Simple tensioner of lossless steel cables

A tensioner and wire rope technology, applied in the direction of lifting device, hoisting device, etc., can solve the problems of inconvenience, wire rope damage operation, etc., and achieve the effect of easy operation and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

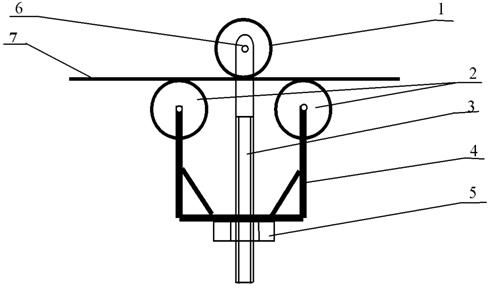

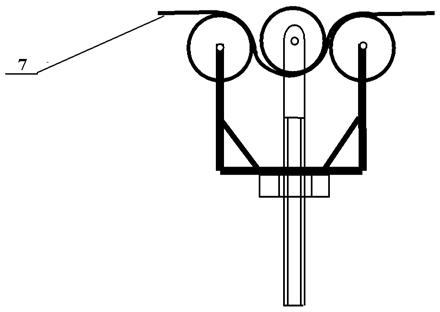

[0019] refer to figure 2 , Figure 3(a), Figure 3(b) and Figure 4 , a simple tensioner for a non-destructive wire rope, comprising a U-shaped fixing frame 4, the two top ends of the U-shaped fixing frame 4 are respectively hinged with fixed wheels 2, and the bottom of the U-shaped fixing frame 4 is connected with a U-shaped fixed The adjusting rod 3 for lifting and lowering, the upper end of the adjusting rod 3 is connected with a detachable adjusting wheel 1, and the adjusting wheel 1 and the fixed wheel 2 are on the same longitudinal plane.

[0020] The above-mentioned adjusting rod 3 is threadedly connected with the stepped adjusting nut 5 located at the lower side of the bottom of the U-shaped fixing frame 4. The outer circle of the step-shaped adjusting nut 5 is smoothly connected with the through hole at the bottom of the U-shaped fixing frame 4. 5 is connected with the bottom of the U-shaped fixing frame 4 by a radial bearing-type smooth surface, and the adjustment nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com