Patents

Literature

110results about How to "Improve suspension ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

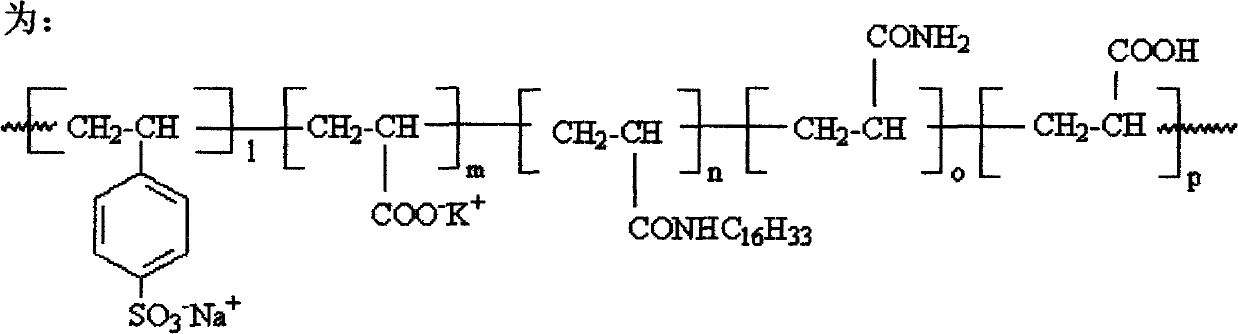

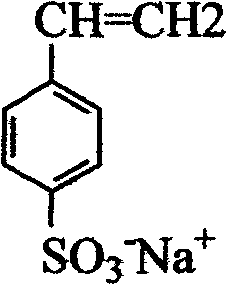

Acrylamide polymer thickener and preparation method thereof, and fracturing fluid

ActiveCN106146730AHigh temperature resistanceImprove high temperature resistanceDrilling compositionPolymer scienceFracturing fluid

