Patents

Literature

162results about How to "Large diameter range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

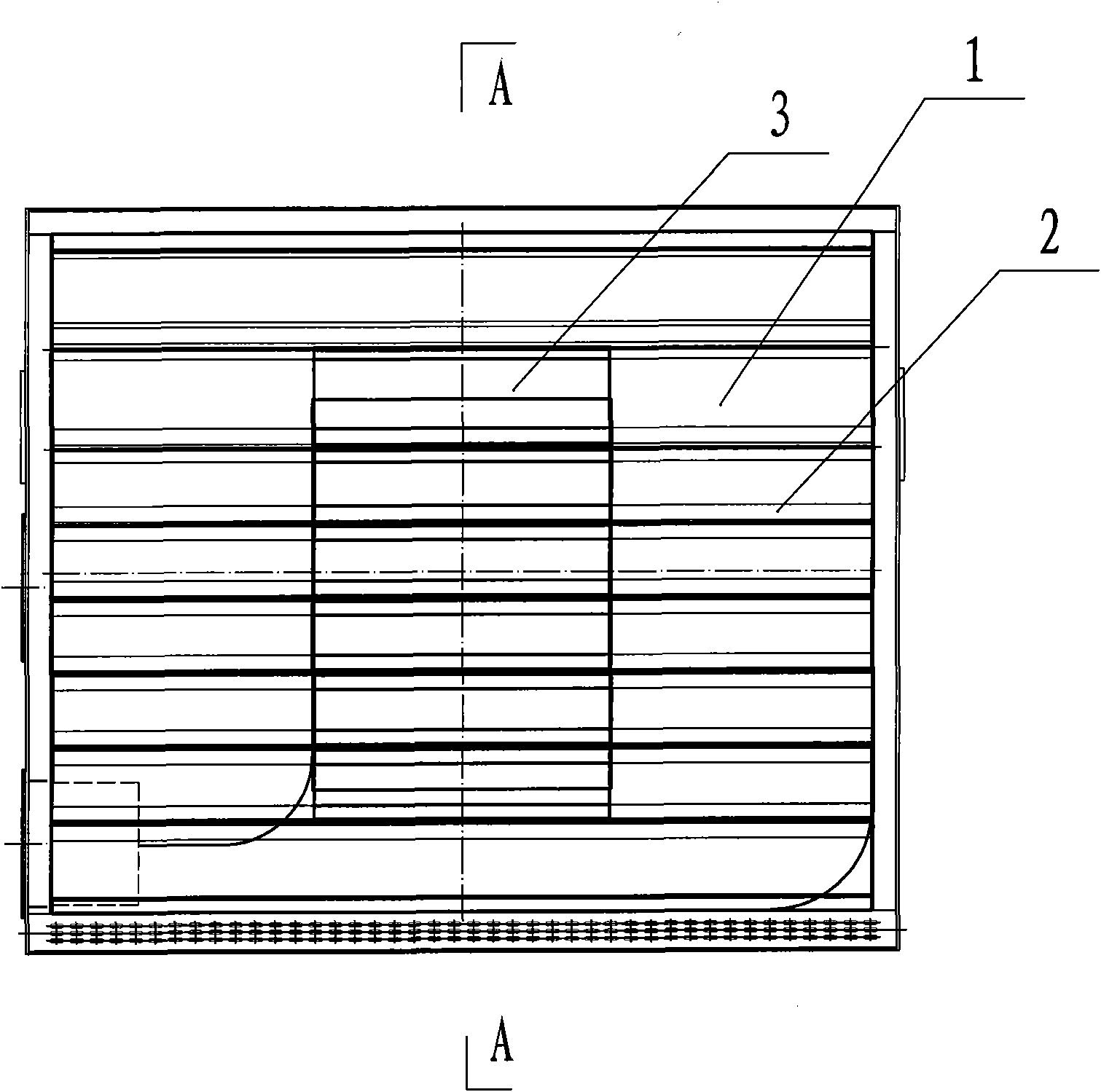

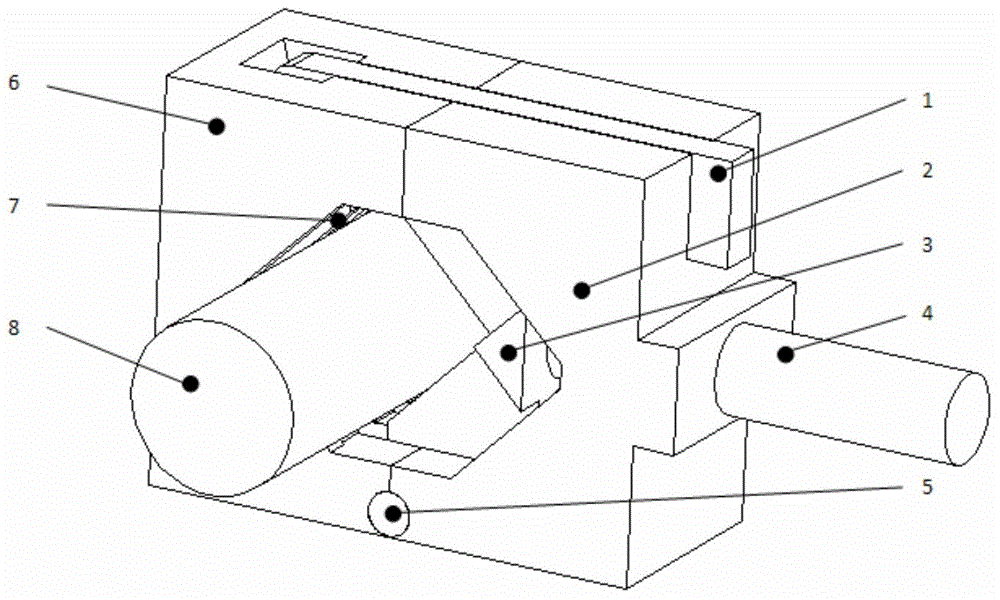

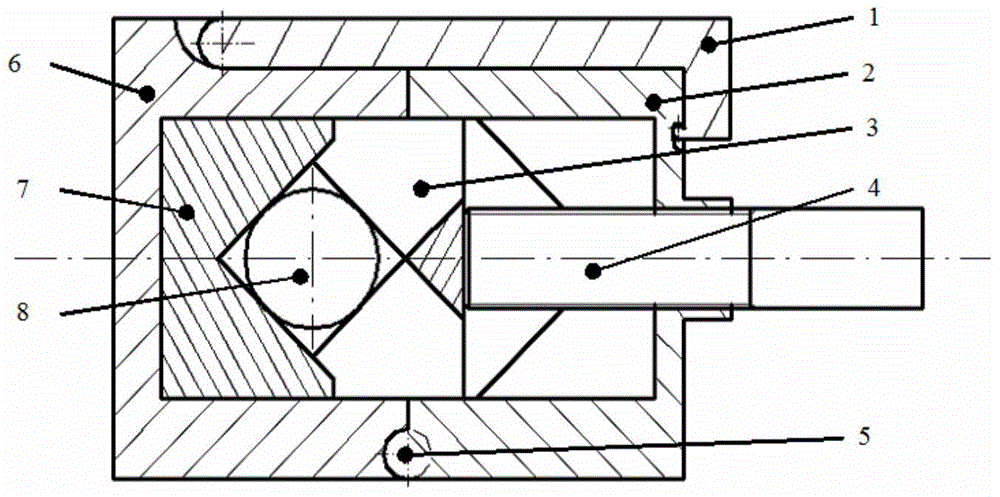

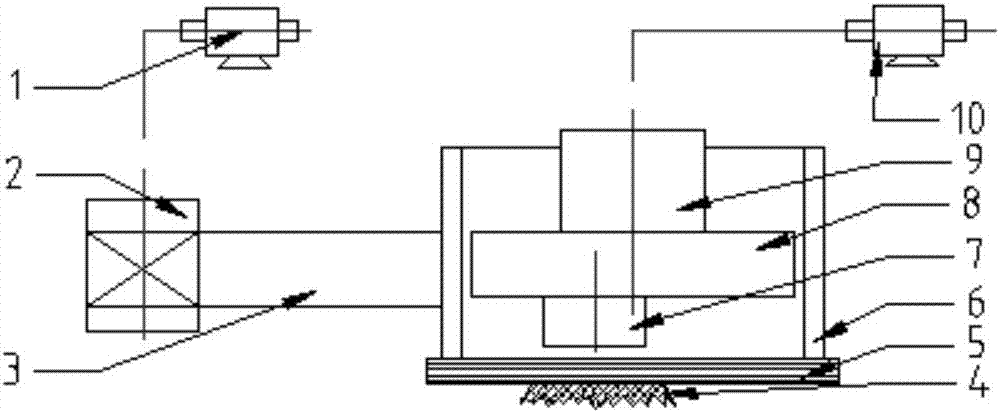

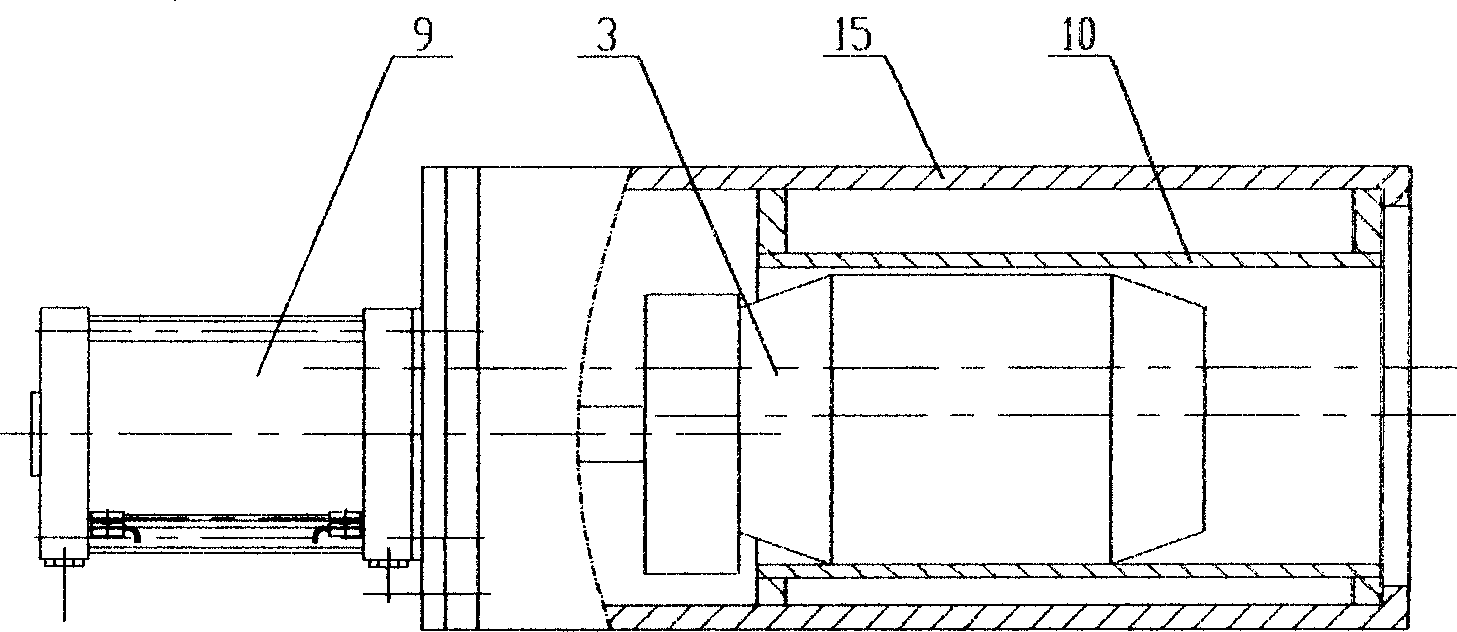

Selective laser melting forming device and method of medical magnesium alloy metal part

ActiveCN101856724ASatisfies complex spatial shape requirements with high degrees of freedomMeet complex space shape requirementsSelective laser meltingOptoelectronics

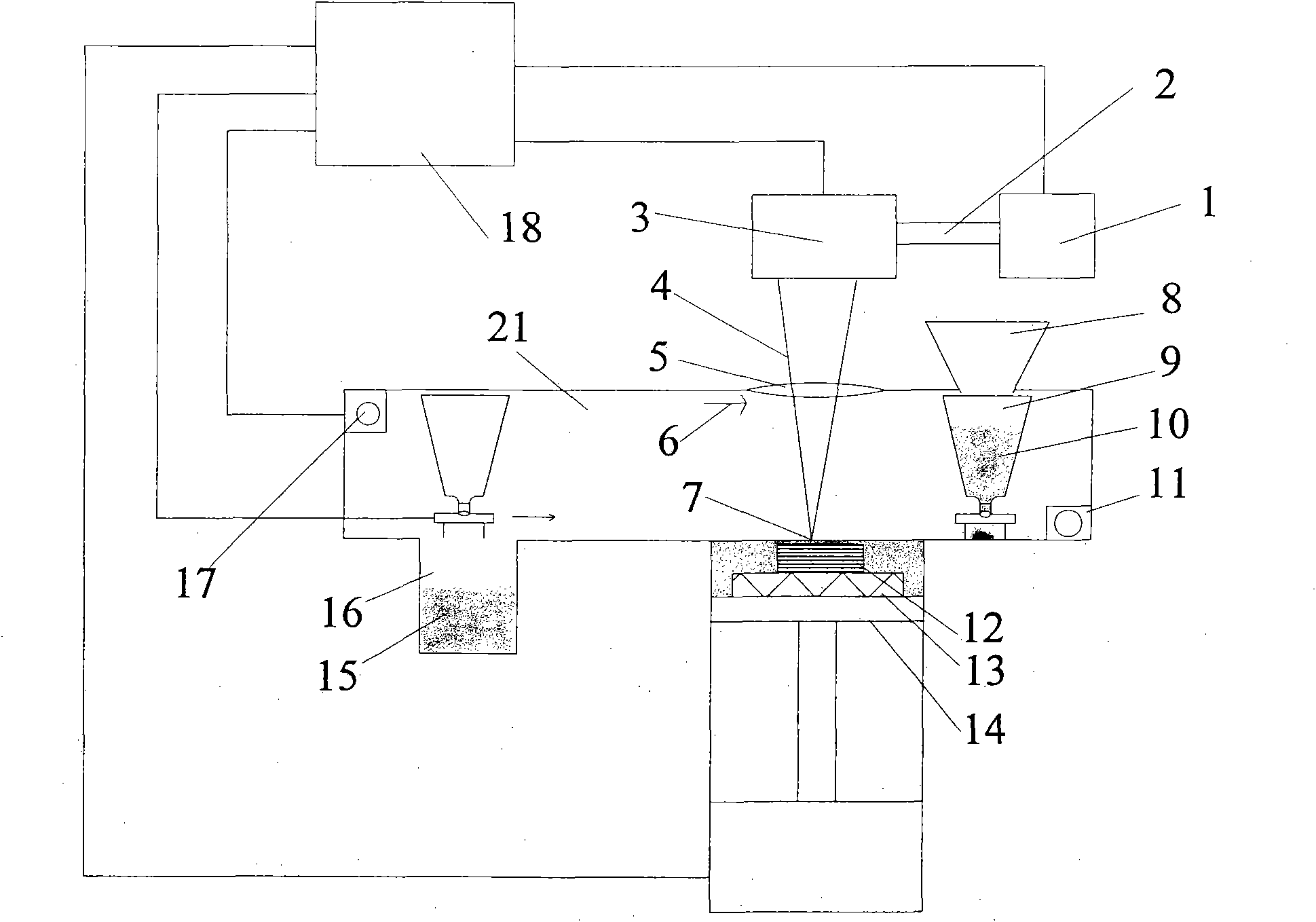

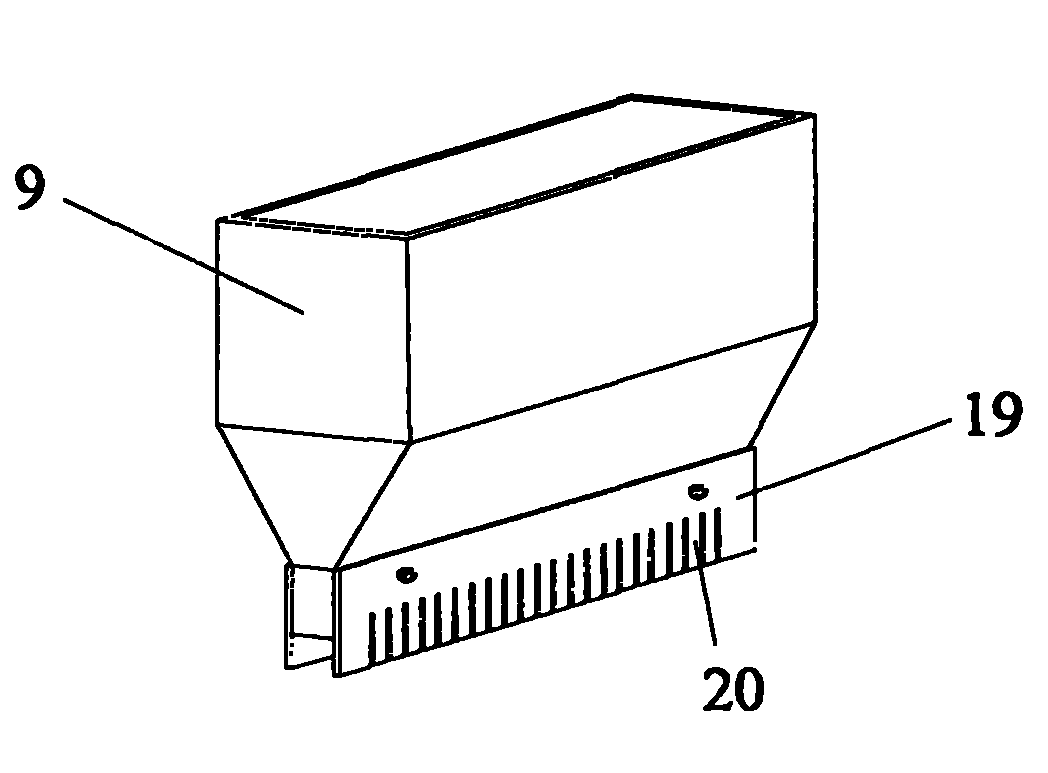

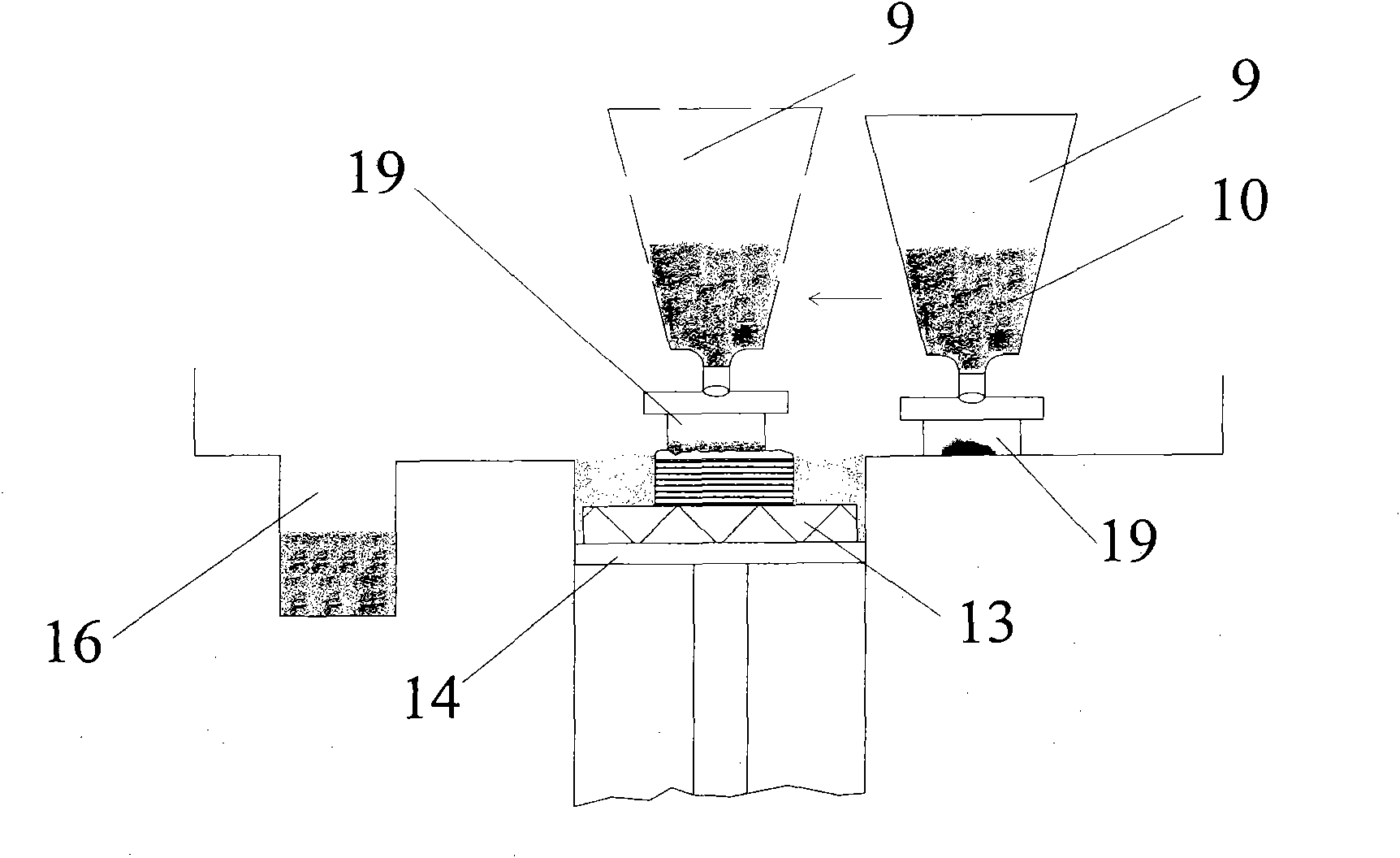

The invention provides a selective laser melting forming device of a medical magnesium alloy metal part, which comprises a control device, a powder delivering and spreading device, a laser transmission mechanism, an air purification device and a closed forming chamber, wherein the powder delivering and spreading device comprises a hopper and powder spreading brushes arranged on two sides below the hopper, the upper part of the hopper is arranged in a way of corresponding to a feeding opening on the upper part of the forming chamber, and the lower parts of the powder spreading brushes horizontally correspond to the upper surface of a forming cylinder; the laser transmission mechanism is arranged outside and above the forming chamber and is arranged in a way of corresponding to the forming cylinder; the side wall of the forming chamber is provided with an air inlet and an air outlet, and the air purification device is connected with the air inlet and the air outlet respectively; and the control device is connected with the powder delivering and spreading device, the laser transmission mechanism, the forming cylinder and the air purification device respectively. The invention also provides a selective laser melting forming method of the medical magnesium alloy metal part. The device and the method can manufacture parts which have complex shapes required in the medical field directly, and have the advantages of high forming efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

