Drill rod centering adjuster

A technology of centering adjustment and adjuster, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of shortening the service life of drill pipe, difficulty in screwing and dismounting the connecting thread of drill pipe, failure, etc., and achieves simple and reliable structure. Lightweight, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

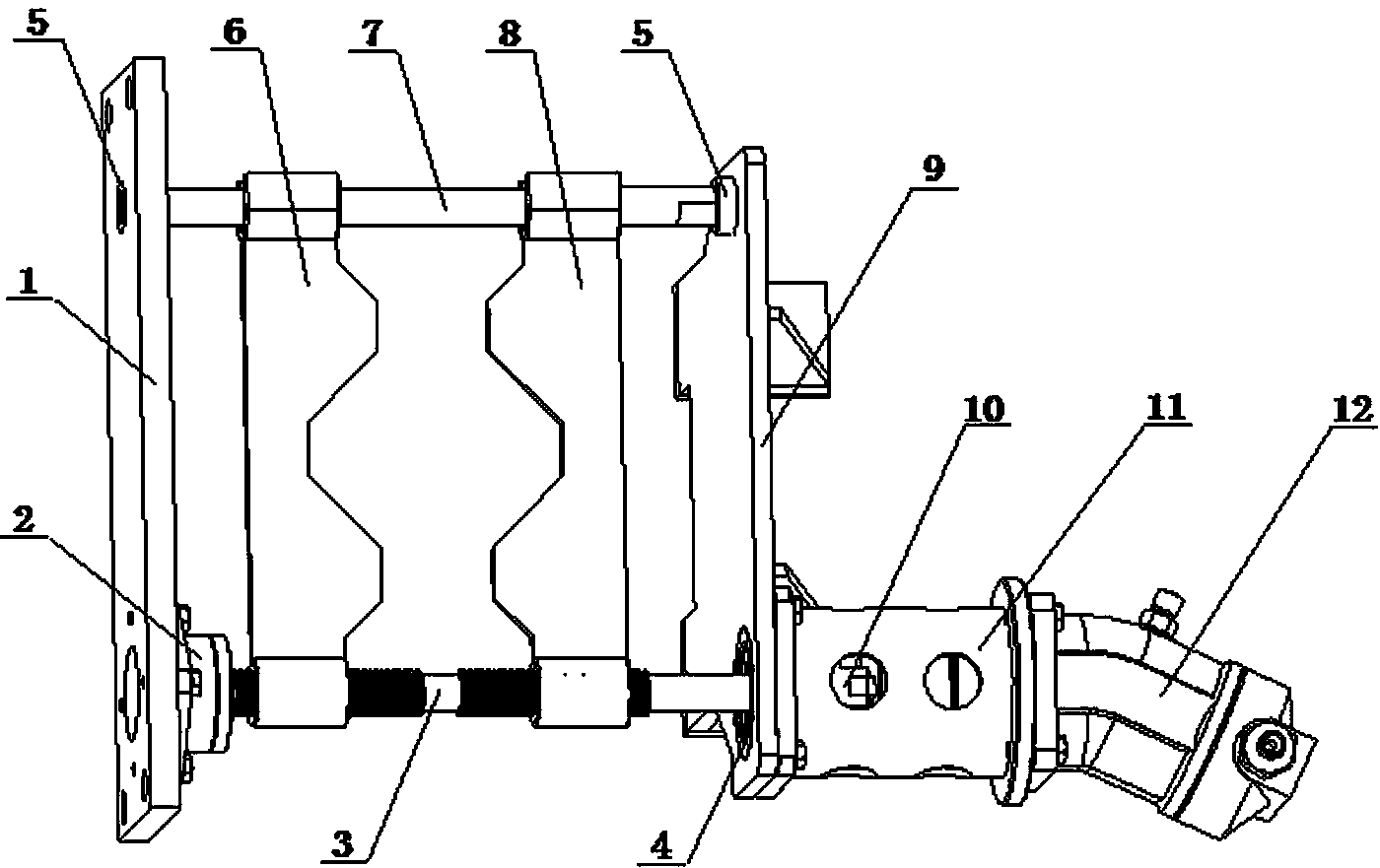

[0017] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

