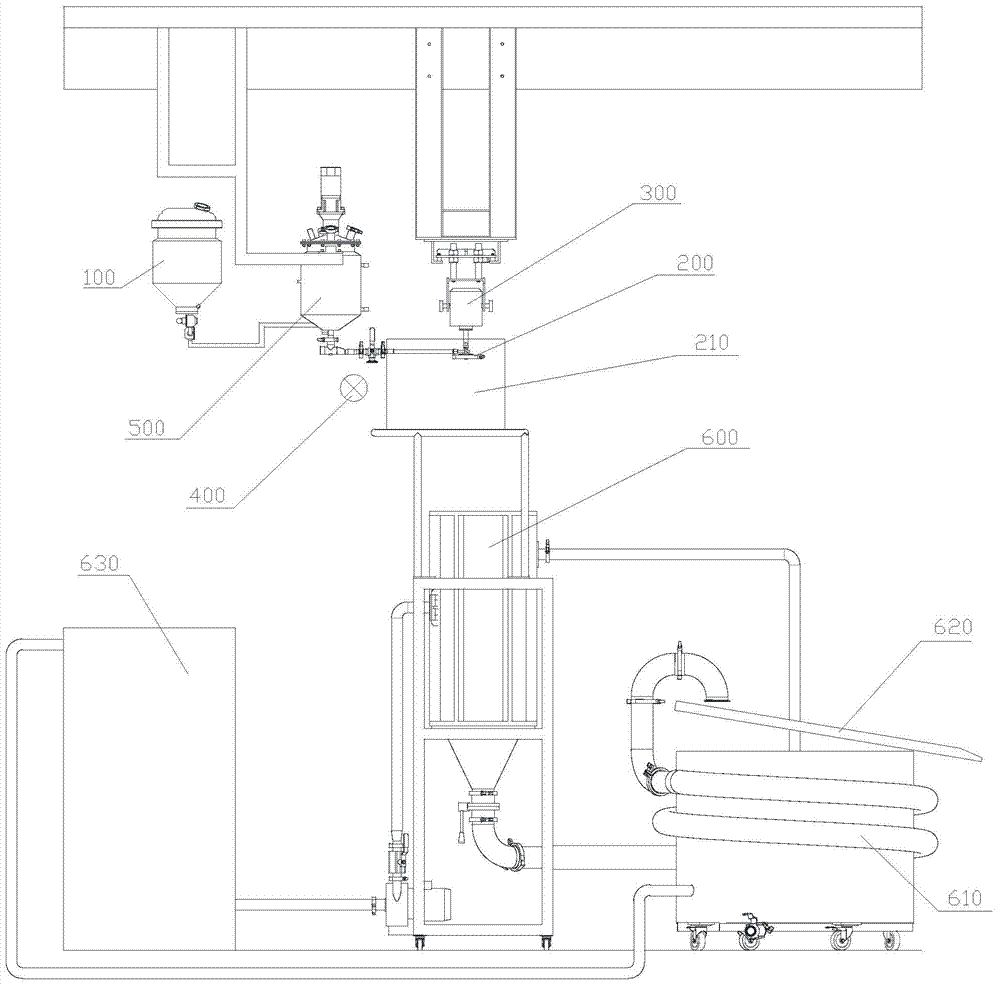

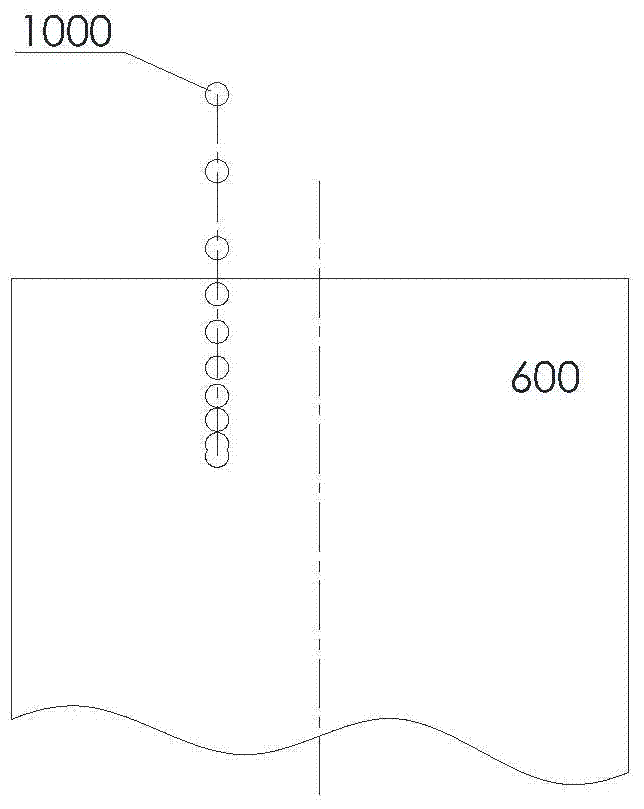

Fully-automatic intelligent sample preparation system and method

InactiveCN107643202AAvoid cross contaminationImprove the level of intelligenceWeighing by removing componentPreparing sample for investigationAssurance qualityMoisture analysis

The invention relates to a fully-automatic intelligent sample preparation system and a fully-automatic intelligent sample preparation method. The system mainly comprises a bulk sample caching and conveying module, a sample preparation module, a total moisture analysis module, a rejected sample temporary storage module, a sample bottle packaging module, a sample bottle conveying and storage moduleand an industrial robot, wherein the industrial robot is an arm type robot, and the bulk sample caching and conveying module, the sample preparation module, the total moisture analysis module, the rejected sample temporary storage module and the sample bottle packaging module are all circumferentially arranged on the working radius of a mechanical arm at intervals. A sample material is transmittedbetween the bulk sample caching and conveying module, the sample preparation module, the total moisture analysis module, the rejected sample temporary storage module and the sample bottle packaging module through the industrial robot, so that unattended fully-automatic sample preparation can be realized, various problems of conventional manual operation can be solved, total moisture analysis datais ensured to be authentic, accurate and free of bias, and coal samples for back-check necessary for a quality objection condition can be ensured in a fully-automatic sample preparation link.