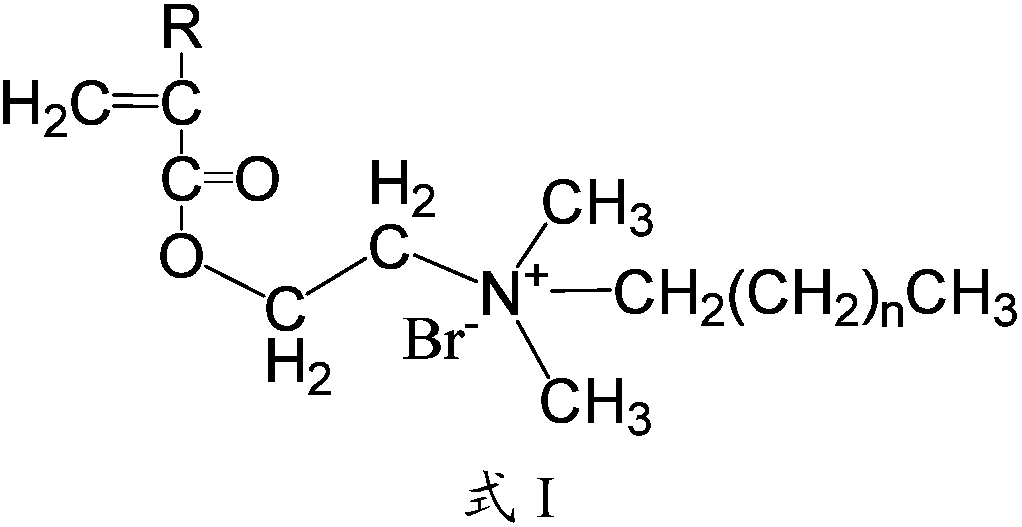

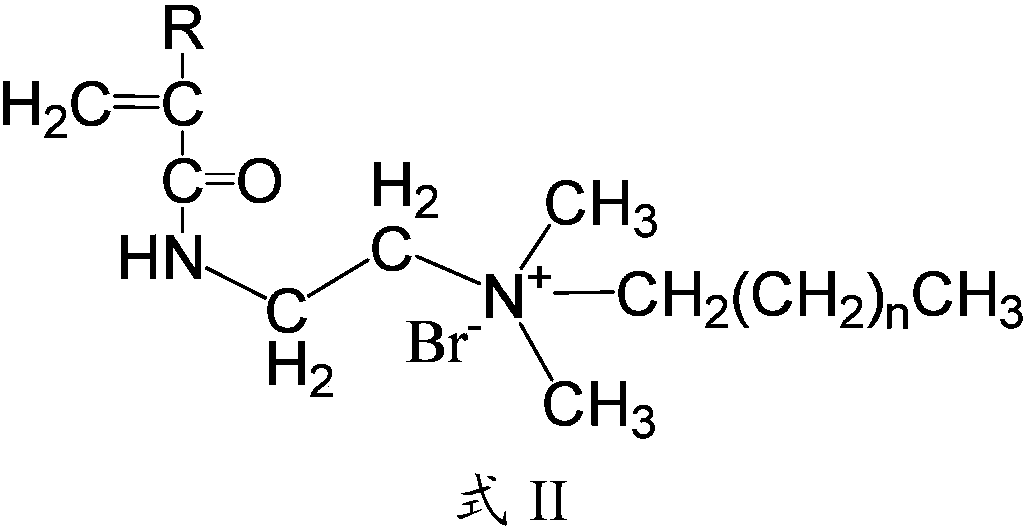

The invention provides an acrylamide polymer thickener and a preparation method thereof, and a fracturing fluid, wherein the acrylamide polymer thickener is composed of the components by the mass percentage: 20%-45% of a hydrophilic propenyl monomer, 4%-6% of a hydrophobic propenyl monomer, 1%-2% of an emulsifier, 0.2%-0.5% of an initiator, a latent crosslinking agent and the balance water, wherein the latent crosslinking agent accounts for 0.5%-1.8% of the total mass of the hydrophilic propenyl monomer and the hydrophobic propenyl monomer; the acrylamide polymer thickener provided by the invention solves the technical problems in the prior art that a polymer thickener has poor temperature resistance and salt tolerance and poor shearing stability, and the prepared acrylamide polymer thickener has high-temperature performance, and can effectively meet the requirements of on-site construction of slick water fracturing.

