Bent-toothed sealing plate and stamping method

A technology of stamping and sealing plate, which is applied in the direction of engine sealing, metal processing equipment, engine components, etc., can solve the problems of difficult control, large tooth shape deformation, and the root of the tooth shape cannot be bent at the bending angle, and achieves good processing quality. , The effect of large diameter range and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

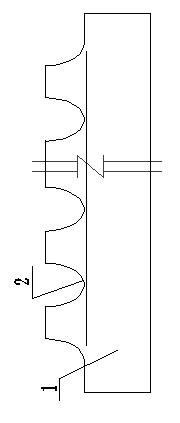

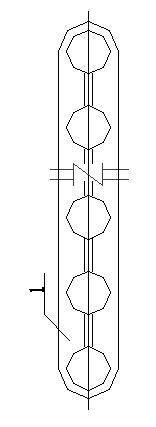

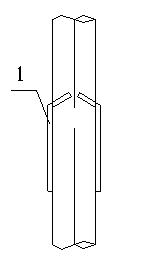

[0023] A tooth-shaped sealing plate with bending, its composition includes: a steel plate, the steel plate 1 is pressed into a bent plate with a curvature of 90--180 degrees, and a group of elliptical arcs are pressed at one end of the bent plate shaped gap 2 or circular arc toothed gap 3.

Embodiment 2

[0025] In the serrated sealing plate with bending described in Embodiment 1, the radian of the elliptical arc or the arc of the circular arc is 42-76% of the diameter of the pipe 5 used in conjunction with it.

Embodiment 3

[0027] A stamping processing method with a bent tooth-shaped sealing plate. First, the flat plate is pressed into a 90--180-degree bent plate, and then the bent plate is placed on a 63--100-ton punching machine along the bending line 4. It is suitable for bending The stamping process is carried out on the special stamping die for stamping the tooth shape of the plate. First, the first elliptical arc or circular arc notch is positioned and punched, and then the workpiece is moved to punch the next elliptical arc or circular arc notch. The positioning adopts the positioning method. Line positioning or using positioning plate positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com