Owner:WISDRI ENG & RES INC LTD

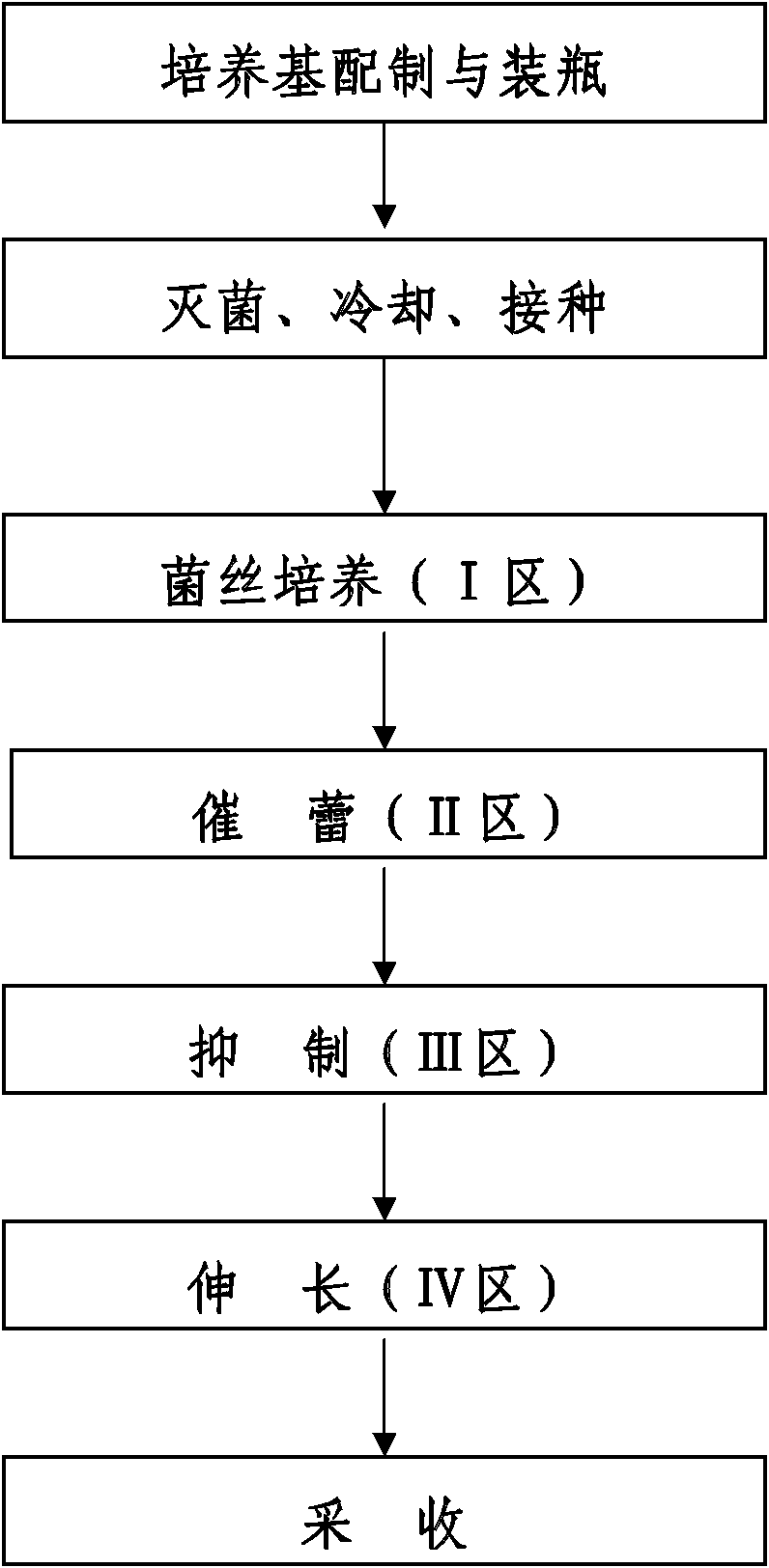

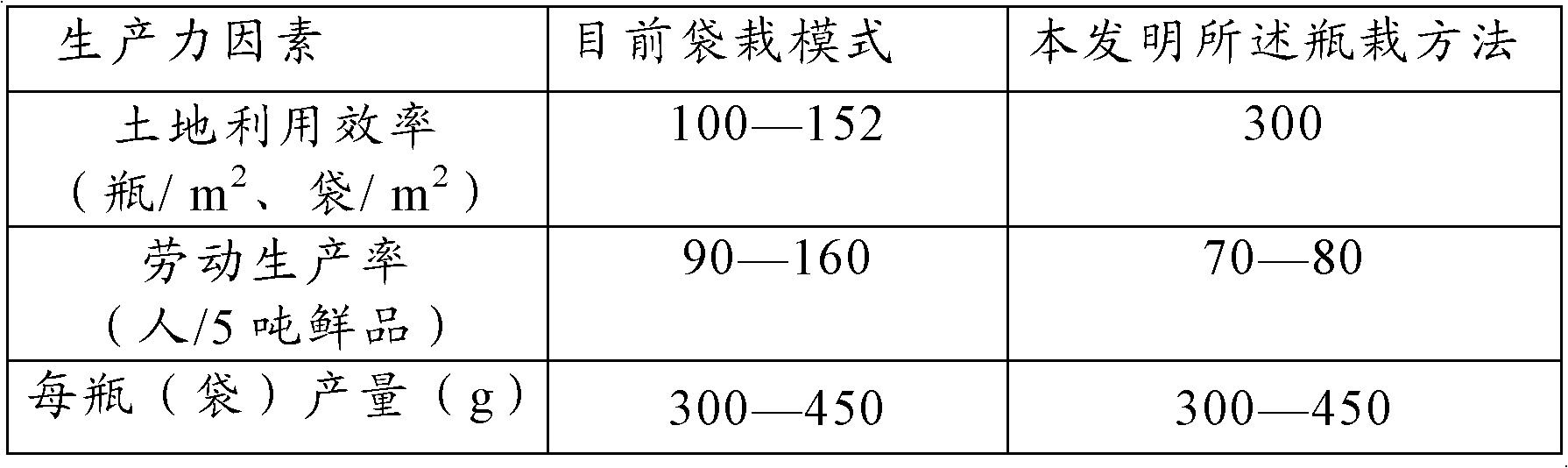

Bottle cultivation method for Hypsizigus marmoreus

The invention discloses a bottle cultivation method for Hypsizigus marmoreus. The bottle cultivation method for the Hypsizigus marmoreus comprises the following steps of: inoculating the Hypsizigus marmoreus on a bottled culture medium, wherein the inoculation ratio is that each bottle of fungal strains are inoculated on 32 to 40 bottles of culture bottles; performing mycelium culture under the conditions of temperature of between 18 and 25 DEG C, humidity of 60 to 80 percent and CO2 concentration of 1,500 to 5,500 ppm; after the Hypsizigus marmoreus are matured, performing mycelium stimulation and supplementing a small amount of water; performing inducement to primordium; after mushroom buds are generated, performing inhibition period culture for 3 to 5 days; when the mushroom buds grow out of the bottleneck, sleeving a plastic sleeve; performing elongating stage culture; and harvesting after the harvesting standard is reached. In the bottle cultivation method, the period is 105 to 125 days and average yield of a single bottle is 300 to 450g. The bottle cultivation method is a factory-like bottle cultivation method using sawdust, cotton seed hulls and corn cobs as main raw materials. By the bottle cultivation method, the mechanization level and the automation degree of the Hypsizigus marmoreus can be increased greatly; production cost is effectively reduced; stable quality isguaranteed; and a popularization prospect is achieved.

Owner:郑雪平

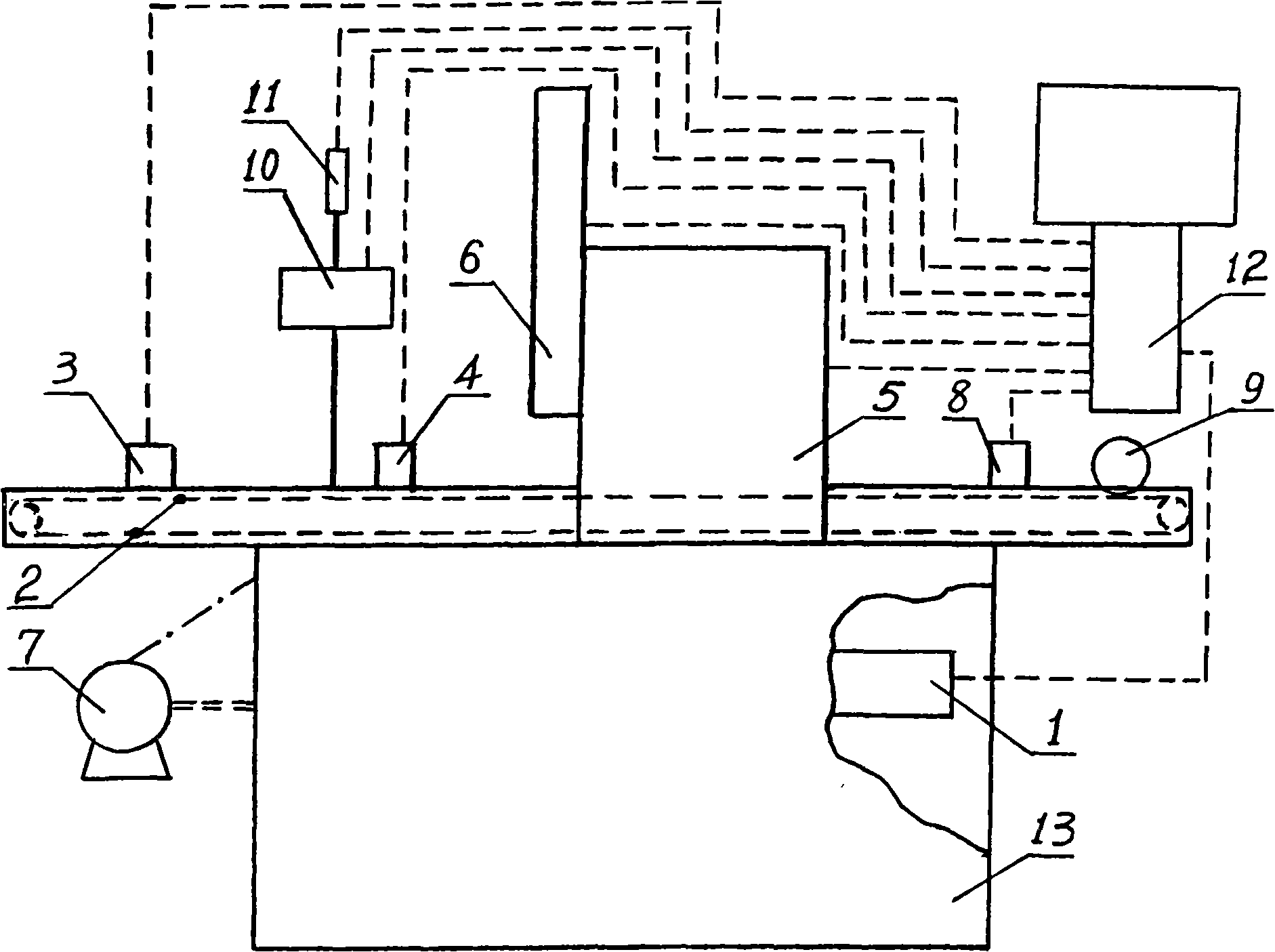

Full-automatic apparatus for printing label for blood products

InactiveCN101269711APrinting and labeling process is smoothLabelling non-rigid containersLabelling machinesElectricityWhole blood product

A full automatic blood product labeling device with printed labels of the invention relates to the technical field of mechanics. A cabinet bracket body is fastened with a controller, a conveying belt, an initiation and a terminal scanners, a trigger switch, a printer, a labeler, a press roll, a display screen and an alarm. A slide groove of the printer is moveably connected with a labeler slide rail, and the printer and the labeler are connected with an air compressor pipe. The controller, the initiation and the terminal scanners, the trigger switch, the printer, the labeler, the display screen and the alarm are connected with a computer, and the controller is also electrically connected with an air compressor. The computer receives signals collected by the initiation and the terminal scanners and the trigger switch and sends commands to the controller, the printer, the labeler and the display screen, and also receives feedback performed by the printer and the labeler and signals identified by the terminal scanner and sends commands to the display screen and the alarm. The controller controls the printer, the labeler and the air compressor. The device is used for printing labels for blood products and labeling the products, and the automatic production ensures the quality, high efficiency and the accuracy.

Owner:余晋林

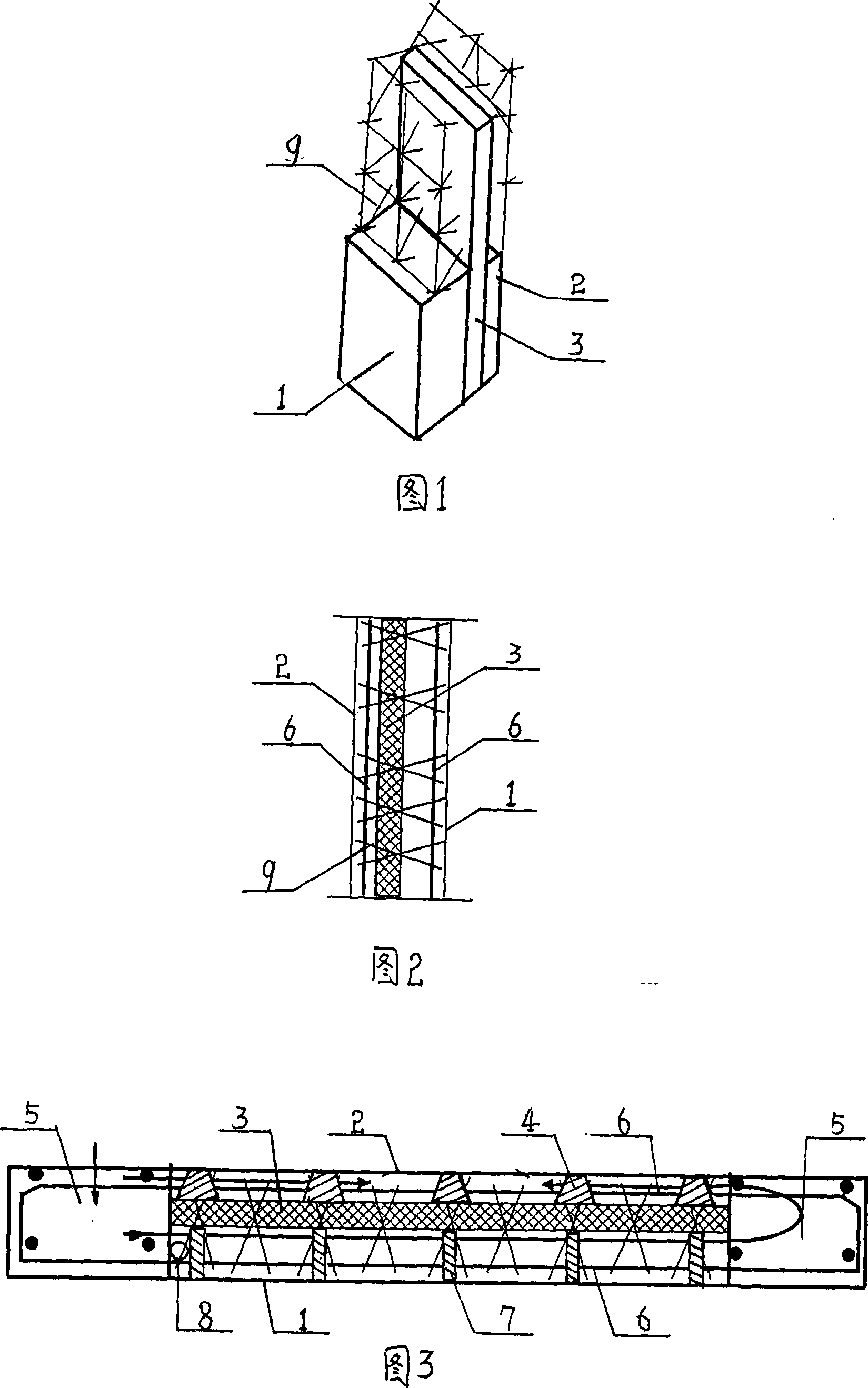

Double-side in-situ placing construction method for CL structure system composite wall board concrete