Owner:PETROCHINA CO LTD

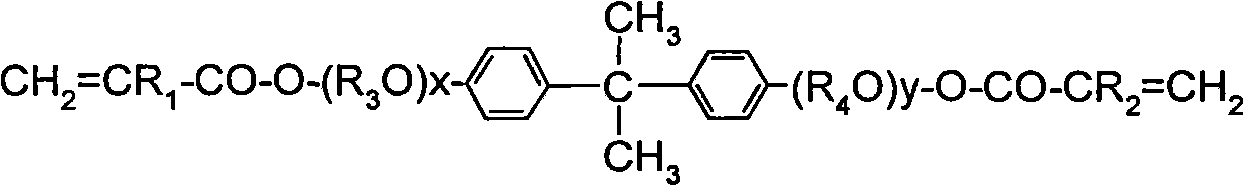

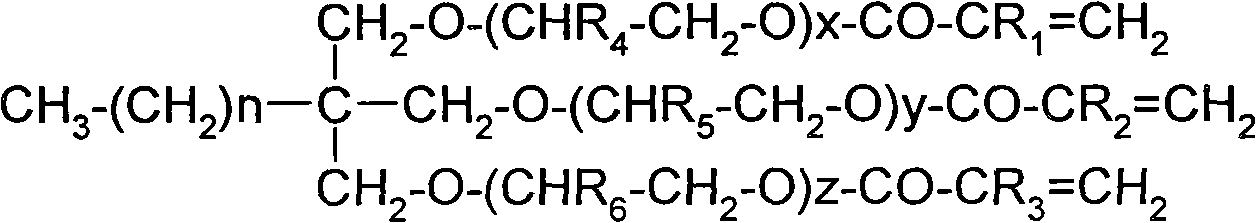

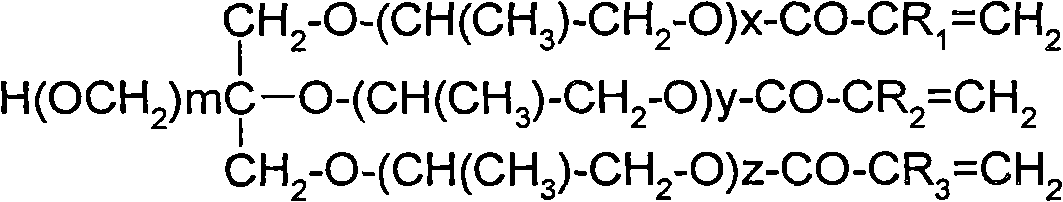

Associative acrylate thickening agent as well as preparation method and application thereof

InactiveCN101974134AGood thickening effectHigh transparencyCosmetic preparationsToilet preparationsEmulsionChemistry

The invention discloses an associative acrylate thickening agent as well as a preparation method and application thereof. The thickening agent in dry weight comprises the following component in percentage by mass: 20-40% of hydrophilic monomer, 50-70% of hydrophobic monomer, 1-10% of reactive surfactant and 0.2-2.0% of cross-linking agent. The preparation method comprises the following steps of: mixing the reactive surfactant, the hydrophilic monomer, the hydrophobic monomer, the cross-linking agent and water to prepare a monomer emulsion; reacting a part of monomer emulsion with a part of initiating agent solution to prepare a seed emulsion; adding the reset monomer emulsion and a part of the initiating agent solution into the seed emulsion; and finally adding the rest initiating agent solution to prepare the associative acrylate thickening agent. The thickening agent has the advantages of strong electrolyte resistance, good compatibility with surfactants, wide pH value application range and excellent thickening capability and suspension capability, and is applicable to the thickening of aqueous systems and system mainly containing water.

