Round bar lifting type stainless steel thin-wall water pipe cutting machine

A lifting type, stainless steel technology, applied in the direction of pipe shearing device, shearing device, metal processing machinery parts, etc., can solve the problems of thin-walled stainless steel water pipe nozzle deformation, difficult to meet the user's requirements, etc., to achieve processing efficiency High, high commercial value and promotion value, the effect of a wide range of diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

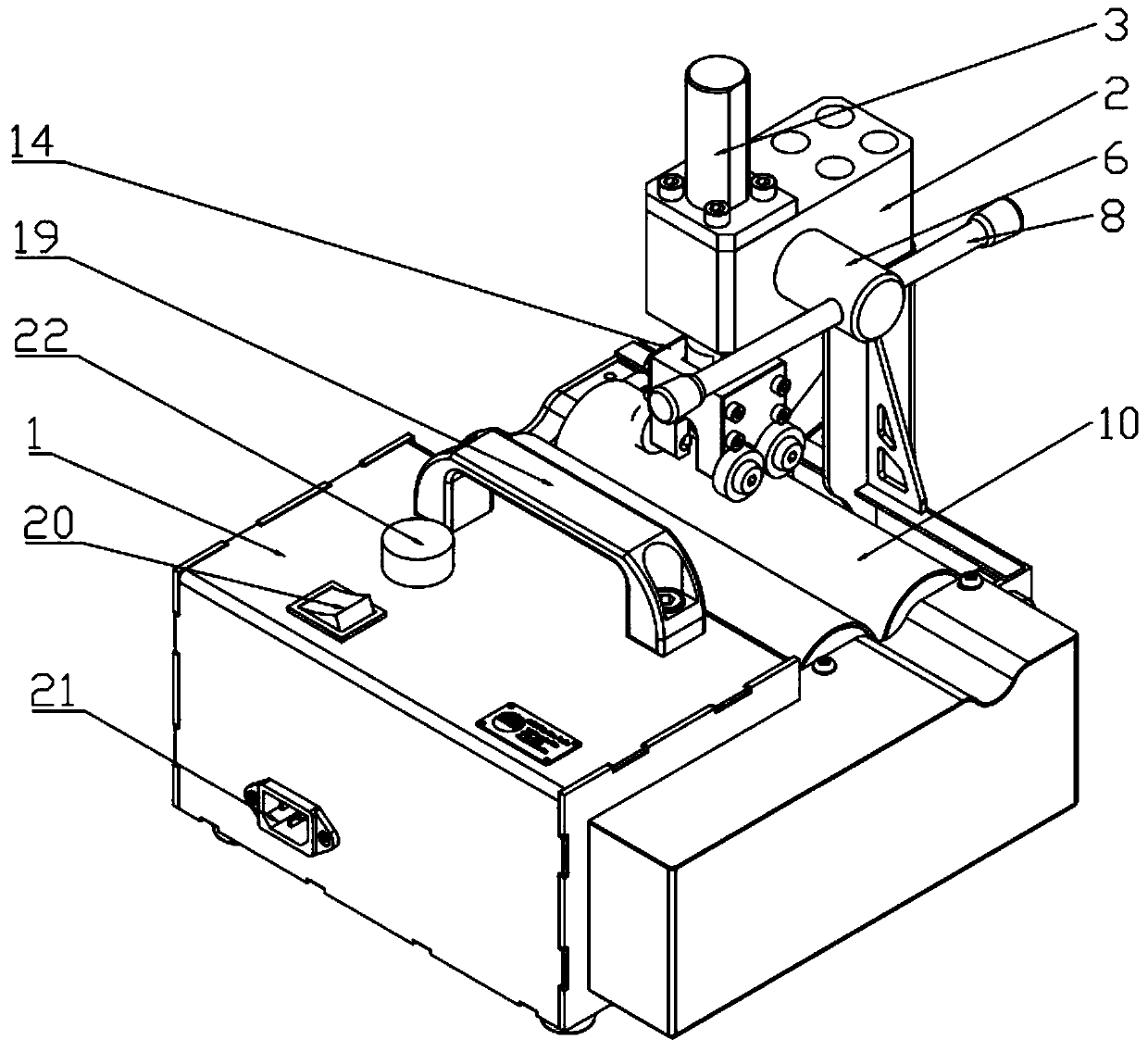

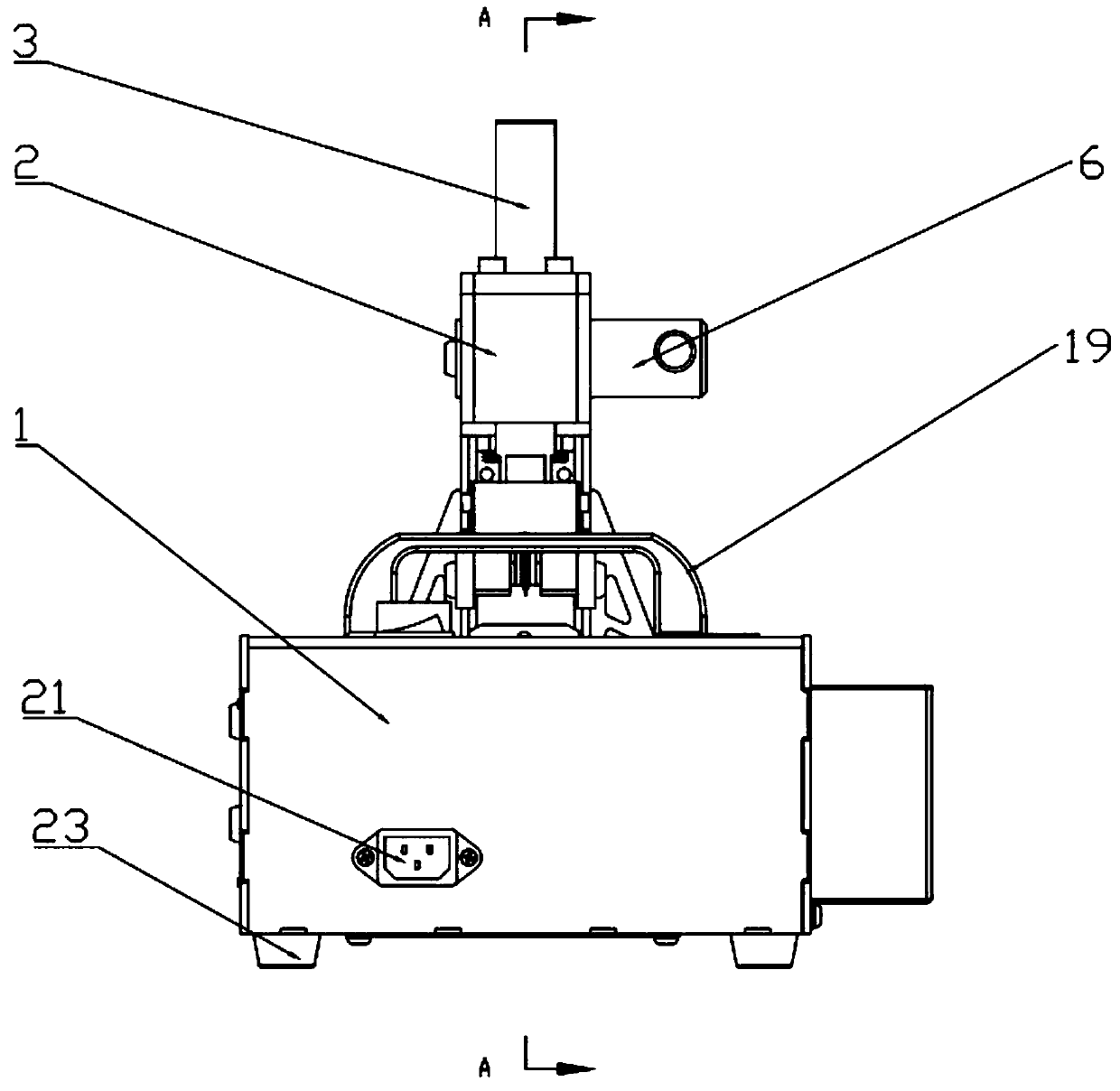

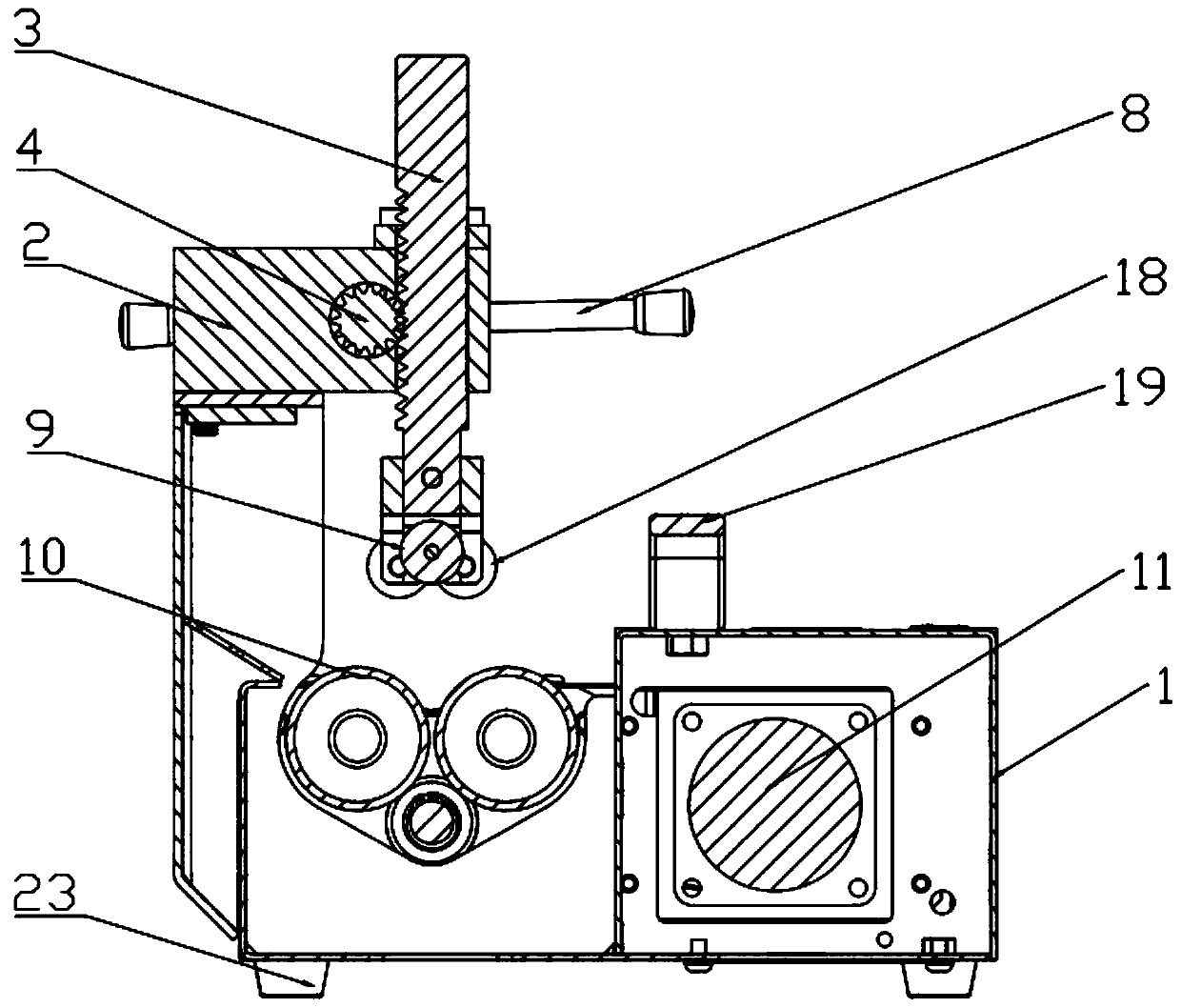

[0018] A kind of round bar lifting type stainless steel thin-walled water pipe cutting machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] combined with Figure 1-6 , a round bar lifting type stainless steel thin-walled water pipe cutting machine, comprising a body 1, a circular cutter part, a drum part positioned on the body 1, and a fixing seat 2 fixed on the body 1; the circular cutter part includes The lifting pressure rod 3 passing through the inside of the fixing seat 2 and slidingly matched with the fixing seat 2, and the pressure wheel fixing device fixed on the lower end of the lifting pressure rod 3, one side of the lifting pressure rod 3 is provided with gear teeth 4 along its axis, so that The inside of the fixed seat 2 is provided with a gear 5 meshing with the gear teeth 4, and the gear 5 is connected to the fixed seat 2 in rotation. One side of the gear 5 is provided with a rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com