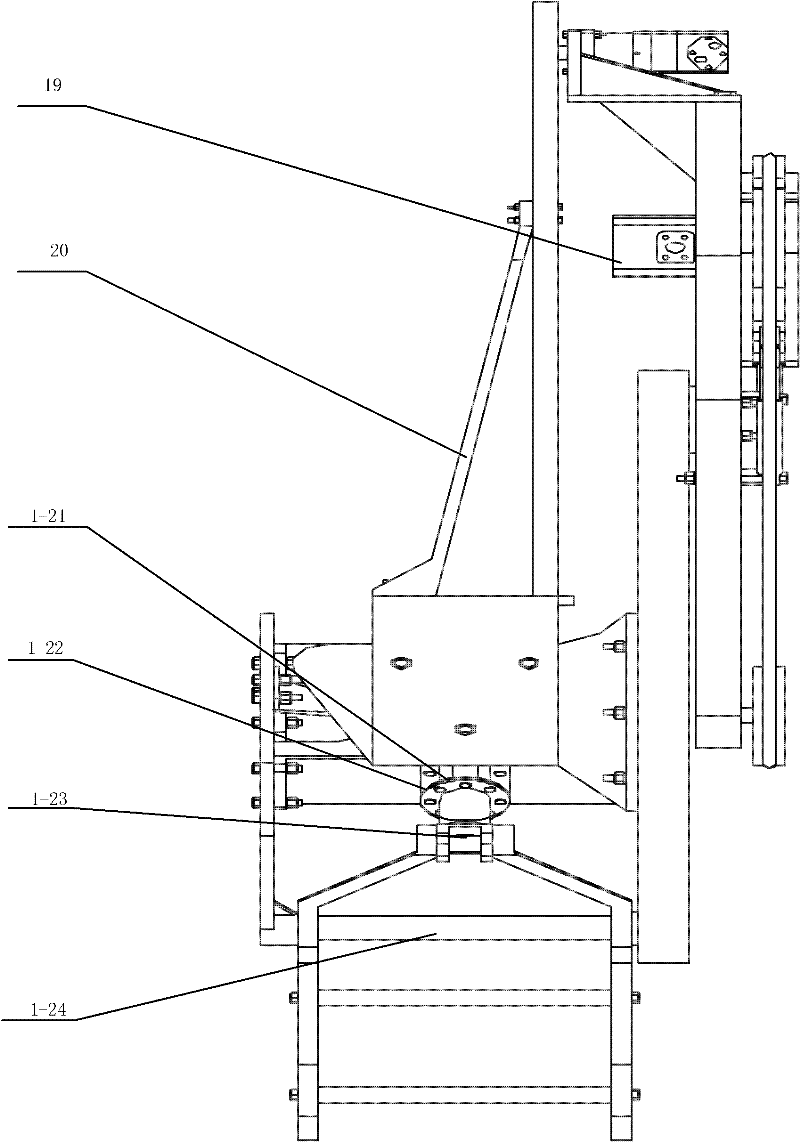

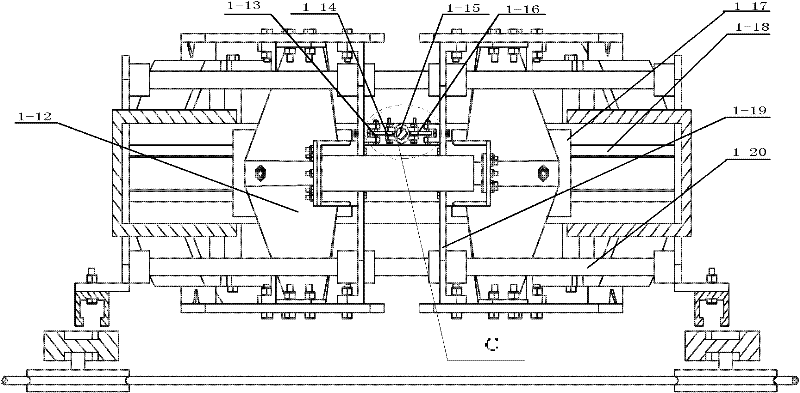

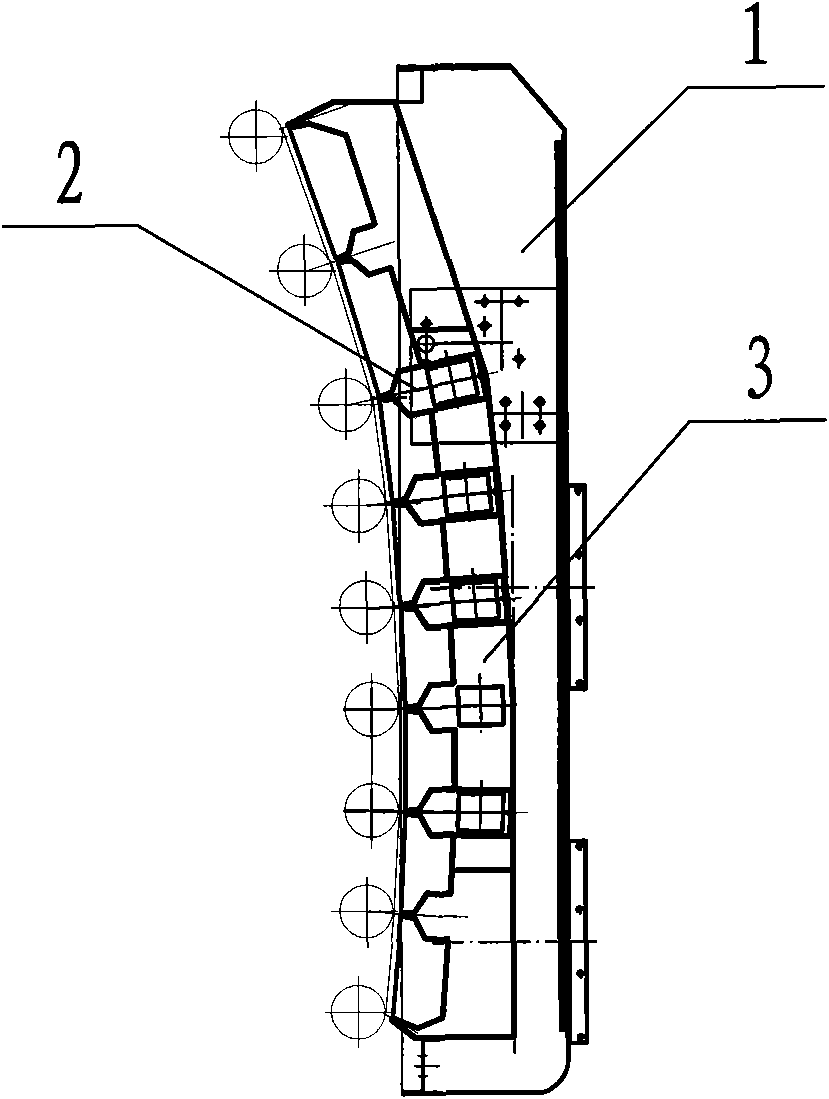

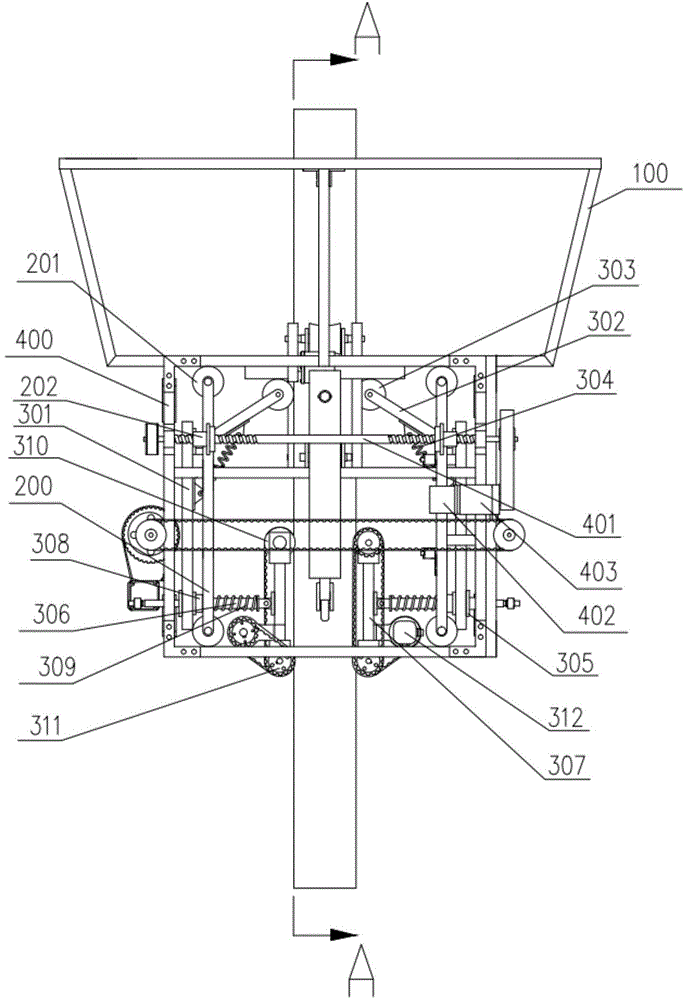

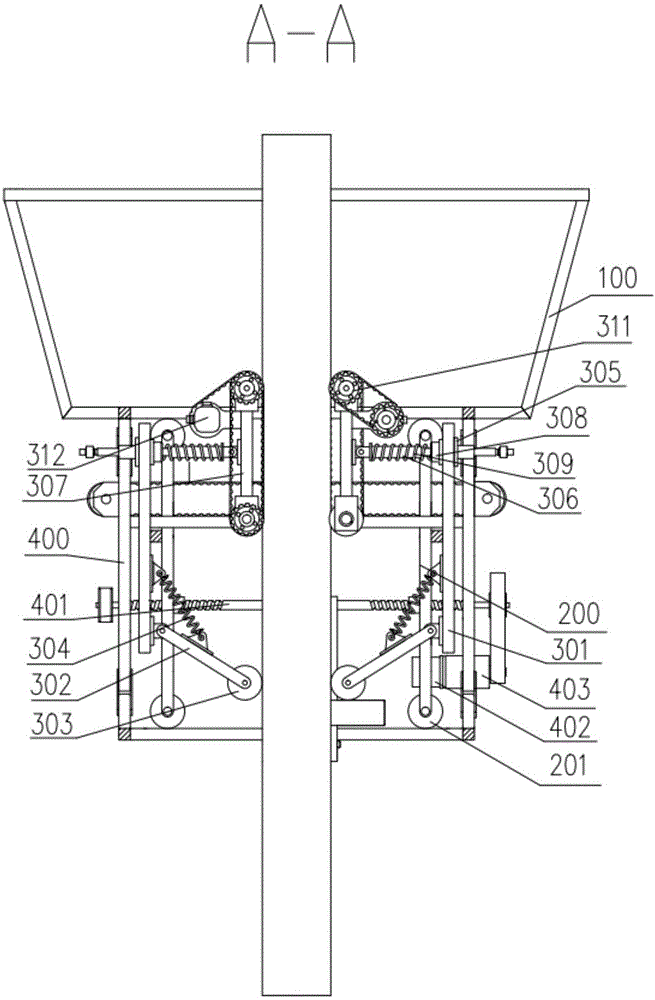

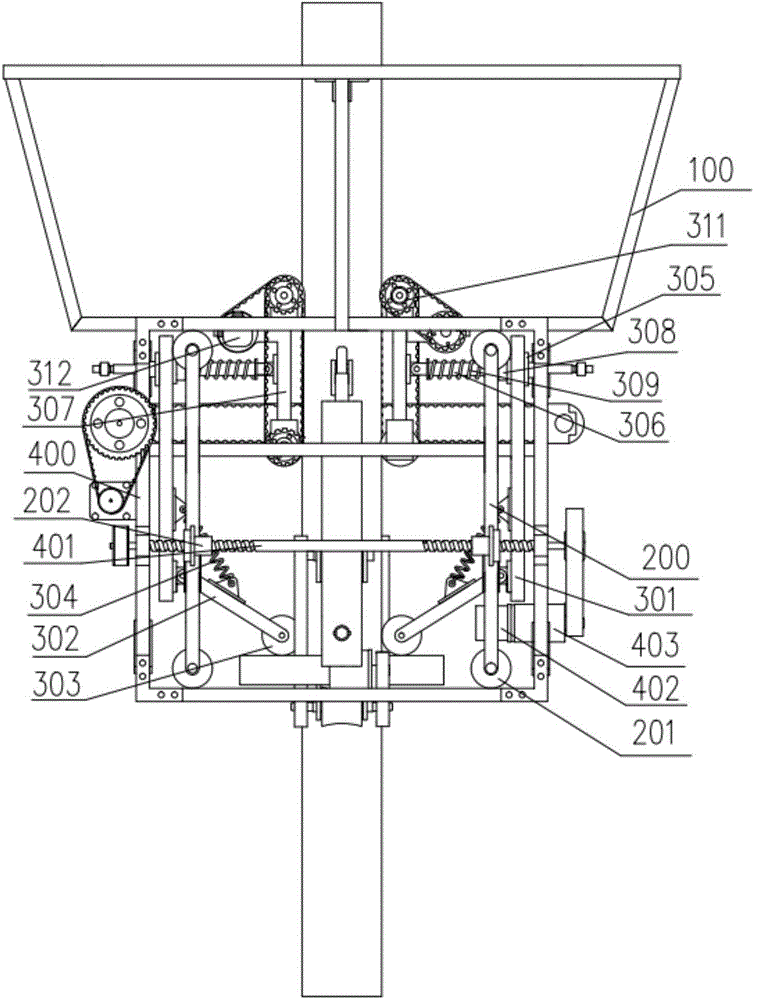

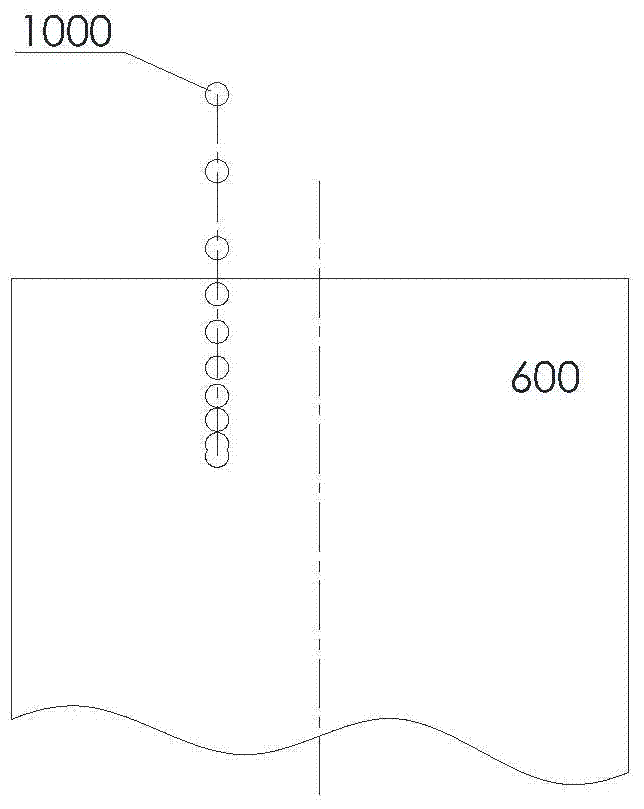

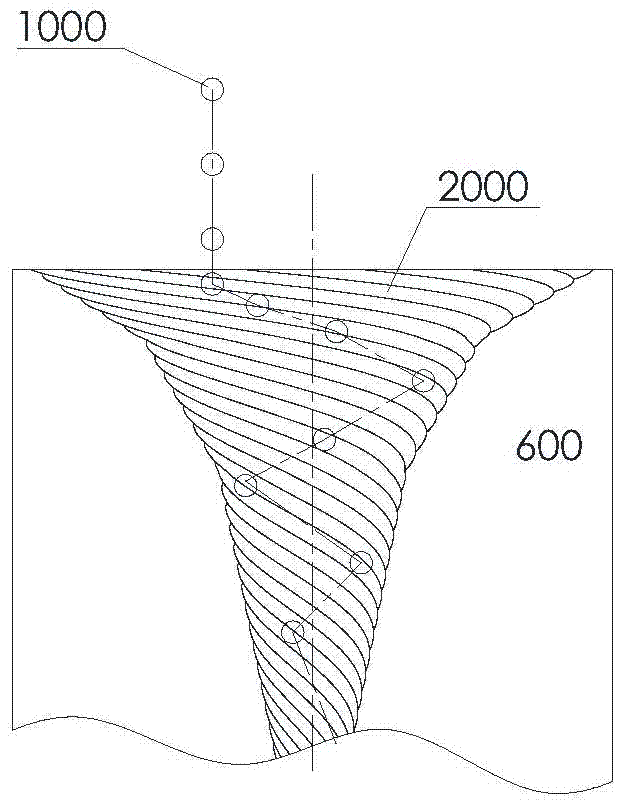

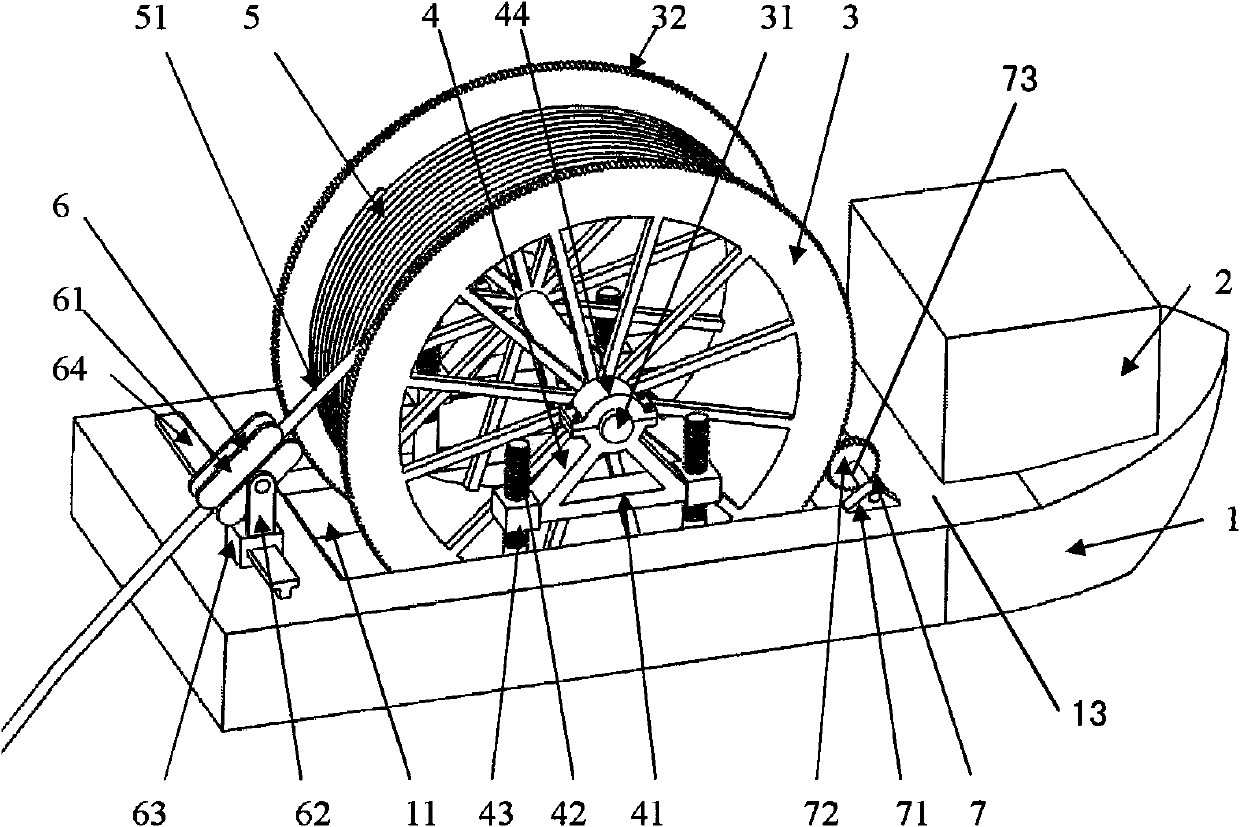

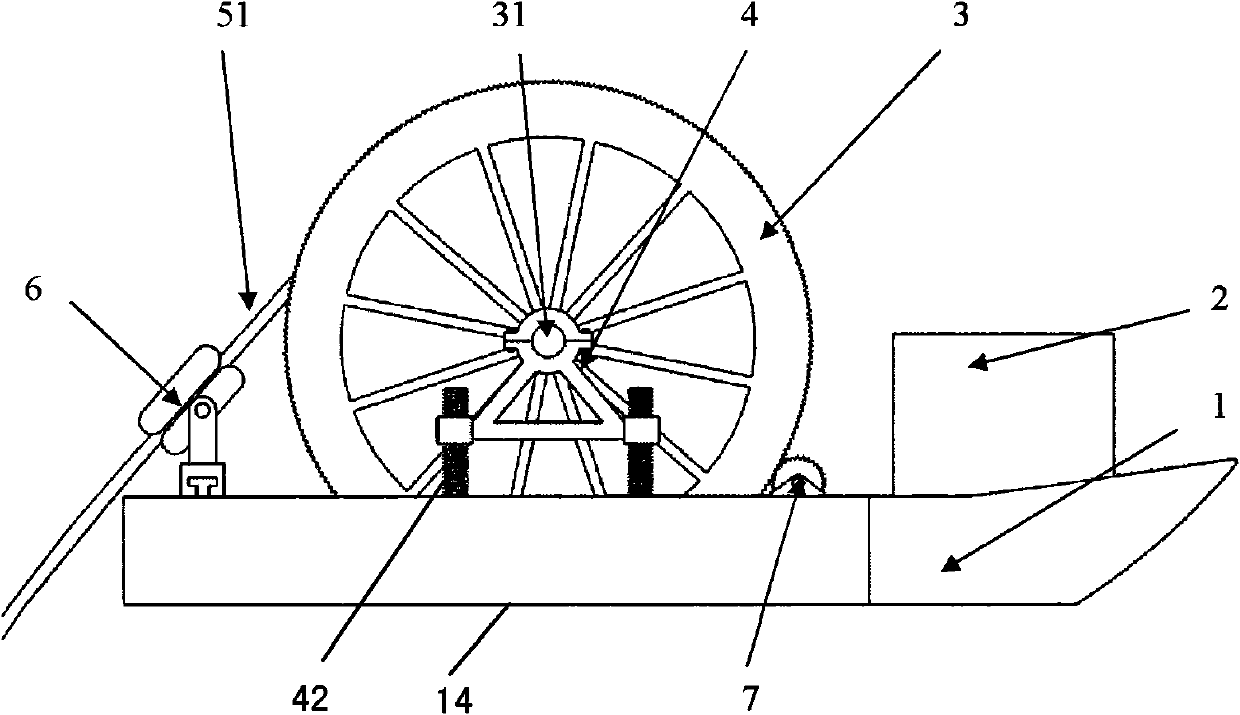

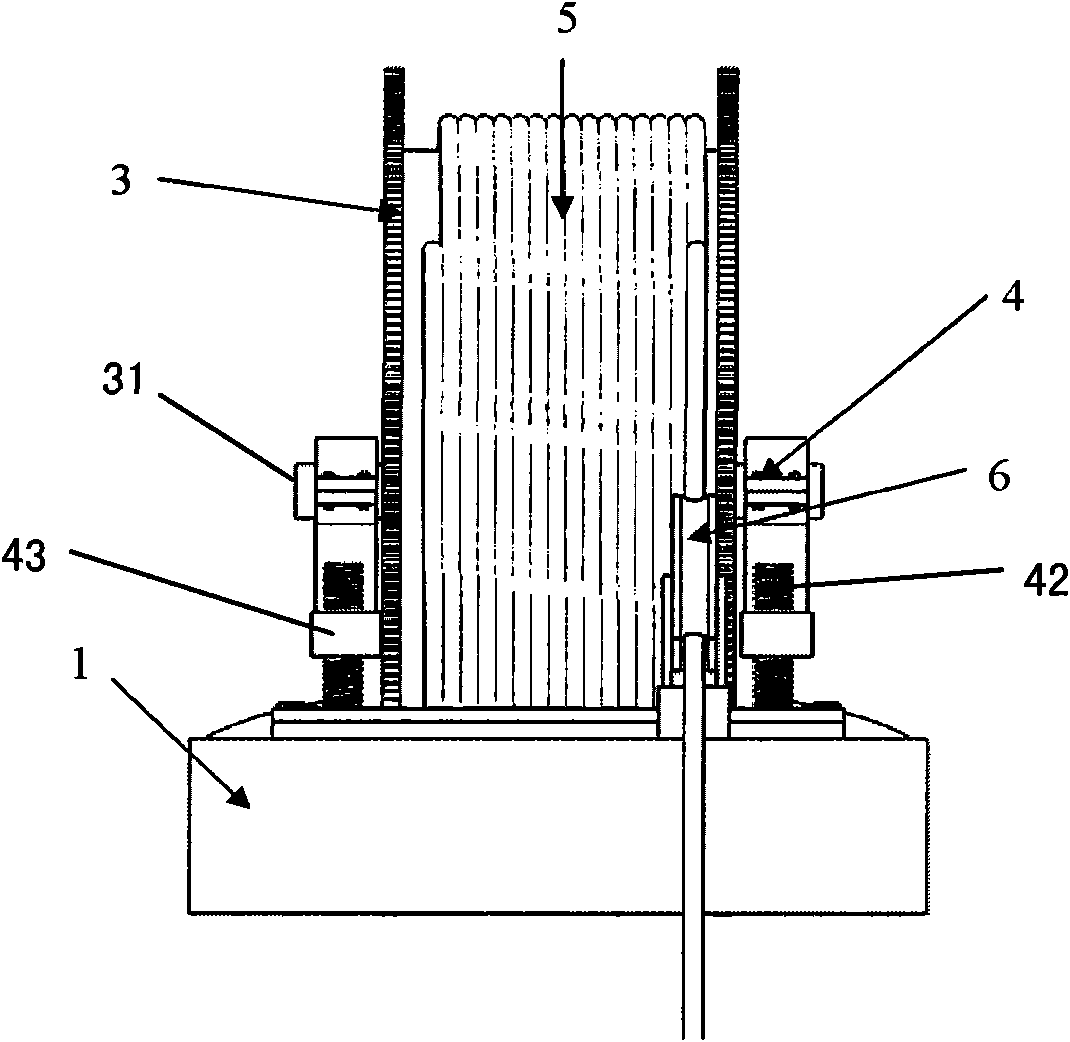

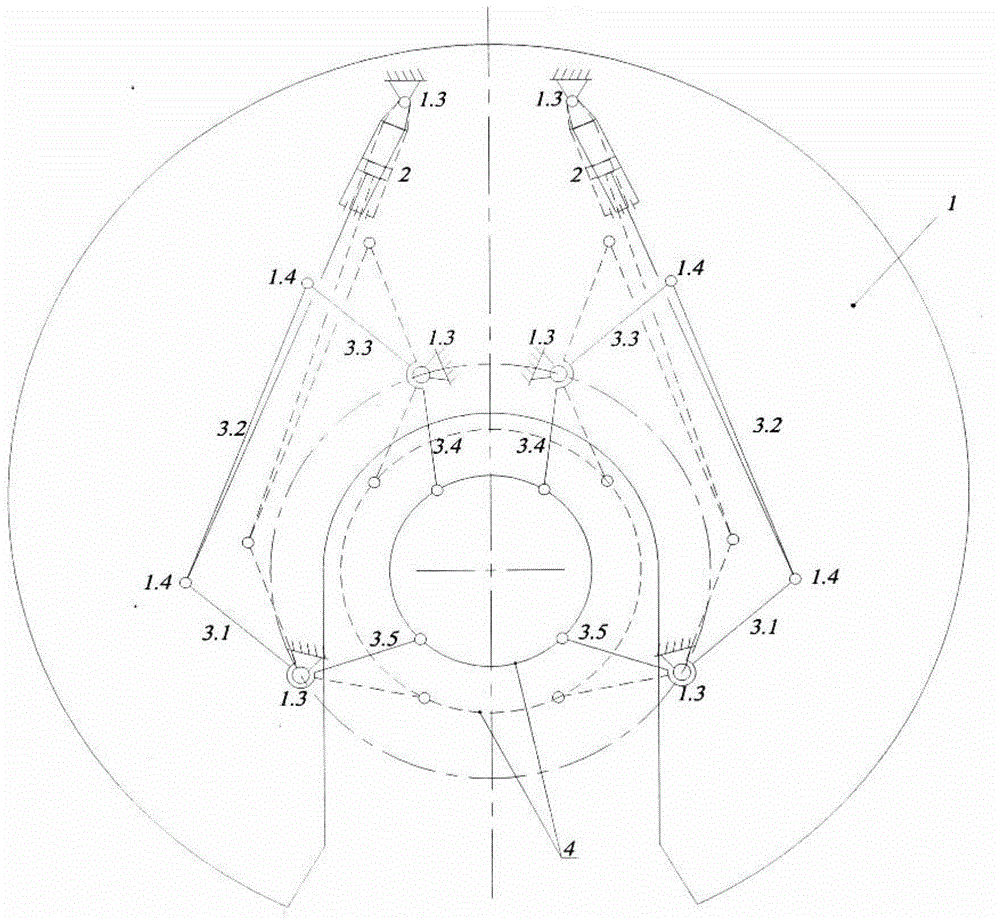

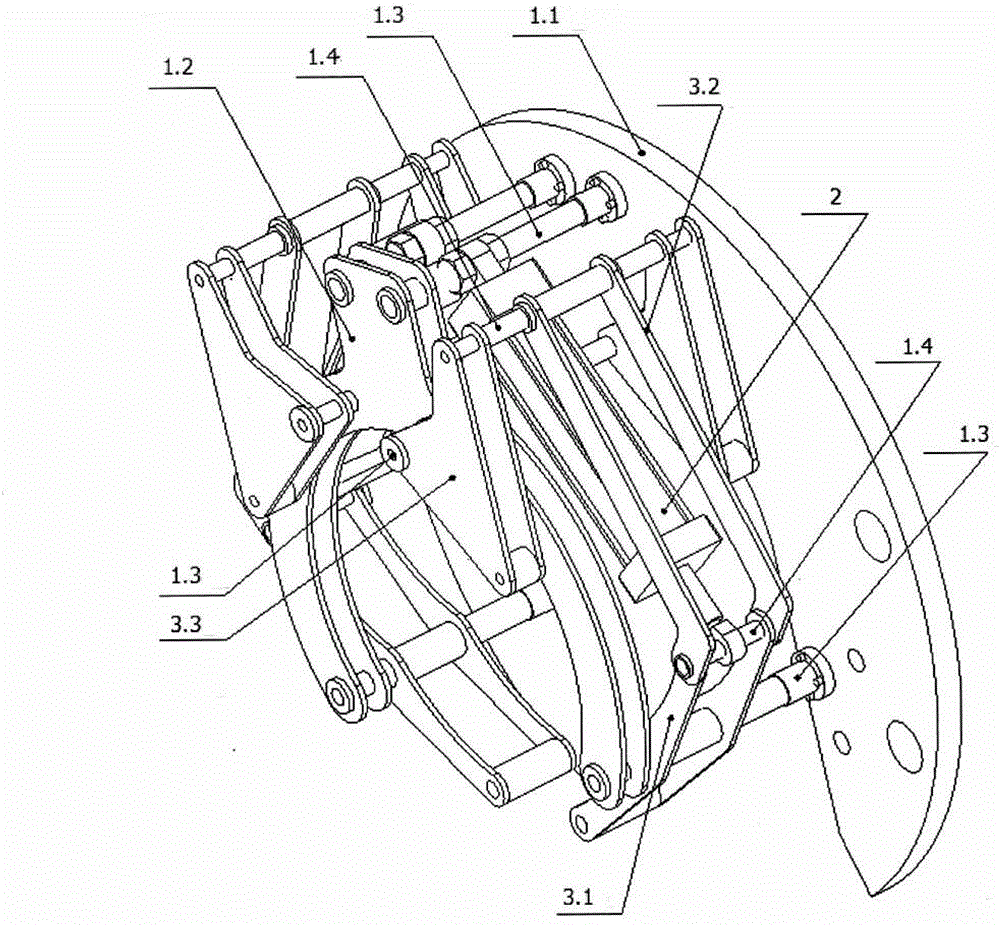

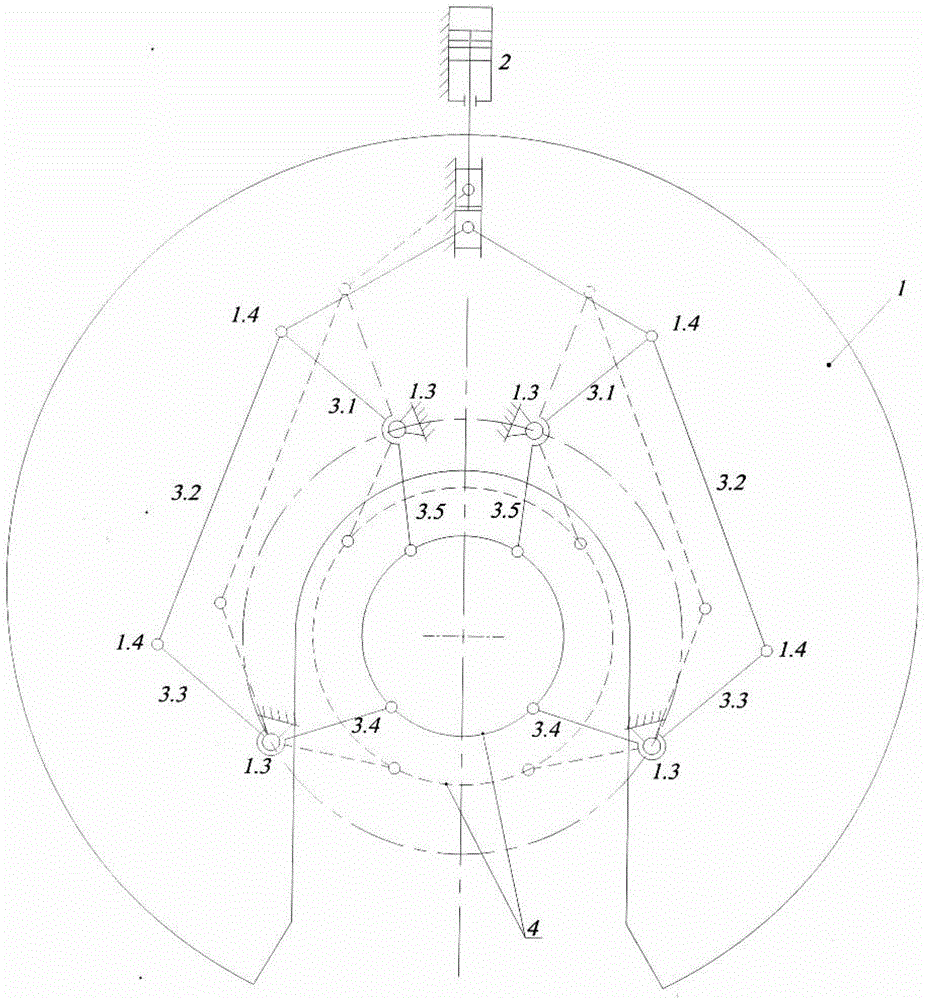

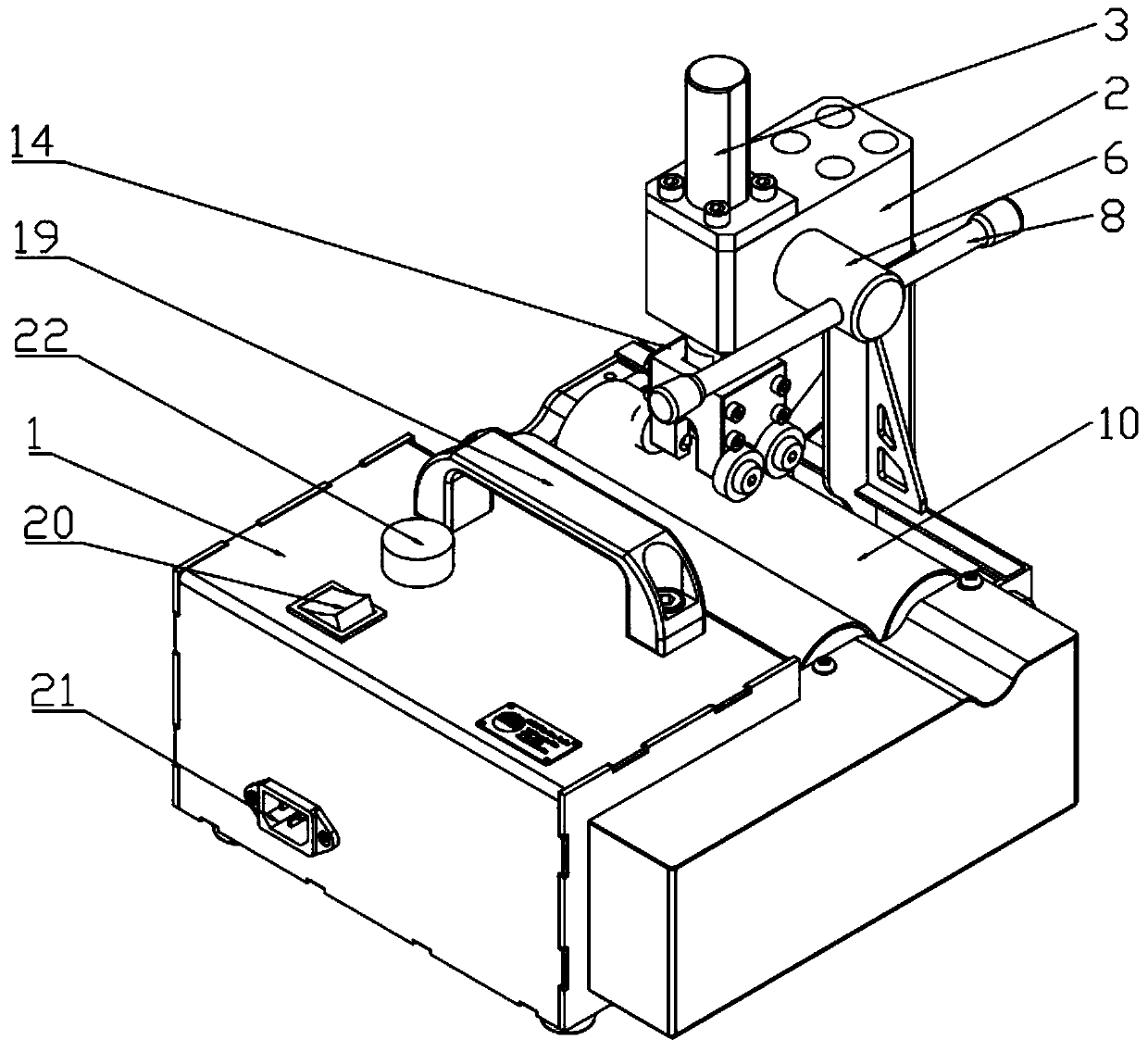

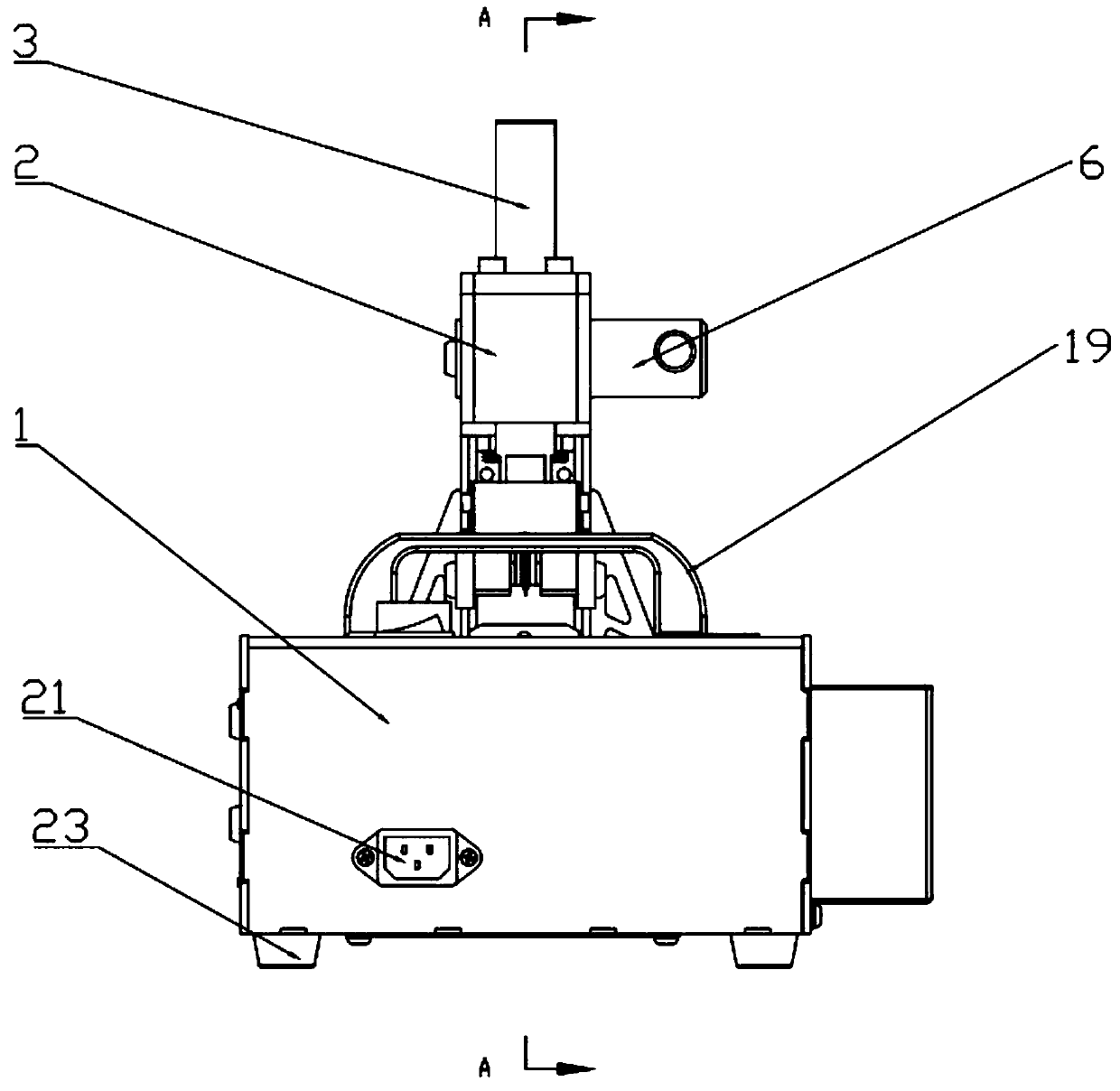

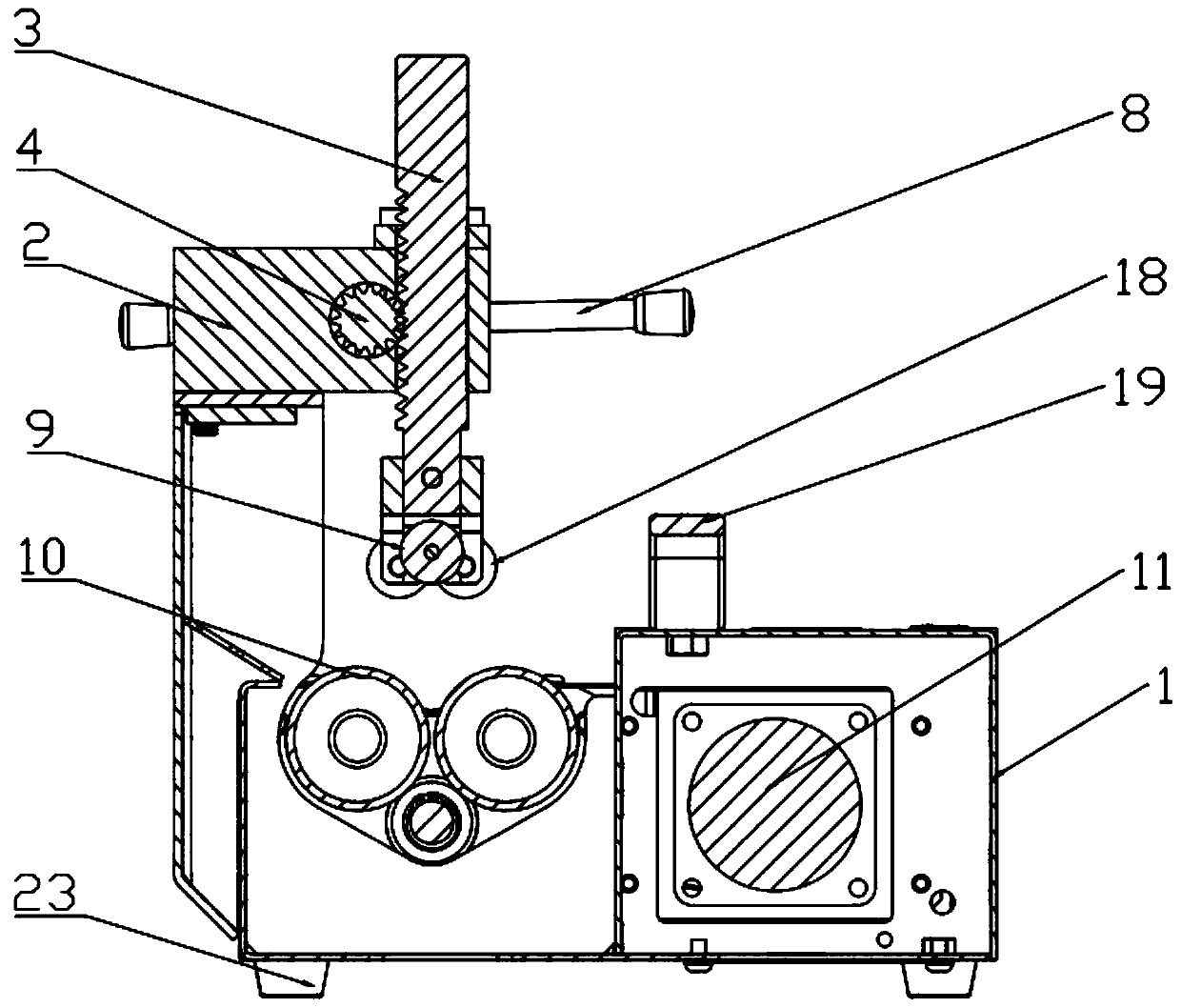

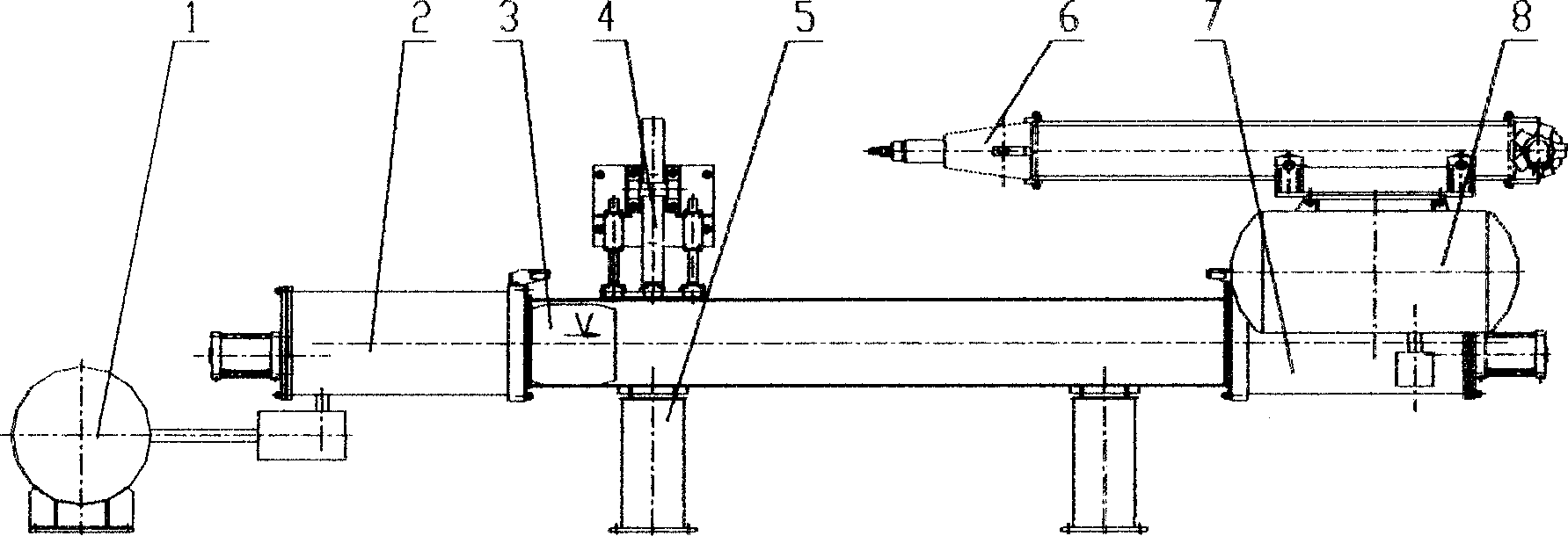

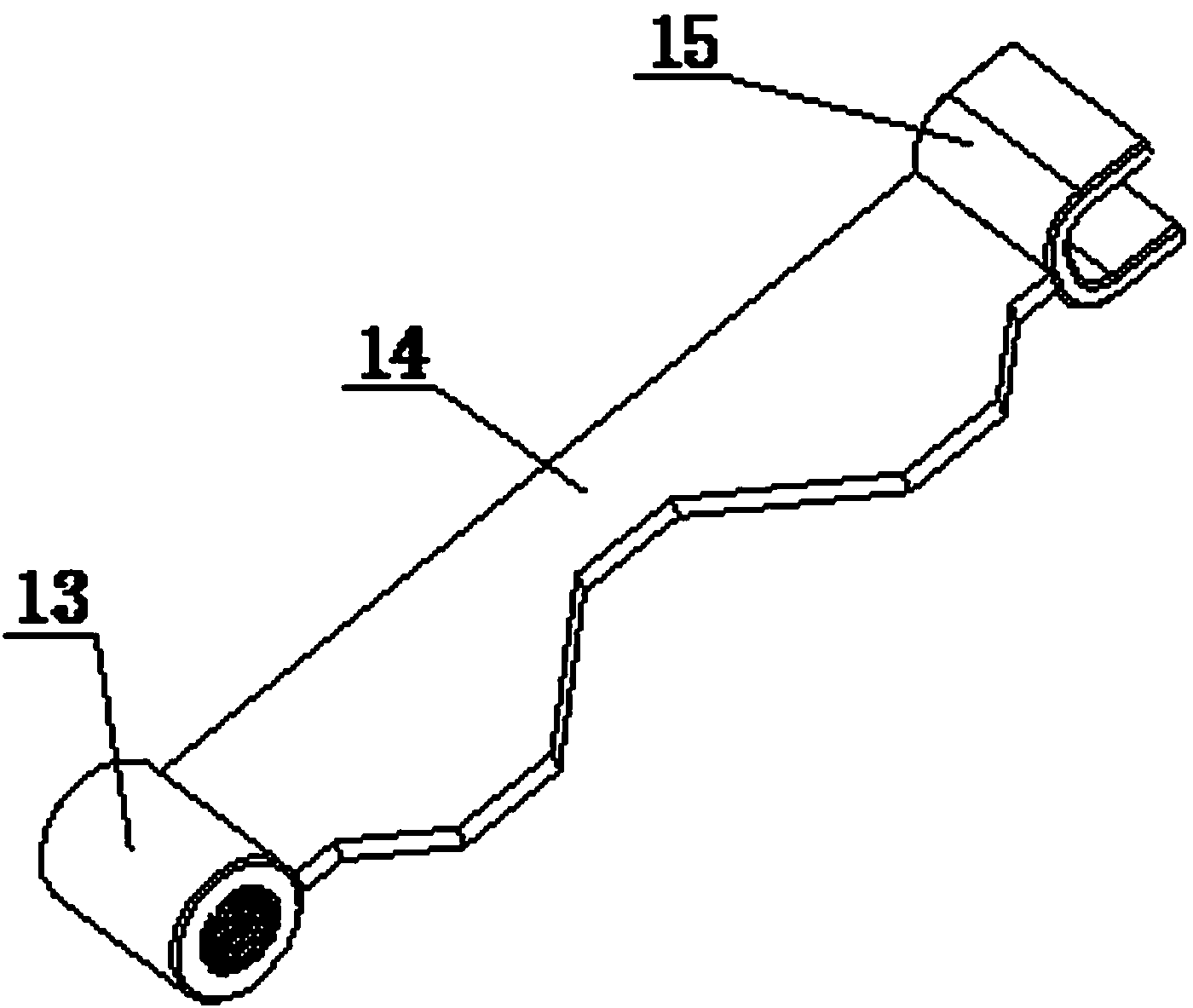

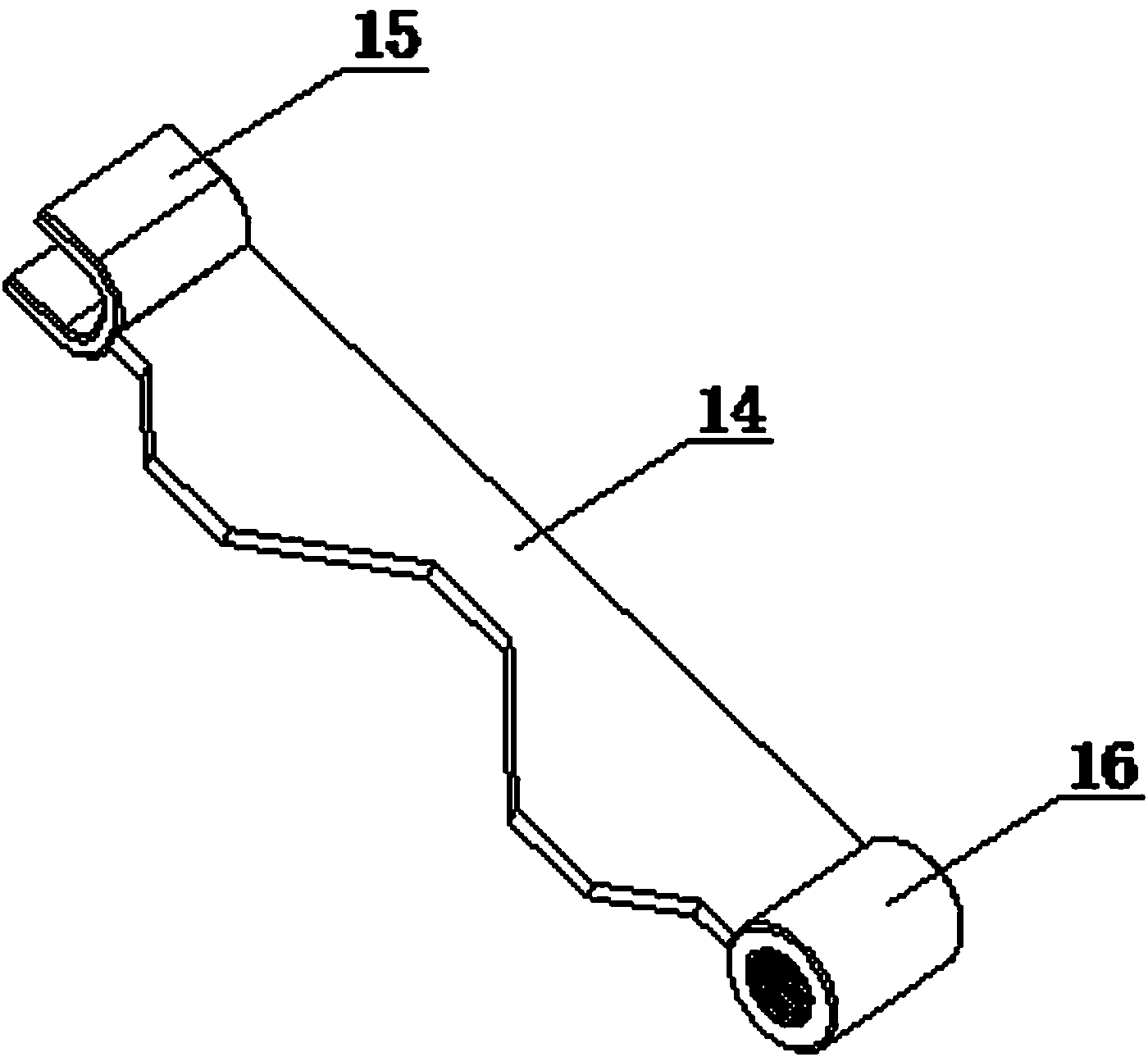

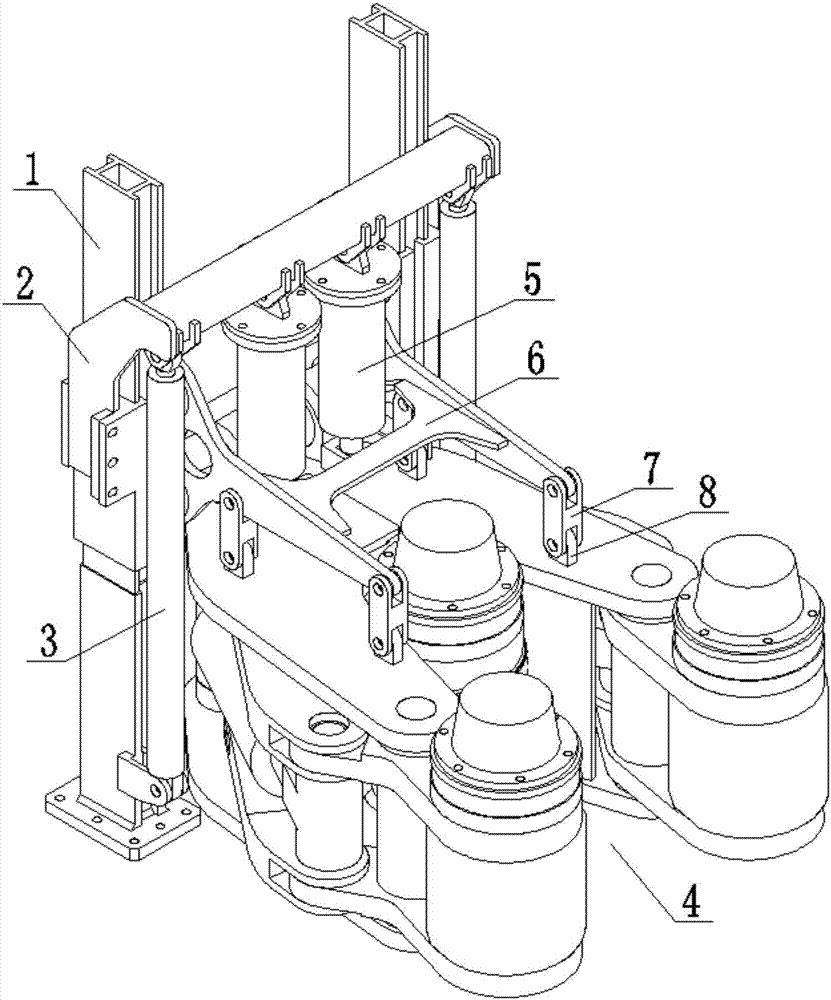

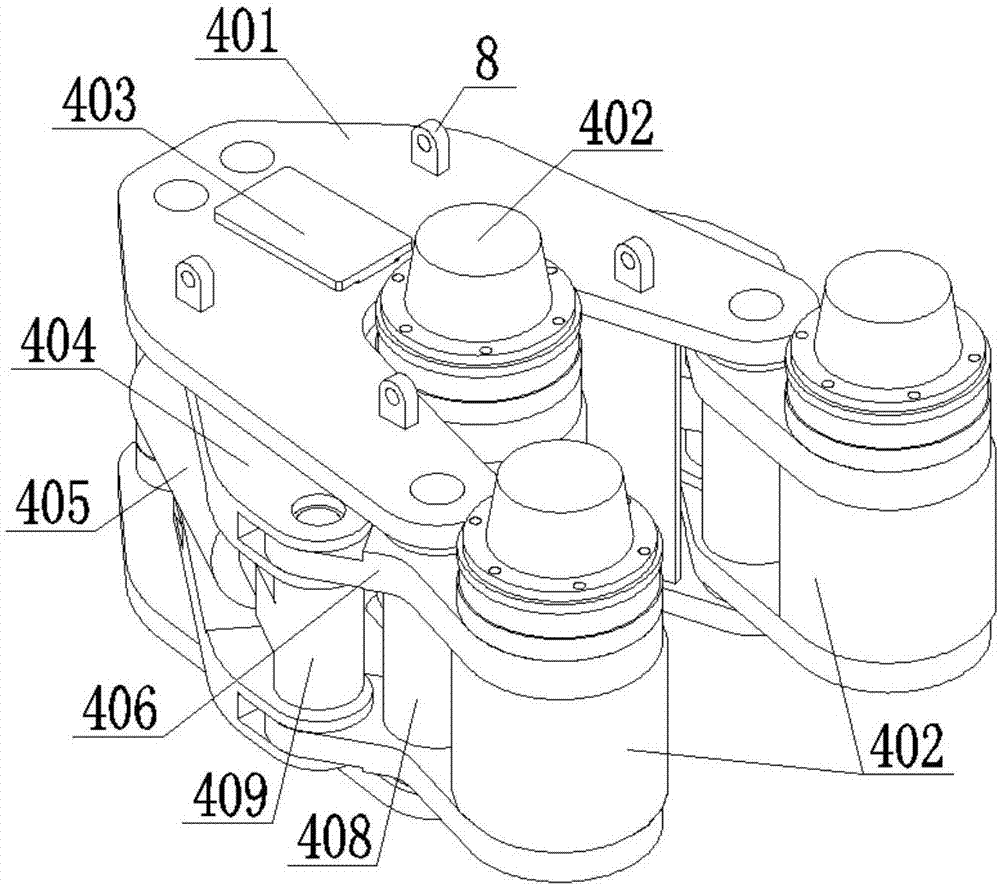

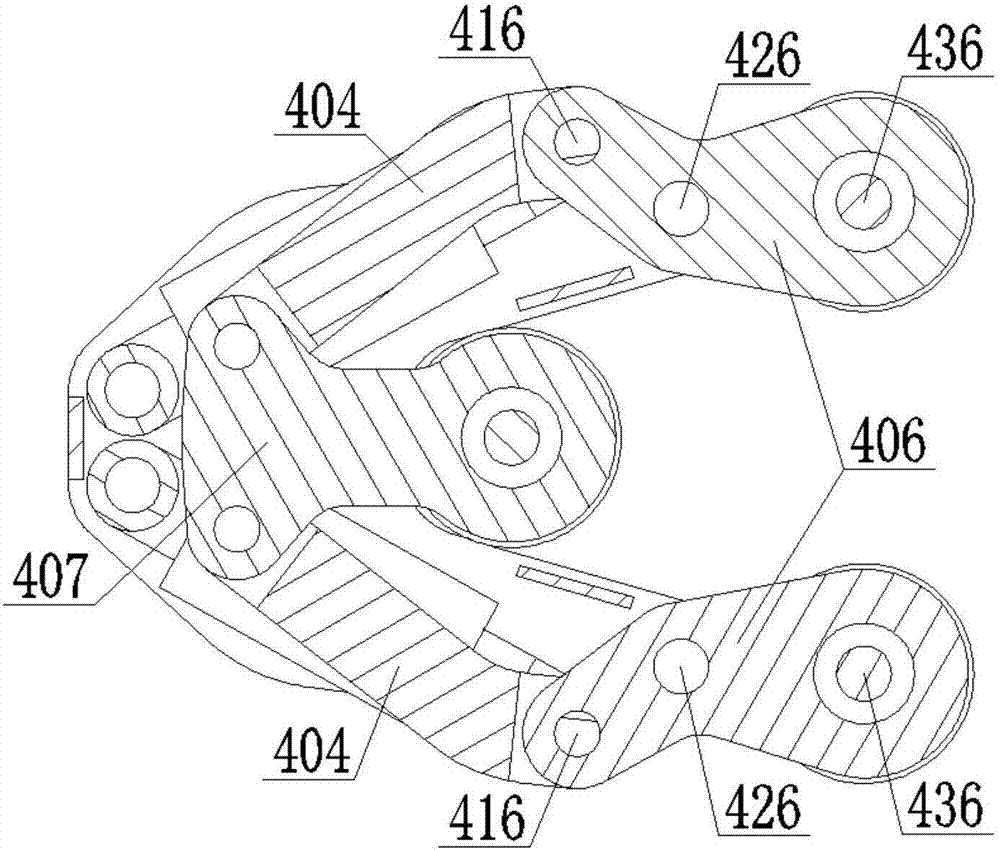

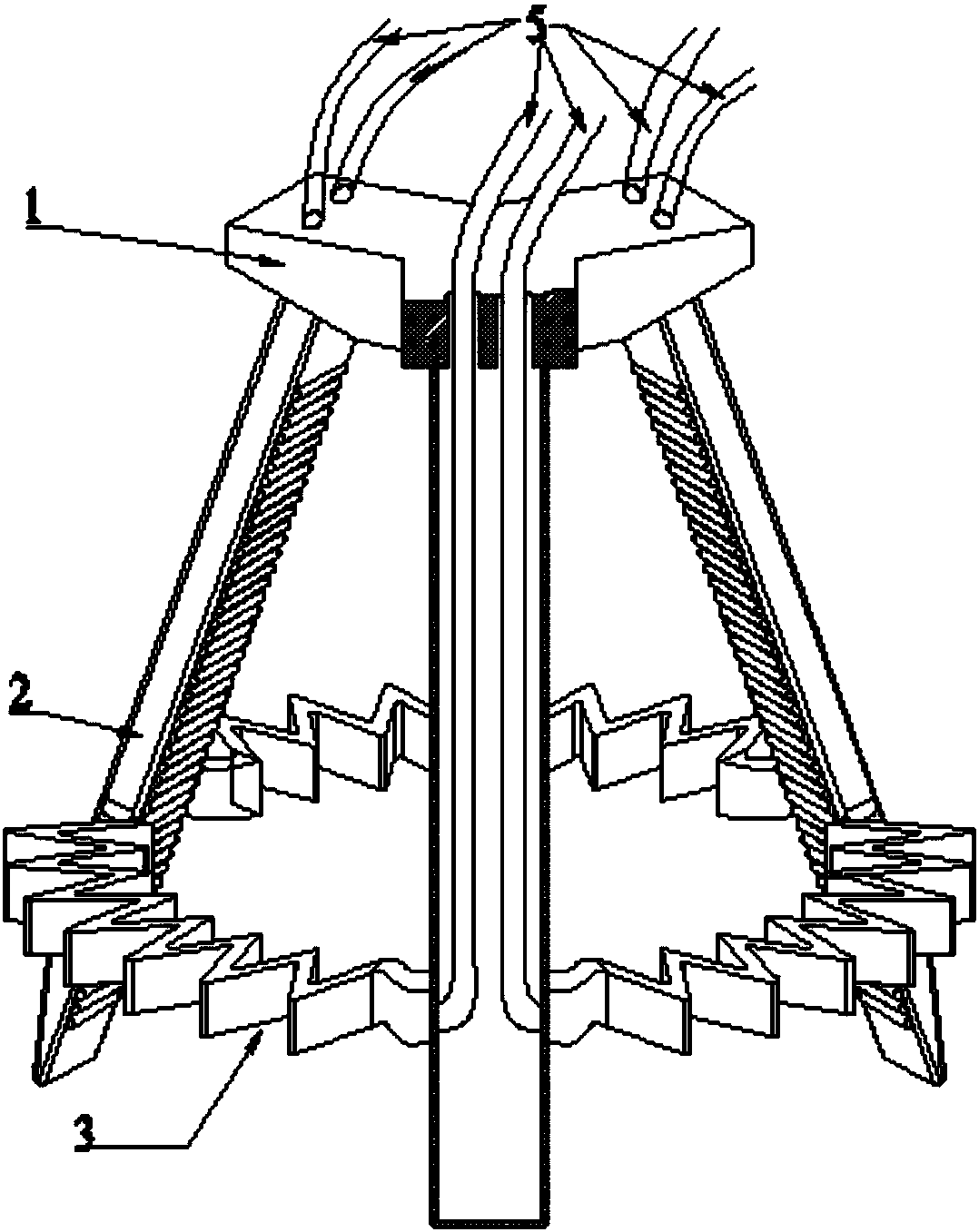

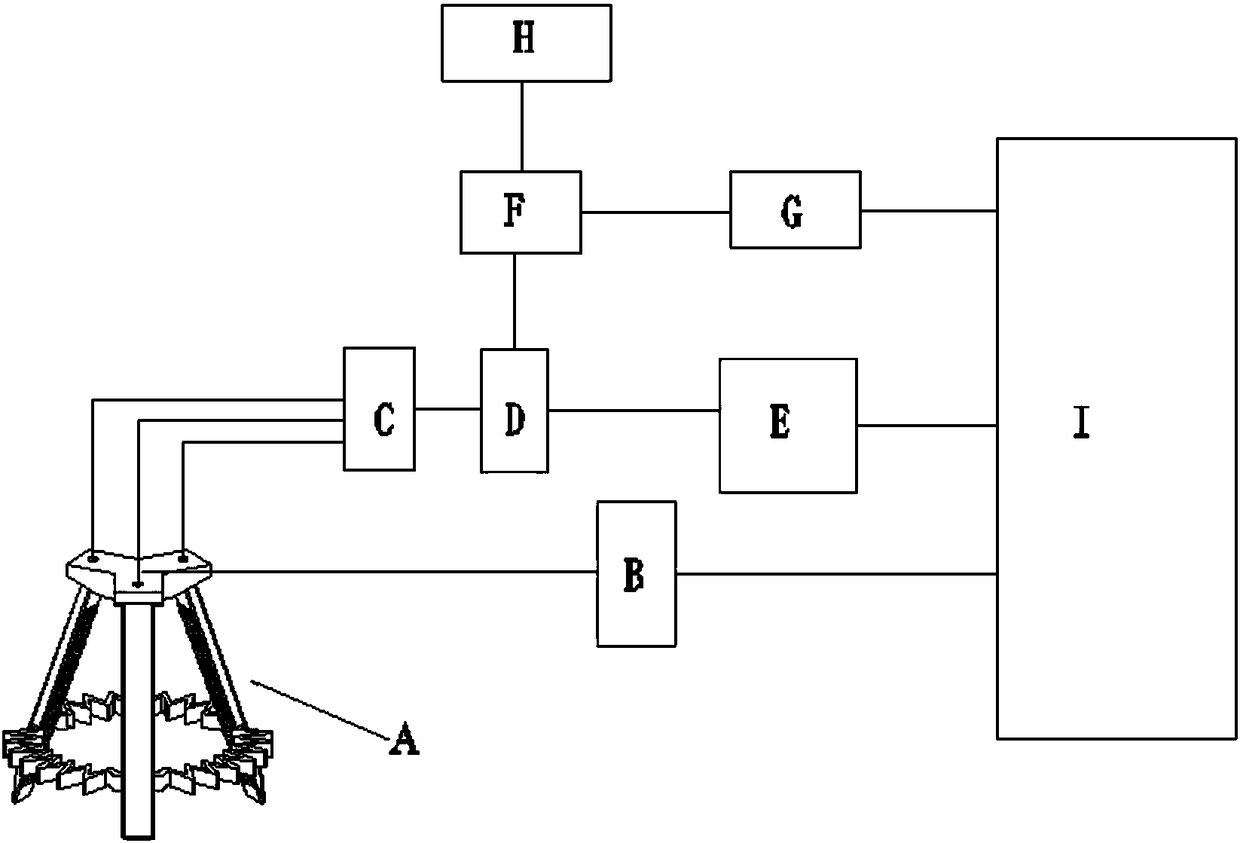

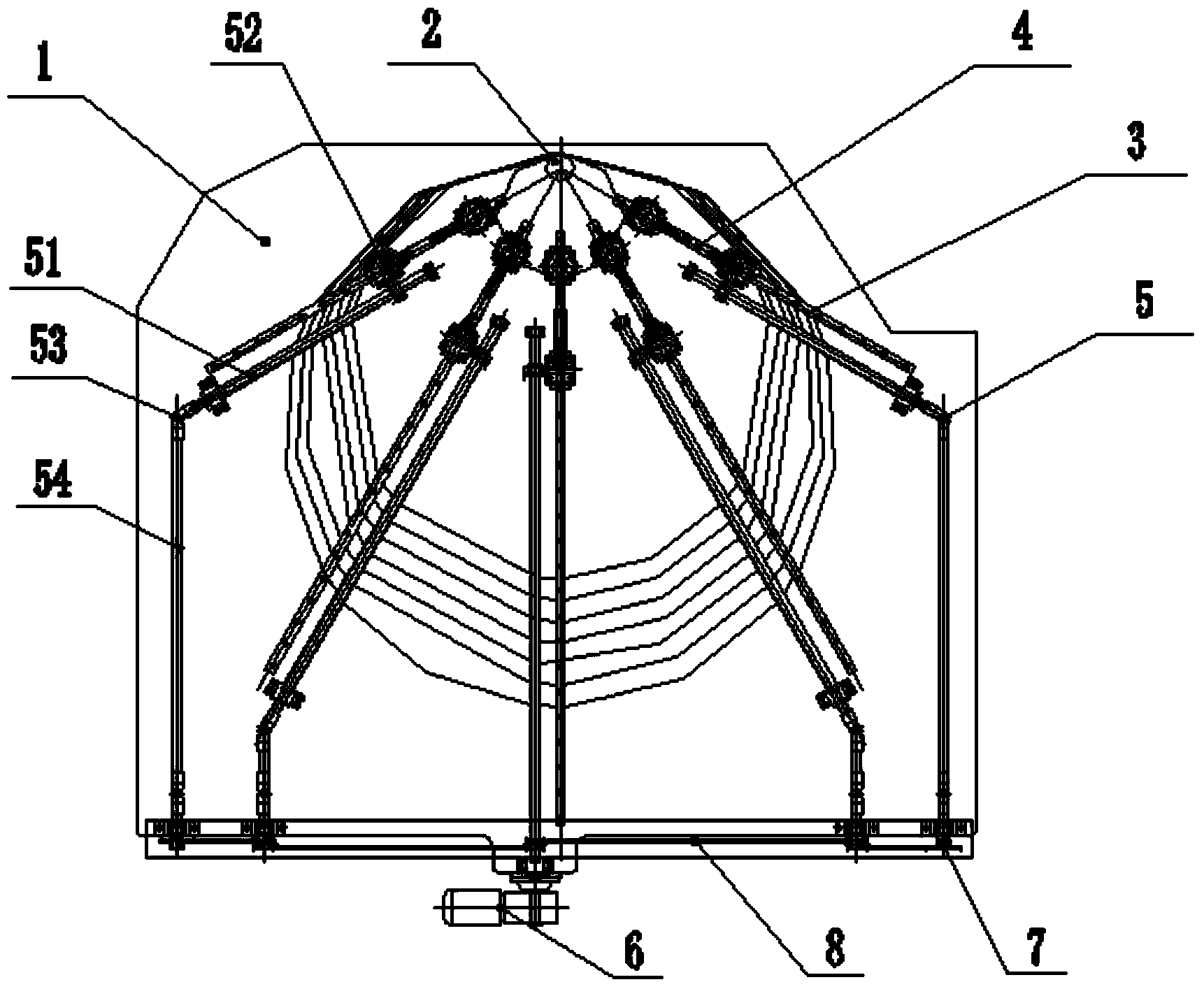

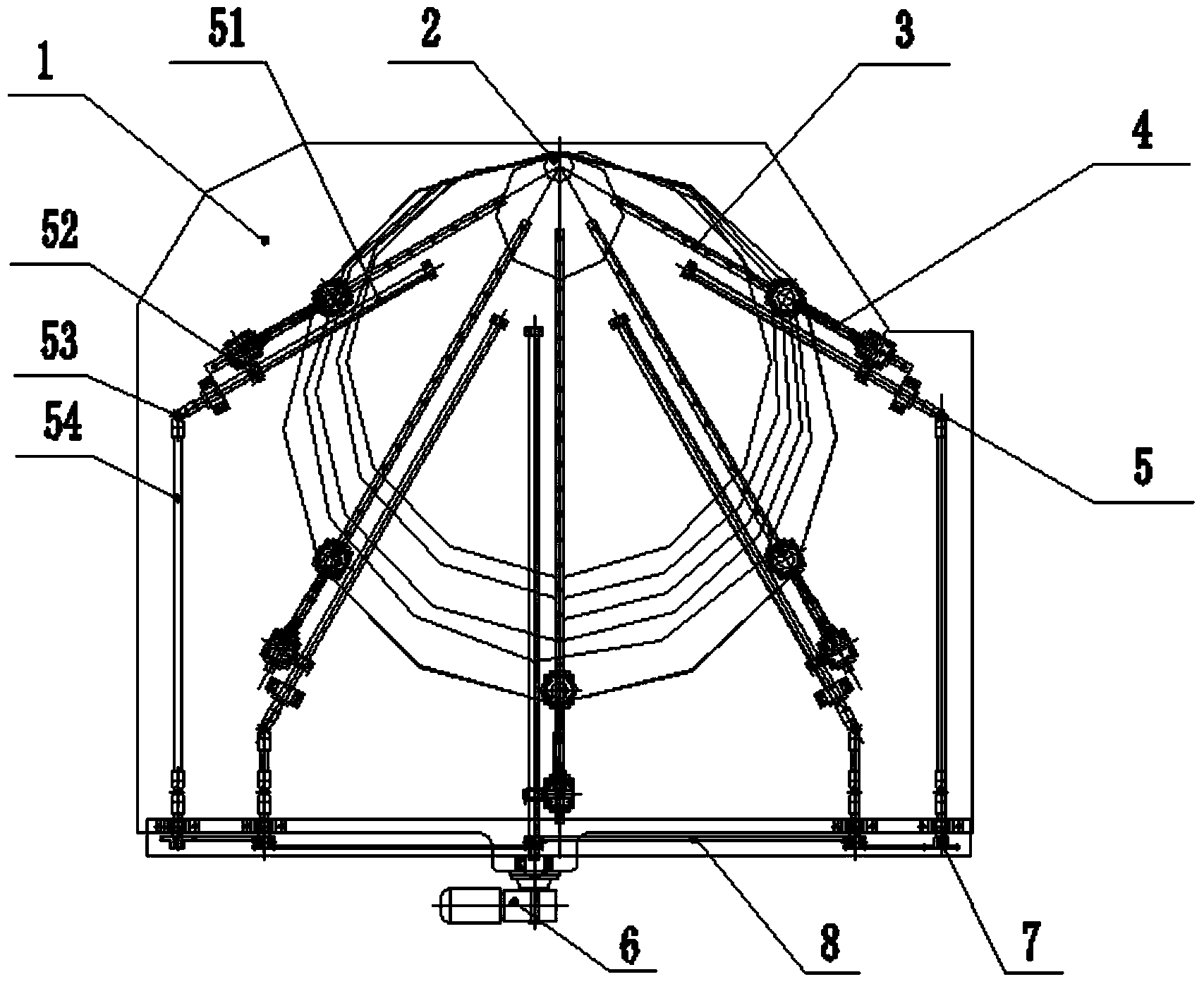

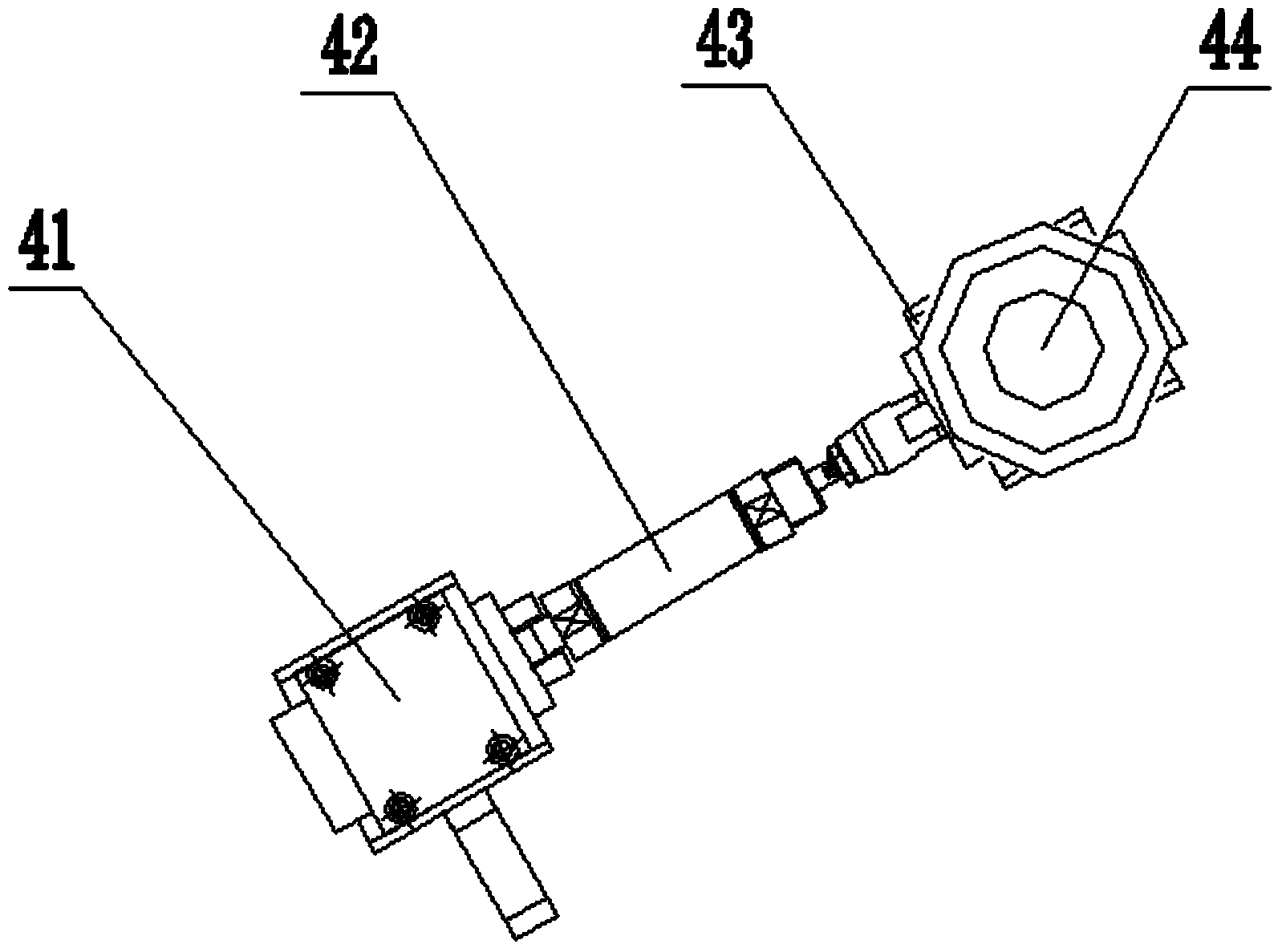

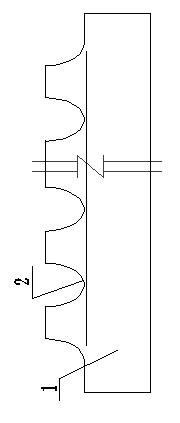

Variable structure adaptive feed type rope saw

InactiveCN102229009ALarge diameter rangeGuaranteed tensionMetal sawing devicesHydraulic cylinderControl system

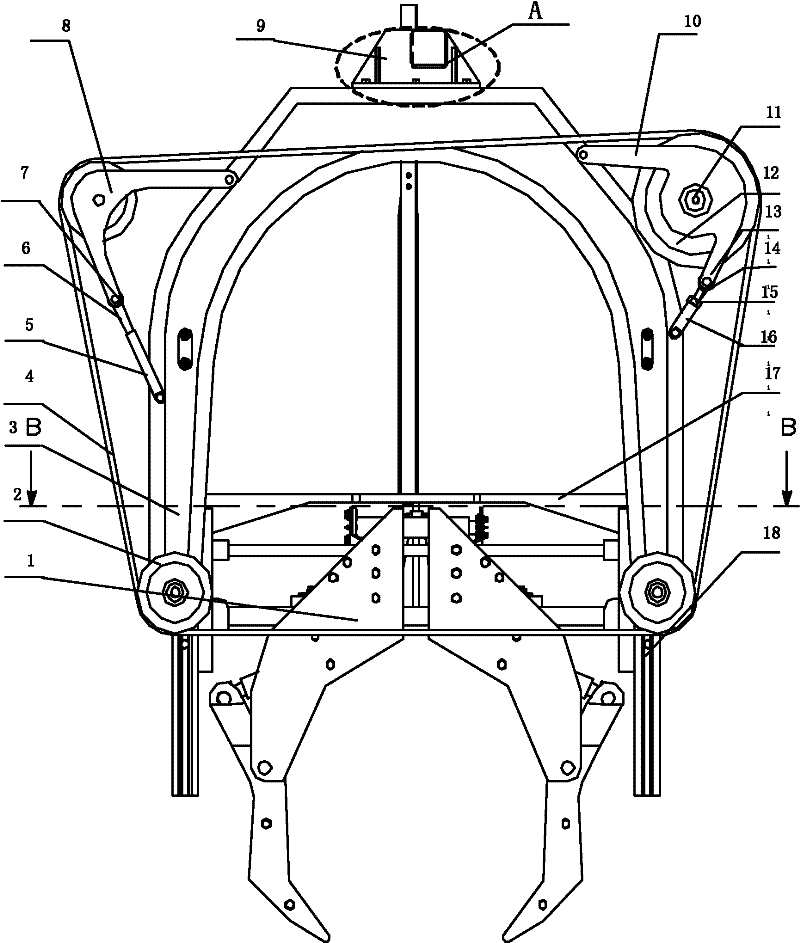

