Automatic control method and device of multifunction crane aluminium discharging

An automatic control device and multi-functional technology, which is applied in the field of aluminum electrolysis to produce aluminum, can solve problems such as the influence of smooth operation of aluminum electrolysis production, and the control of suction precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the invention:

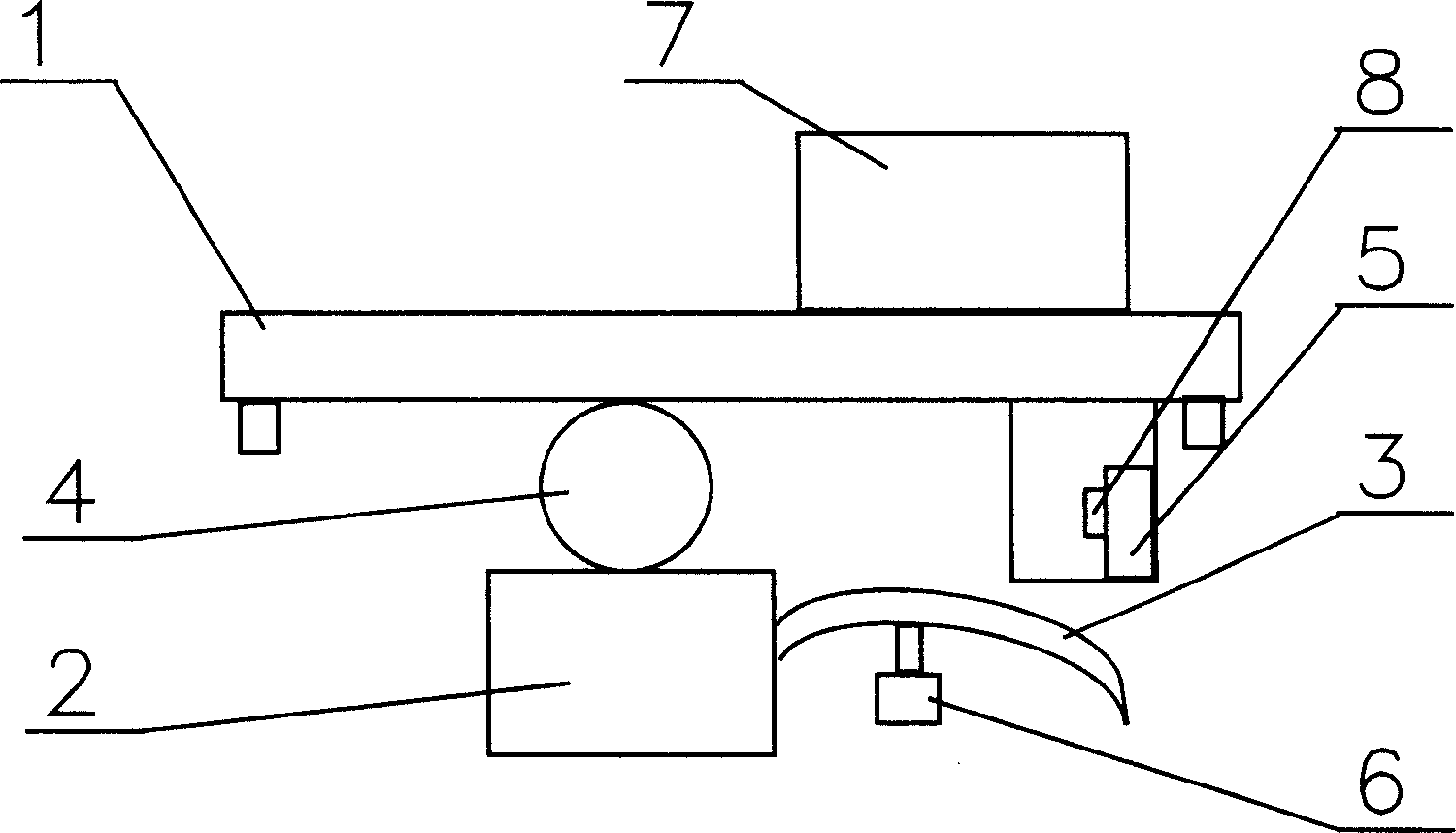

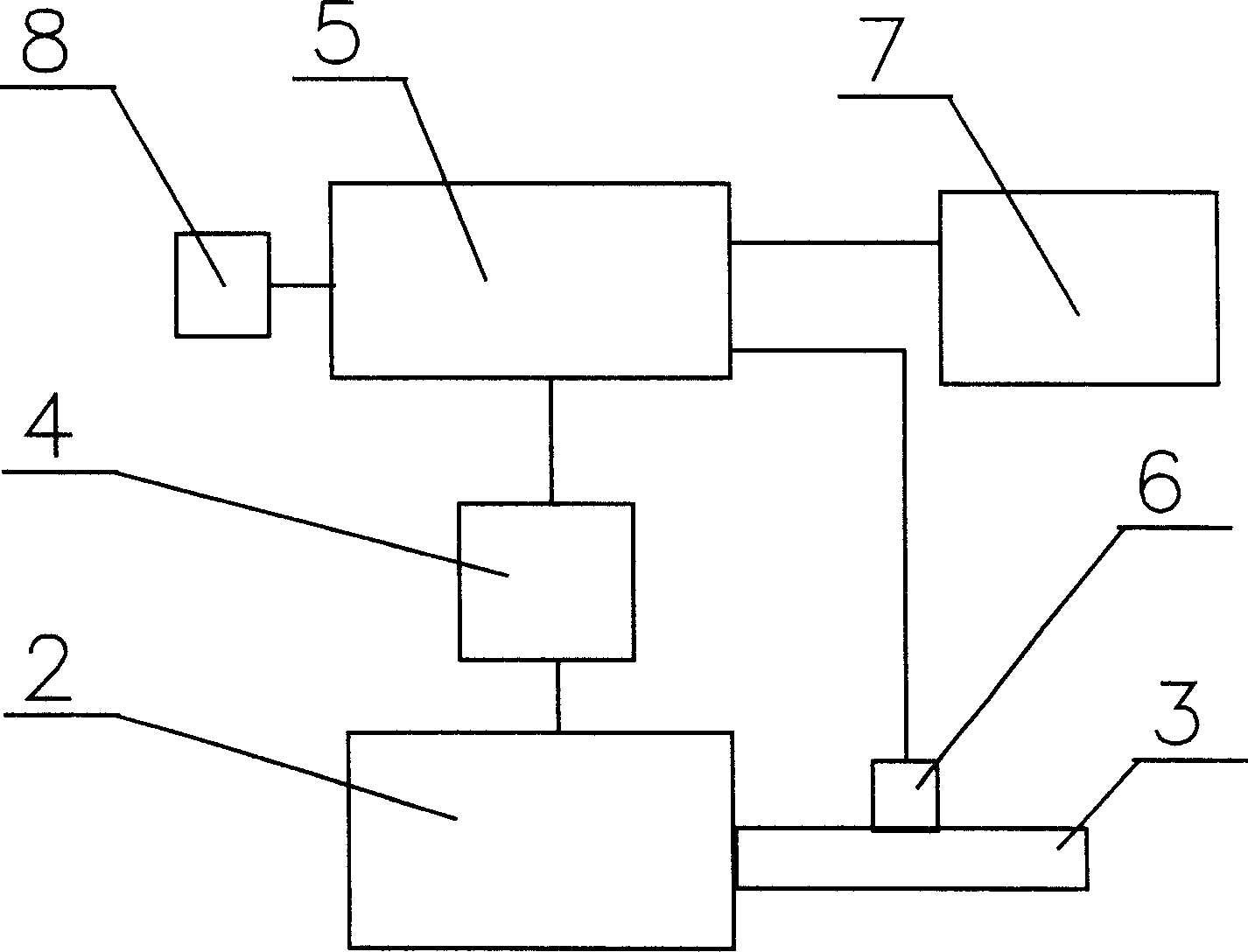

[0017] The present invention can be transformed on the existing electrolytic multi-functional crane, and an electronic scale (4) is connected between the existing multi-functional crane (1) and the ladle (2) during production, and the electronic scale (4) Can adopt the electronic scale that the model that sells on the market is PT650, then install program controller (5) in the cab on the multi-function crane, program controller (5) can adopt the Siemens S7 series PLC that sells on the market, will The signal output terminal of the electronic scale (4) is connected with the signal input terminal of the program controller (5), and a solenoid valve capable of controlling the opening and closing of the vacuum pump is installed on the vacuum pump of the siphon system (3) of the ladle (2) (6), connect the control signal output terminal of the program controller (5) to the relay of the solenoid valve (6) to control the action of the solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com