Multiple color press unit type gravure press

A gravure printing machine and unit-type technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., to achieve the effect of simple and convenient operation, reasonable design of the whole machine, and sensitive adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

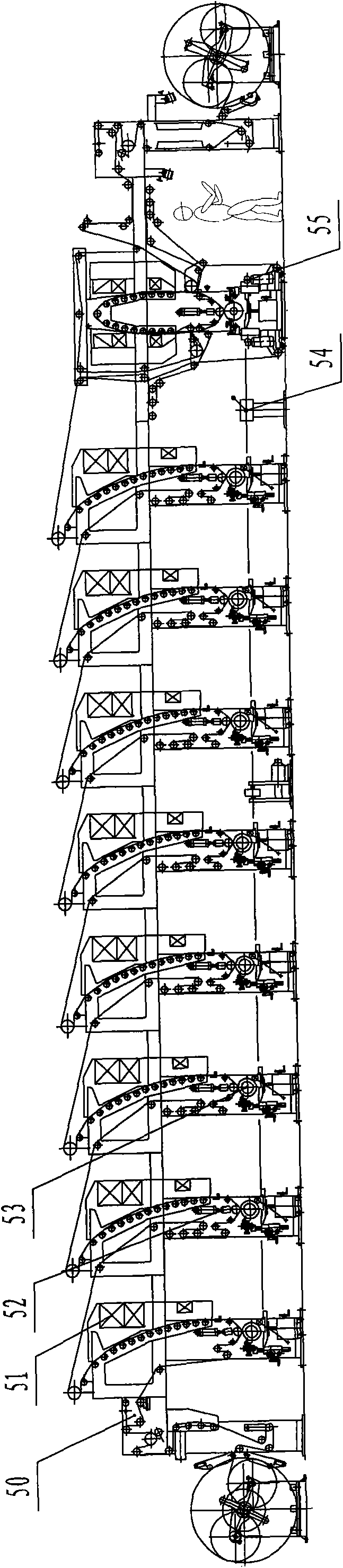

[0036] Such as figure 1 As shown, a multi-color gravure printing machine with a structure including a wide-width gravure drying box 51, a direct pressure clutch pressure storage mechanism 53, an automatic horizontal plate adjustment mechanism 52 for a gravure printing machine, and a reversing gear box 54. Scraper dolly 55, horizontal pendulum roller mechanism 50.