The invention mainly aims to provide a variable structure adaptive feed type rope saw for cutting composite pipes with different diameters amphibiously. The rope saw consists of a clamping mechanism, a cutting mechanism, a feeding mechanism and a tensioning mechanism; the clamping mechanism comprises a V-shaped plate, the V-shaped plate is formed by folding two mutually independent half plates, each half plate is connected with respective sliding block, and the sliding block and a guide rail I form a sliding pair; the two half plates fixed on respective sliding blocks can move relatively in the radial direction along the guide rail I; the half plates are connected with a hydraulic cylinder respectively, and the hydraulic cylinder is connected with a control system; and the lower ends of the half plates are connected with clamping claws through fixing pins, and the rear ends of the clamping claws are connected with the hydraulic cylinder. The rope saw is suitable for the pipes with diameters of phi 300 to phi 1,500 millimeters, so the diameter range of the cut pipes is greatly expanded; and meanwhile, different cutting speeds can be automatically adjusted according to different cutting states to adapt the rope saw, and the cutting efficiency is improved.

Owner:HARBIN ENG UNIV

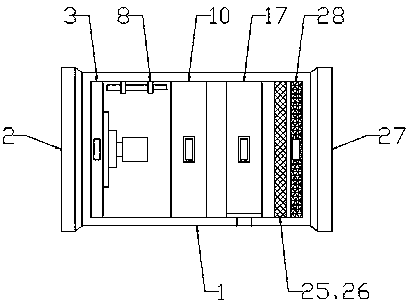

Multiple color press unit type gravure press

InactiveCN101774293ATo achieve the purpose of automatic controlSensitive adjustmentRotary intaglio printing pressPrinting press partsEngineeringPrinting press

