Steel pipe inner wall washing gun

A technology for cleaning the inner wall of steel pipes and guns, which is applied to spray guns, explosion generating devices, abrasives, etc. It can solve problems such as high noise, large impact on the body, and hemp pits on the surface of steel to achieve reduced movement resistance, good working environment, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

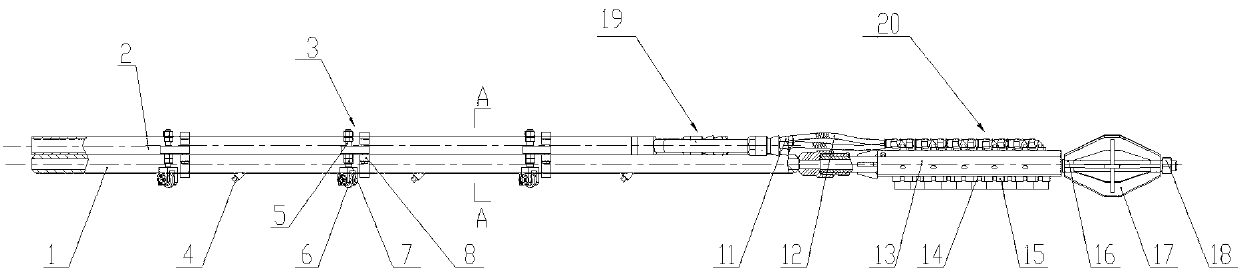

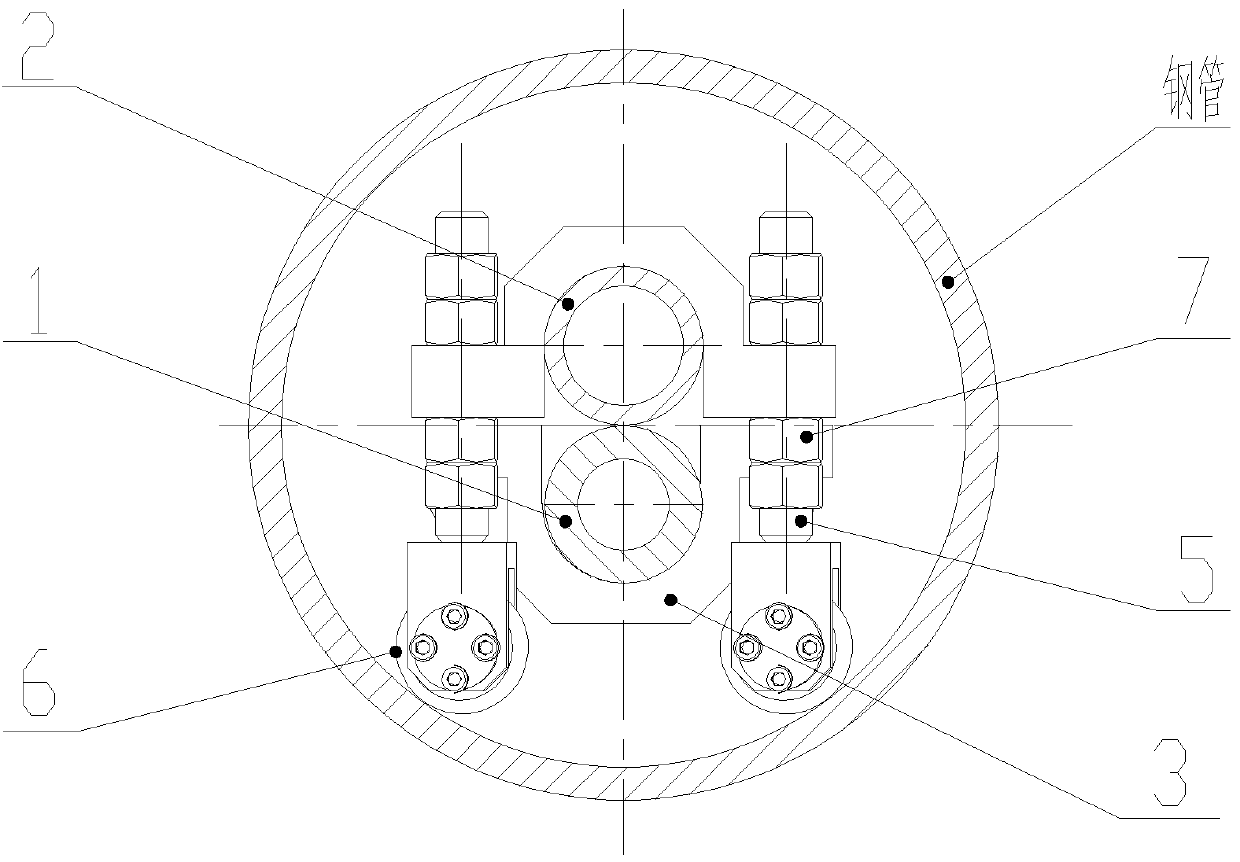

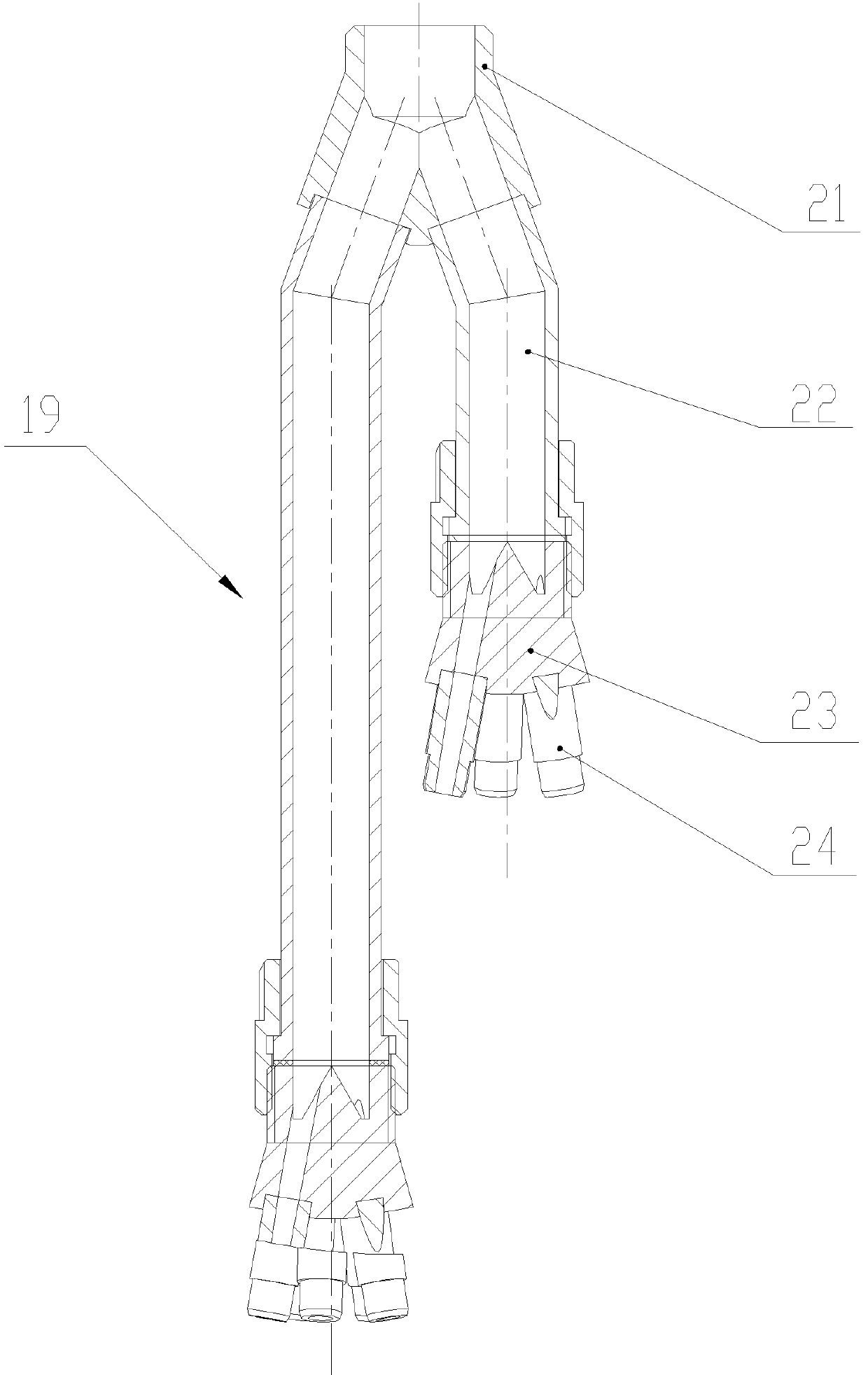

[0020] preferred embodiment, such as figure 1 Shown, steel pipe inner wall cleaning gun of the present invention is used for steel pipe inner wall descaling, and it comprises such as Figure 1 to Figure 5 As shown, the steel pipe inner wall cleaning gun provided by the present invention includes a high-pressure water supply pipe 1 and a sand supply pipe 2, and the sand supply pipe 2 is located above the high-pressure water supply pipe 1, and the water supply pipe 1 and the sand supply pipe 2 are fixed together, the pipe clamp assembly 3 includes two pipe clamps 8 matched up and down, the two sides of the pipe clamp 8 are fastened by the adjusting bolt 5 and the adjusting nut 7, the lower end of the adjusting bolt 5 has a U-shaped slot 9, and the clamping Support wheel 6 is arranged in groove 9. There are four adjusting nuts 7, two each up and down, and the supporting wheel 6 is fixed on the pipe clamp 8. The end of the sand supply pipe 2 is connected to a tree-shaped sand se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com