Automatic molding system for biomass flat-die particle

A technology of biomass and flat die, which is applied in the direction of mold extrusion granulation, biofuel, waste fuel, etc., can solve the problems of poor connection of flat die forming, complicated equipment, short maintenance cycle, etc., and improve technology integration Horizontal, reduced maintenance, wide diameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

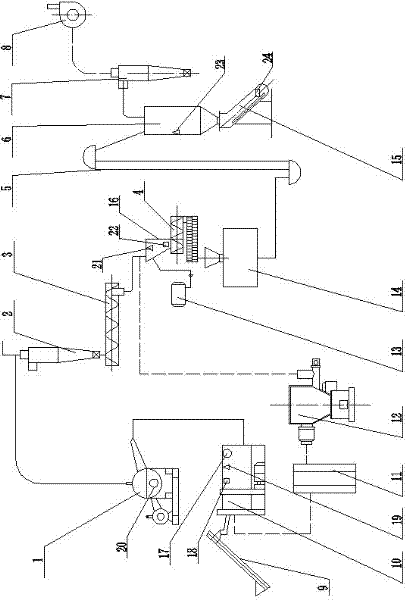

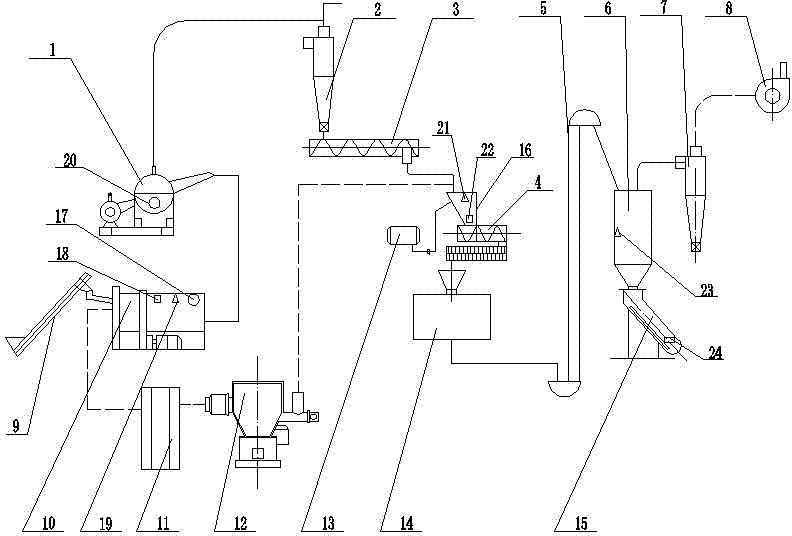

[0030] Such as figure 1 As shown, the biomass flat die granule automatic molding system of the present invention includes a drying part, a pulverizing part, a material conveying part, a molding part and a cooling and drying separation part, the discharge port of the drying part is connected with the feeding port of the pulverizing part, and the pulverizing The discharge port of the part is connected with the feed port of the forming part through the material conveying part, and the discharge port of the forming part is connected with the feed port of the cooling, drying and separating part.

[0031] The drying part includes a fluidized gasifier 12, a settling chamber 11 and a drier 10. The hot gas outlet of the fluidized gasifier 12 is connected to the air inlet of the drier 10 through the settling chamber 11. The feed inlet of the drier 10 is provided with an upper The feeder 9; the dryer 10 is provided with a first current sensor 17, a first humidity sensor 18 and a first te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com