The invention relates to a printing machine, in particular to a multiple color press unit type gravure press which overcomes the defects of each assembly structure in the traditional gravure press. The gravure press comprises a board gravure press drying box, a direct pressing type on-off pressure material storing mechanism, a gravure press automatic transversal template adjusting mechanism, a reversing gear box, a scraper trolley and a horizontal swinging roller mechanism. On the whole, through the series technical improvement on each assembly of the multiple color press unit type gravure press, the invention has more reasonable design for the whole machine, enhances the production efficiency, saves the materials, more importantly, enhances the printing quality and improves the product quality.

Owner:YUNCHENG PLATE MAKING PRINTING MACHINERY MFG

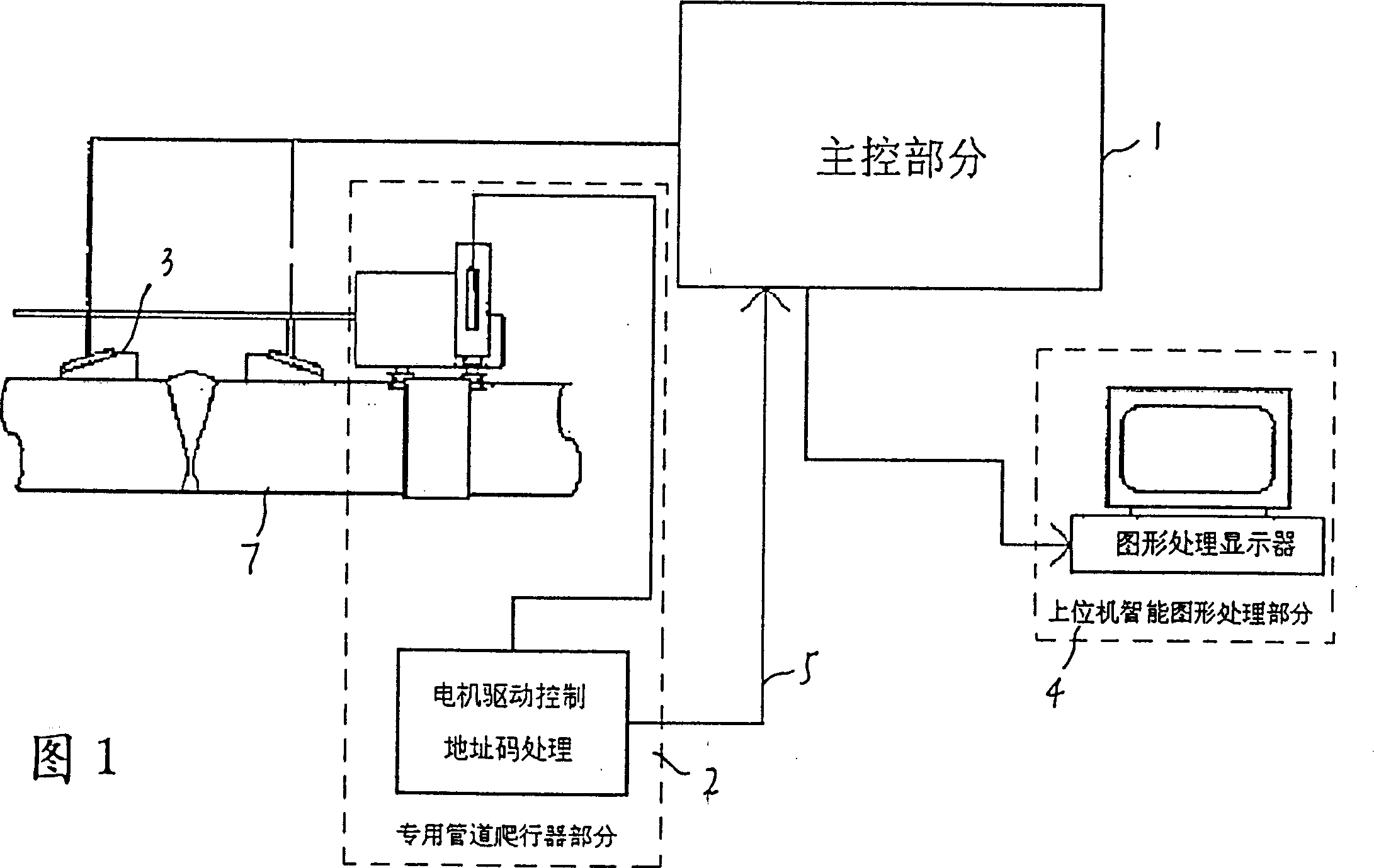

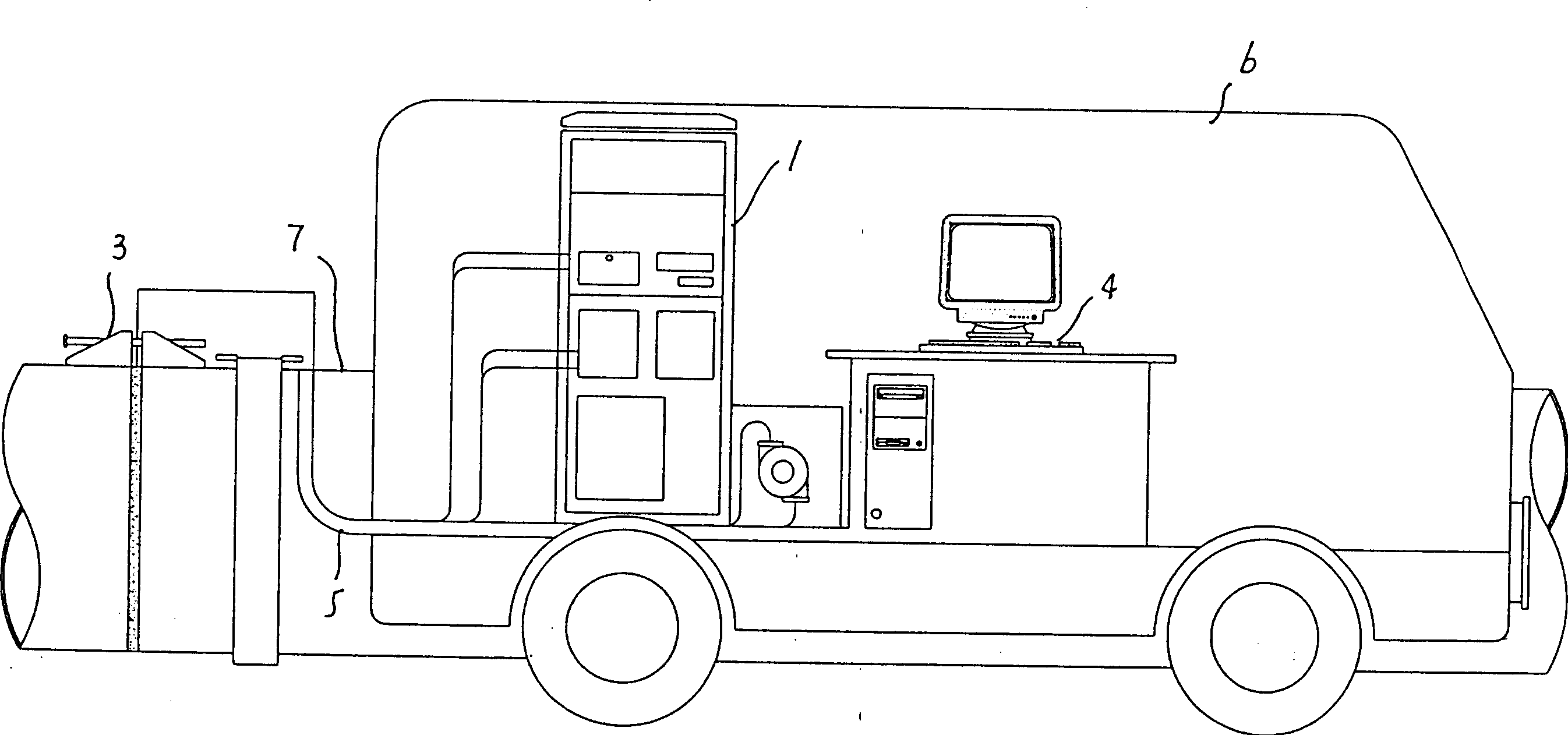

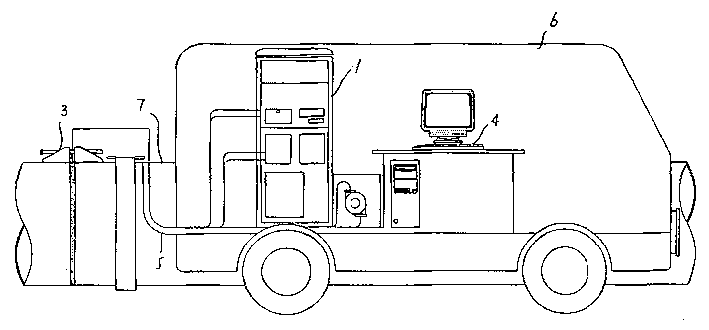

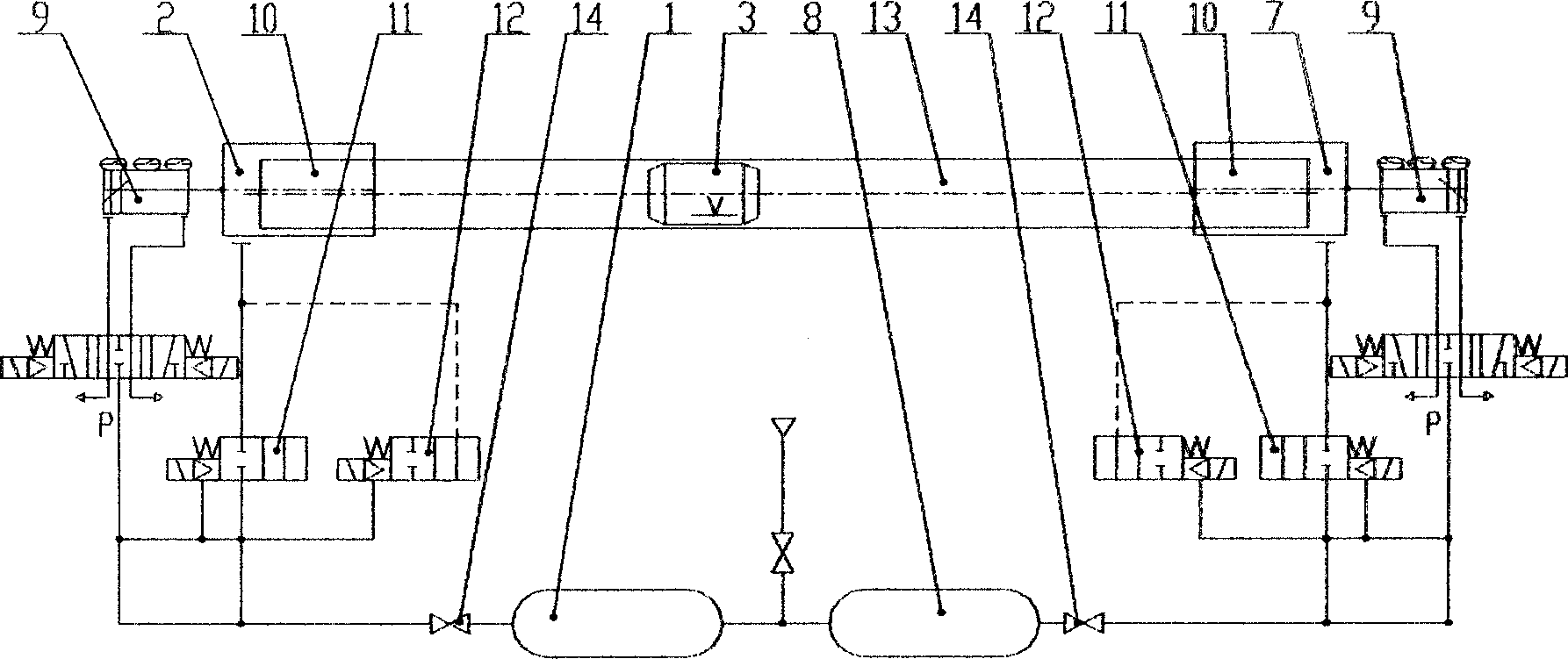

Large-bore pipe ring welded seam phased-array ultrasonic automatic detection system

InactiveCN1412552AReduce volumeReduce weightAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWeld seam

The present invention discloses a phased-array ultrasonic wave automatic detection system for detecting large-bore pipe circumferential weld. Said system mainly includes main control portion, specialpipeline creeper portion, ultrasonic wafer array probe portion, upperseat machine intelligent graphic processing portion, cable portion and special assembly car portion. The diameter range of pipe which can be detected by said system is large, from 4 inches to 56 inches.