The present invention relates to the building construction technique filed, concretely to a construction method for two-side in-place-casting the CL structure system composite wall plate concrete, the invention settles the problems of high construction and transportation cost, large installing difficulty, weak wholeness and hard guaranteeing the construction quality caused by that the existing CL structure system composite wall plate adopts single-side prefabricating and single-side casing-in-place, and the method comprises the steps of CL rack board manufacturing and baiting; directly prefabricating the square pyramid concrete cushion block on the polystyrene board of the inner wall side CL rack board; CL rack board installing and tying to the steel bar of the edge component; arranging the formwork of the wall; prefabricating the rectangular concrete cushion block, before the closing of the formwork inserting a rectangular concrete block with position corresponding with the square pyramid concrete cushion block at the side of the CL rack board of the exterior wall side, and the concrete of inner wall and exterior wall is simultaneously casted. The invention has the advantages of simplifying the construction working procedure, reducing the quality control point, guaranteeing the quality, shortening the construction time for a large scale, increasing the economic benefit, and the wall concrete has the advantages of compactness, good whole structural property and smooth external appearance.

Owner:CHINA RAILWAY 12TH BUREAU GRP

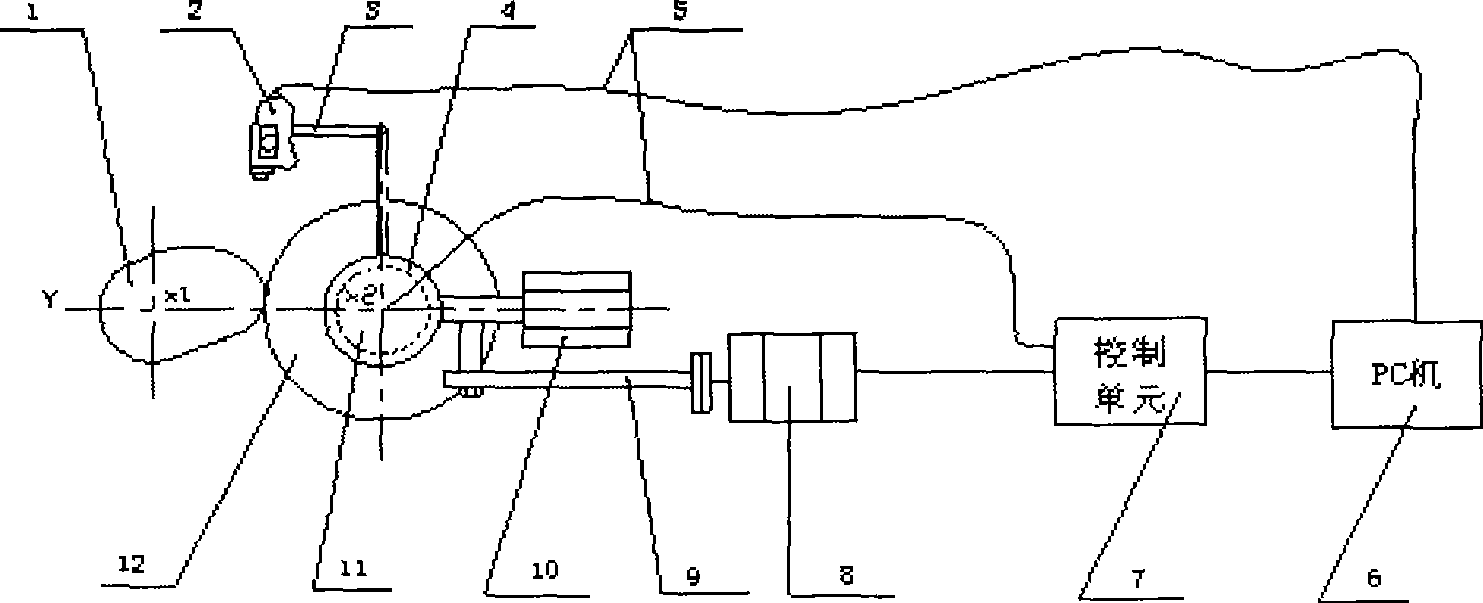

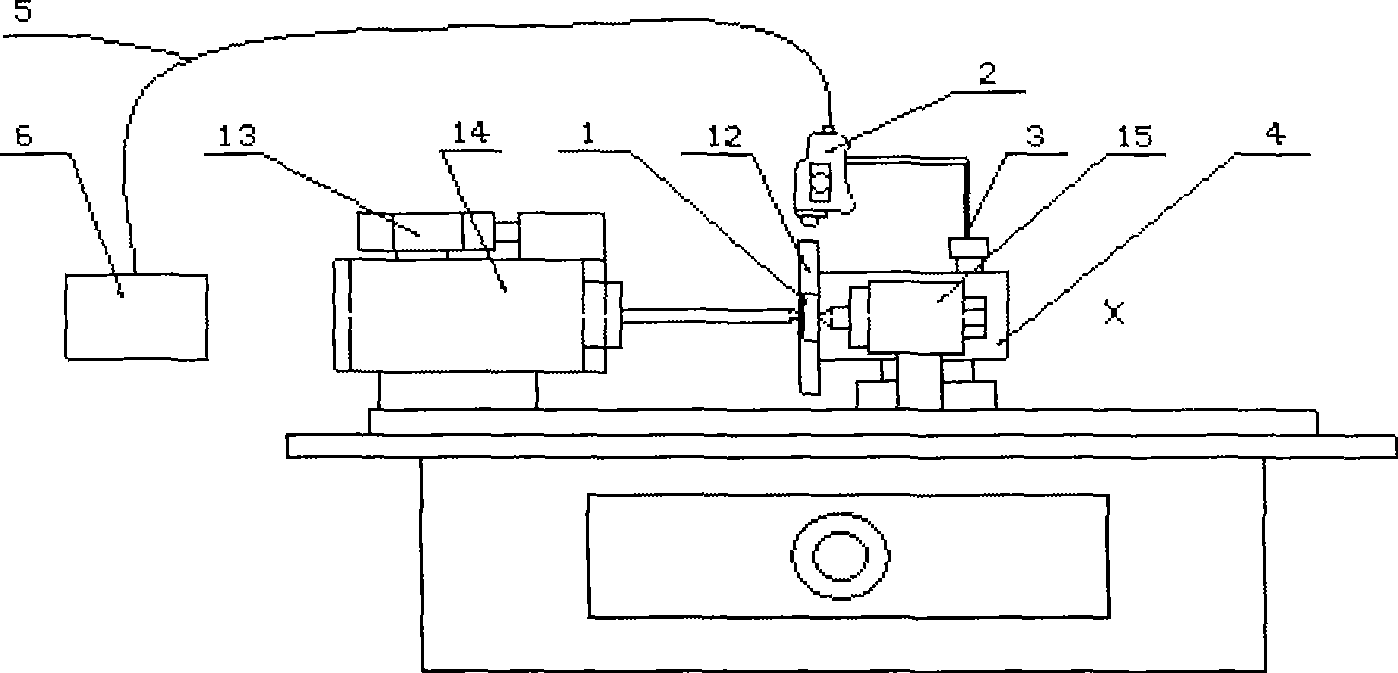

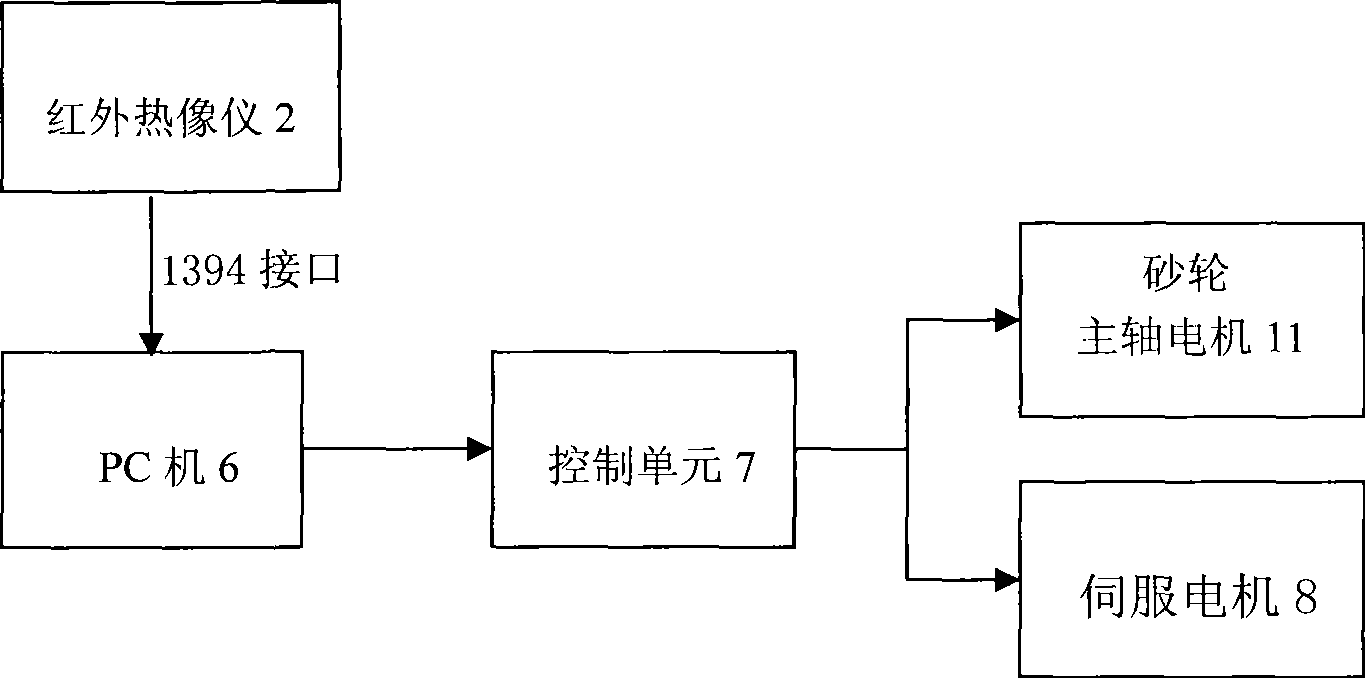

Cam grinding control system and method based on PC and infrared thermal imaging system

InactiveCN101396807ADoes not affect processingBelt grinding machinesGrinding feed controlControl systemAssurance quality

The invention discloses a cam grinding control system and a method on the basis of a PC and an infrared thermal imager. The system comprises a cam to be processed, a grinding wheel bracket, a PC machine, a control unit, a servo motor, a ballscrew, a linear motor, a mainshaft unit and a grinding wheel; the infrared thermal imager is fixedly connected with the grinding wheel bracket by a connecting rod; the camera of the infrared thermal imager aims at the processing surface of the grinding wheel; the output port of the infrared thermal imager is connected with the PC machine by a 1394 interface; the method uses the temperature field data at the processed area of the grinding wheel measured by the infrared thermal imager as the input variable, and dynamically tracks and adjusts the rotation speed of the grinding wheel mainshaft unit and the feeding quantity of the grinding wheel by a fuzzy control algorithm carried out by the PC machine, thus reasonably applying the grinding process with ensured quality and achieving the control in real time is carried out while the processing efficiency is ensured.

