Condensed-water discharging system and control method thereof

A technology of drainage system and condensate water, applied in the direction of evaporator accessories, etc., can solve the problems of low degree of automation, affecting the dynamic balance of impellers, and high operating power of pumps, and achieves the effect of reducing labor workload, improving labor efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

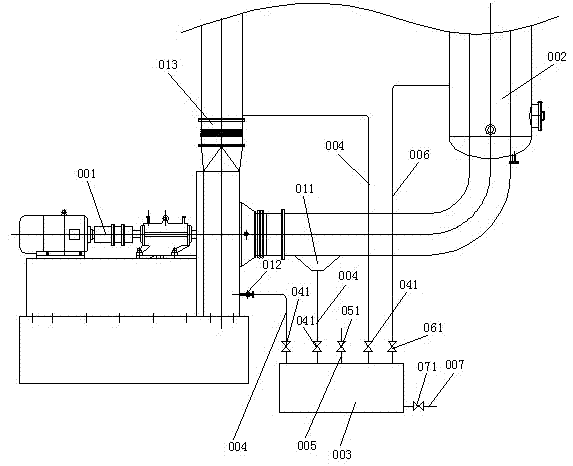

[0008] Embodiment 1: A condensed water drainage system, the drainage system is used for the MVR evaporator, the MVR evaporator includes a mechanical compression fan 001 and a vacuum system 002, it is characterized in that it includes a condensate storage tank 003, and the condensate storage The top of the tank 003 is provided with three condensed water inlet pipes 004 respectively connected to the water collecting bucket 011 before the inlet of the mechanical compression fan 001, the condensed water outlet 012 at the inner bottom of the volute of the mechanical compression fan and the outlet 013 of the mechanical compression fan. The top of the tank 003 is provided with a row of vacuum pipes 005 and a vacuum pipe 006 connected to the vacuum system 002, the bottom of the condensate storage tank 003 is provided with a condensate discharge pipe 007, and the three condensate water inlet pipes 004 are all provided with There is a normally open solenoid valve 041, the vacuum exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com