Steel ring inner-diameter adjusting device for bead filler laminating machine

A technology of adjusting device and apex, applied in tires, other household appliances, household appliances, etc., can solve the problems of difficult to guarantee position accuracy, low production efficiency, long adjustment time, etc., so as to shorten adjustment time, improve production efficiency and improve production efficiency. Production quality, results in a wide range of diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

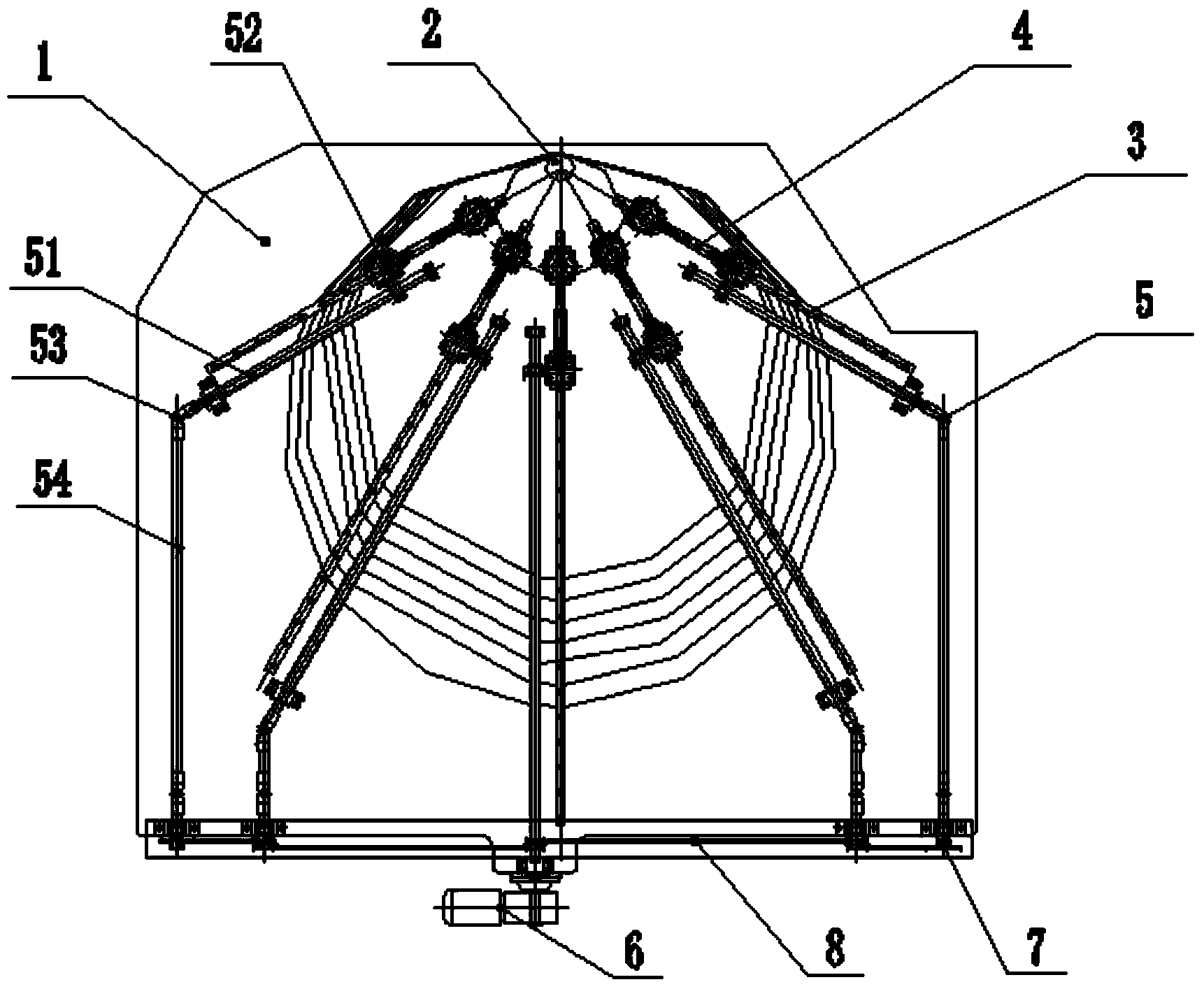

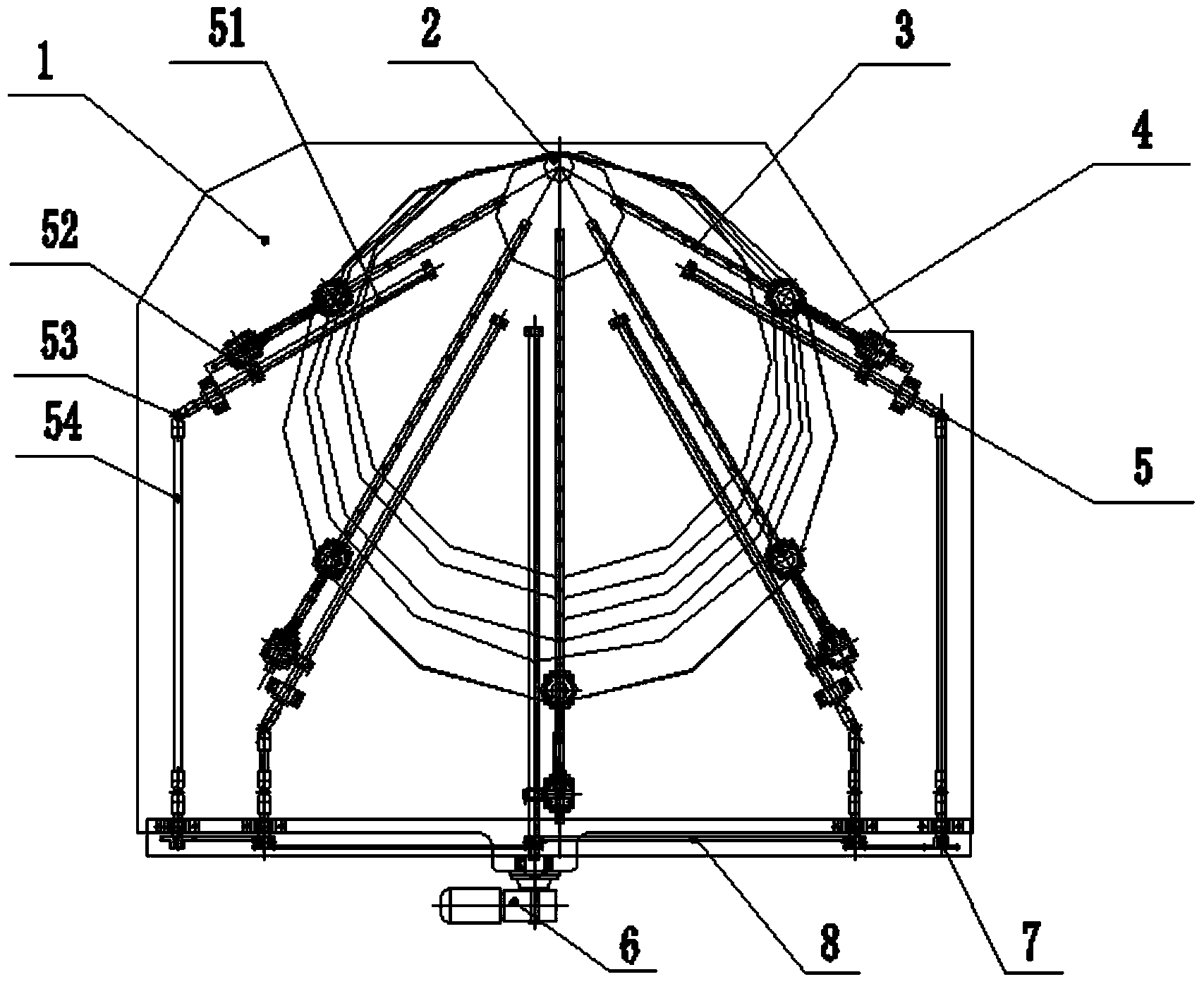

[0018] Such as Figure 1-3 As shown, a device for adjusting the inner diameter of the steel ring of an apex glue laminating machine includes a bracket 1, a fixed guide wheel 2 fixed on the bracket 1 and a number of linear guide rails 3 pointing to the axis of the fixed guide wheel 2, preferably 5 pieces, the expansion-contraction mechanism 4 that is movably arranged on each linear guide rail 3, the adjustment mechanism 5 that is movably connected with the expansion-contraction mechanism 4, the adjustment mechanism 5 that is arranged in the middle is fixedly connected with the drive mechanism 6, and the adjustment mechanism in the middle 5 is synchronously driven by a driving mechanism 6 with other adjusting mechanisms 5 . in:

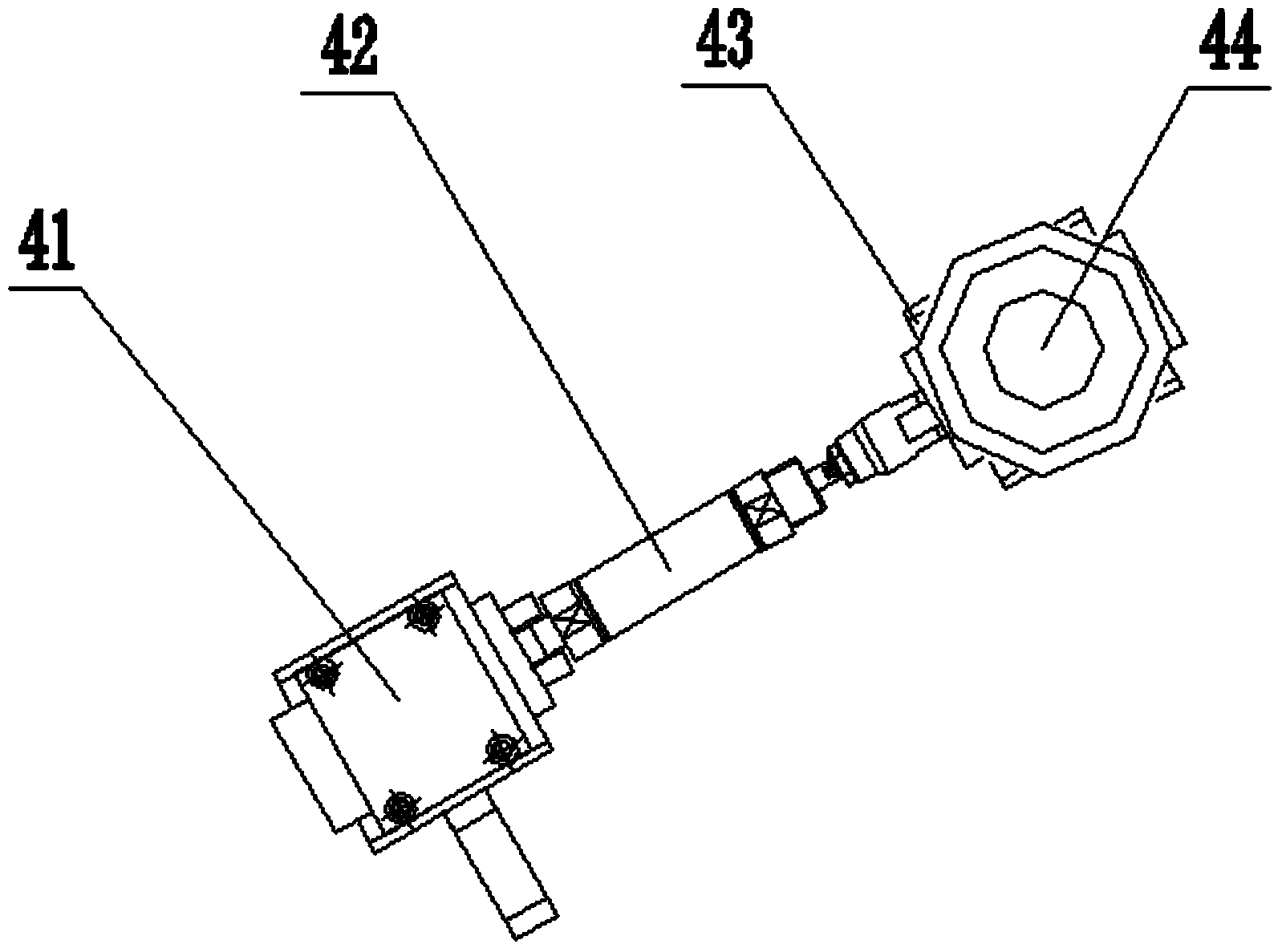

[0019] Each adjustment mechanism 5 comprises a lead screw 51, and the lead screw 51 is connected with a connecting rod 54 through a un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com