Owner:中国石油天然气管道科学研究院有限公司 +3

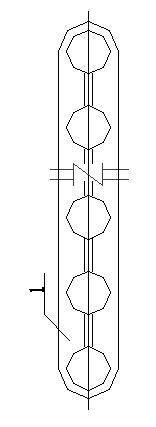

Cable climbing robot

A cable climbing robot comprises an outer frame and an inner climbing mechanism, wherein a ball screw with opposite turning directions at two ends is connected between upright tubes of each side face of the outer frame through bearings, and every two opposite ball screws are driven by a motor; each side face of the outer frame is provided with a slide block formed in a way that a cross rod connects two vertical rods, and slide block guide wheels at the upper and lower ends of the vertical rods are in contact with top rods and bottom rods of the outer frame; the outer sides of the two vertical rods both are fixedly provided with screw nuts; two pairs of clamping support plates are respectively fixed to two opposite pairs of cross rods, certain ends of the inner sides of the clamping support plates are hinged to guide rods with guide wheels, and extension springs are arranged between the guide rods and the clamping support plates, and the other ends of the clamping support plates are provided with guidance rods; the ends, extending inwards, of the guidance rods are hinged to balance beams, and pressure sensors and compression springs sleeve the guidance rods between the balance beams and the clamping support plates; the upper and lower ends of the balance beams are respectively provided with driven wheels and driving wheels connected with drive motors. The robot can be used for cables with great diameter differences, is good in clamping force and strong in cable climbing and obstacle crossing abilities.

Owner:SOUTHWEST JIAOTONG UNIV

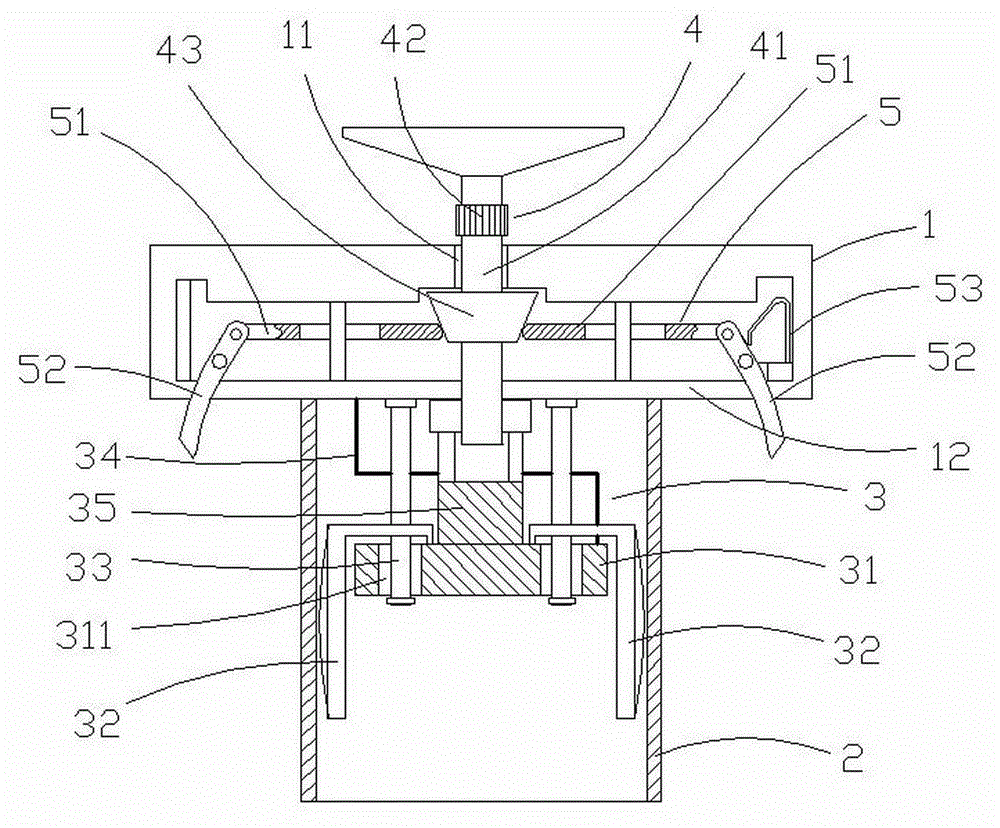

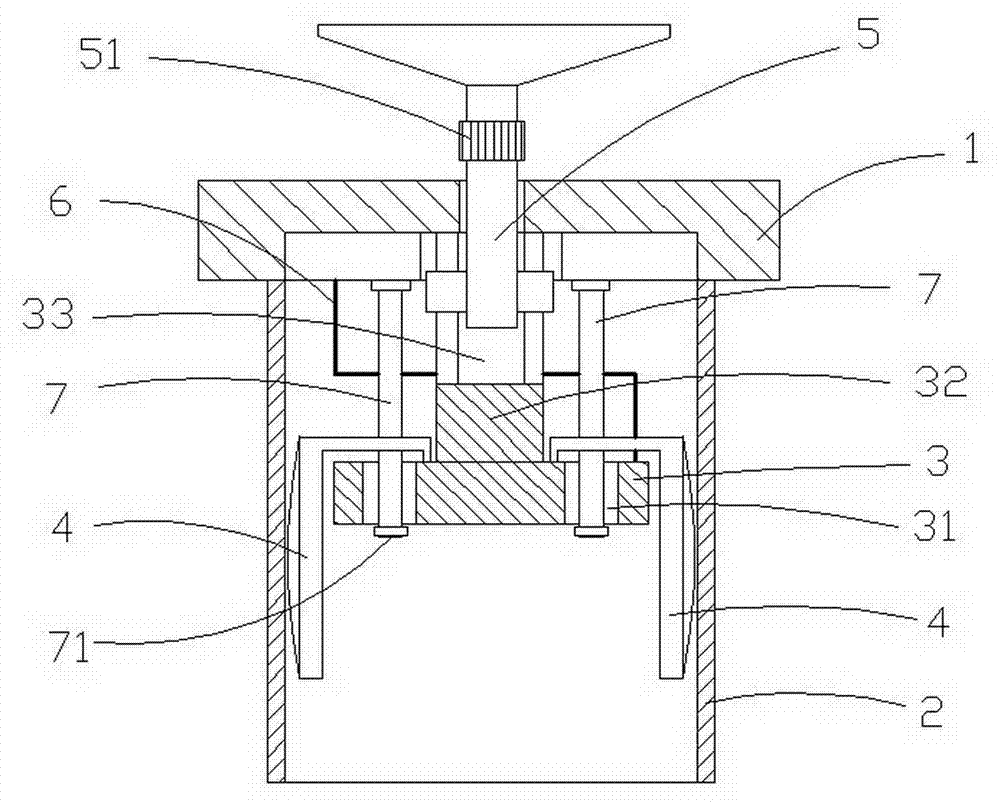

Sealing bottle plug

The invention discloses a sealing bottle plug. An expansion mechanism is arranged in an inner cavity of an elastic plunger body of the bottle plug. Four circumferentially-arranged supporting arms are arranged on a drive disc of the expansion mechanism. Jacking parts of the supporting arms surround the inner circumferential wall of the elastic plunger body and abut against the inner circumferential wall. When a rotary handle of a rotating mechanism drives the drive disc to rotate, the supporting arms expand and shrink radially to drive the elastic plunger body to shrink and expand radially at the unequal amount; in order to lock the expansion diameter of the elastic plunger body, a locking disc on the rotary handle is moved downwards to be clamped with a locking hole, and meanwhile, a conic control column pushes two clamping hooks of a clamping component to shrink towards each other, so that a bottle opening is clamped, and the bottle opening is sealed and clamped. By the adoption of the sealing bottle plug, according to bottle bodies of different calibers, the bottle plug is adjusted to be matched with bottle openings, the sealing performance is high, reuse is achieved, and practicality is high.

Owner:刘婷婷

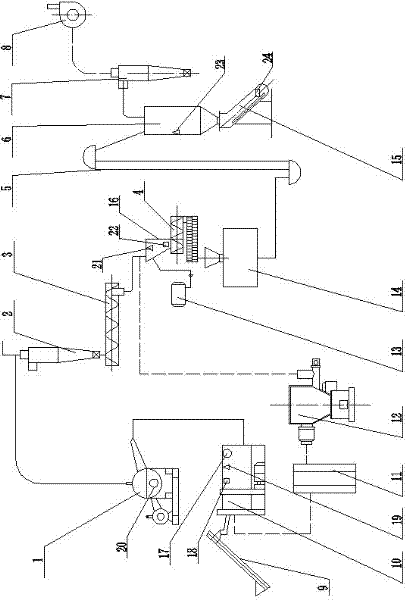

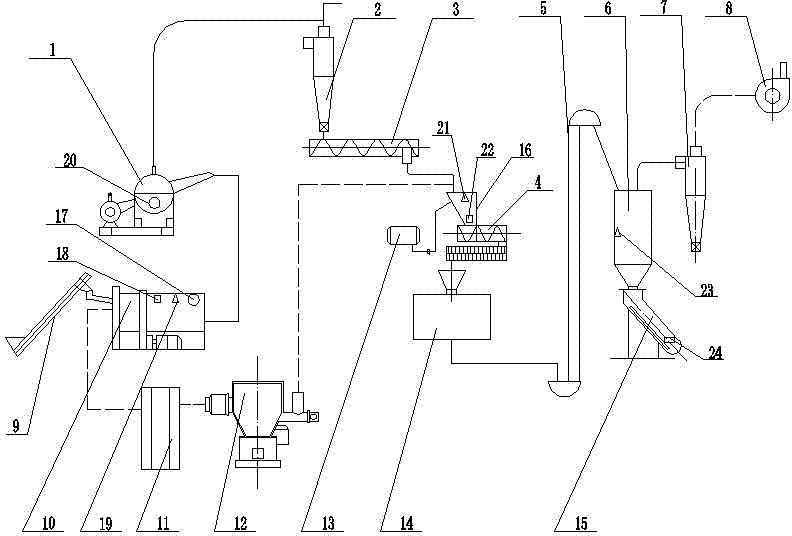

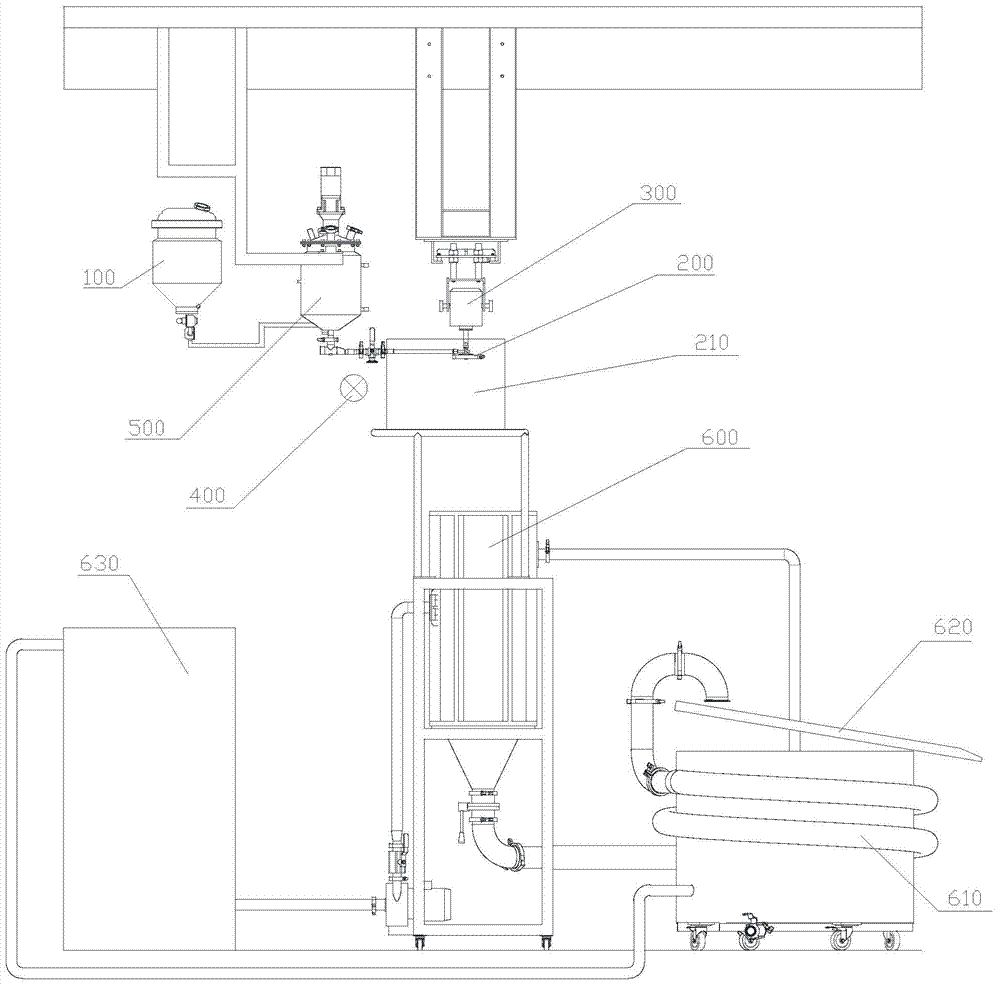

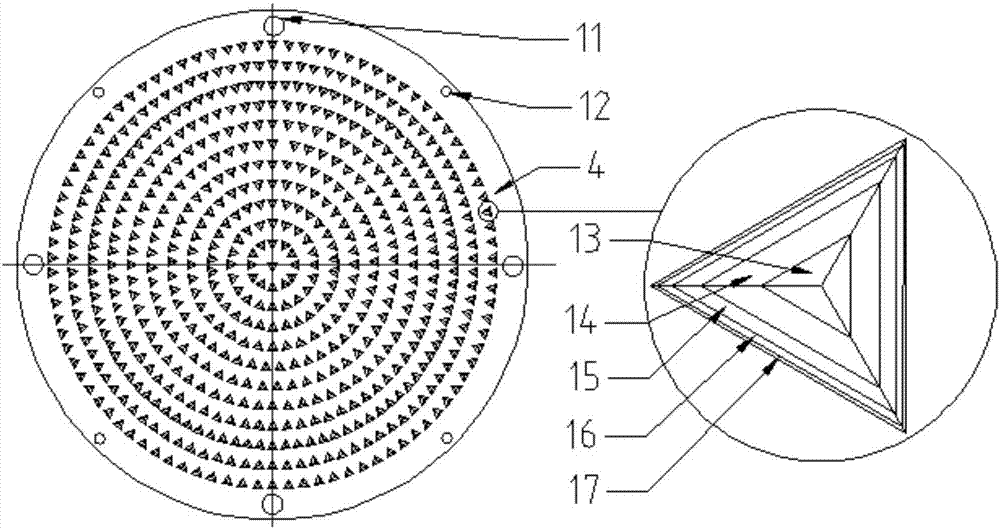

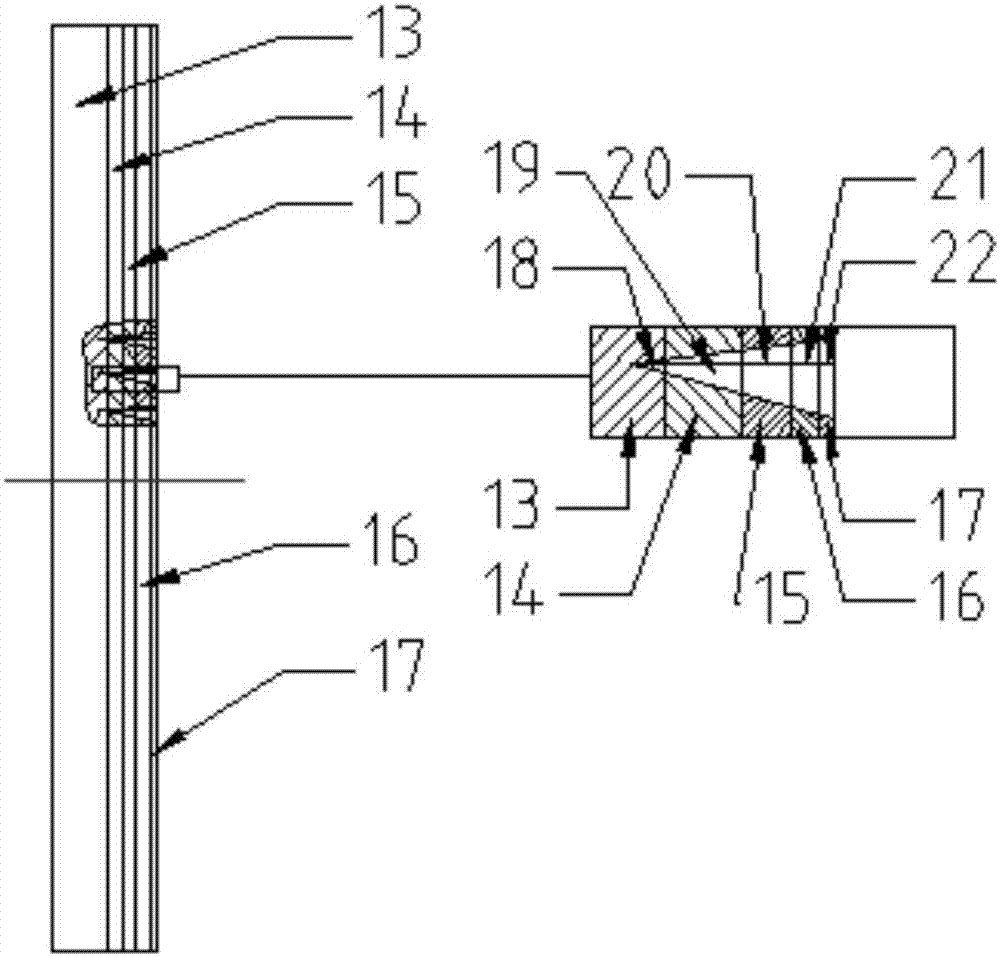

Automatic molding system for biomass flat-die particle

InactiveCN102517112AIn line with the actual operating mechanismReduce wearBiofuelsSolid fuelsAutomatic controlProcess engineering

The invention discloses an automatic molding system for a biomass flat-die particle, which comprises a drying part, a crushing part, a material conveying part, a molding part and a cooling and drying separating part, wherein the discharge hole of the drying part is connected with the feeding hole of the crushing part; the discharge hole of the crushing part is connected with the feeding hole of the molding part through the material conveying part; and the discharge hole of the molding part is connected with the feeding hole of the cooling and drying separating part. The automatic molding system for the biomass flat-die particle includes a set of intelligent and automatic large-scale energy treatment process routes integrating straw drying, straw crushing and straw cold-state compact molding. According to the automatic molding system for the biomass flat-die particle, the automatic operation of all links of biomass molding is realized by adopting an integral automatic control system, thereby, manual operations are reduced, and the automatic operation of the system under optimized working conditions is ensured; energy consumption and labor cost are low; and a heat source is provided by adopting the fluidized-bed combustion technology in the biomass drying process without consuming traditional energy sources, and the heat utilization efficiency of equipment can reach over 60 percent.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Steel pipe inner wall washing gun

InactiveCN103100982ALarge diameter rangeNo pollution in the processBlast gunsAbrasive feedersRolling resistanceHigh-speed grinding

The invention discloses a steel pipe inner wall washing gun comprising a sand supplying pipe and a high-pressure water supplying pipe located below the sand supplying pipe, wherein the tail end of the sand supplying pipe is connected with a sand separator; the tail end of the high-pressure water supplying pipe is connected with an injection head; the injection head comprises a plurality of independent injection units; and all the injection units are communicated with the sand separator. The sand supplying pipe and the high-pressure water supplying pipe respectively convey mortar and high-pressure water to the injection units; the mortar and the high-pressure water are mixed in nozzles of the injection units to form a grinding material jet flow which moves at a high speed so as to form a linear injection section; and the impact and the washing of the high-speed grinding material injection flow are used so that scales on the inner wall of a steel pipe can be removed in a continuous, efficient and environment-friendly manner. The sand supplying pipe and the high-pressure water supplying pipe are fixed through a pipe clip assembly and a supporting wheel of the pipe clip assembly is contacted with the inner wall of the steel pipe to support a whole de-scaling gun; the de-scaling gun and the inner wall of the steel pipe are in rolling friction, so that the movement resistance is reduced and no barrier exits when the de-scaling gun and the steel pipe move relatively. Furthermore, the height of the supporting wheel is adjustable so as to adapt to the size of the diameter of the steel pipe to be washed.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

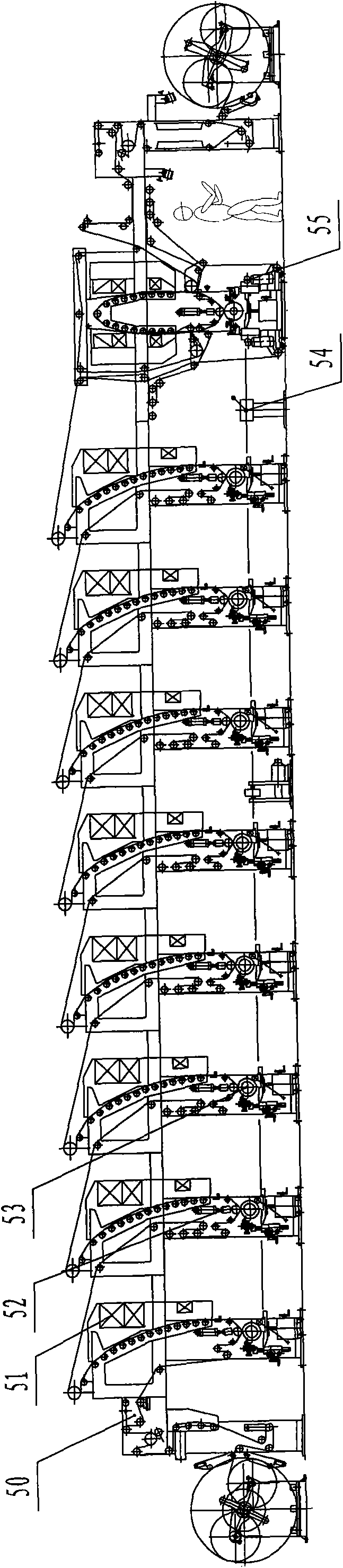

Liquid cooling dropping pill production line

InactiveCN104274327AReduce impactSmooth feedingPharmaceutical product form changeMelting tankEngineering

The invention provides a liquid cooling dropping pill production line, which comprises a dropping pill system, a liquid cooling circulation system and a control system, wherein the dropping pill system comprises a material melting tank and a dropper connected with the material melting tank, a vibration device is arranged between the material melting tank and the dropper, an on-line monitoring device is arranged on the dropper, the on-line monitoring device comprises a pulse signal emitting mechanism, the emitting frequency of the pulse signal emitting mechanism is identical to the vibration frequency of the vibration device, and the control system controls and regulates dropping parameters according to the monitoring results of the on-line monitoring device. The liquid cooling dropping pill production line has the advantages that the high-frequency cutting dropping is combined, the dropping pill quality is detected in real time on line and is controlled and regulated, the yield is improved, and the drilling pill diameter range is expanded; a plurality of tangential inlets are formed inside the tank wall of a cooling tank, and the impact force caused by cooling liquid surface on liquid drips when the liquid drips enter the cooling tank can be effectively reduced; the swarming and the pulse can be effectively eliminated, so the material conveying of a dropping pill machine is stable; the dropping pill cooling time is increased through regulating the length-to-diameter ratio of a discharging pipeline, the quality is ensured, and meanwhile, the energy consumption is reduced.

Owner:TIANJIN TASLY PHARMA CO LTD

Method for preparing suspension liquid of steady Nano carbon tube by using tannic acid

InactiveCN101049925AImprove suspension abilitySuspension stabilityNanostructure manufactureNatural productDistilled water

This invention discloses a method for preparing stable carbon nanotube (CNT) suspension by using tannic acid. The method comprises: (1) affing distilled water into tannic acid to obtain 5-500 mg / L tannic acid aqueous solution; (2) adding CNT (inner diameters less than or equal to 100 nm) to obtain 10-1000 mg / L CNT solution; (3) ultrasonicating in an ultrasonic cleaner for 30-60 min; (4) standing for more than 24 h, transferring the CNT suspension into another container. The dispersant in this invention, tannic acid, is a nontoxic and water-soluble natural product, and has high suspension ability to CNT. The obtained CNT suspension is stable, and the method is suitable for a wide range of conditions.

Owner:ZHEJIANG UNIV

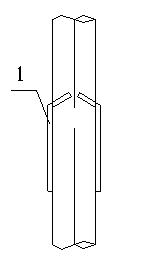

Shaft holder

InactiveCN103821803AEffective clamping and lockingNeutral goodFriction grip releasable fasteningsAgricultural engineeringIn real life

The invention relates to a shaft holder comprising a V-shaped block, a shell, a V-shaped block compressing screw and a left and right shell body locking latch. The V-shaped block comprises a left fixed V-shaped block and a right movable V-shaped block, the shell comprises a left shell body and a right shell body, the left fixed V-shaped block and the right movable V-shaped block are wrapped by the shell body, the left fixing V-shaped block is fixedly connected with the shell body, mesh teeth in cross banding are evenly arranged on a teeth mouth portion corresponding to the left fixed V-shaped block and the right movable V-shaped block, so that the left fixed V-shaped block and the right movable-V shaped block can be meshed correspondingly to adaptive to diameter range changes of different clamping targets; the shaft holder is capable of solving the problem that the existing simple shaft holder cannot lock tightly and is narrow in application range, and meeting actual demand in real life or industry production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