Owner:GUANGZHOU SHINE POLYMER TECH

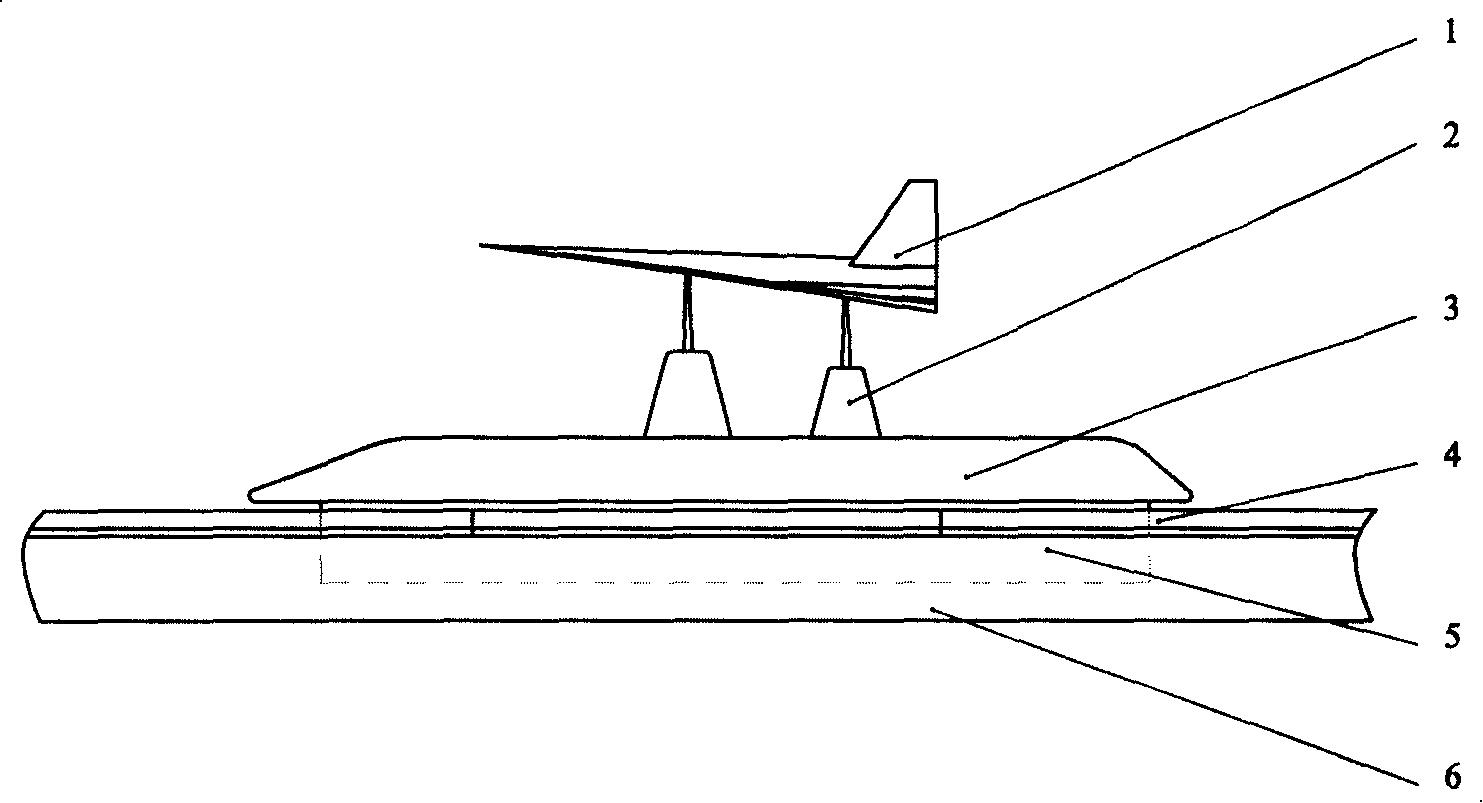

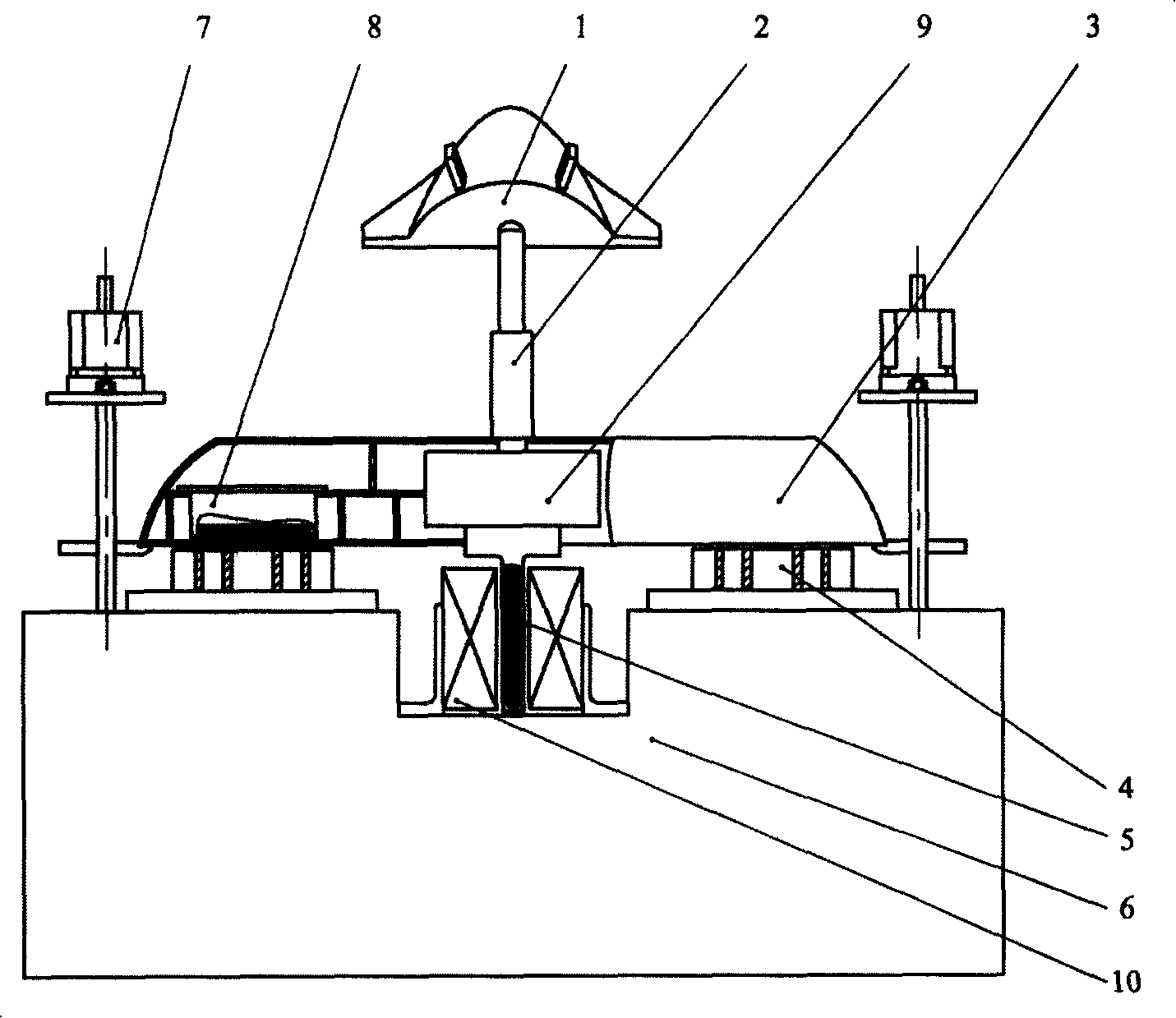

Ground surface high speed superconductor magnetic levitation sled test device

InactiveCN101191759AReduce lossStrong self-stabilizing suspension abilityStructural/machines measurementHigh-temperature superconductivityPower regulation

The invention discloses a ground high-speed superconducting magnetic suspension sleigh test device and belongs to the high-speed test device technical field. The invention provides a technical proposal of the ground high-speed sleigh test device with low energy consumption, high security and reliability as well as high efficiency. The test device comprises a permanent magnetic guide track and a foundation, a high temperature superconductor, a thin-wall liquid nitrogen low-temperature retainer, a magnetic suspension sleigh, a propulsion device for double-edged high-temperature superconductor linear synchronous motor, an electric energy supply and power regulation system and so on. The highly self-stabilizing magnetic suspension system is realized by the action of the electromagnetic force of the bulk high-temperature superconductor and the high electric field permanent magnetic guide track, the high propulsion is produced by the action of the secondary of a high-temperature superconductor linear motor positioned at the bottom of the magnetic suspension sleigh and the three-phase winding of a double-sided linear motor positioned at the foundation, such proposal contributes to the minimized quality design of the magnetic suspension sleigh test device and the realization of larger speed range. The invention is expected to realize the ground acceleration of 0 to 10g and the ground operation linear speed of more than 1000m / s, and is mainly used in technical problem research of weapon systems such as aviation, spaceflight and so on, as well as civil high-tech products during the operation with high speed and high acceleration.

