Liquid cooling dropping pill production line

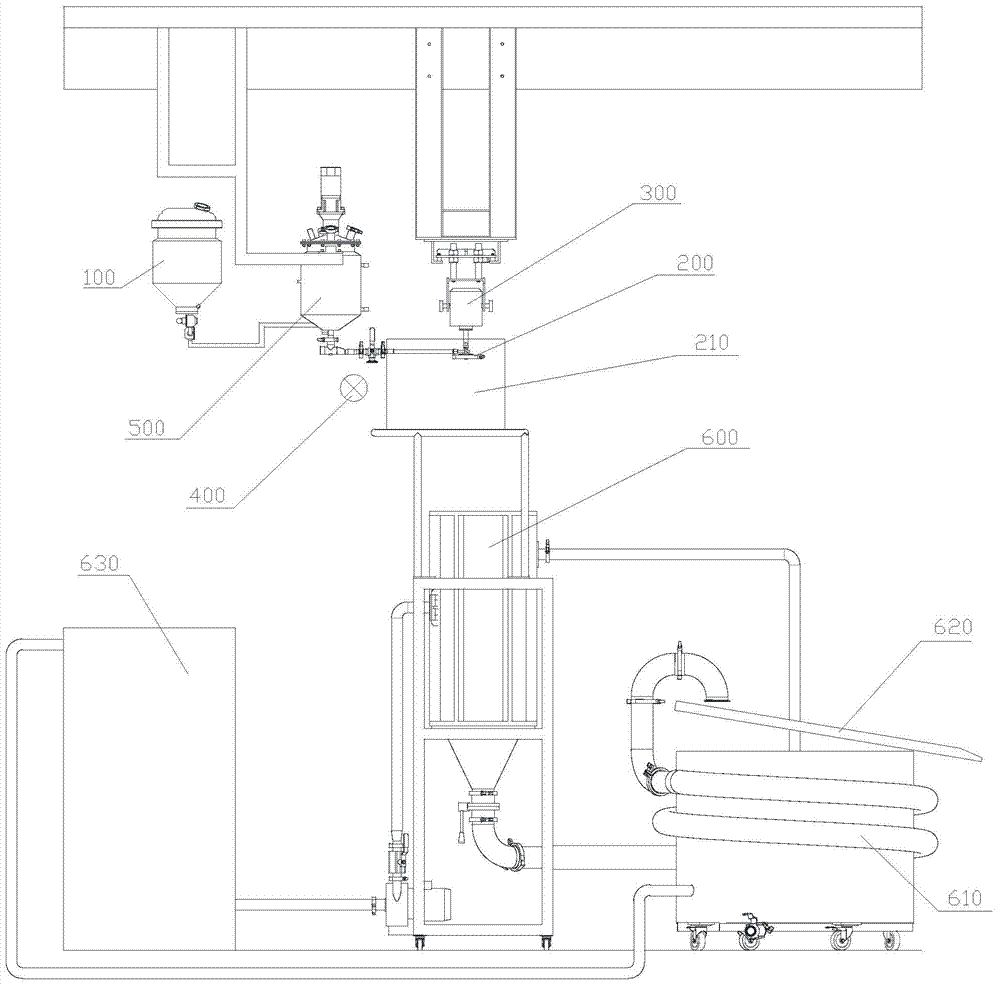

A technology of cold dripping pills and production lines, which is applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problem of unsatisfactory effect of dripping small pills or large pills, large differences in the size of the pill weight, large size difference of the equipment, etc. Large and other problems, to achieve the effect of widening the diameter range, eliminating surging and pulse, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Preparation of Compound Danshen Dripping Pills