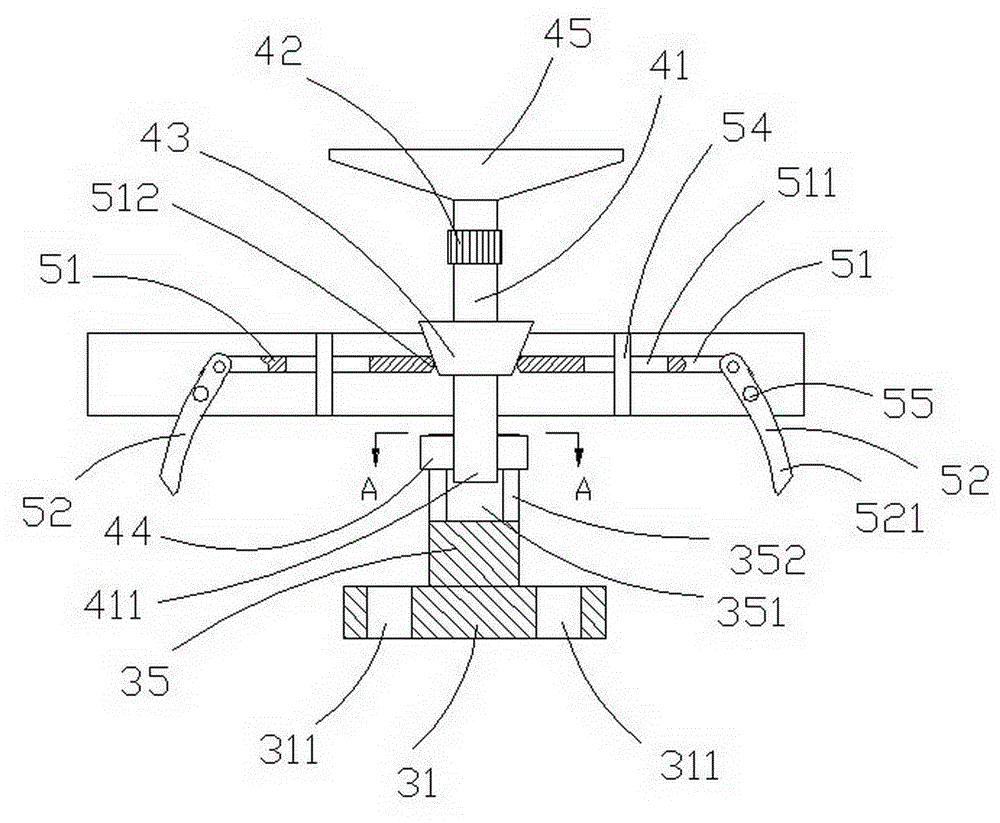

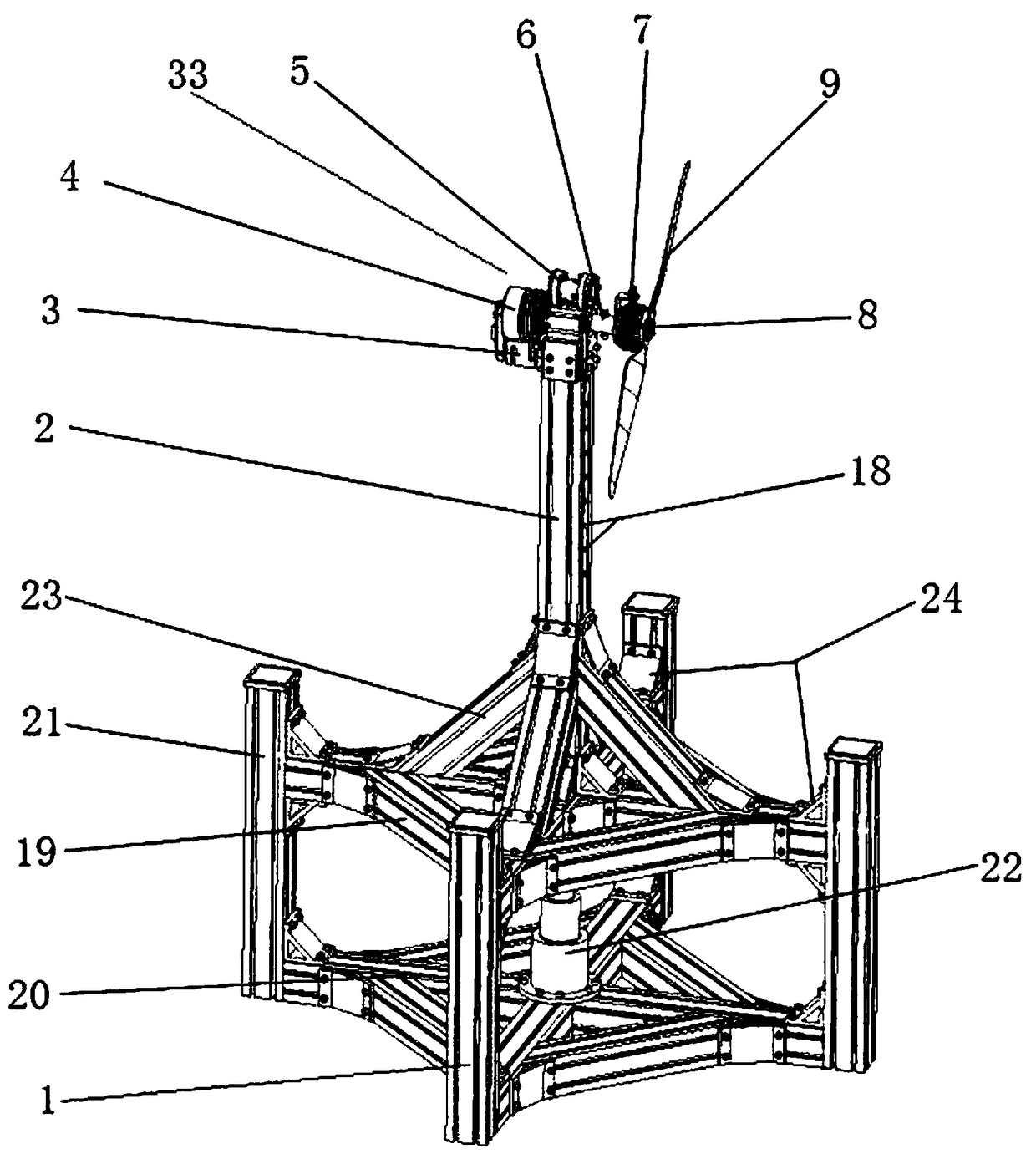

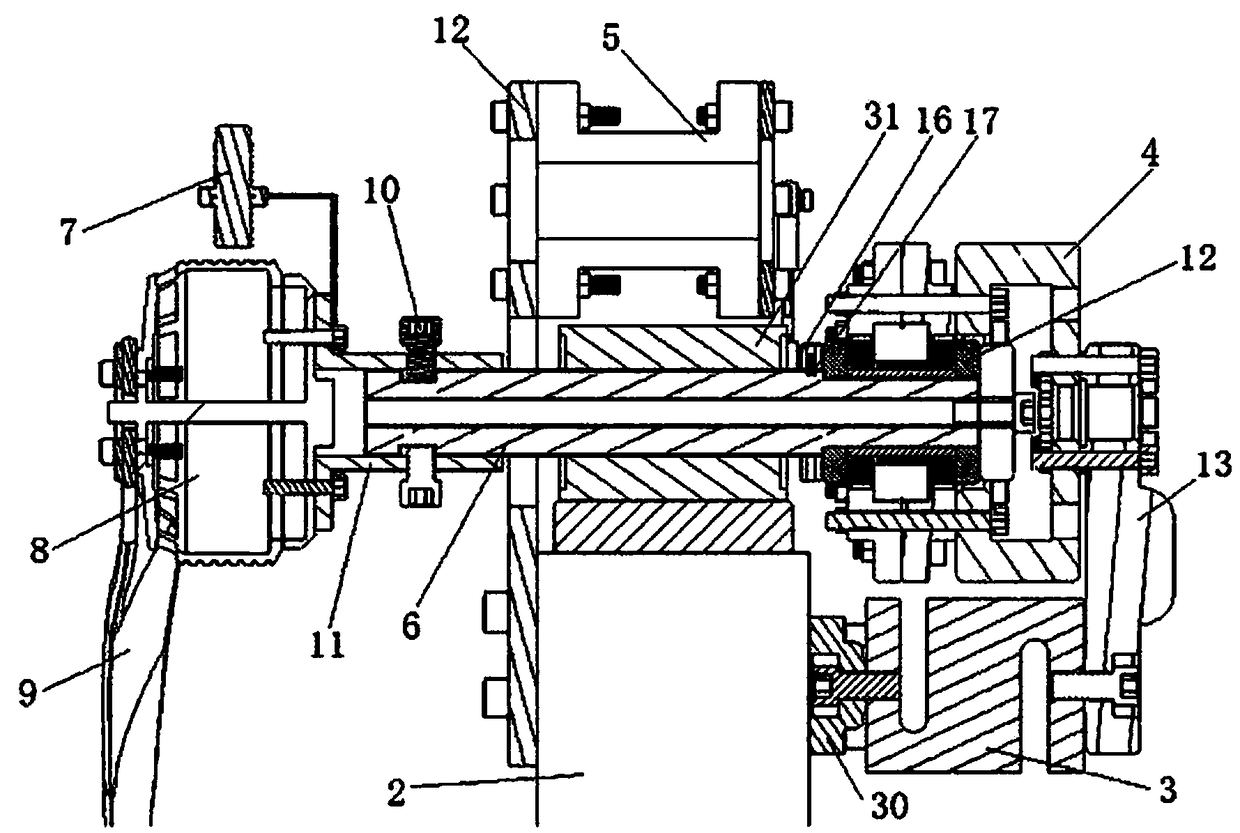

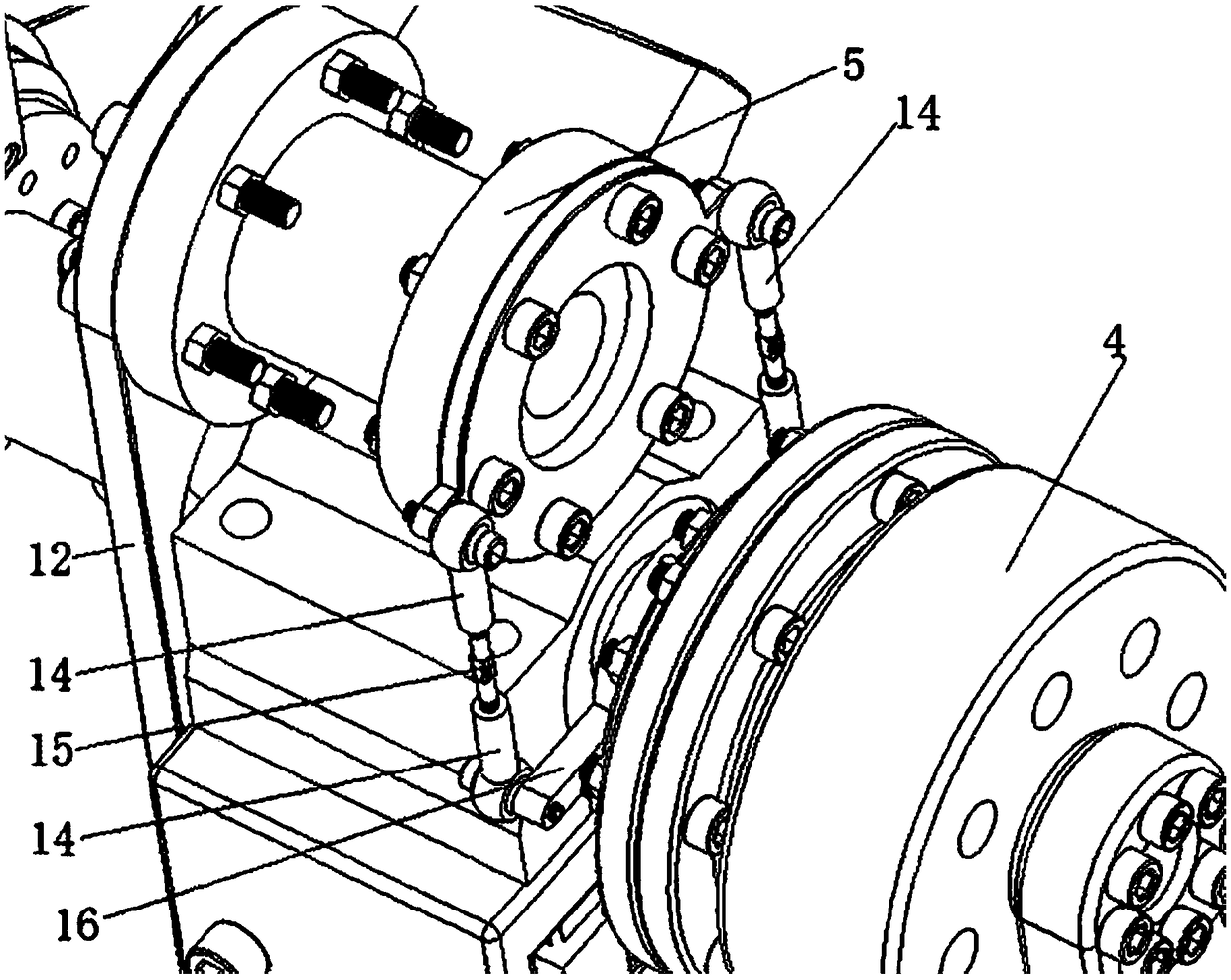

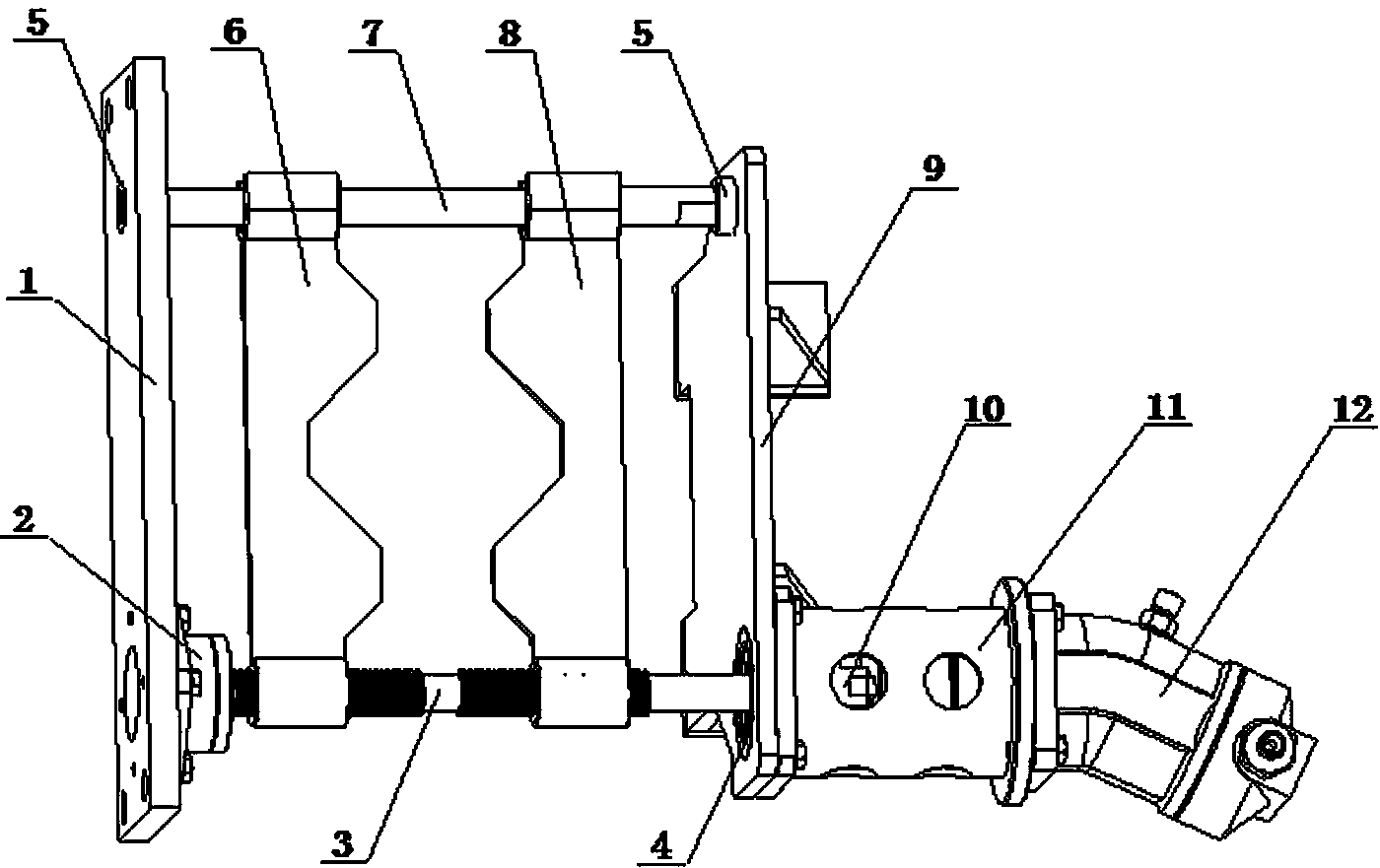

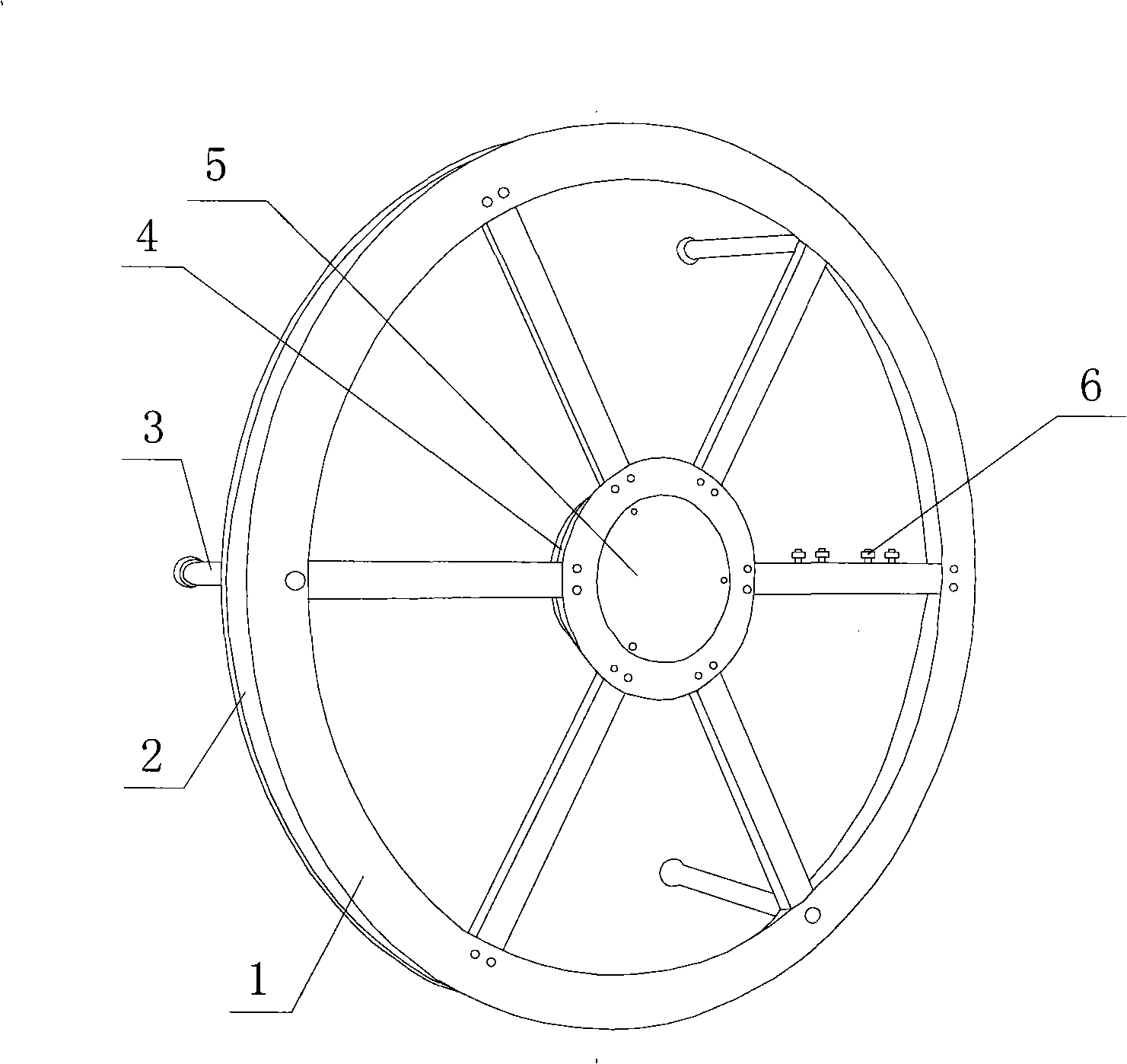

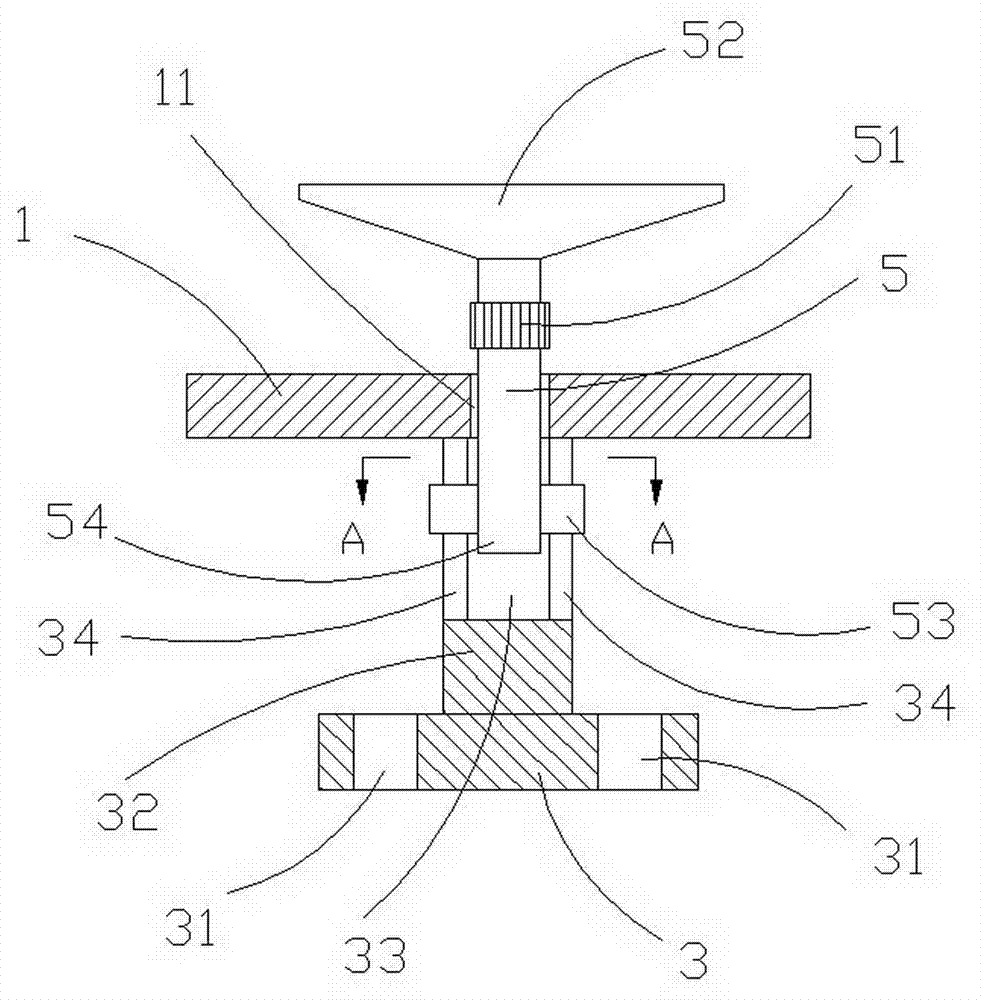

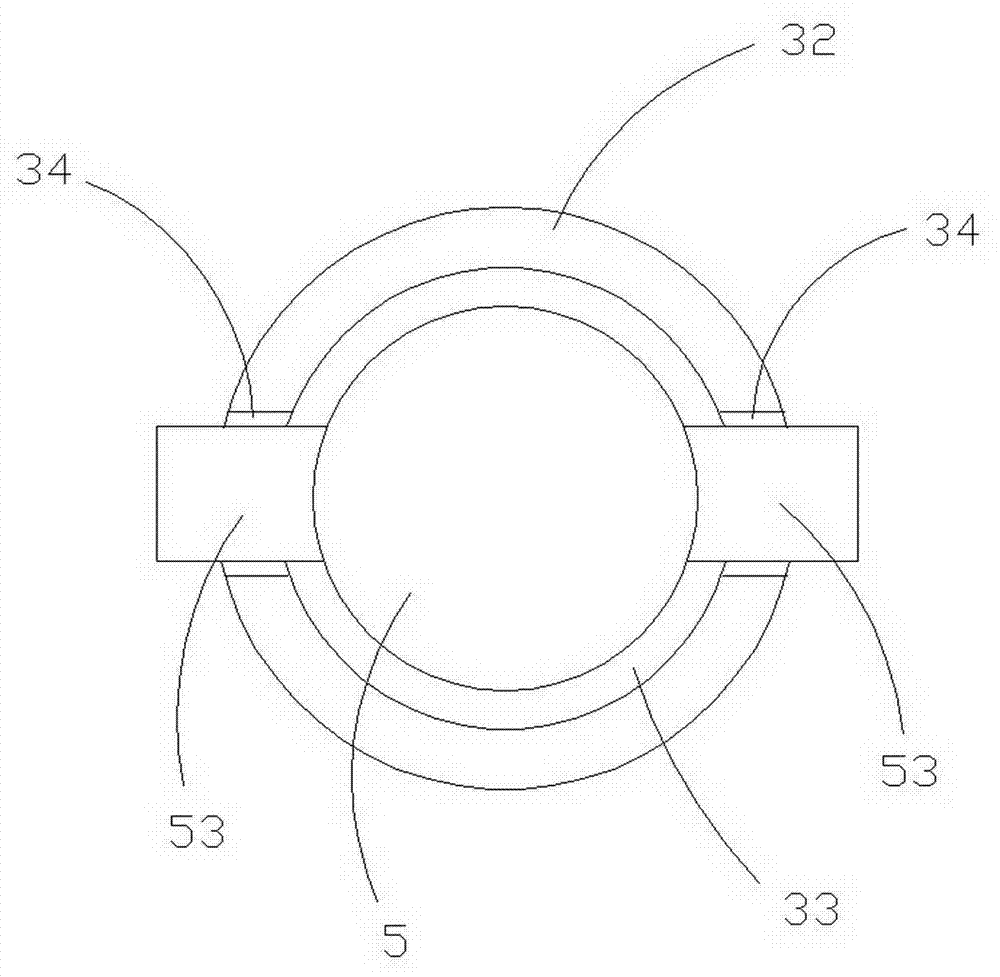

Blade performance test bench for rotorcraft

ActiveCN109018430ALarge diameter rangeMeet performance measurement accuracy requirementsAircraft components testingBrushless motorsTension compression

The invention discloses a blade performance test bench for a rotorcraft. The bench comprises a bench body, power system and a measurement and control system, the bench body comprise a support seat, Asupport bar and a blade test mechanism, The blade test mechanism comprises an S-shaped tension-compression force teste module, a Force Transfer Ring, a Torque Sensor, a force spindle, Speed sensors and brushless motors, an inorganic brush is connected with the paddle to be tested, one end of the force transmission spindle is fixed with a flange by a stop bolt, A brushless motor is mounted on the flange, the force transmission ring is connected with the force transmission main shaft through a rolling bearing, the force transmission ring is connected with an S-shaped tension-compression force measurement module through a force transmission rod, the torque sensor is connected with a torque rocker arm through a fish-eye joint bearing and a double-head threaded pull rod, and the torque rocker arm is installed on the force transmission main shaft through a screw. The length of the support rod and the replaceable brushless motor of the invention make the range of the measurable blades wide, and the S-shaped tension-compression force measuring module and the torque sensor can be replaced to meet different testing requirements and precision requirements.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Reel-type submarine pipeline laying workboat and working method thereof

InactiveCN102020003ALarge diameterReduce the degree of bending deformationPipe-laying vesselsOcean bottomEngineering

The invention relates to a reel-type submarine pipeline laying workboat and a working method thereof. The workboat comprises a boat body, a reel, a reel driving mechanism for driving the reel to rotate, a pipeline wound on the reel, and a pipeline tensioning and straightening mechanism; the boat body comprises a deck and a bottom case; a sinking slot for the reel to sink is formed on the lower part of the deck of boat body, and passes through the deck; the workboat also comprises a reel lifting mechanism; and the reel lifting mechanism can drive the reel to rise and fall along the sinking slot. A laying method for the workboat comprises the following steps of: reducing the height of the reel through the reel lifting mechanism to meet the requirement of stability on the boat; adjusting tensile force and a straightening angle of the pipeline through the pipeline tensioning and straightening mechanism; driving the reel to rotate by using the reel driving mechanism to lay the pipeline; and after the pipeline is laid, lifting the reel by using the reel lifting mechanism, and returning the workboat. The invention can greatly increase the diameter of the reel on the premise of keeping the stability of the workboat, so that the pipe diameter range of the laid pipeline is enlarged.

Owner:LICE SCI & TECH SHANGHAI

Adjustable polishing head mechanism for magnetic compound fluid

The invention relates to an adjustable polishing head mechanism for magnetic compound fluid. The adjustable polishing head mechanism comprises a magnet rotating mechanism and a liquid carrying plate rotating mechanism. A permanent magnet in the magnet rotating mechanism is eccentrically fixed to the lower portion of a magnet disc. The magnet disc is connected with a first motor through a main shaft. The first motor drives the main shaft to drive the permanent magnet to rotate, and a high-speed rotating magnetic field is produced. A connecting bracket in the liquid carrying plate rotating mechanism is a round sleeve and is installed on the outer side of the magnet rotating mechanism. A liquid carrying plate serves as an end cover of the connecting bracket and is installed below the permanent magnet. A V-shaped belt is connected to a V-shaped belt wheel and the connecting bracket in a sleeving mode. A second motor is connected with the V-shaped belt wheel through a coupler and drives the connecting bracket and the liquid carrying plate on the connecting bracket to rotate through the V-shaped belt wheel, so that the magnetic compound fluid on the liquid carrying plate rotates, and thus polishing removing of a workpiece is achieved. The adjustable polishing head mechanism for the magnetic compound fluid has the characteristics of being simple in structure, high in material removing efficiency, wide in applicable magnetic cluster size range and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

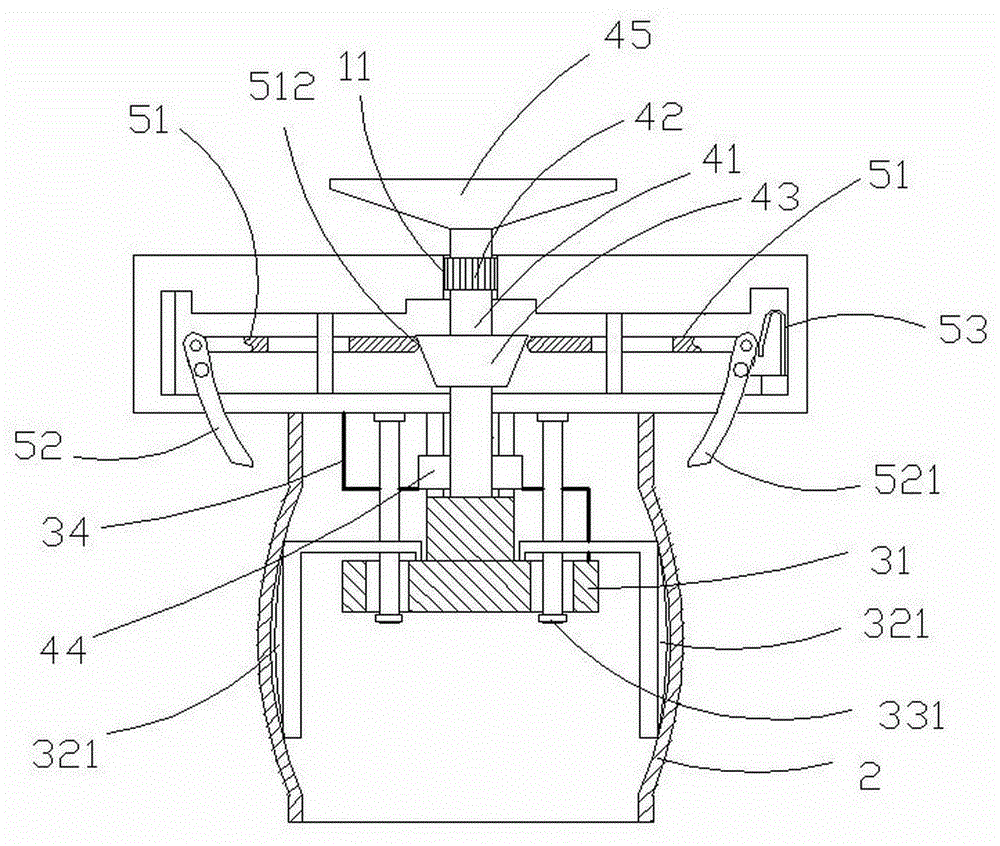

Double-rocker self-adaptive centering clamp

InactiveCN103331713ARealize multi-point clampingLarge diameter rangeWork holdersHydraulic cylinderSelf adaptive

A double-rocker self-adaptive centering clamp is provided with a rack, wherein a driving hydraulic cylinder and a double-rocker mechanism are arranged on the rack, the top end of the driving hydraulic cylinder body and the rack are hinged into a whole, the end of a piston rod of the driving hydraulic cylinder, and one end of a driving rocker of the double-rocker mechanism are combined with a connecting rod in a hinged mode to form a whole. The other end of the driving rocker and the rack are hinged into a whole. The connecting rod is combined with a driven rocker in a hinged mode to form a whole. When used for machining or maintaining a tubular pile, the double-rocker self-adaptive centering clamp not only can clamp a workpiece to be clamped and make no displacement generated between the clamped workpiece and the clamp, but also can achieve multi-point clamping on a cylindrical workpiece and ensure that a rotating operating machine tool can operate concentric with the clamp all the time when making peripheral operation along a circular guide rail fixedly connected with the clamp concentrically, concentric operation can be performed on the cylindrical workpieces different in diameter, and the range of diameters for adapting to the tubular piles is widened. In the clamping process, self-adaptive centering is performed, adjusting and correcting are not needed, and the clamping operation can be performed conveniently, fast and efficiently.

Owner:CHINA NAT OFFSHORE OIL CORP +2

High voltage electrostatic lampblack purifier

InactiveCN108386885AHandling large air volumeImprove purification efficiencyCombination devicesDomestic stoves or rangesDrive motorLight pipe

The invention discloses a high voltage electrostatic lampblack purifier. The high voltage electrostatic lampblack purifier comprises a purifier shell which is in a rectangular shape; an air inlet is formed in the front end of the purifier shell, and is internally provided with an air sucking device; the portion, located behind a fan driving motor, in the purifier shell is provided with an ultraviolet sterilization device; the portion, located behind a lamp tube support, in the purifier shell is provided with a high voltage electrostatic device; the portion, located behind a charge framework, in the purifier shell is provided with an oil dirt adsorbing device; the portion, located behind an adsorbing framework, in the purifier shell is provided with a silencing plate; the rear end of the purifier shell is provided with an air outlet; a rear filtering device is arranged in the air outlet; a maintaining plate is arranged on one side of the purifier shell; and a power source box is arranged on the other side of the purifier shell, and is electrically connected with the air sucking device, the ultraviolet sterilization device, the high voltage electrostatic device and the oil dirt adsorbing device. The high voltage electrostatic lampblack purifier has the beneficial effects of being simple in structure and high in practicability.

