Plasma and dual TIG (tungsten inert gas) composite welding device and method of medium plate

A plasma welding and welding device technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high requirements on the gap and misalignment of the group, poor adaptability of the welding process, welding wire spatter, etc. Welding efficiency, solving difficult to ensure quality, reducing the effect of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is a plasma and double TIG combined welding device and method for medium and thick plates. Efficiency, ensure welding quality.

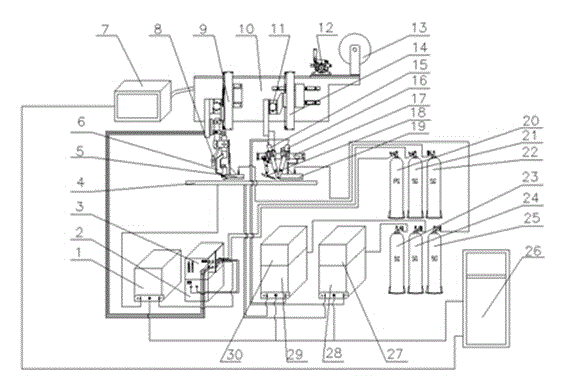

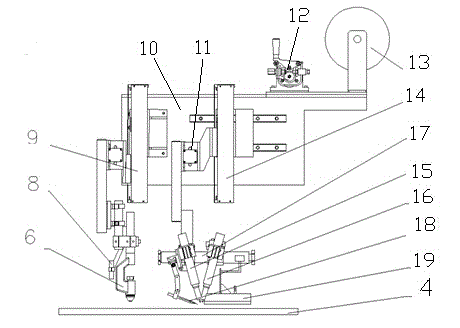

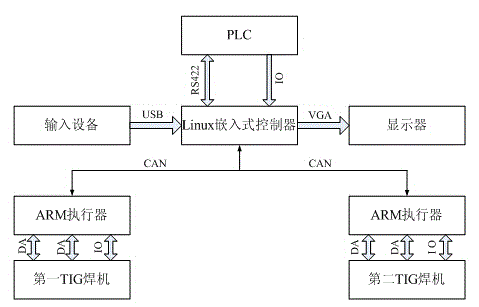

[0030] The combined plasma and double TIG welding device of the present invention includes a plasma welder 1, a plasma cooling device 2, a plasma controller 3, a welding head 10, a plasma torch 6, a weld alignment mechanism 8, a plasma arc length adjustment mechanism 9, a Wire wheel 12, welding wire reel 13, double TIG arc length adjustment mechanism 14, double TIG position and angle adjustment device 17, first TIG welding torch 15, second TIG welding torch 16, wire feeding mechanism 18, double TIG welding drag cover 19, double TIG welding torch swing mechanism 11, ion gas 20, shielding gas 21, plasma tow shield shield gas 22, first TIG torch shield gas 23, second TIG torch shield gas 24, double TIG tow shield shield gas 25, PLC control device 26, The second TIG welding cooling water tank 27 , the second TIG welding mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com