Adjustable polishing head mechanism for magnetic compound fluid

A fluid polishing and adjustable technology, applied in the field of polishing head mechanism, can solve the problem of low removal efficiency, and achieve the effect of compact and orderly structure, high feasibility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the above-mentioned drawings.

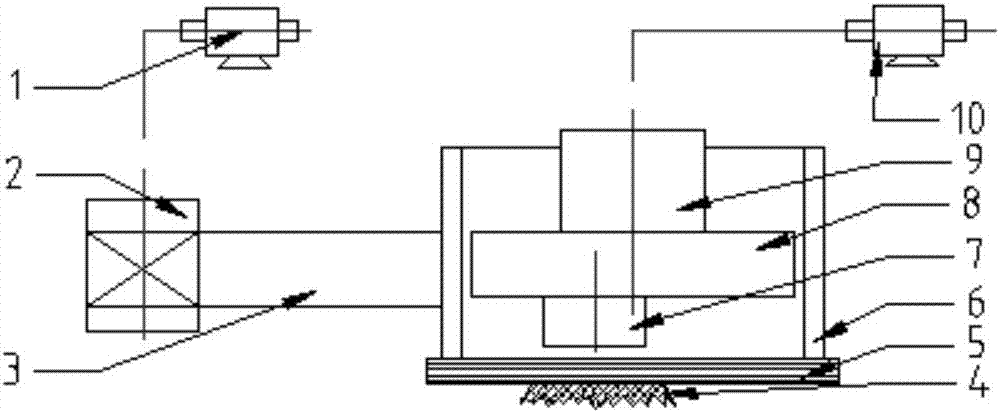

[0045] like figure 1 As shown, an adjustable magnetic composite fluid polishing head mechanism includes a magnet rotation mechanism and a liquid carrier plate rotation mechanism.

[0046] The magnet rotation mechanism includes: a main shaft 9, a magnet disk 8, a permanent magnet 7 and a motor one 10. Wherein the permanent magnet 7 is eccentrically installed under the magnet disc 8 by screws, the magnet disc 8 is connected with the main shaft 9 by screws, the main shaft 9 is installed on the motor one 10 through a shaft coupling, and the main shaft 9 is driven by the motor one 10 to drive the permanent magnet 7 to rotate, Generates a high-speed rotating magnetic field.

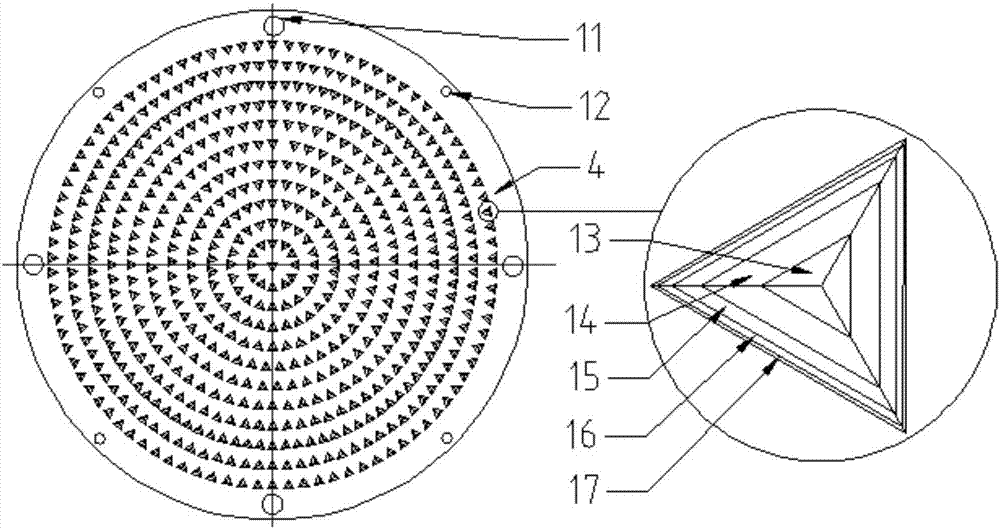

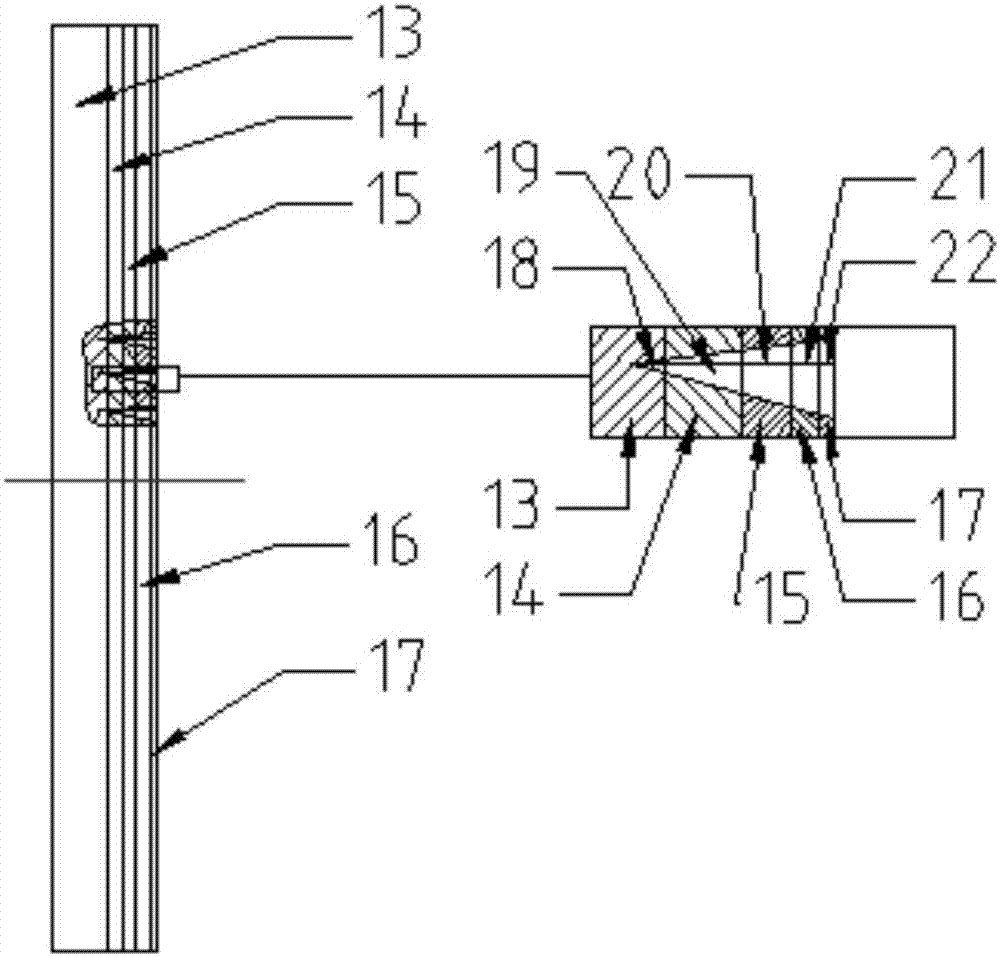

[0047] like figure 1 , shown in 2, the liquid carrier plate rotation mechanism includes: connecting bracket 6, liquid carrier plate 5, V-belt 3, V-belt pulley 2 and moto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com