Owner:李博文

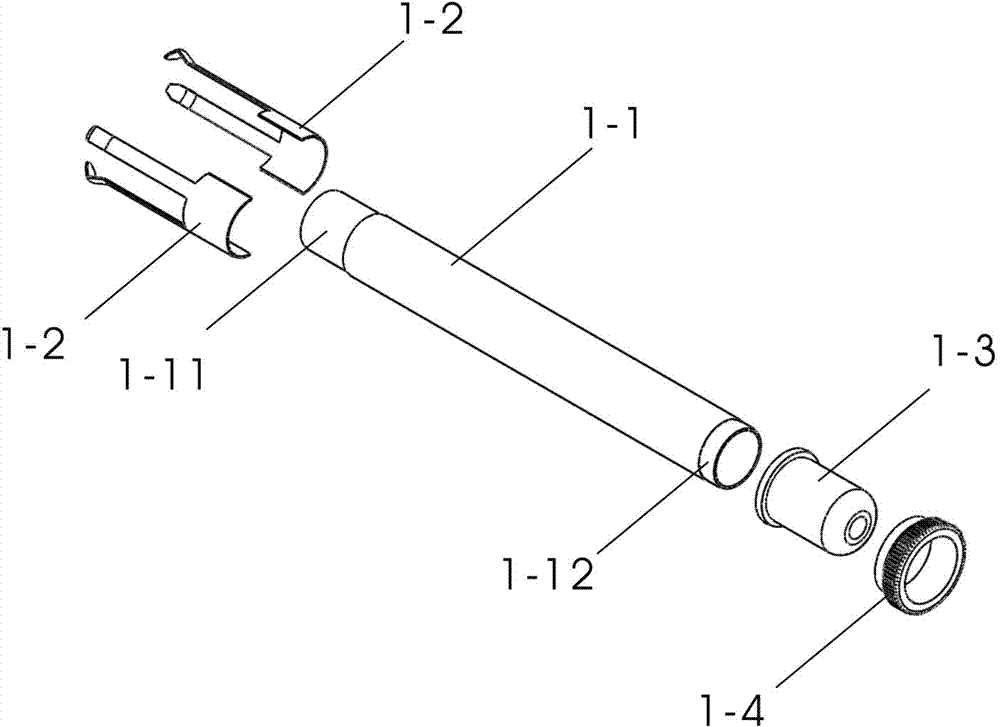

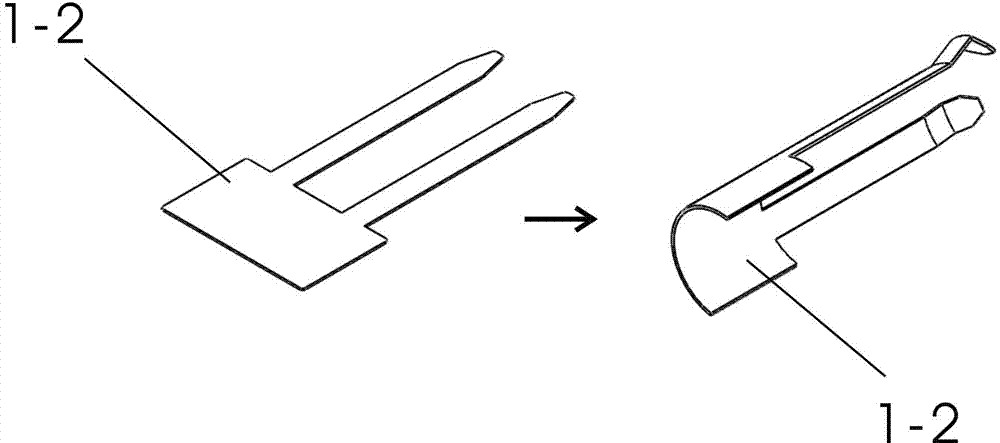

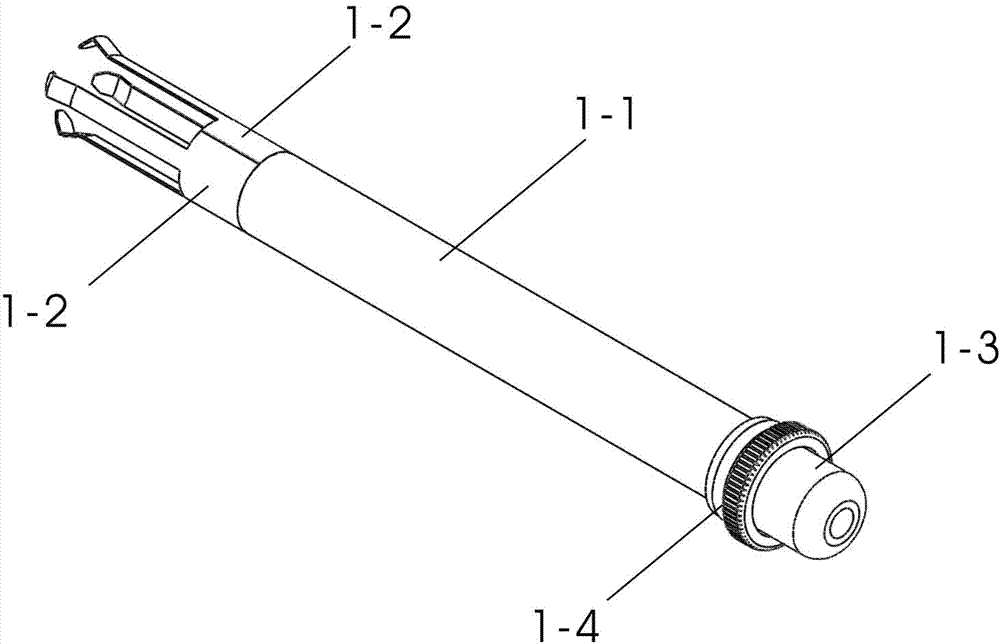

Moxa holding device, warming moxibustion rod handle and manufacturing method of moxa holding device

InactiveCN104490594AIncrease elasticityExtended service lifeDevices for heating/cooling reflex pointsHigh volume manufacturingHard metal

The invention discloses a moxa holding device which is characterized by comprising a pipe body and a gripper, wherein the pipe body and the gripper are independently molded; the gripper is fixedly arranged at the top of the pipe body; the width of the fingertip of the gripper is gradually decreased. According to the moxa holding device, a structure that the pipe body is separated from the gripper is adopted, and the pipe body and the gripper are separately molded during production and are then assembled together; by virtue of the structure and the production method, not only is the production efficiency improved, but also large-batch production is facilitated; furthermore, the fingertip of the gripper is designed as a conical shape, and can contract to achieve a quite small bore diameter, so that moxa sticks with smaller size can be held; such a conical fingertip can not be obtained through a production method of grooving a copper pipe to form a gripper by virtue of a mold in the prior art; in addition, the gripper is made of a hard metal material, so that not only is the rebound stability of the gripper ensured, but also the service life of the gripper is prolonged.

Owner:邹少波

Round bar lifting type stainless steel thin-wall water pipe cutting machine

PendingCN110280826ALarge diameter rangeImprove processing efficiencyTube shearing machinesPositioning apparatusEngineeringRound bar

The invention discloses a round bar lifting type stainless steel thin-wall water pipe cutting machine. The machine comprises a machine body, a round cutter part, a roller part located on the machine body, a fixed seat fixed on the machine body; the round cutter part comprises a lifting pressure rod and a pressing wheel fixing device, wherein the lifting pressure rod penetrates through the interior of the fixed seat and is in sliding fit with the fixed seat, the pressing wheel fixing device is fixed at the lower end of the lifting pressure rod, and wheel teeth are arranged on one side of the lifting pressure rod along the axis of the lifting pressure rod; a gear meshed with the gear teeth is arranged in the fixed seat, and the gear is rotationally connected with the fixed seat; one side of the gear is provided with a rotating shaft, and the end, far away from the gear, of the rotating shaft extends out of the fixed seat and is rotationally connected with the fixed seat; and the rotating shaft is in sliding connection with a rotating rod matched with a through hole, and the lower end of the lifting pressure rod is rotationally connected with a round cutter. According to the round bar lifting type stainless steel thin-wall water pipe cutting machine, when a thin-wall stainless steel water pipe is cut, a pipe orifice cannot deform, and burrs cannot be generated; and the operation is simple, the machined diameter range of the thin-wall stainless steel water pipe is wide, the machining efficiency is high, and the machine has high commercial value and popularization value.

Owner:爱牛管道工具(上海)有限公司

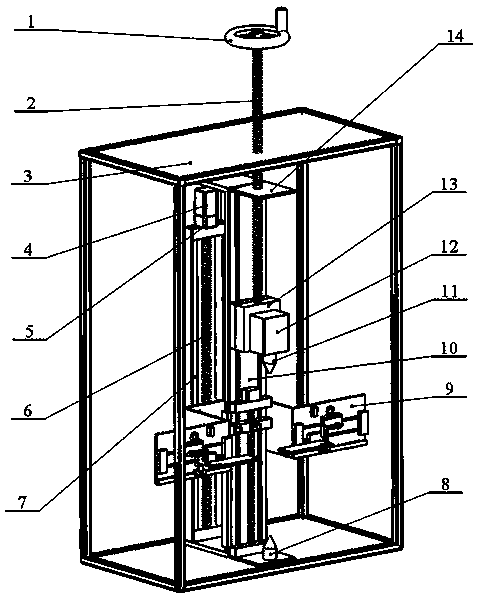

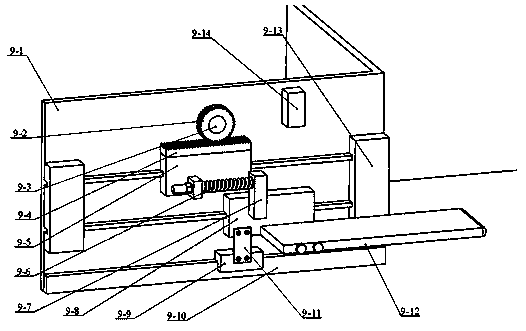

Speed reducer worm diameter and length automatic detection device and method

PendingCN110823114AMeet the requirements of measurement accuracyLarge diameter rangeUsing optical meansComputer moduleEngineering

The invention discloses a speed reducer worm diameter and length automatic detection device and method. The device comprises an upper computer module, a driving module, a connecting module, a diameterautomatic detection module, a length automatic detection module, a measured piece clamping module, a supporting module and a limiting module. In the detection process, displacement of a left measuring head and a right measuring head is measured through a grating ruler, and the diameter of a measured shaft section of the speed reducer worm is calculated in combination with the initial distance ofthe two measuring heads; the starting position and the ending position of the measured shaft section of the speed reducer worm are obtained through the grating ruler and a laser displacement sensor, and then the length of the measured worm shaft section is obtained through calculation. The speed reducer worm diameter and length automatic detection device and method can adapt to batch detection ofthe diameters and the lengths of different shaft sections of the speed reducer worms of various specifications.

Owner:HANGZHOU JIACHENG MACHINERY

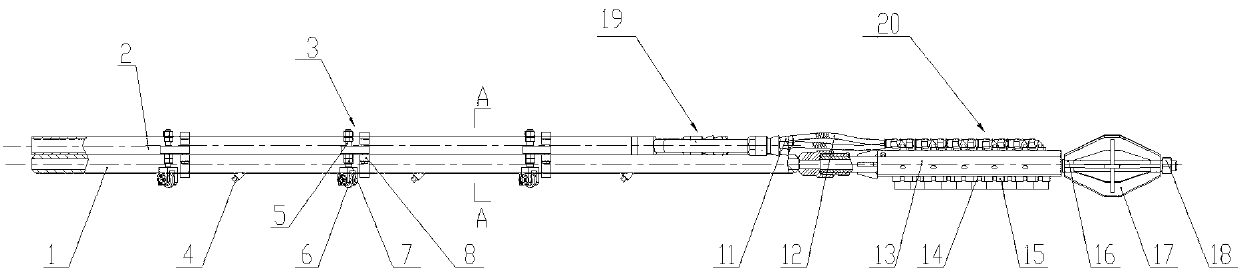

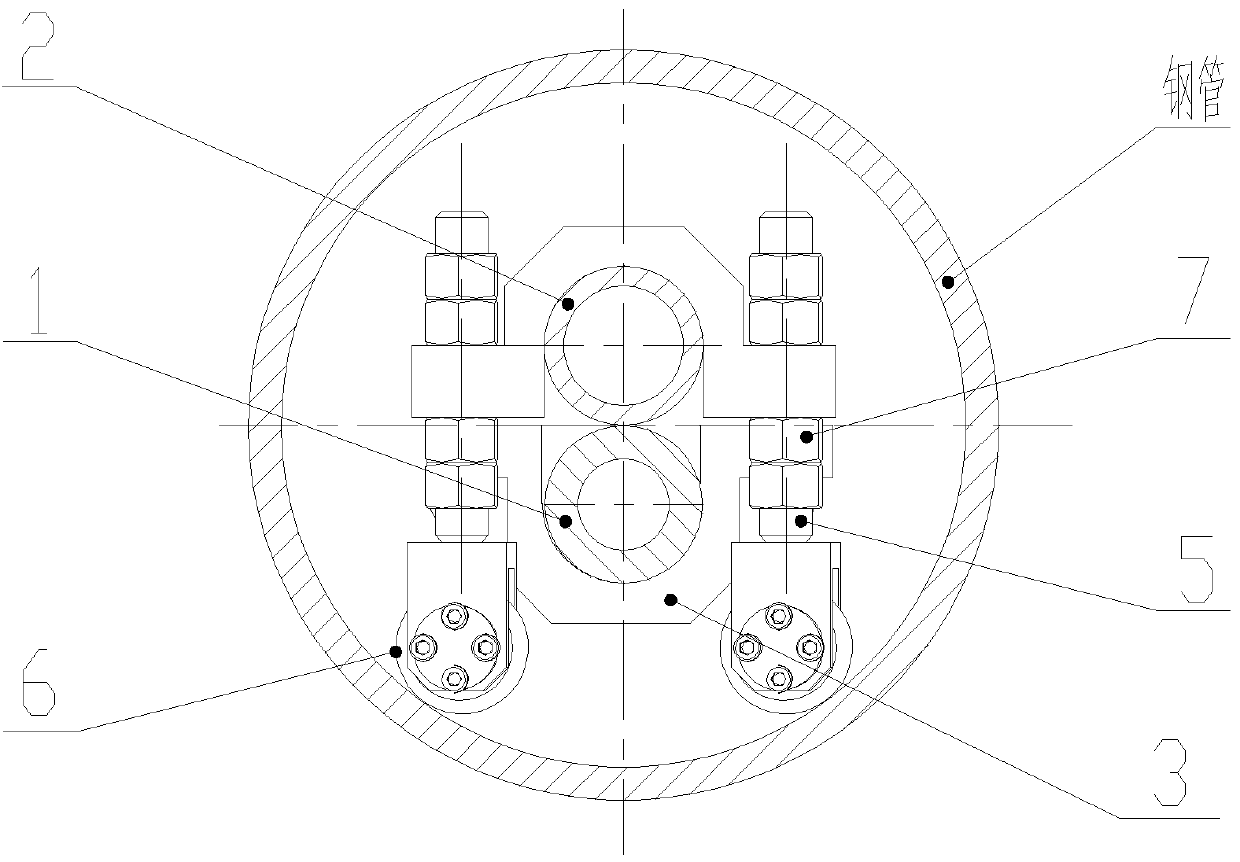

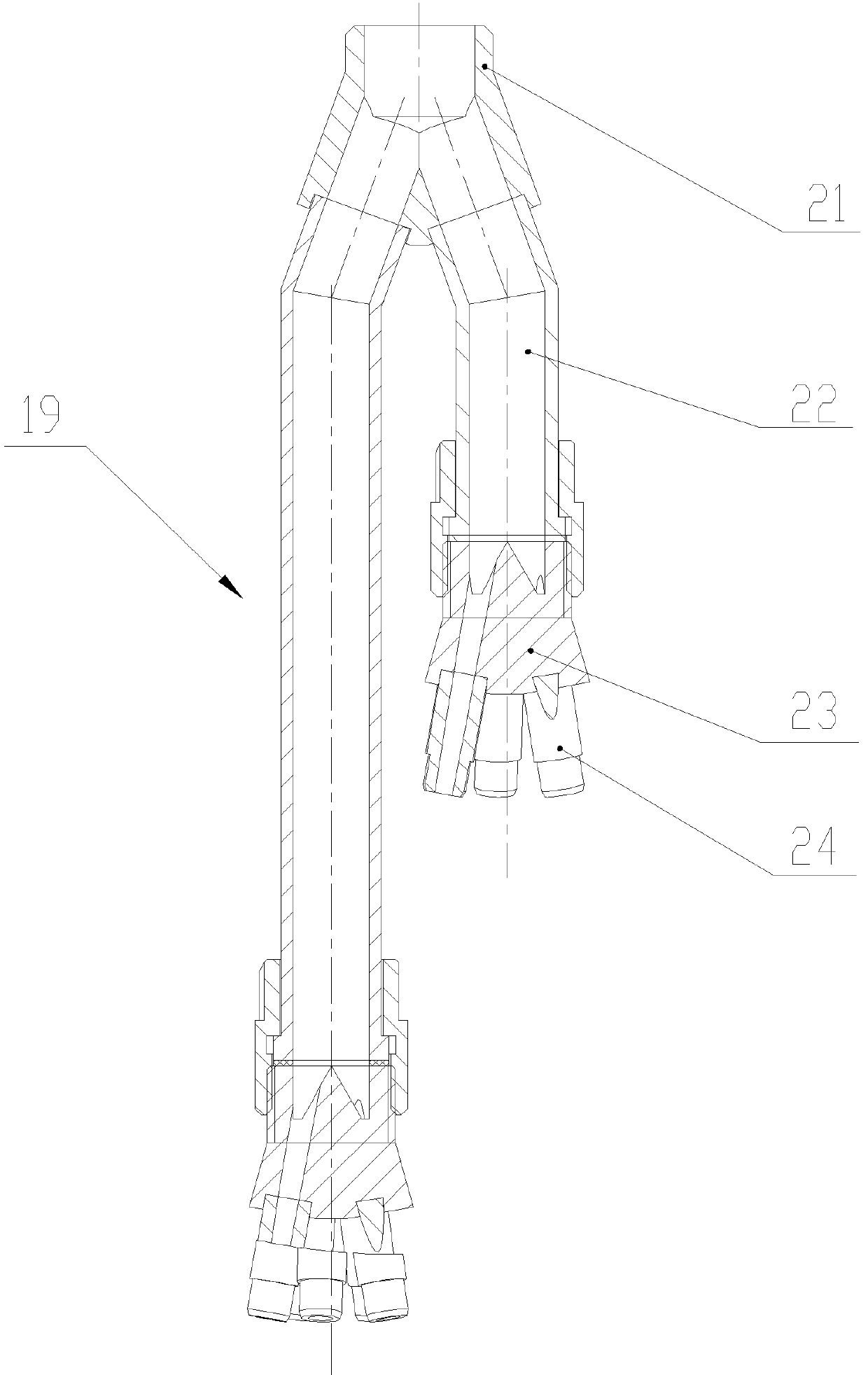

Pneumatic path drifting machine and drifting method

InactiveCN1825053AImprove work efficiencyCompact structureMechanical diameter measurementsPetroleumSteel tube

The invention relates to a testing device for petroleum steel tube. The feature is that it at least includes front diameter lance, back diameter lance, moving dolly, gas tank, clamping device and bench. A core rod sleeve is fixed in the tube of front diameter lance and back diameter lance. The inner diameter and the center of core rod sleeve is the same as that of tube. Diameter core rod is installed in the core rod sleeve in the tube of front diameter lance and back diameter lance. The steel tube is fixed on the bench and is clamped on the out surface of steel tube by clamping device. The front diameter lance is connected to the left end face and the back diameter lance is connected to the right end face. The two diameter lances are connected to gas tank through tube. The invention has advantages of simple structure, low cost, easy to maintain and wide suitable tube diameter range.

Owner:XIAN HEAVY DUTY MACHINERY RES INST +1

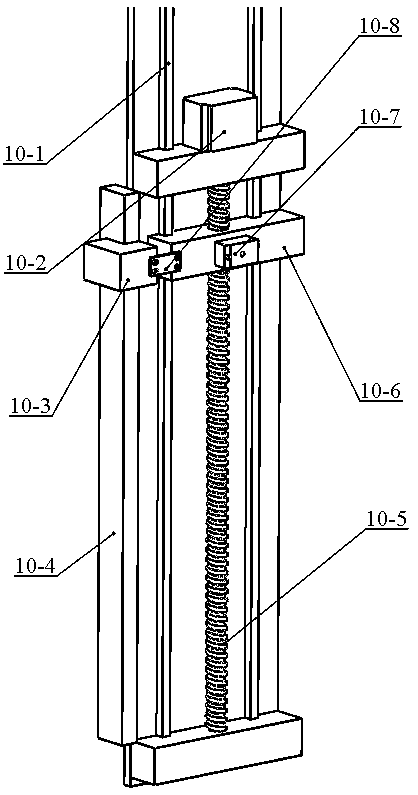

Drill rod centering adjuster

ActiveCN103850659ASmall form factorMultiple installation spacesDrilling rodsDrilling casingsHydraulic motorCoupling

The invention discloses a drill rod centering adjuster. The drill rod centering adjuster comprises a first adjuster fixed plate, a second adjuster fixed plate, a lead screw, a guide rod, a left V-shaped opening assembly, a right V-shaped opening assembly, a coupling and a hydraulic motor, wherein a guide rod and a lead screw are arranged in parallel between the first adjuster fixed plate and the second adjuster fixed plate, the two ends of the guide rod are fixed on a guide rod seats of the first adjuster fixed plate and the second adjuster fixed seat, the two ends of the lead screw are mounted on the rolling bearings of the first adjuster fixed plate and the second adjuster fixed plate, one end of the left V-shaped opening assembly sleeves the guide rod, while the other end of the left V-shaped opening assembly is in threaded connection with the lead screw, one end of the right V-shaped opening assembly sleeves the guide rod, while the other end of the right V-shaped opening assembly is in threaded connection with the lead screw, the V-shaped openings of the left V-shaped opening assembly and the right V-shaped opening assembly are opposite to each other, and one end of the coupling is connected with the lead screw, while the other end of the coupling is connected with the rotating shaft of a hydraulic motor. The drill rod centering adjuster is small in appearance, and simple and reliable in structure; the diameter range of drill rods which can be centered and adjusted by the drill rod centering adjuster is large, and the drill rod centering adjuster is controlled hydraulically; besides, the drill rod centering adjuster is easy to process and manufacture.

Owner:HUNAN SEA BULL GEOLOGICAL EXPLORATION CO LTD

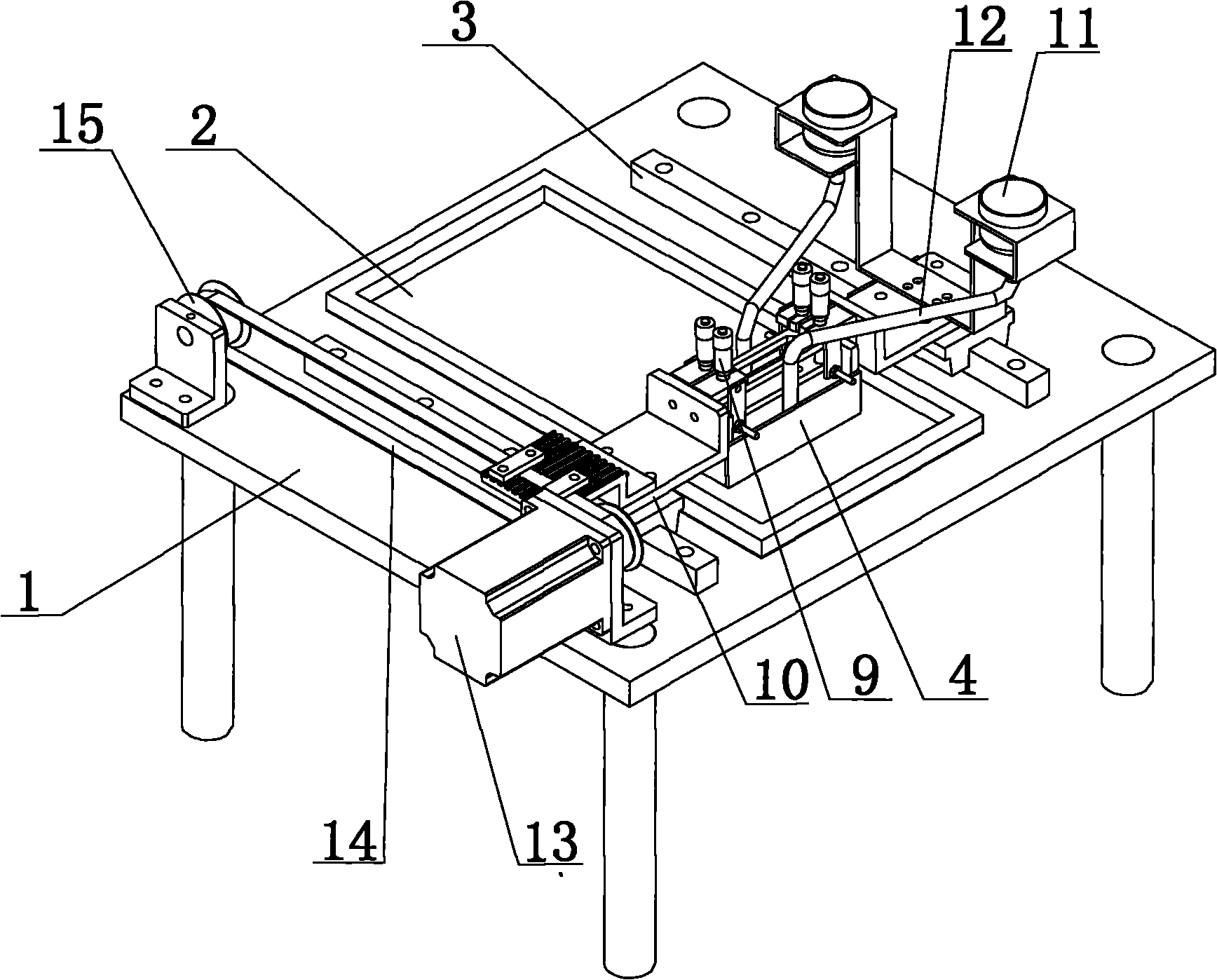

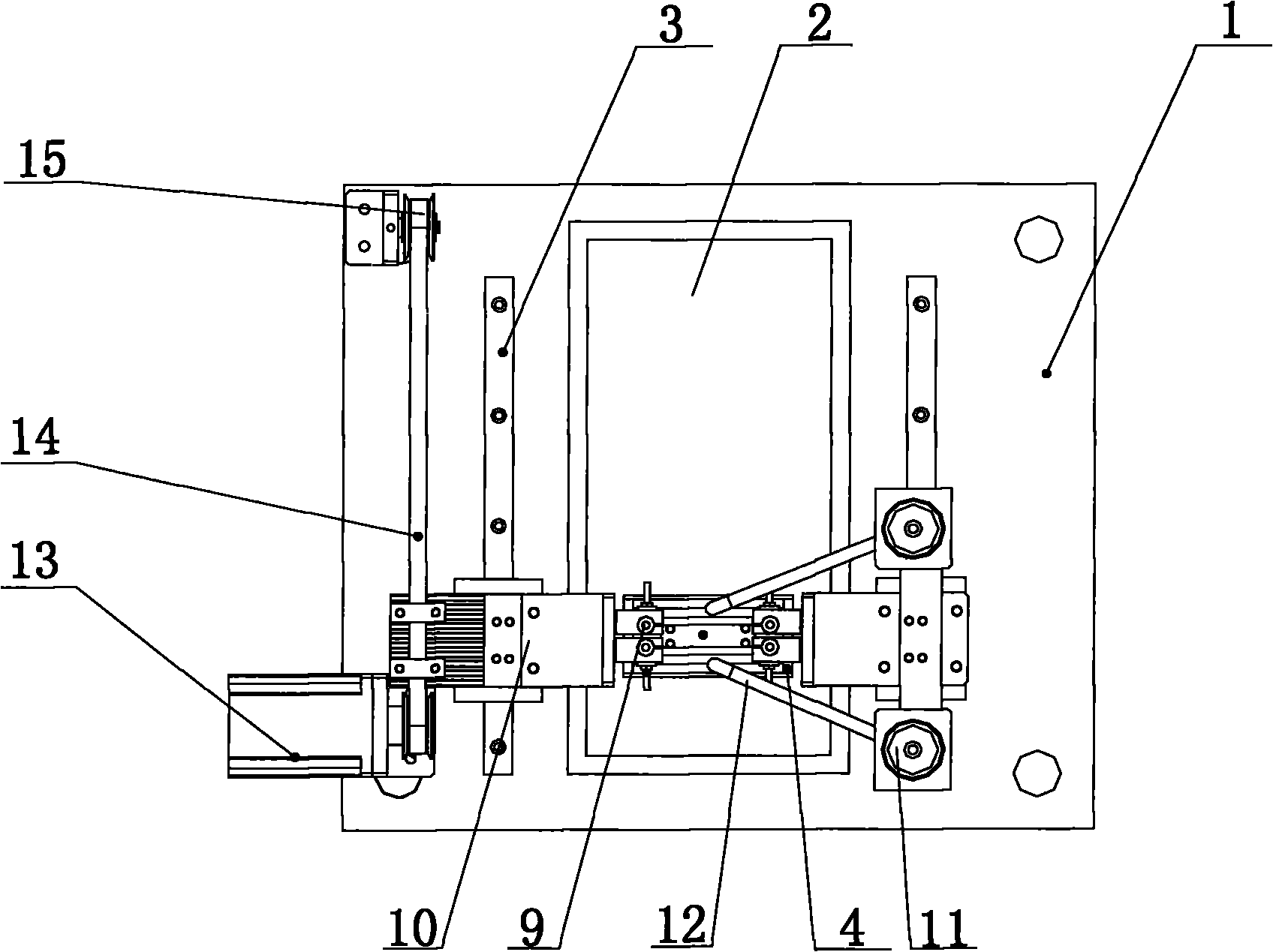

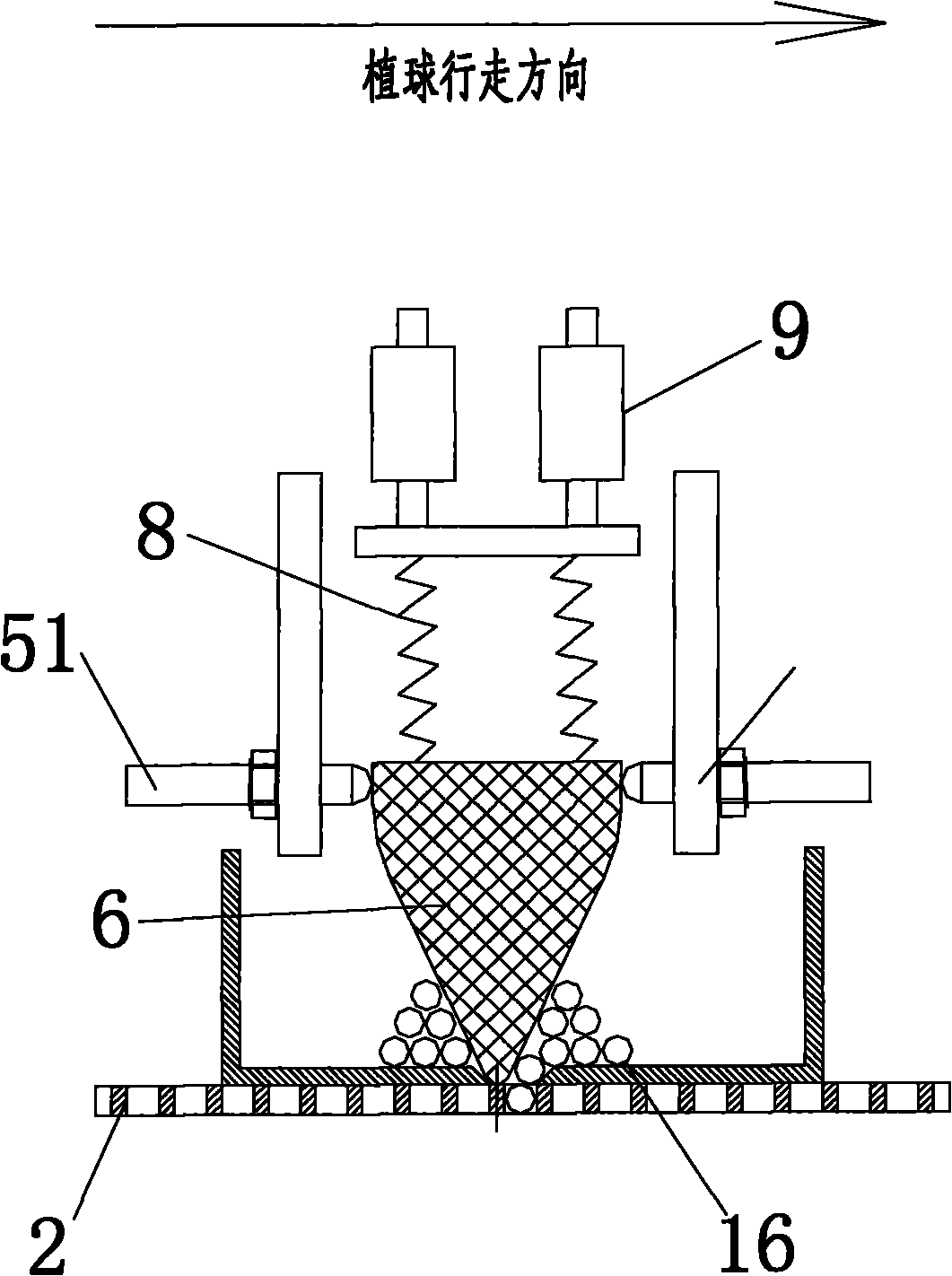

Ball-planting device of semiconductor packaging equipment

ActiveCN101604618BLow costReduce workloadSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The invention relates to a ball-planting device of semiconductor packaging equipment, which comprises a stander, a net plate, two guide rails, a ball-planting mechanism and a driving mechanism. The net plate is fixed on the stander; the ball planting mechanism is positioned above the net plate and fixed in sliding fit with the two guide rails, and the ball-planting mechanism comprises a tin ball container, a pair of limit pieces, a scraper, a connecting plate, a plurality of springs, a plurality of dial indicators and a sensor; wherein the bottom of the tin ball container is provided with gaps, the pair of limit pieces is fixed on the tin ball container, the longitudinal section of the scraper has a cone shape with wide upside and narrow underside, the lower ends of the plurality of springs are fixed to the upper end of the scraper, the upper ends of the springs are connected with the plurality of dial indicators through the connecting plate, and the sensor is arranged in the tin ballcontainer; and the driving mechanism is in transmission connection with the ball-planting mechanism. The ball-planting device of the semiconductor packaging equipment has the advantages of low cost, simple and convenient control and debugging, wide applicability, little damage to tin balls, high success rate, high utilization rate, and the like.