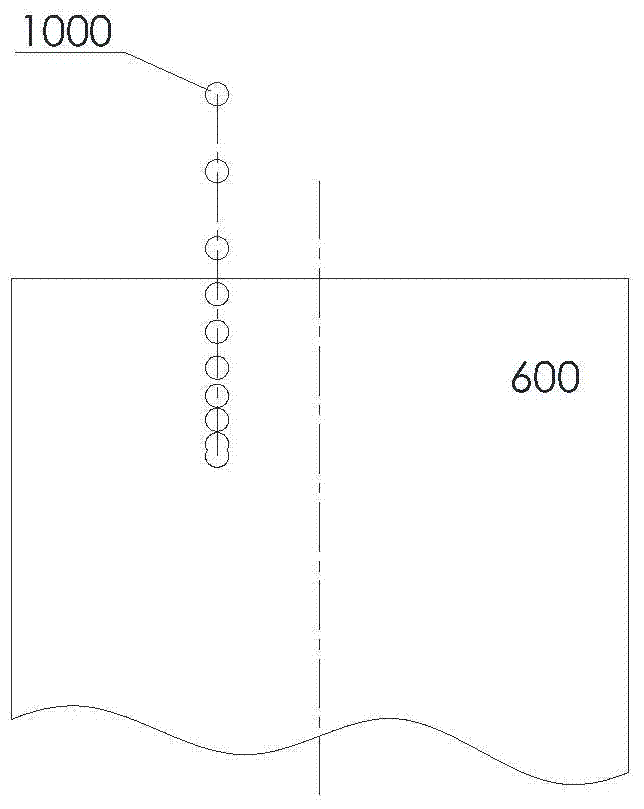

[0040] Get 600g of Danshen Sanqi extract, 5g of borneol, and 2000g of PEG-6000 (polyethylene glycol-6000) auxiliary material. First add PEG-6000 into the chemical material tank 100, heat it to 90°C, melt it in advance, then add the extract of Danshen Panax notoginseng, and mix evenly to form a liquid. Adjust the vibration frequency of the pneumatic vibrating dripper 200 to 50Hz, the dripping speed to 10Kg / hr, the dripping acceleration to 4.5G, and the dripping pressure to 1.8Bar. The heat preservation chamber 210 is insulated with an electric heating jacket, and the temperature of the dripper is controlled at 85°C. Observe the shape of the dropping pills with the naked eye through the strobe light. The size and shape of a single dropping pill are moderate, and there is no adhesion between the upper and lower dropping pills, and the normal dripping system continues to be maintained. The heating temperature of...

Embodiment 2

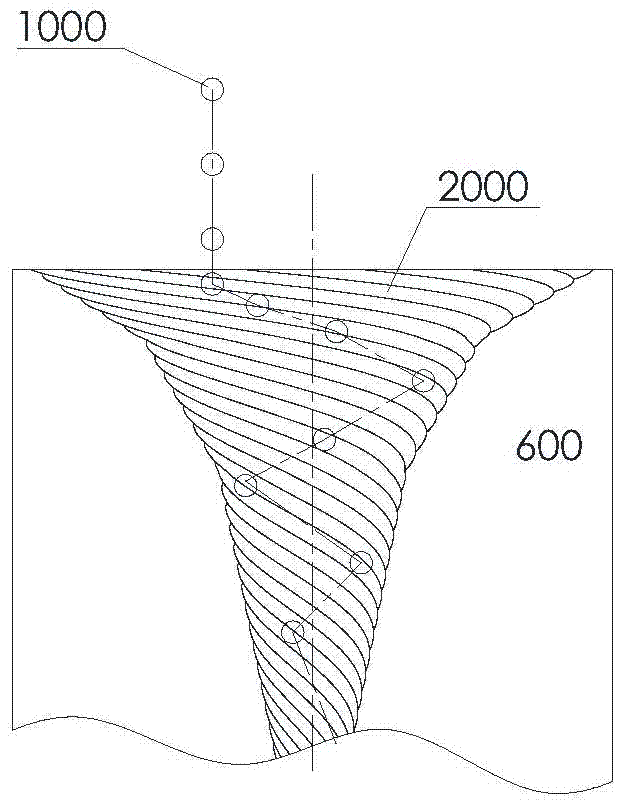

[0041] Embodiment two preparation Danshen dripping pills

[0042] Take 600g of salvia miltiorrhiza extract, add 60g of water, add 1500g of PEG-6000 auxiliary material, put it into a chemical tank and heat to 90°C, make it melt completely and mix evenly into a liquid. The liquid medicine is transported to the dripper under pressure, the dripping vibration frequency is 90Hz, the dripping speed is 40Kg / hr, the dripping acceleration is 20G, and the dripping pressure is 4Bar. Infrared heating is used for heat preservation, and the dripping temperature is controlled at 100°C. Observe the shape of the dropping pills through the strobe light and the camera, compare the shape of the dropping pills captured by the camera with the preset standard shape of the dropping pills, and find that the distance between the upper and lower dropping pills is too close and there is adhesion, reduce the dripping pressure to 3Bar, vibration frequency 140Hz, dripping speed 12Kg / hr, and continue to obser...

Embodiment 3

[0043] Embodiment three preparation Huoxiangzhengqi dripping pills

[0044] Take Huoxiangzhengqi Extract 200g, Patchouli Oil 1ml, Perilla Leaf Oil 2ml, Polyethylene Glycol 600g, add it into the chemical tank at the same time, heat to 65-85°C, melt, mix evenly to form a liquid. The medicinal liquid is introduced into the buffer tank, then sent to the dripper by pressurizing the buffer tank, and drips out from the bottom of the dripper into the cooling tank. Adjust the vibration frequency of the electric vibrating dripper to 200Hz, the dripping speed to 30Kg / hr, the dripping acceleration to 10G, and the dripping pressure to 0.5Bar. Observe the shape of the droplet with the naked eye through the strobe light, and find that the volume of the cutting droplet is too large, adjust and increase the vibration frequency to 300Hz to reduce the volume of the cutting droplet; adjust and increase the vibration acceleration to 10G to increase the shear force of the droplet , the dropping sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com