Owner:BEIHANG UNIV

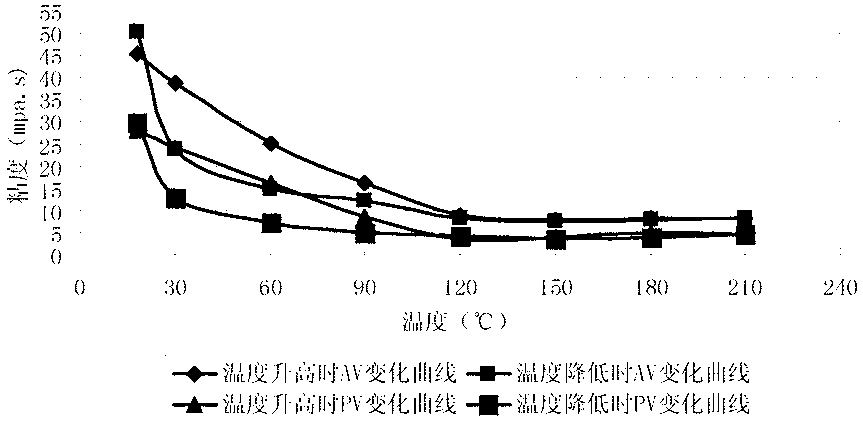

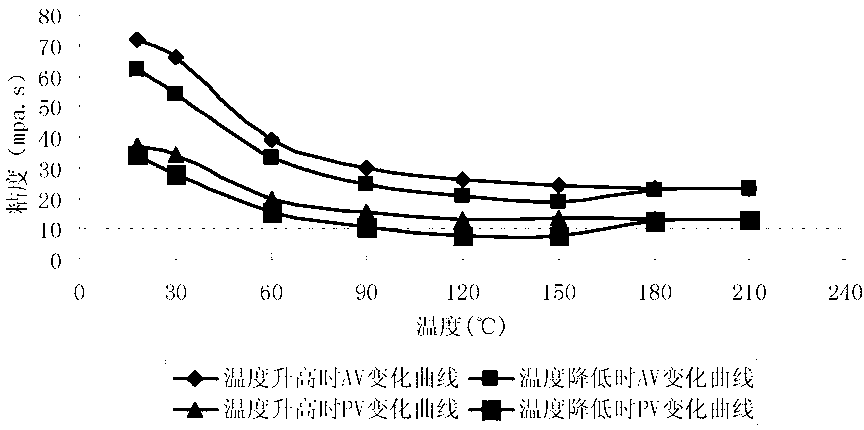

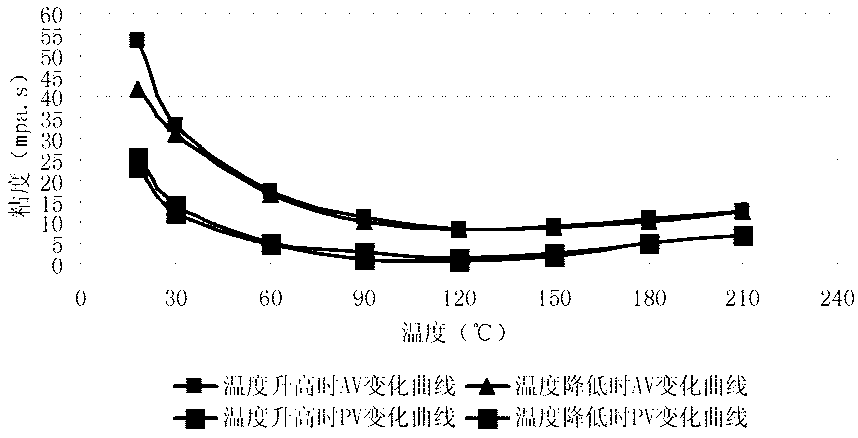

Temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent and preparation method thereof

The invention provides a temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent and a preparation method thereof. The temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent has the advantages of cleanliness, low damage, environmentally friendly characteristics, good viscosity increasing effects, very strong suspension properties,good thermal adaptability allowing a super-wide temperature range of 25 to 240 DEG C, good salt resistance, excellent shear stability, small frictional resistance, obvious fracture effects, long lasting time spent on production after compression, and good cost performance.