Owner:SHANGHAI UNIV

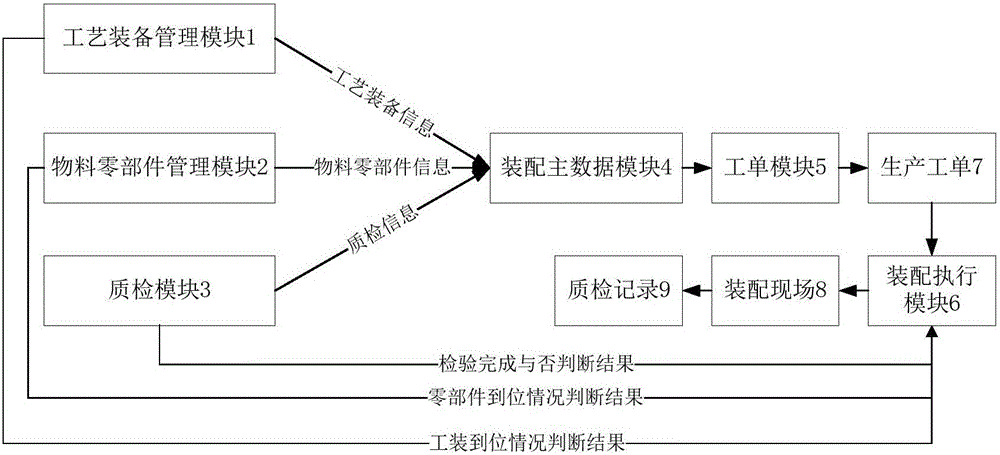

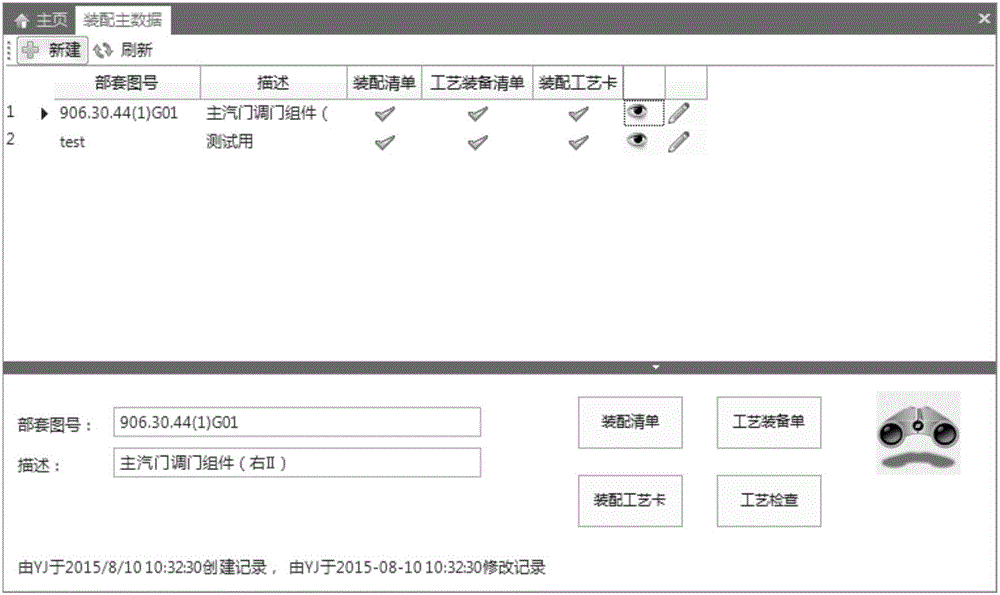

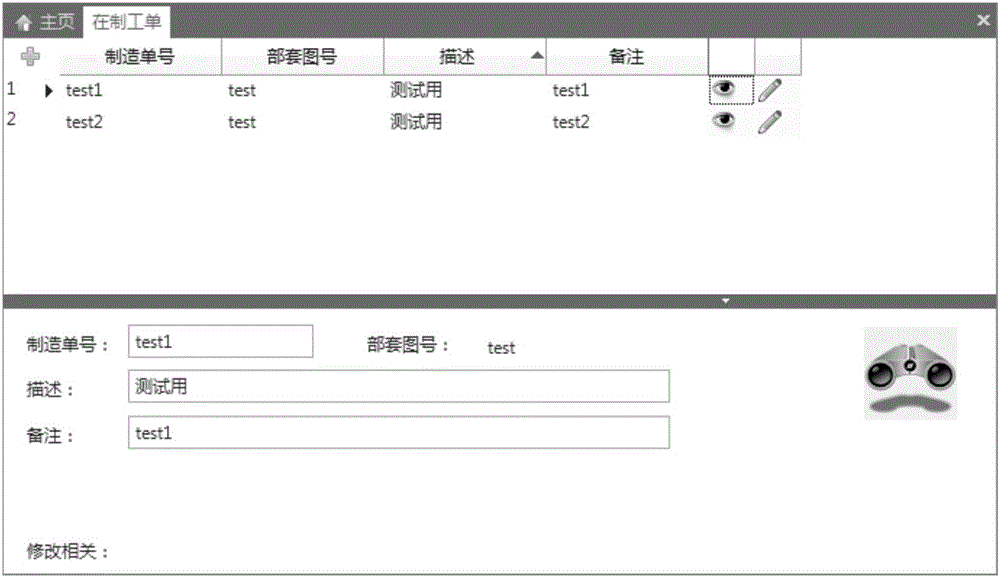

A project-type product assembling process management and control system

ActiveCN106155016AAssembly precisionAvoid missingTotal factory controlProgramme total factory controlProcess equipmentProject type

The invention provides a project-type product assembling process management and control system. An assembly execution module is a general basis to guide field assembly; a material component management module displays the type, quantity and other technical requirements of material components needed for each process step, judges whether the material components are in place according to an actual delivery situation and passes the results to the assembly execution module; a process equipment management module shows the type and quantity of process equipment needed for each process step, determines whether the process equipment is in place according to on-site equipment, actual distribution and application conditions and passes the results to the assembly execution module; a quality inspection module provides inspection items in an assembly process in each process step and passes test results to the assembly execution module; an assembly master data module contains a lot of assembly item information; and a work order module associates the information in the assembly master data module with a work order, and then passes the information to the assembly execution module to guide the field assembly. The project-type product assembling process management and control system of the invention guides on-site assembly operation, performs quality inspection, records the process information and solves the problems of wrong assembly and missed assembly to ensure the quality.