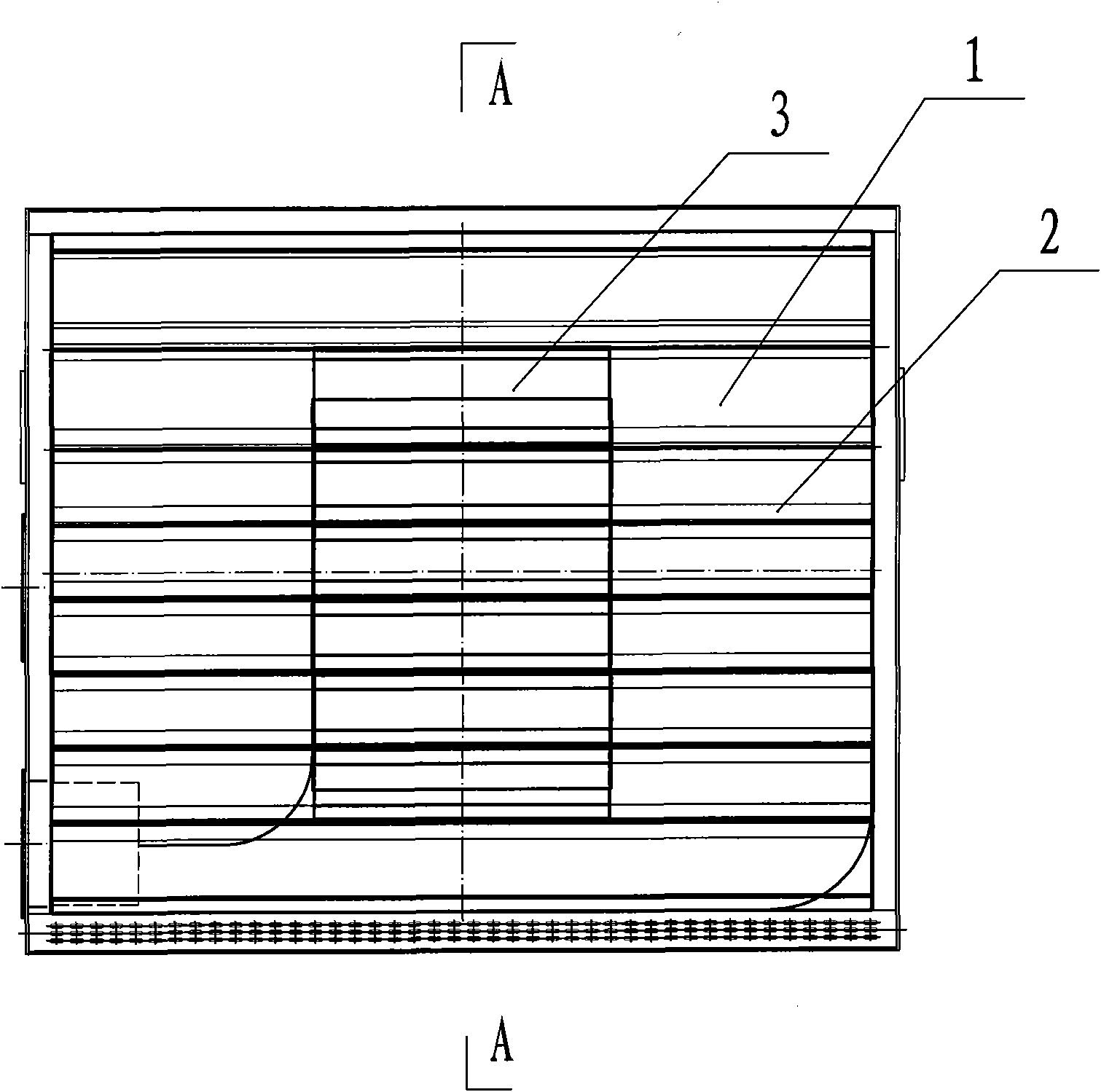

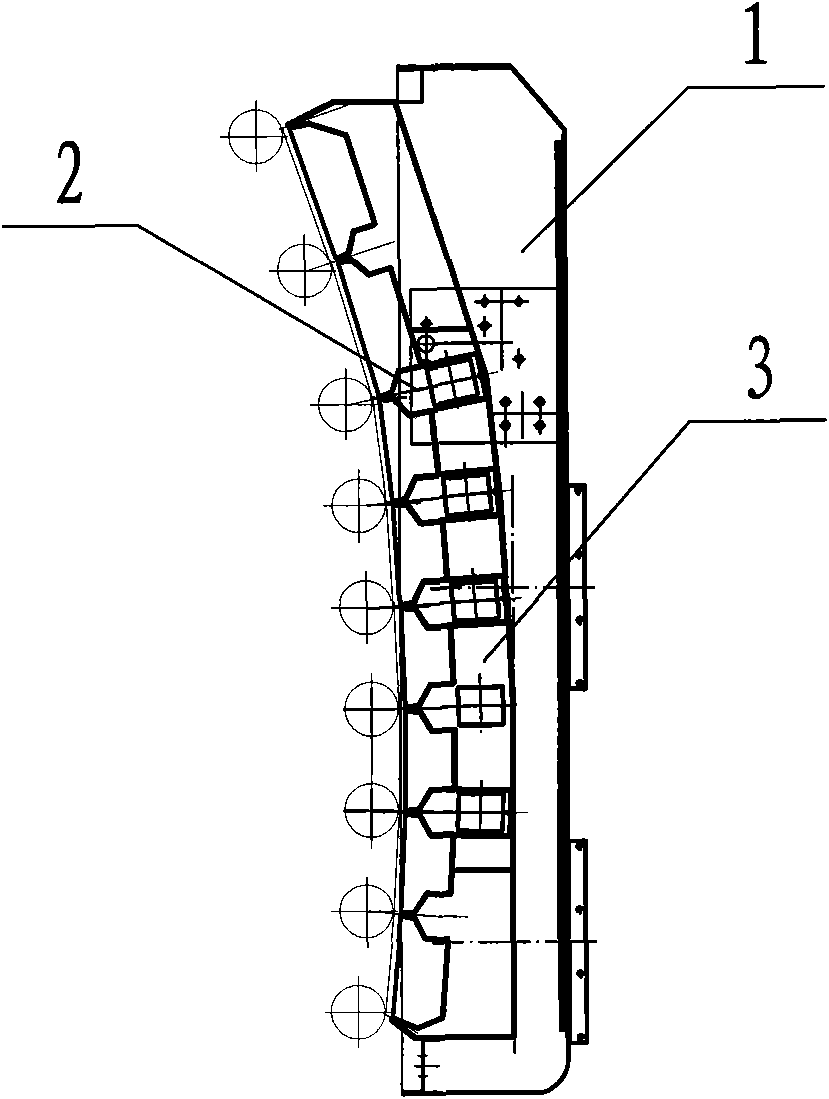

[0037] Such as figure 2 , 3 As shown in , 4, the drying box 51 of the wide-width gravure printing machine has a structure including a box body 1, and a blowing box 2 is provided on the side of the box body 1 facing the printing film, and a slit-shaped blowing nozzle is opened on the blowing box 2, There is a rectangular return air hole 3 in the middle of the side facing the printing film of the box body 1, and the area of the return air hole 3 is not less than one-third of the entire drying area. The box body 1 is provided with an air inlet 5 and an air outlet 4, and several blowing boxes 2 are connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com