Owner:北京爱普聚合科技有限公司

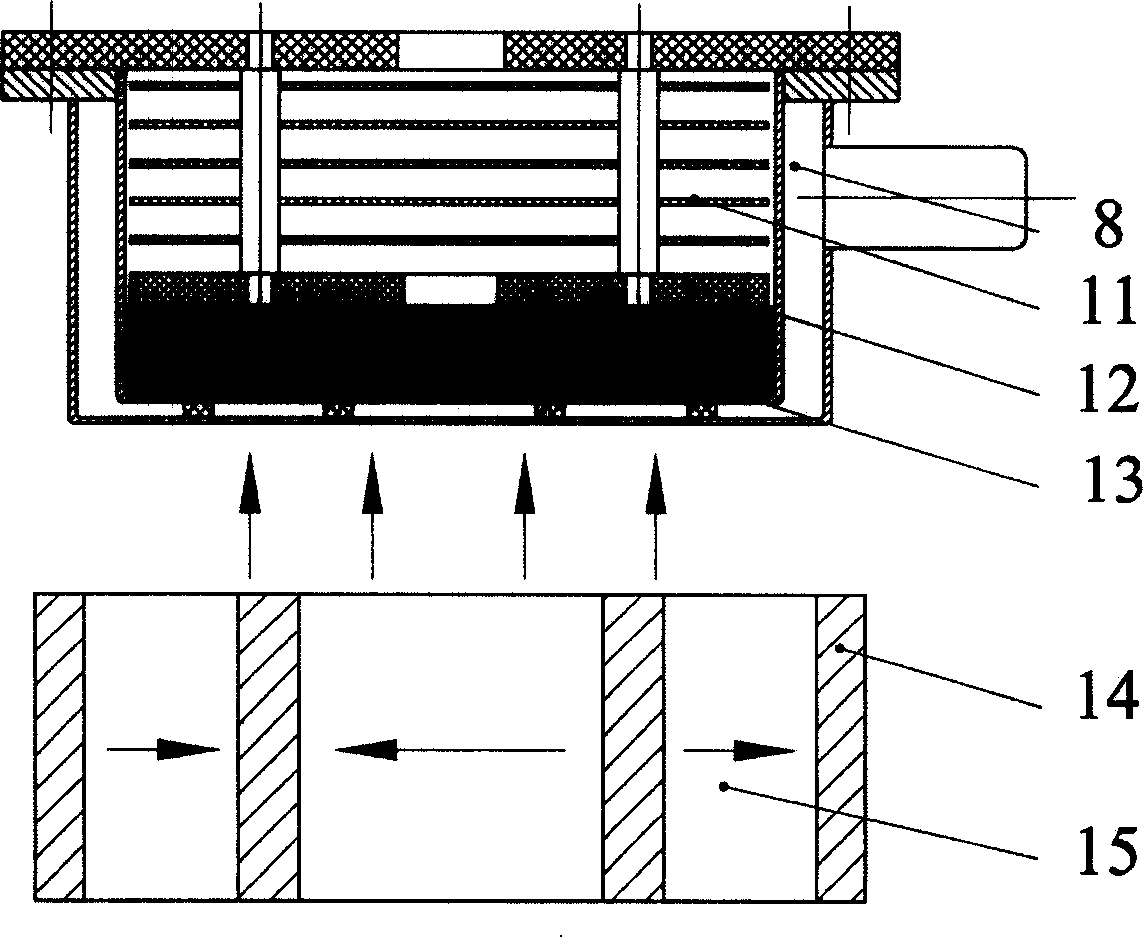