Owner:SHANGHAI JIAO TONG UNIV

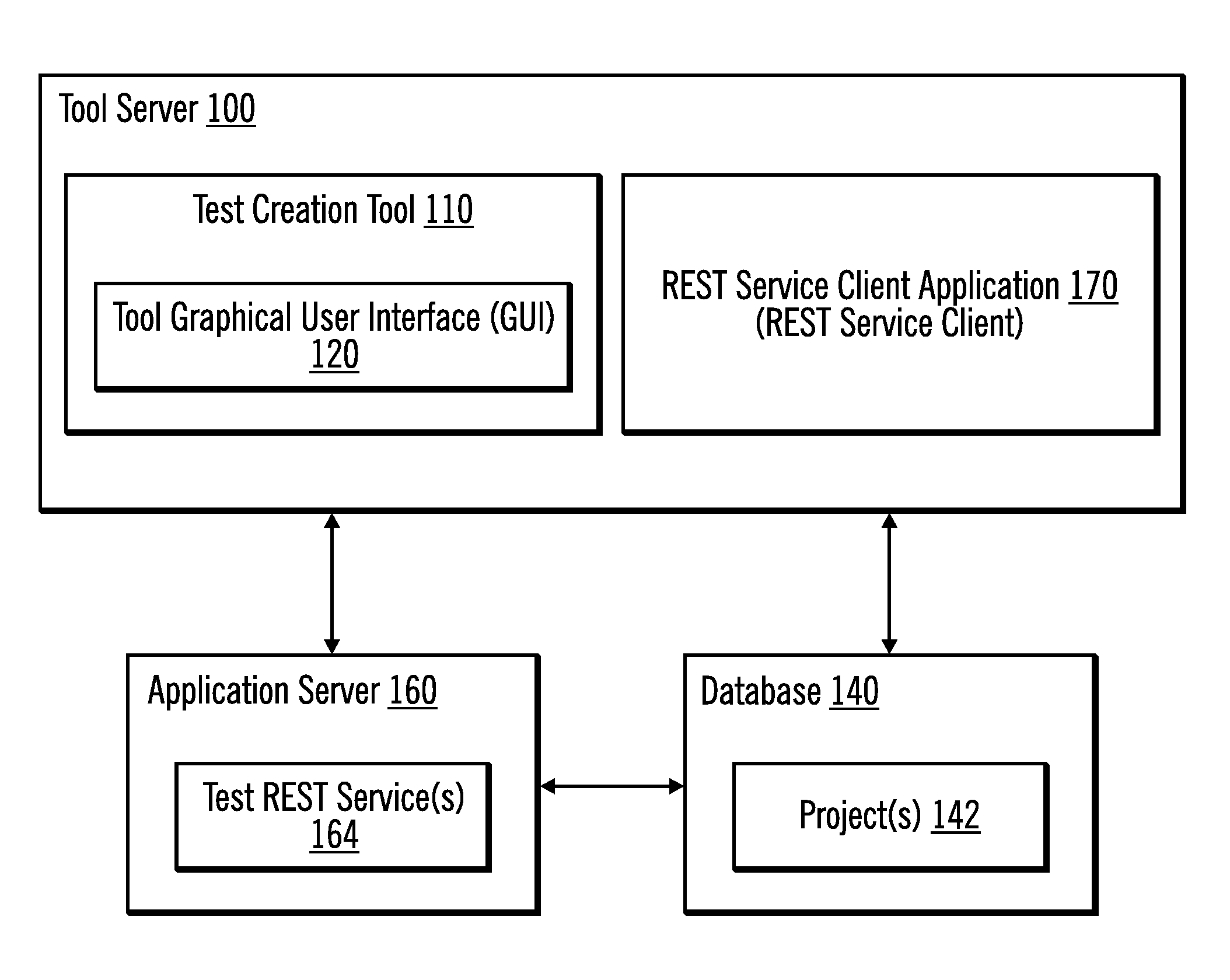

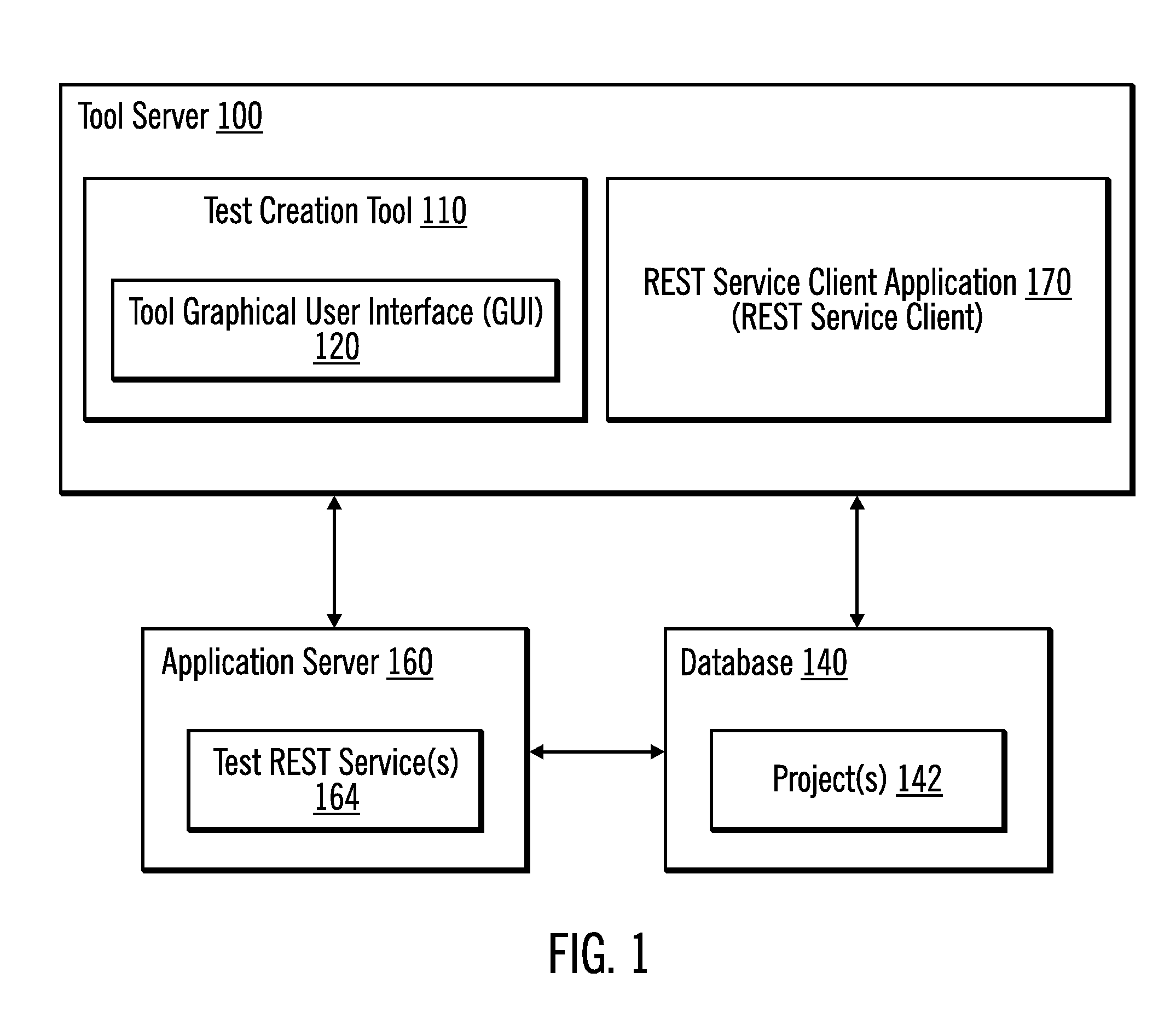

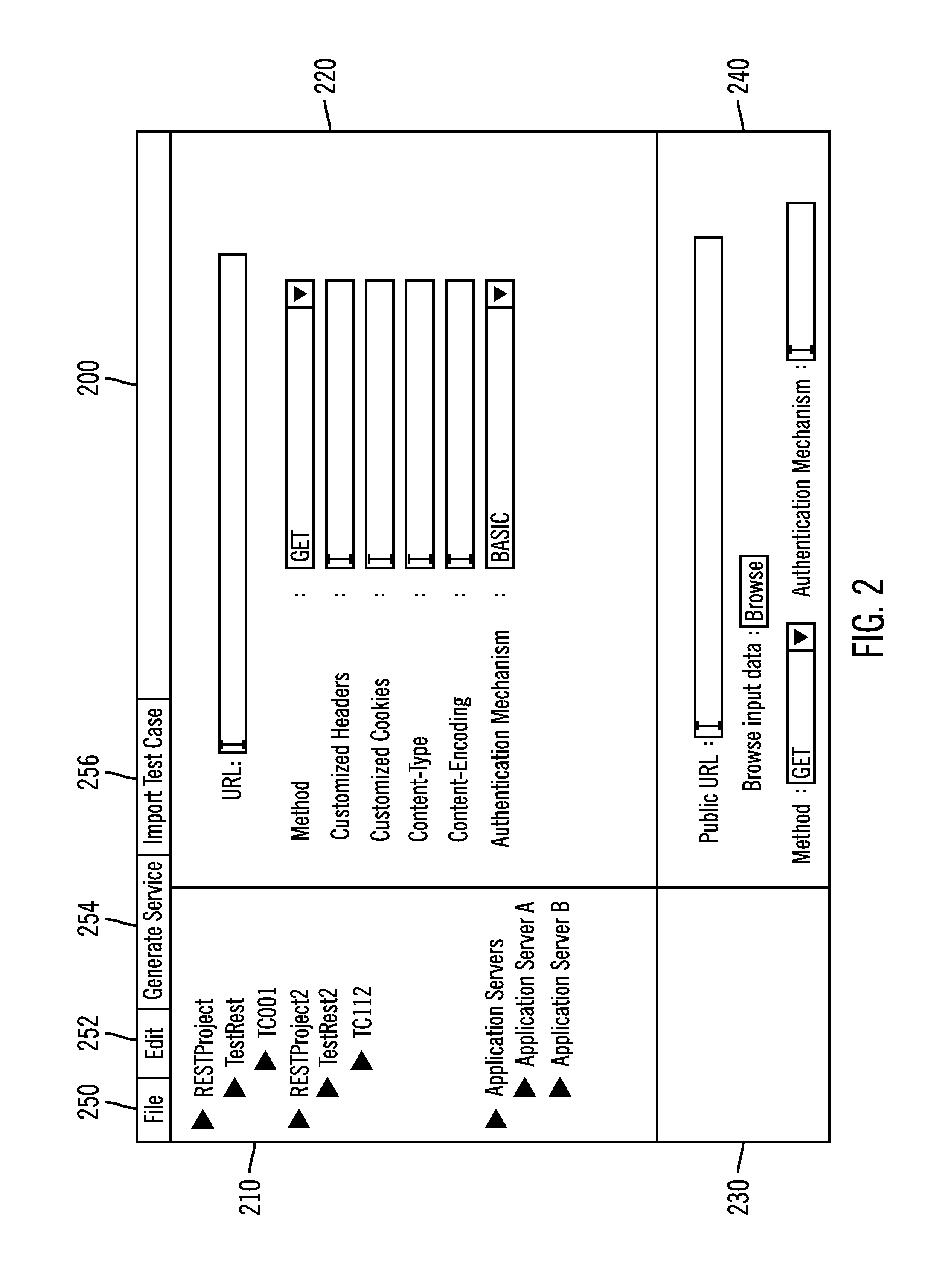

Auto-generating representational state transfer (REST) services for quality assurance

Provided are techniques for auto-generating Representational State Transfer (REST) services for quality assurance. One or more test cases and artifacts are received for a project. A test Representational State Transfer (REST) service is generated for the project using the one or more test cases and the artifacts. The test REST service is deployed on an application server for use in testing features of a REST service client application.

Owner:IBM CORP

Welding method for overhaul of furnace chamber heat exchange tube

InactiveCN101767260AEasy to operateImprove maintenance efficiencyWorkpiece edge portionsWelding apparatusButt weldingAssurance quality

The invention discloses a welding method for overhaul of a furnace chamber heat exchange tube, comprising a butt joint A, a butt joint B and a butt welding line, a cover board is arranged between the butt joints tangentially, an inner beveled edge with a certain angle is milled at the joint edge position of the butt joint A and the butt joint B, the contact parts of the cover board and the butt joints are respectively milled into outer beveled edges with a certain angle; the butt joint A and the butt joint B are assembled, the butt welding line is welded, and then the cover board and the cover board welding line at the joint position are assembled, after welding is carried out, and the welding is qualified through nondestructive examination, banding and heat treatment are carried out to the whole welding line and are qualified, system pressure test is carried out; when in construction, the heat exchange tube does not need to be changed in a large area, after defect part is examined, the heat exchange tube is changed locally by adopting the method, before construction, standard and interchangeable joints and the cover board can be machined according to pipe diameter, material quality and specification and the like by a drawing after the defect part is examined, the operability is strong, the overhauling efficiency can be greatly improved and the quality is ensured simultaneously.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD +1