Owner:厦门市原子通电子科技有限公司

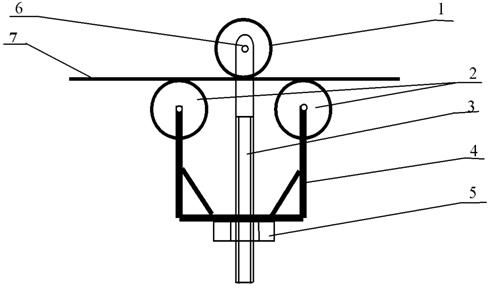

Simple tensioner of lossless steel cables

InactiveCN102491240ARealize any amount of tension adjustmentEasy to operateLifting devicesHoisting equipmentsLongitudinal planeEngineering

The invention relates to a simple tensioner of lossless steel cables. The simple tensioner is characterized by comprising a U-shaped fixing bracket, wherein two top ends of the U-shaped fixing bracket are hinged with fixing pulleys respectively; the bottom of the U-shaped fixing bracket is connected with a regulating stem which can go up and down relative to the U-shaped fixing bracket; the upper end of the regulating stem is connected with a detachable regulating pulley; and the regulating pulley and the fixing pulley are arranged at a same longitudinal plane. The regulating stem is in threaded connection with a stair-step shaped regulating nut, and the excircle of the stair-step shaped regulating nut is connected with a through hole at the bottom of the U-shaped fixing bracket smoothly. The simple tensioner disclosed by the invention has simple principles, low manufacturing cost and great popularization value both in power transmission line works and various cableways such as forestry cableways, freight transport cableways, passenger transport cableways, overhead power transmission lines and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

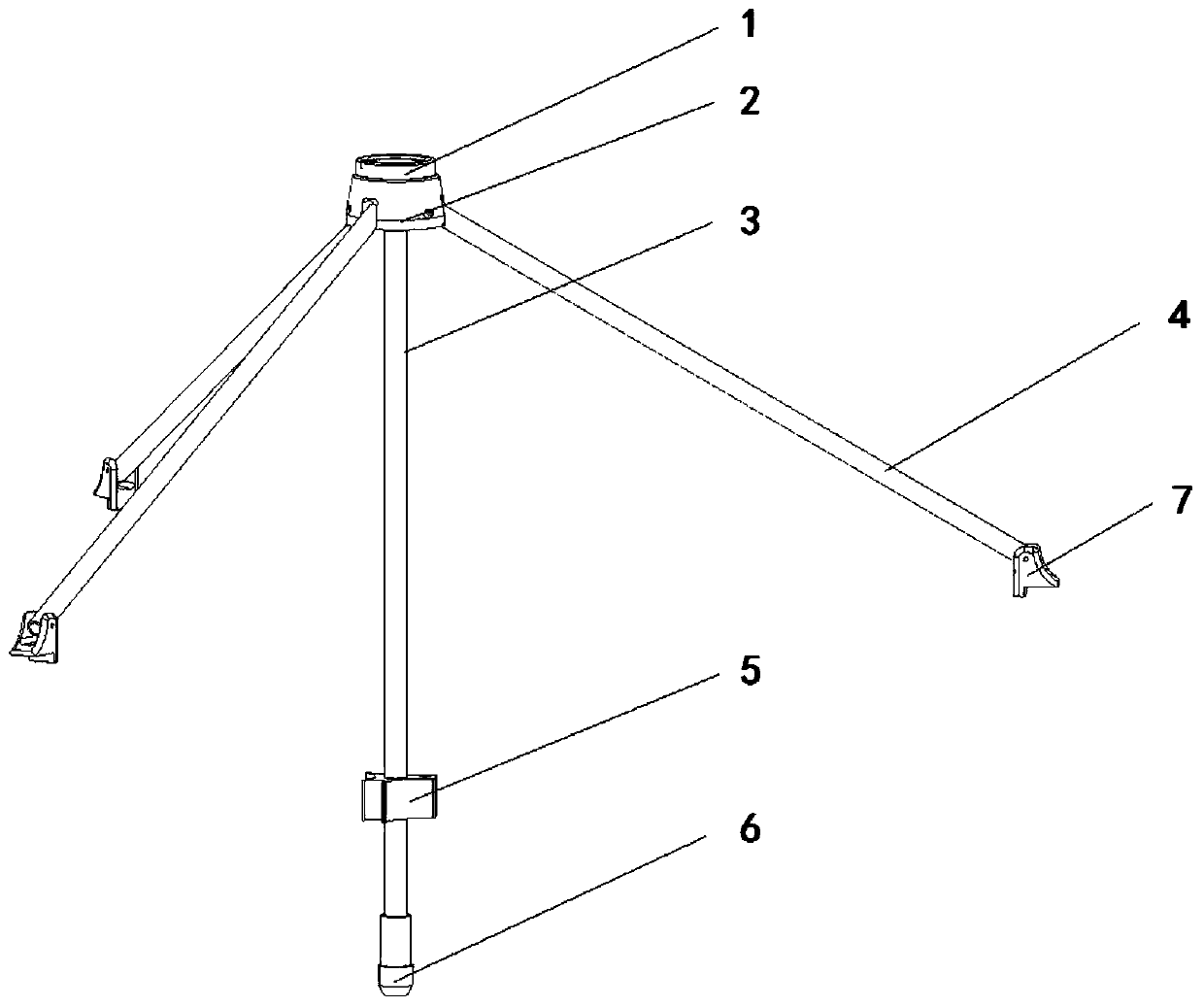

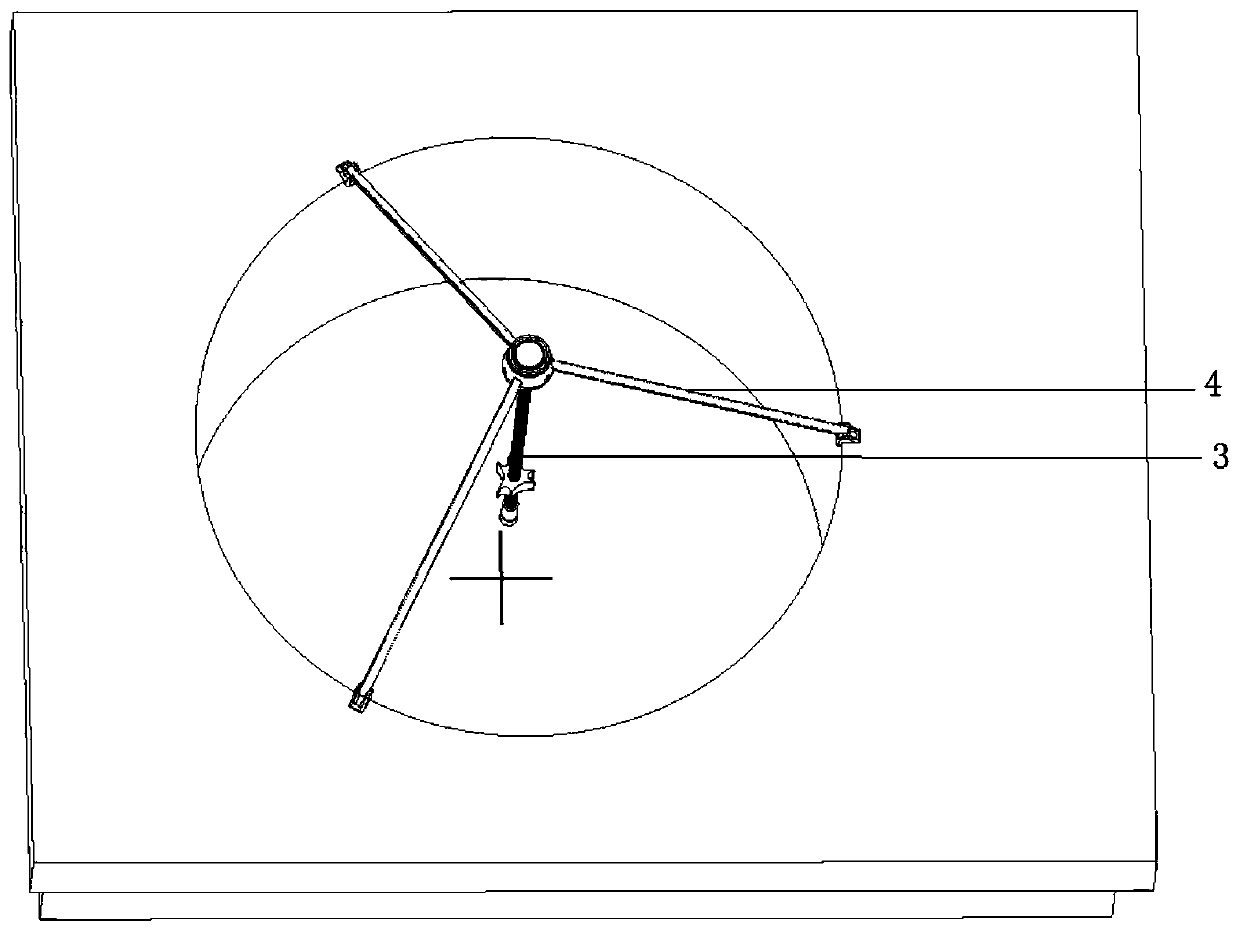

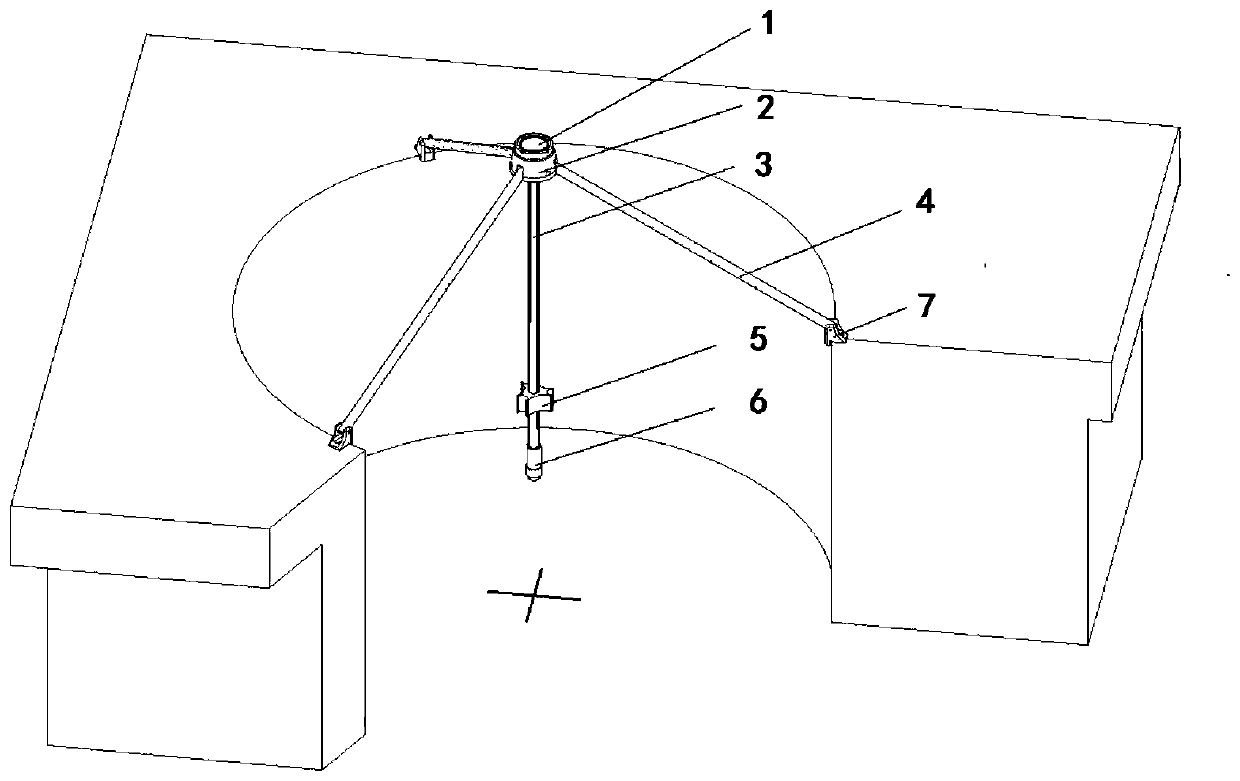

Laser assisted centering device for assembling large-diameter equipment

InactiveCN110174094ALower skill thresholdLarge diameter rangeReference line/planes/sectorsSurveying with inclination sensorLaser assistedEngineering

The invention discloses a laser assisted centering device for assembling large-diameter equipment, and the device comprises a center rod, wherein a bubble level is connected to the upper end of the center rod, a cross laser head is connected to the lower end of the center rod, and a leg is connected to the center rod. When centering the large-diameter equipment, the laser assisted centering deviceprovided by the invention directly identifies the center point by a cross laser line to obtain an intuitive result, thereby eliminating the need of pulling and measuring links, avoiding errors causedby indirect measurement, having higher accuracy, large applicable diameter range, quick adjustment with no need for other auxiliary instruments and measuring tools, simple operation and reliable results, and reducing operating steps, workload as well as worker skill threshold.

Owner:BAOJI PETROLEUM MASCH CO LTD

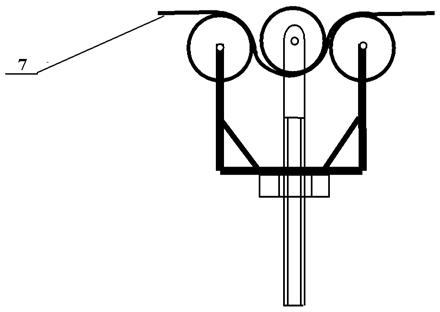

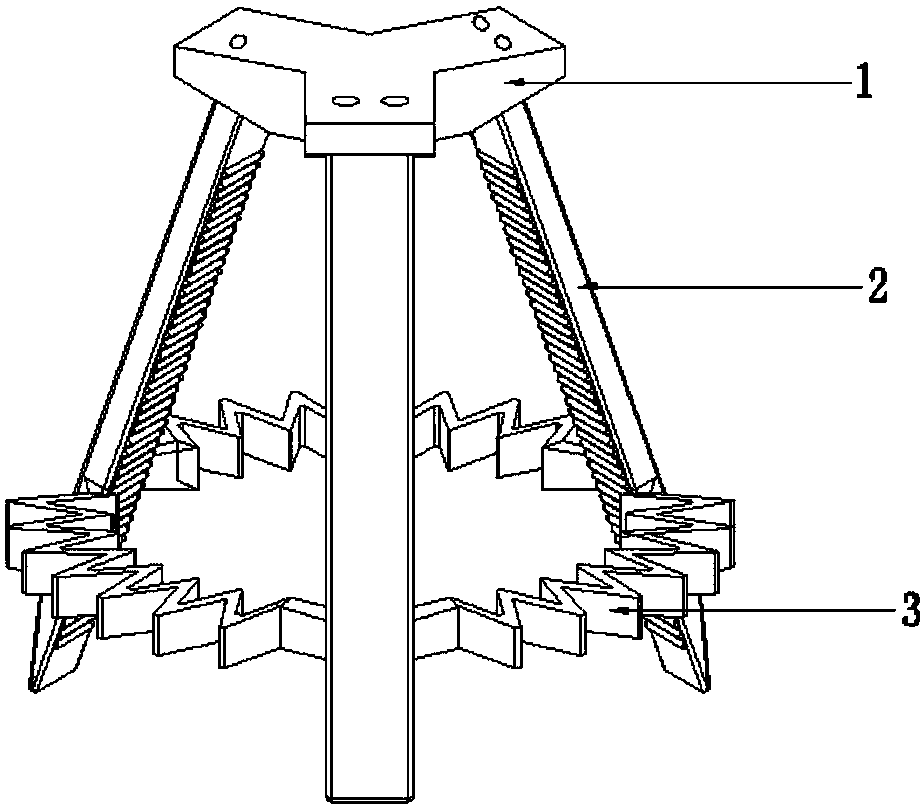

Spinning wrench device acting or moving synchronously with spinner wheel

PendingCN107269237ANot easy to go off trackReduce distanceDrilling rodsDrilling casingsPhysicsWrench

The invention relates to a spinning wrench device acting or moving synchronously with a spinner wheel. The spinning wrench device comprises stand columns and a spinning wrench mounted on the stand columns. The spinning wrench comprises a rack, clamping oil cylinders, clamping arms and a rear spinning roller support, wherein two spinning assemblies are mounted on the clamping arms, and a spinning assembly is mounted on the rear spinning roller support; the rack is hinged to the middle of the clamping arms, the end portions of the clamping arms are hinged to one ends of connecting arms correspondingly, and the other ends of the connecting arms are hinged to the rear spinning roller support; one ends of the clamping oil cylinders are connected with hinged points of the clamping arms and the connecting arms correspondingly, and the other ends of the clamping oil cylinders are hinged to the rack; the connecting lines of the middles and the ends of the clamping arms are not collinear with the motion directions of the clamping oil cylinders; and a guide device is arranged between the rear spinning roller support and the rack. According to the spinning wrench device, all of the spinning assemblies can enclasp one another toward the center of a tube tool synchronously so that aligning of the tube tool is facilitated, and in the spinning process, all of the spinning assemblies are not prone to be off tracking through connective matching of the connecting arms, the clamping arms and the rear spinning roller support.

Owner:SICHUAN KUNLUN GASOLINEEUM EQUIP MFG

Soft touching hand for grabbing object through stretching and contracting of telescopic ring

The invention relates to the field of mechanical arms, in particular to a soft touching hand for grabbing an object through stretching and contracting of a telescopic ring. The telescopic ring is inflated through an air guide pipe and begins to stretch; and meanwhile, outwards push force is exerted on each touching hand finger, and the soft touching hand is made to be unfolded. When the object needs to be grabbed, an external mechanical arm drives the soft touching hand to approach the object, a distance sensor feeds a signal back to a PLC control system when detecting the object, then the PLCcontrol system controls an external electromagnetic valve to perform air exhausting on the telescopic ring, and the telescopic ring begins to contract; and meanwhile, pull force towards the inner ring is generated on the touching hand fingers, the soft touching hand is folded, and the purpose of grabbing the object is obtained.

Owner:JIANGYIN DINGLI HI TECH CRANE MACHINERY

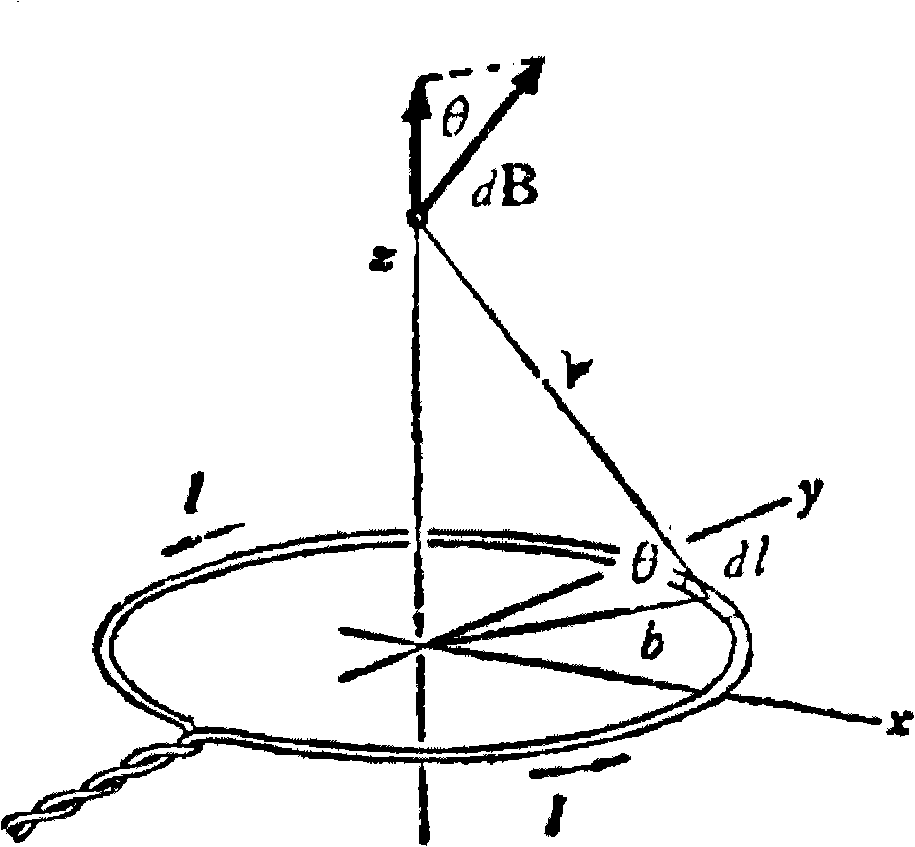

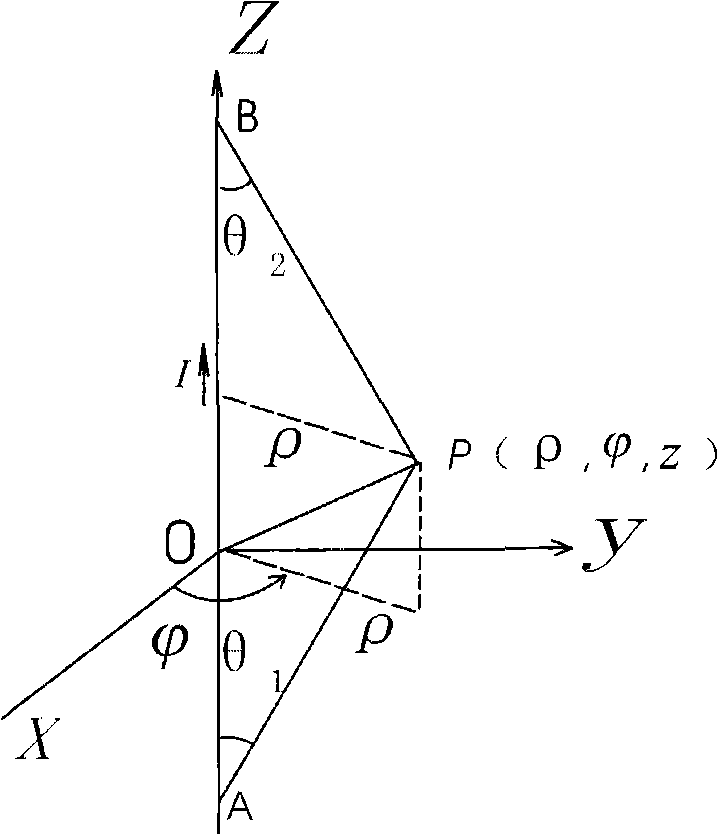

Method for detecting underground steel pipe corrosion condition by ground artificial magnetization

InactiveCN101408625AEffective detection of corrosion conditionsLow detection costElectrical/magnetic thickness measurementsElectric/magnetic detectionField emission deviceMeasurement point

The invention relates to a method for detecting the corrosion condition of an underground steel pipe. The method for detecting the corrosion condition of the underground steel pipe by ground artificial magnetization is characterized by comprising the following steps: (1) a reference point is chosen at the ground of a site without the magnetic field influence of steel objects, a magnetometer is adopted to respectively measure a magnetic field vertical component value when a magnetic field emission device provides power supply (the magnetic field emission device emits magnetic fields to the surrounding space) and a magnetic field vertical component value when the magnetic field emission device does not provide power supply, and an artificial magnetic field vertical component value of the reference point is obtained based on the difference of the two values; (2) the measurement same as that in the step 1 is performed on a measurement point arranged on the ground above the underground steel pipe to obtain an artificial magnetic field vertical component value of the measurement point; (3) the artificial magnetic field vertical component value of the measurement point is subtract from the artificial magnetic field vertical component value of the reference point to obtain a magnetic field vertical component value generated at the measurement point under the artificial magnetic field magnetization of the underground steel pipe; and (4) that whether the underground steel pipe is corroded and the corrosion degree are determined according to the size of the magnetic field vertical component values of various measurement points; the smaller the magnetic field numerical value is, the more severe the corrosion is. The method has the advantages of low cost and wide scope of applicable pipe diameters, and can effectively detect the corrosion condition of the underground steel pipes.

Owner:刘崧 +1

Steel ring inner-diameter adjusting device for bead filler laminating machine

The invention provides a steel ring inner-diameter adjusting device for a bead filler laminating machine. The steel ring inner-diameter adjusting device comprises a bracket, fixed guiding wheels uniformly fixedly arranged on the bracket, a plurality of linear guide rails pointing to the axes of the fixed guide wheels, harmomegathus mechanisms respectively movably arranged on the linear guide rails, and adjusting mechanisms movably connected with the harmomegathus mechanisms; the adjusting mechanism arranged at the middle is fixedly connected with a drive mechanism, and the middle adjusting mechanism and other adjusting mechanisms are driven by the drive mechanism in a synchronization mode. The steel ring-inner diameter adjusting device has the beneficial effects that according to production needs of bead filler lamination of bead rings with different sizes, the adjusting time is shortened, the adjusting device can be quickly driven to adjust positions of mobile guide wheels, the mobile guide wheels are allowed to form circular annular distribution so as to satisfy different bead ring diameters, the diameter adjustment scope of the circular annular distribution is wide, the precision is improved, and the production efficiency and the production quality are improved.

Owner:TIANJIN LONGDA WEIYE RUBBER MACHINERY

Bent-toothed sealing plate and stamping method

ActiveCN102537349AGuaranteed bending angleNo deformationEngine sealsMetal-working apparatusStructural engineeringMachining

Disclosed are a bent-toothed sealing plate and a stamping method. A tube panel of a heating surface of a boiler is provided with the bent-toothed sealing plate, teeth are in irregular arc shapes, and a bend starting line is close to a tooth root. According to a conventional machining method, firstly, the teeth are stamped by a flat plate, and then bending is performed. Consequently, tooth deformation is large, the tooth root cannot be bent, bending angles are not easy to control, and quality requirements can only be met by taking corrective measures. The bent-toothed sealing plate comprises a steel plate (1) which is pressed into a bent plate with bending deflection of 90-180 degrees, and a group of elliptic arc notches (2) or arc toothed notches (3) are pressed at one bent end of the bent plate. The bent-toothed sealing plate is used for the tube panel of the heating surface of the boiler.

Owner:HARBIN BOILER

Unequal expansion bottle stopper

The invention discloses an unequal expansion bottle stopper which comprises a cover plate and an elastic plunger body, wherein the cover plate is connected with the elastic plunger body; a driving disc is arranged inside the inner cavity of the elastic plunger body; four support arms are arranged on the driving disc at equal interval peripherally; the top pressing parts of the support arms longitudinally encircle the circumferential wall inside the elastic plunger body and are connected with the circumferential wall inside the elastic plunger body in a propping manner; positioning guide pins fixed on the cover plate are connected with arc-shaped guide holes in the support arms and the driving disc in a penetration manner; a rotating handle passes through a locking hole and is inserted into a shaft hole of a rotating shaft of the driving disc; the driving disc can be driven to rotate by rotating the rotating handle, then the support arms are radially expanded and withdrawn, at the same time, the diameter of the elastic plunger body is also correspondingly increased or decreased, and rotation of the driving disc can be locked after the locking disc moves downwards to be meshed with the locking hole. The bottle stopper can be radially unequally expanded and withdrawn, and according to bottle bodies of different opening diameters, the bottle stopper can be adjusted to be applicable to the bottle openings, and thus the bottle openings can be sealed.

Owner:南通亚龙消防器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com