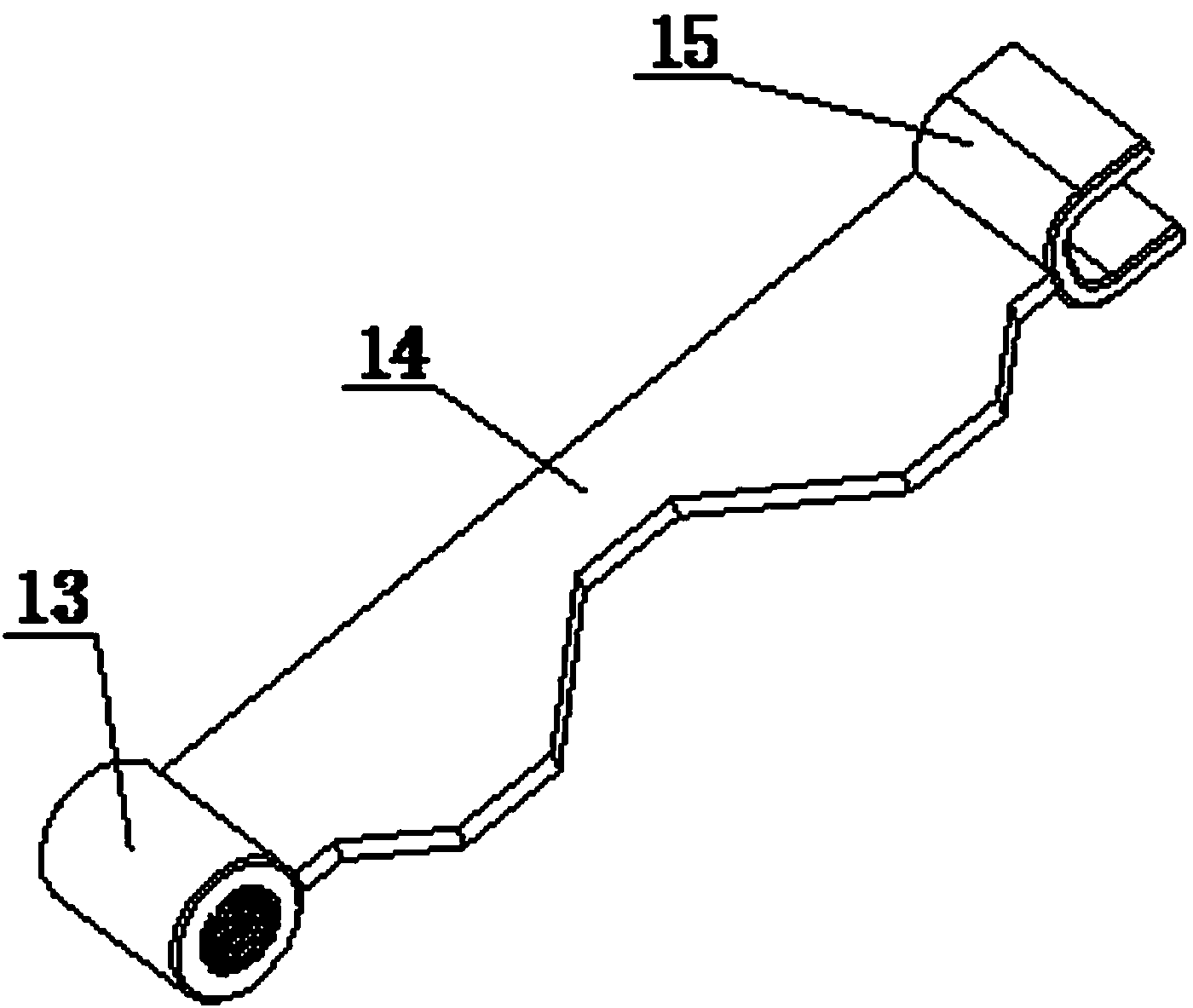

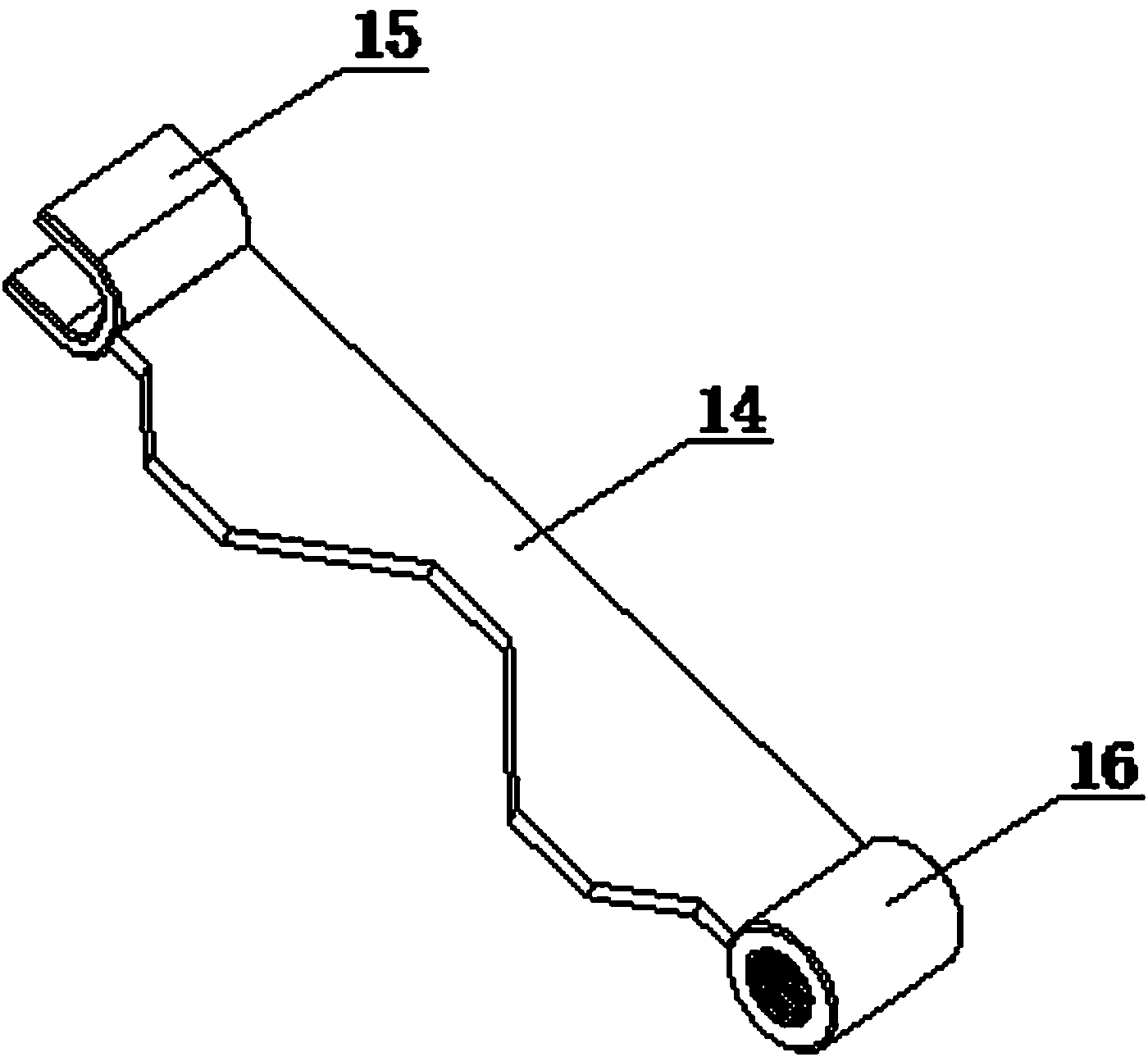

[0018] see figure 1 -3, figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. It includes adjuster fixing plate 1, screw rolling bearing 2, screw 3, screw rolling bearing 4, guide rod seat 5, left V-shaped mouth assembly 6, guide rod 7, right V-shaped mouth assembly 8, adjuster fixing plate 9 , coupling 10, adjuster fixing frame connecting cylinder 11, hydraulic motor 12, left V-shaped mouth assembly 6 includes left nut 13, splint 14, sliding sleeve 15, right V-shaped mouth assembly 8 includes right nut 16, splint 14, Sliding sleeve 15; the adjuster fixing plate 1 is parallel to the adjuster fixing plate 9, the screw rolling bearing 2 is installed on the adjuster fixing plate 1, the screw rolling bearing 4 is installed on the adjuster fixing plate 9, the screw rolling bearing 2 and the screw The ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com