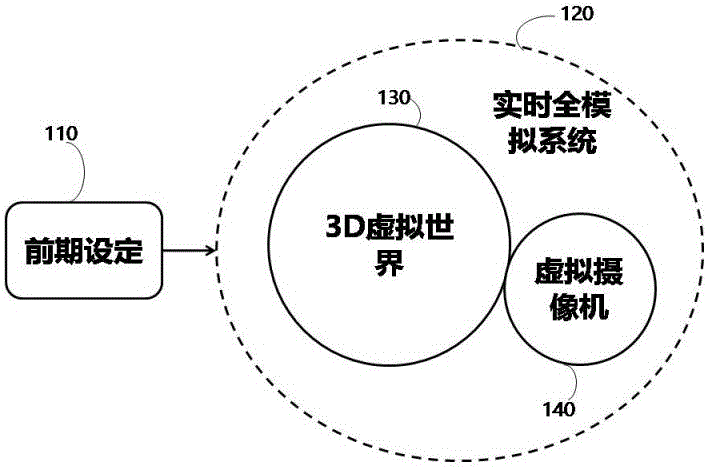

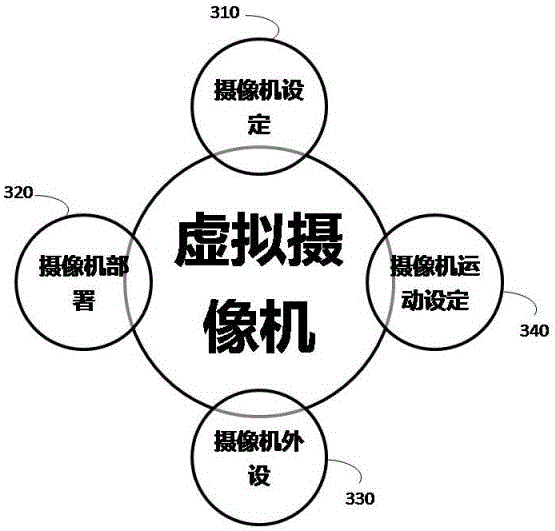

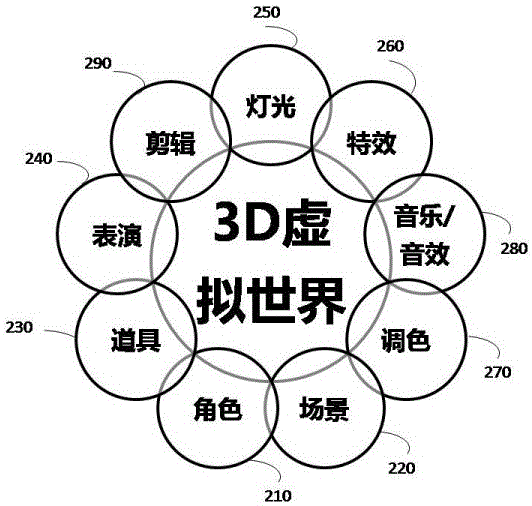

Real-time full-simulation animated film making method and real-time full-simulation animated film making system

The invention discloses an animated film making method process and an animated film making system based on a real-time rendering system. According to the animated film making method process and the animated film making system, a plurality of real-time dynamic virtual worlds are constructed for animated film making, and system mated virtual cameras are used for shooting the real-time simulated dynamic virtual worlds so as to complete making of a whole animated film. The animated film making method process and the animated film making system have the advantages that animated film making efficiency is improved greatly on the premise of guaranteeing quality, cost is reduced, wider creative spaces and higher freedom degree are provided for directors and photographers, and a whole film making process is visual in real time and flexibly adjustable at any time.

Owner:北京中科深智科技有限公司

Pickling material

ActiveCN101301065AIncrease exchange speedImprove permeabilityFruits/vegetable preservation using acidsMeat/fish preservation using acidsSodium BentoniteAssurance quality

The invention provides an auxiliary material for food pickling in the field of food, in particular a pickling material. The pickling material is prepared by mixing, based on the proportion by weight,50 to 60 parts of salt, 10 to 20 parts of bentonite, 5 to 15 parts of medical stone granules, 5 to 15 parts of dried jujube wood granules and 5 to 10 parts of lime. The inventive pickling material is used for pickling food to increase the exchange speed of salt and water in the food, improve the penetrability of salt, shorten the pickling period, ensure the quality, prolong the shelf life, and improve the grade. The pickling material is suitable in the pickling process of vegetable and meat.

Owner:王大帅

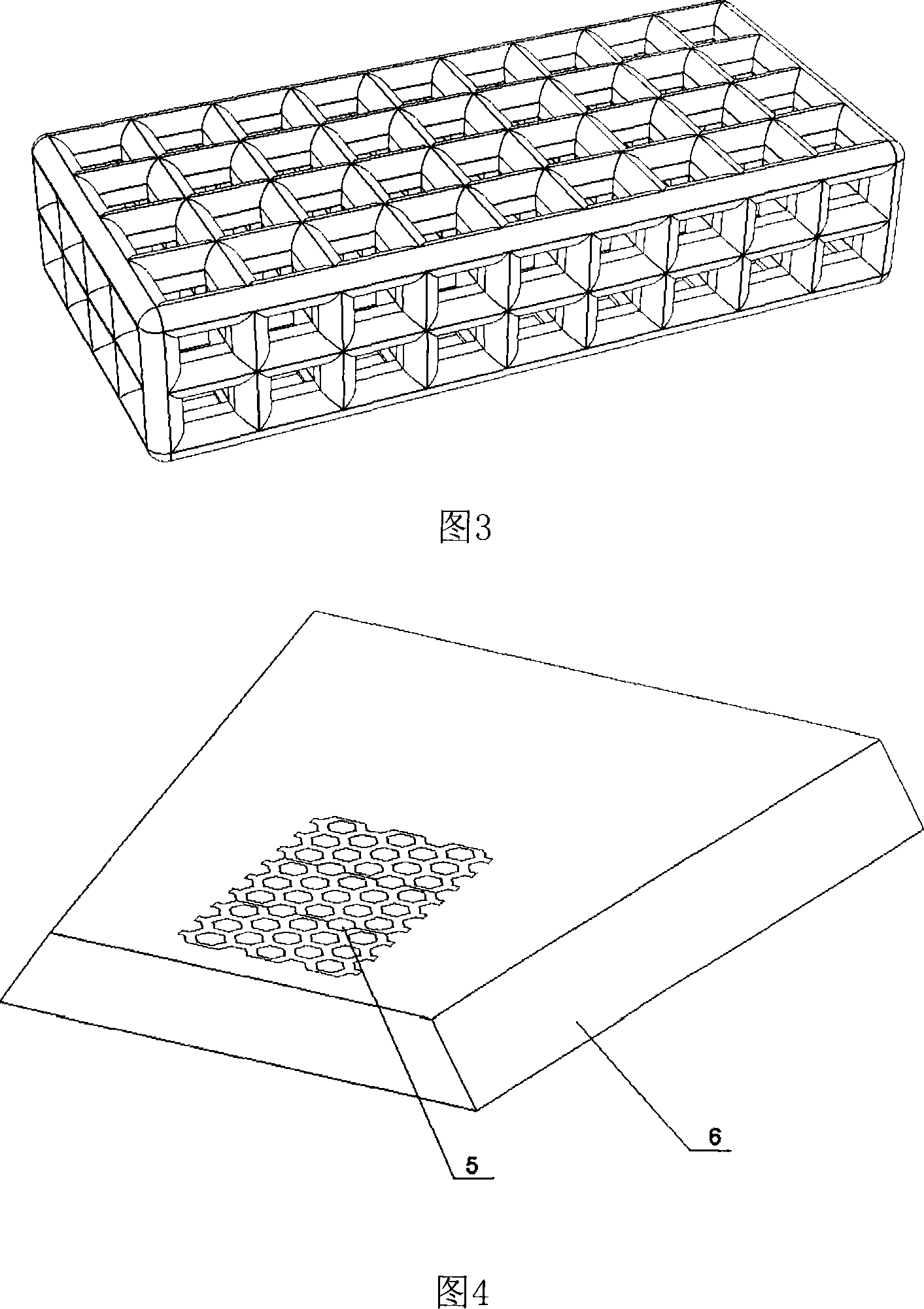

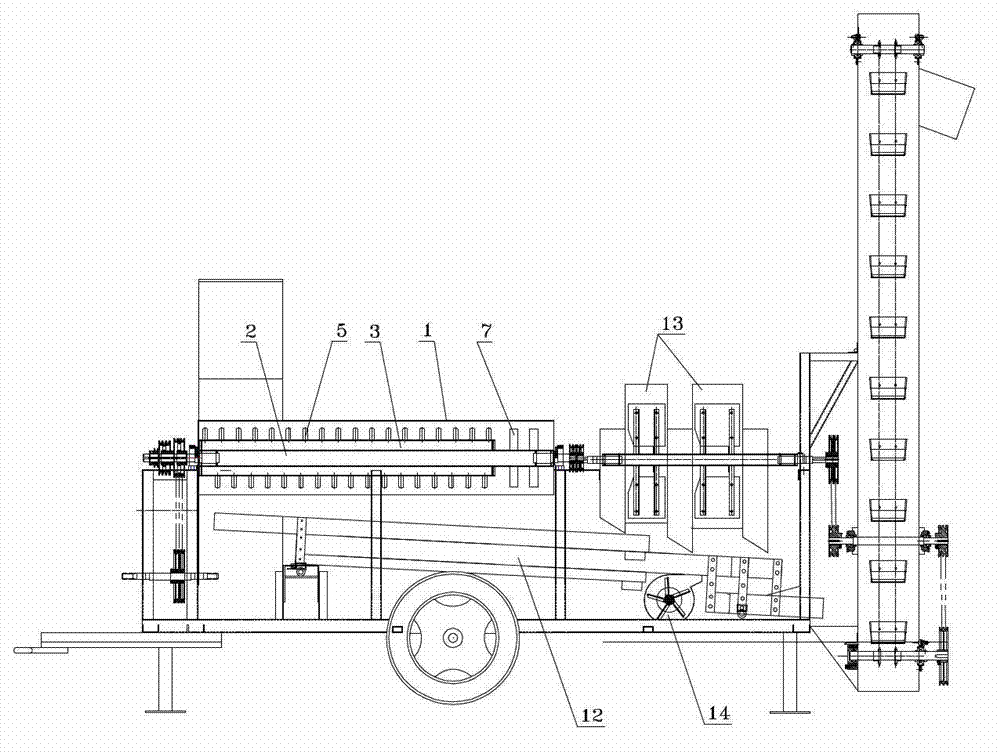

Grinder for charging roller of full-automatic printer

InactiveCN101695826AReduce labor intensityIncrease productivityLapping machinesAssurance qualityMagnet

The invention discloses a grinder for a charging roller of a full-automatic printer, which comprises a loading device, a material receiving and grabbing device, a grinding device, a grabbing and unloading device and a loading and unloading air cylinder stand, wherein the loading device comprises a fixing feeding plate and a movable feeding plate, a plurality of array-type jagged tooth slots are arranged on the loading device, and the movable feeding plate is connected with a lifting air cylinder; and the material receiving and grabbing device comprises a loading claw and a permanent magnet, the loading claw is connected with an air cylinder of the loading claw, and the permanent magnet is connected with a driving air cylinder of the permanent magnet. In the grinder for the charging rollerof the full-automatic printer, the whole process of loading and unloading adopts a structure of 'a jagged array-type feeding plate' and 'a combination type of the loading claw and the permanent magnet' to realize quick and convenient action and high repeated positioning accuracy in the processes of loading, grabbing, feeding, unloading and integral operation, and due to the reduction of manual operation, quality stability is guaranteed and safety is increased.

Owner:安徽尚美电气科技有限公司

Nutritional equilibrium and comprehensive breakfast instant block and preparation method thereof

InactiveCN101185522AScientific and reasonable collocationNutritional diversityFood preparationAdditive ingredientBifidus factor

The invention relates to a fast breakfast food cake with balanced and complete nutrition. The invention comprises aging superfine full wheat powder of 2.5-3.5 portions by weight, compound superfine vegetable powder of 1-1.5 portions, compound albumen powder of 2-3 portions, compound superfine fruit powder of 1-2 portions and aging superfine brown rice powder of 2.5-3.5 portions. The invention also discloses the preparation technique of the fast breakfast food cake. The invention not only guarantees the energy supply but also is rich in protein, dietary fiber (including pectin substance), vitamins, mineral substances and oligosaccharide (bifidus factor) , etc. which are reasonably assorted and present full nutrition. The product of the invention also has the advantages of handy and convenient making, being portable, safety and hygiene, long quality guarantee period, clear color difference in different layers and appetite inspiration, etc. and solves the deficiencies of troublesome preparation of traditional breakfast, undiversified nutrition, insufficient or excessive of the absorption of food of carbohydrate or protein and that the quality and quantity of fruits and vegetables are difficult to be guaranteed in breakfast.

Owner:UNIV OF JINAN

Aluminum alloy refueling truck coating process

The invention discloses an aluminum alloy refueling truck coating process. The process includes the following operation steps of 1, cleaning and oil removing: 1.1, using cleaning cloth and the like to clean obvious sundries on the surface of a complete truck without obviously damaging a tank and the surface of a frame; 1.2 before workpieces are coated, checking the tank and the surface of each workpiece, performing ungrease treatment on local oil stains, coating the surfaces of the oil stains with a diluent to wash the oil stains, checking cleaning parts after the surface of the diluent is dried, and cleaning again if the surfaces still have oil stains; and 2, wiredrawing treatment: 2.1 performing polishing and sgraffito treatment on aluminum alloy and stainless steel surfaces with abrasive paper as uniform as possible. The aluminum alloy refueling truck coating process is simple and good in effect, cost is lowered, and quality is guaranteed.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Liquid cooling dropping pill production line

InactiveCN104274327AReduce impactSmooth feedingPharmaceutical product form changeMelting tankEngineering

The invention provides a liquid cooling dropping pill production line, which comprises a dropping pill system, a liquid cooling circulation system and a control system, wherein the dropping pill system comprises a material melting tank and a dropper connected with the material melting tank, a vibration device is arranged between the material melting tank and the dropper, an on-line monitoring device is arranged on the dropper, the on-line monitoring device comprises a pulse signal emitting mechanism, the emitting frequency of the pulse signal emitting mechanism is identical to the vibration frequency of the vibration device, and the control system controls and regulates dropping parameters according to the monitoring results of the on-line monitoring device. The liquid cooling dropping pill production line has the advantages that the high-frequency cutting dropping is combined, the dropping pill quality is detected in real time on line and is controlled and regulated, the yield is improved, and the drilling pill diameter range is expanded; a plurality of tangential inlets are formed inside the tank wall of a cooling tank, and the impact force caused by cooling liquid surface on liquid drips when the liquid drips enter the cooling tank can be effectively reduced; the swarming and the pulse can be effectively eliminated, so the material conveying of a dropping pill machine is stable; the dropping pill cooling time is increased through regulating the length-to-diameter ratio of a discharging pipeline, the quality is ensured, and meanwhile, the energy consumption is reduced.

Owner:TIANJIN TASLY PHARMA CO LTD

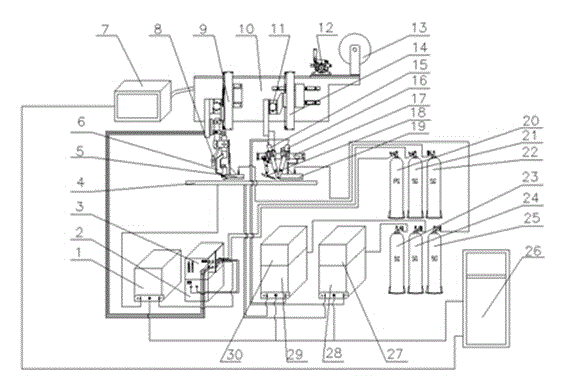

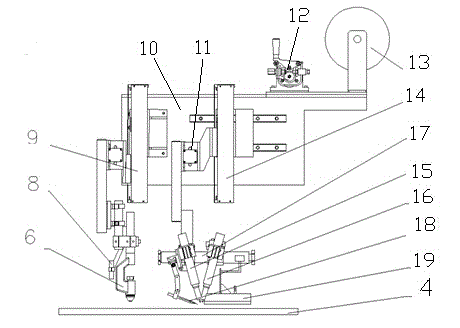

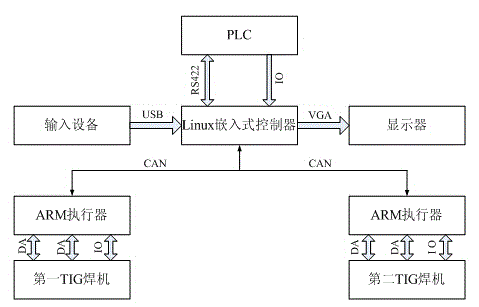

Plasma and dual TIG (tungsten inert gas) composite welding device and method of medium plate

ActiveCN104308380AAvoid interferenceFlexible process parameter settingWelding apparatusAssurance qualityProgrammable logic controller

The invention provides a plasma and dual TIG (tungsten inert gas) composite welding device and method of a medium plate, and belongs to the technical field of plasma and TIG welding equipment and method. The device and the method are used for improving the efficiency and welding quality of plasma and TIG welding of the medium plate. The technical scheme is that two TIG welding machines are combined with a plasma welding machine; cooperative control parameters of dual TIG welding are adjusted by a programmable logic controller (PLC), a Linux embedded controller, a CAN bus and an ARM executor so as to realize the cooperative control requirements. According to the device and the method, the plasma and TIG composite welding advantages are fully exerted; the problems that the plasma welding efficiency of the medium plate is low and the quality is difficult to guarantee in the prior art can be solved; the device and the method are innovation of a plasma and TIG composition welding technology. The plasma welding efficiency of the medium plate is effectively improved; the welding quality is guaranteed; the production development requirements can be met; the device and the method have obvious economic effect.

Owner:TANGSHAN KAIYUAN WELDING AUTOMATION TECH INST

Automatic material loading and taking device for LED lamp heat dissipation cup injection molding

InactiveCN105904684AReduce labor intensityIncrease productionCoatingsAssurance qualityWork in process

The invention discloses an automatic material loading and taking device for LED lamp heat dissipation cup injection molding. The device comprises a molding rotary table on which three molding molds are uniformly distributed in a circumferential direction, an automatic loading mechanism arranged corresponding to a loading station of the molding rotary table, and an automatic unloading mechanism arranged corresponding to an unloading station of the molding rotary table; the automatic loading mechanism includes a lifter for lifting semi-finished LED lamp heat dissipation cups to a rotary table feeder, a material separation structure for separating the semi-finished LED lamp heat dissipation cups output by the rotary table feeder into at least two rows, a material channel conveying structure for conveying the at least two rows of semi-finished LED lamp heat dissipation cups according to corresponding material channels, and a loading manipulator for grabbing the semi-finished LED lamp heat dissipation cups on the material channel conveying structure to a molding mold; and the automatic unloading mechanism includes an unloading manipulator for taking down the finished LED lamp heat dissipation cups on the molding mold. The device not only can improve the yield and guarantee the quality, but also can reduce the labor intensity of workers, achieves full automation, and reduces the production cost.

Owner:ZHEJIANG CHENFENG SCIENCE AND TECHNOLOGY CO LTD

Full-quantity molten iron converter smelting control method

ActiveCN109423533APrevent splashAvoid pollutionManufacturing convertersProcess efficiency improvementTemperature controlSteelmaking

The invention relates to the technical field of converter steelmaking, in particular to a full-quantity molten iron converter smelting control method. The method specifically comprises the following steps of carrying out deslagging operation, carrying out calculation of the total amount of ore and the total amount of molten iron, carrying out iron converting control, carrying out oxygen supply control, carrying out slagging control, carrying out temperature control and carrying out end point control. According to the control method, splashing in the whole-iron smelting process is avoided, thenvarious defects such as environmental pollution and metal material loss caused by splashing can be avoided, and the smooth smelting process is realized; and the end point carbon temperature hit rateof whole-iron smelting is improved, various hazards caused by end point high-temperature overoxidation are avoided, the quality is ensured, and the important significance in an iron and steel plant isachieved.

Owner:ANGANG STEEL CO LTD

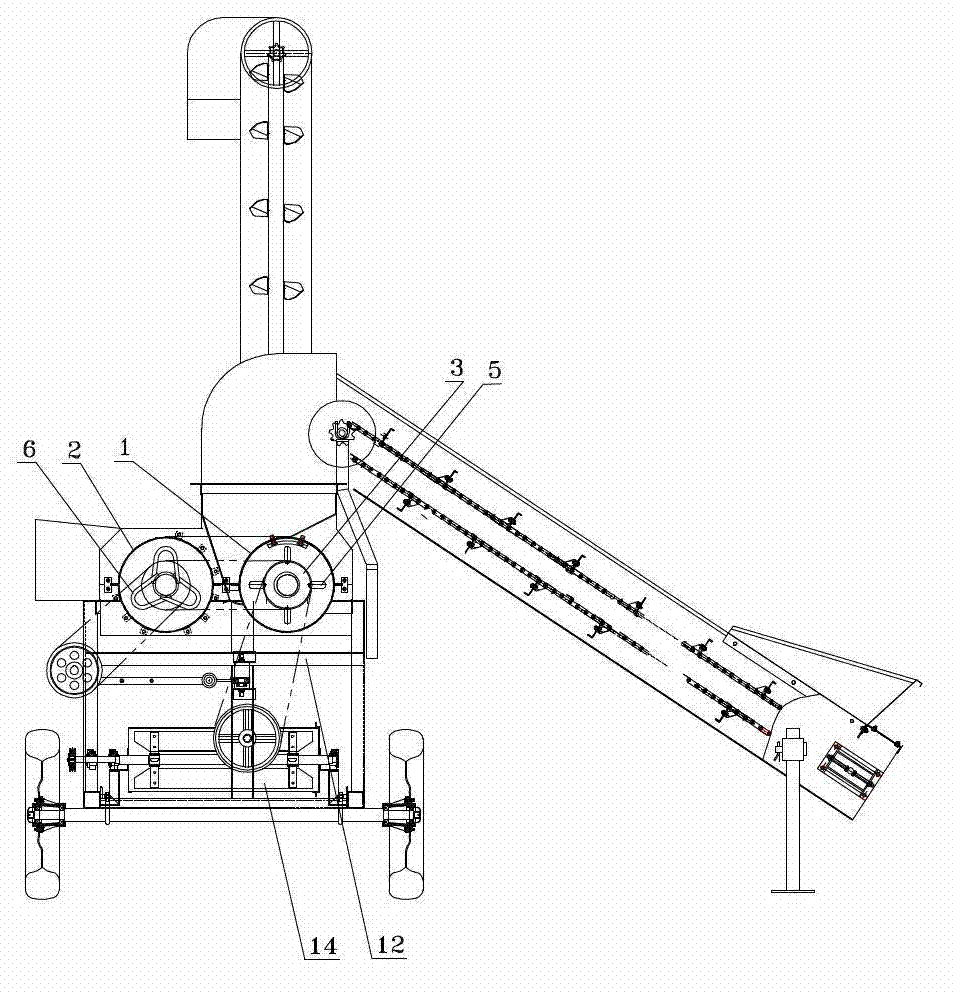

Efficient corn-threshing method

An efficient corn-threshing method mainly solves the problems that existing corn-threshing methods are low in threshing efficiency and poor in threshing and separating effect. The efficient corn-threshing method is characterized by comprising conveying corn cobs or corn cobs with skins to a main threshing barrel (1) through a feeding device; performing primary threshing on the corn cobs, and performed primary screening; performing secondary threshing on the corn cobs through an auxiliary threshing roller (4), and performing primary screening; performing secondary screening out of corns by swinging an upper sieve plate (9), a middle screen (10) and a lower sieve plate (11); performing third screening out of the corns above the upper sieve plate (9), the middle screen (10) and the lower sieve plate (11) through a suction fan (13) of a careful selection device; performing fourth screening out of the corns through a blower (14) of a cleaning device; and finally bagging the corns or loading the corns to a vehicle through an output loading device. The efficient corn-threshing method has the advantages of being high in efficiency and guaranteeing quality.

Owner:QIQIHAR BEIKUN AGRI MACHINERY MFG

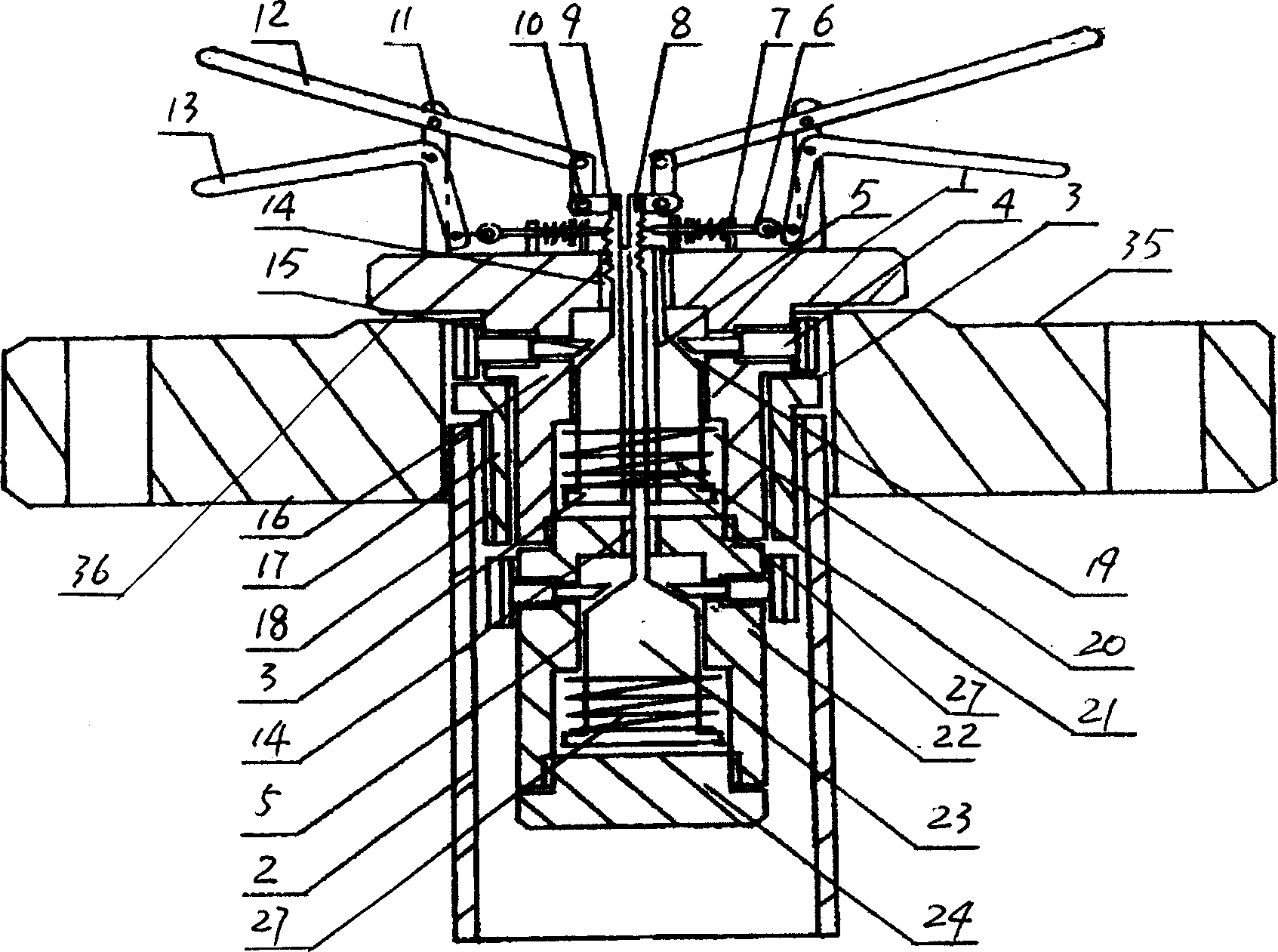

Flange positioner

InactiveCN1733418APrecise positioningLabor savingWelding/cutting auxillary devicesAuxillary welding devicesAssurance qualityEngineering

This invention provides a flange locator for welding of flange and pipe that comprises location device and locking device. Wherein, it can ensure the quality and accuracy of locating without adjusting to the parallel surface and axiality; when welding flange, operating flange locator to cover the flange on tension mechanism and convex desk of axis sleeve; keeping the flange inner diameter close to axiality location bar and covering into pipe to catch the flange on location plate surface by pressing locking compression bar; then, the parallel surfaces and axiality are completed. The invention can increase work efficiency more than one time.

Owner:中国建筑第八工程局工业设备安装公司一公司 +1

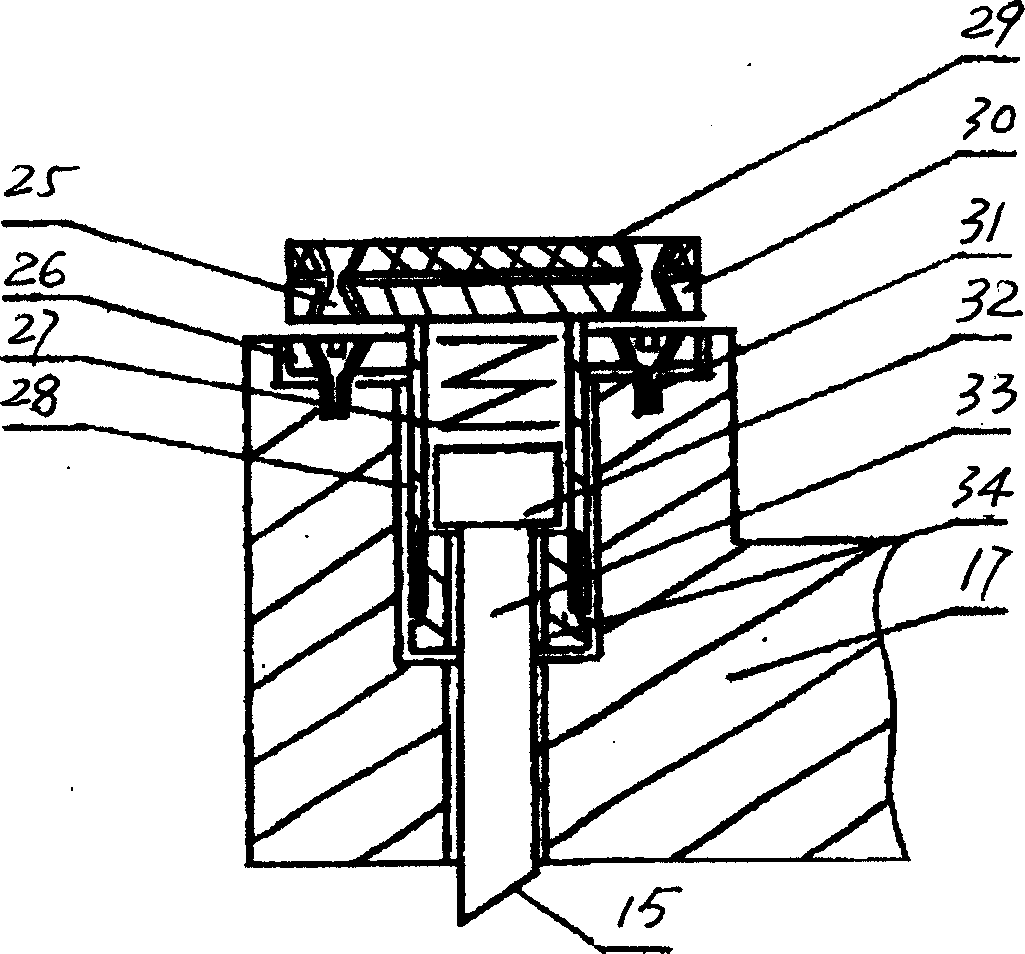

Elastic locating mechanism

ActiveCN103707090AIncrease delaySimple structurePositioning apparatusMetal-working holdersAssurance qualityEngineering

The invention relates to an elastic locating mechanism, in particular to a locating mechanism with elasticity and belongs to the technical field of locating machining. The elastic locating mechanism comprises a base body. A locating sleeve is arranged in the base body. A moving sliding sleeve is arranged in the locating sleeve in a sliding mode. The upper portion of the base body is connected with a bearing base which is connected with a bearing. The inner portion of the bearing base is connected with a guiding sleeve through a screw. Sliding locating pins are arranged in the guiding sleeve and the moving sliding sleeve in a sliding mode. The lower portion of the base body is connected with an oil way cushion block through a bolt. The lower end of the oil way cushion block is connected with an oil cylinder cushion block. An oil cylinder is fixed at the lower end of the oil cylinder cushion block. The elastic locating mechanism is good in protecting performance and convenient to maintain, machining accuracy is improved, quality is guaranteed, several procedures and a plurality of machining portions of machined parts can be located at one time, machining accuracy and production efficiency are improved, equipment and personnel are reduced, and accordingly operation cost is lowered.

Owner:WUXI BEST PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com