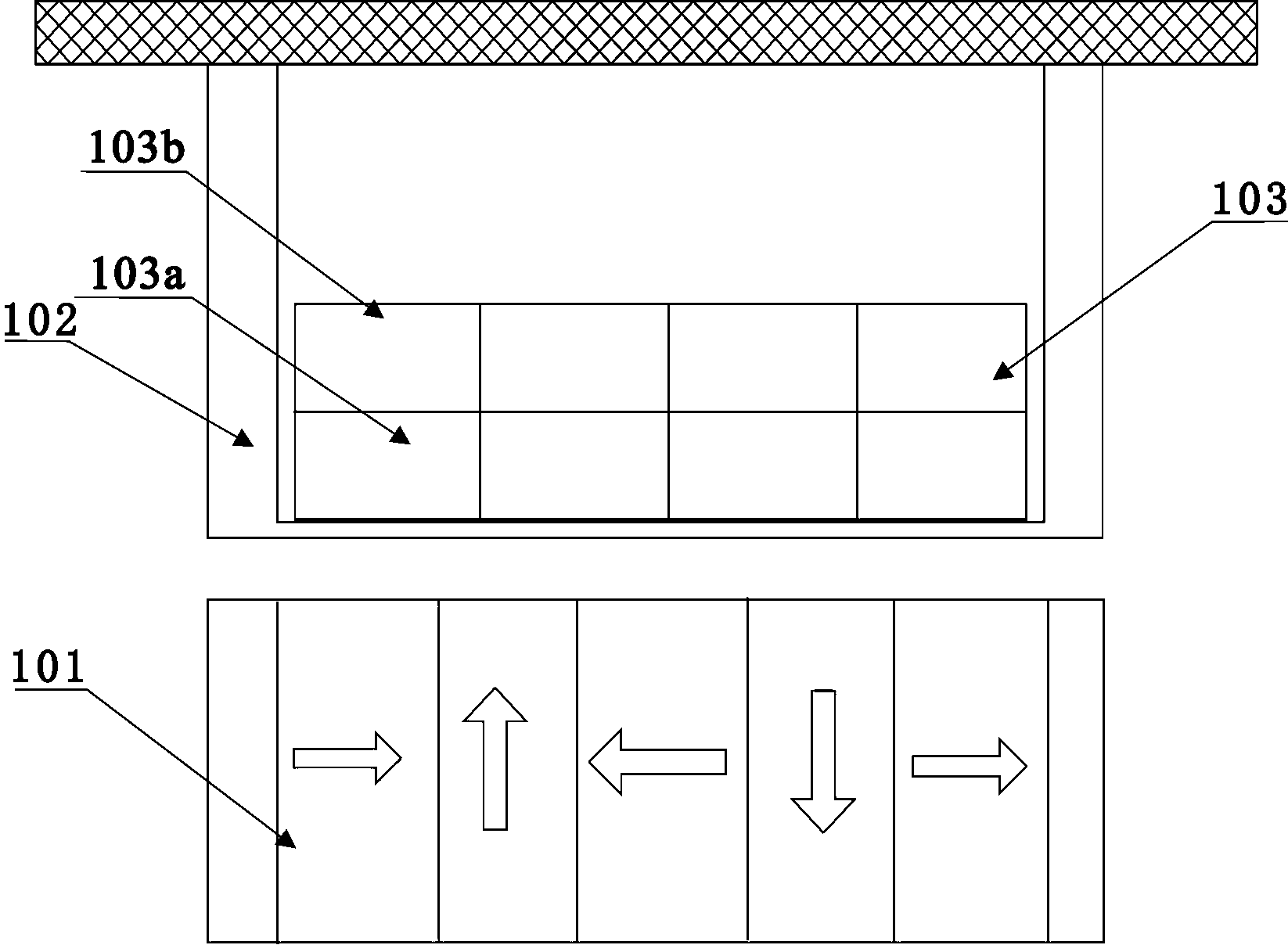

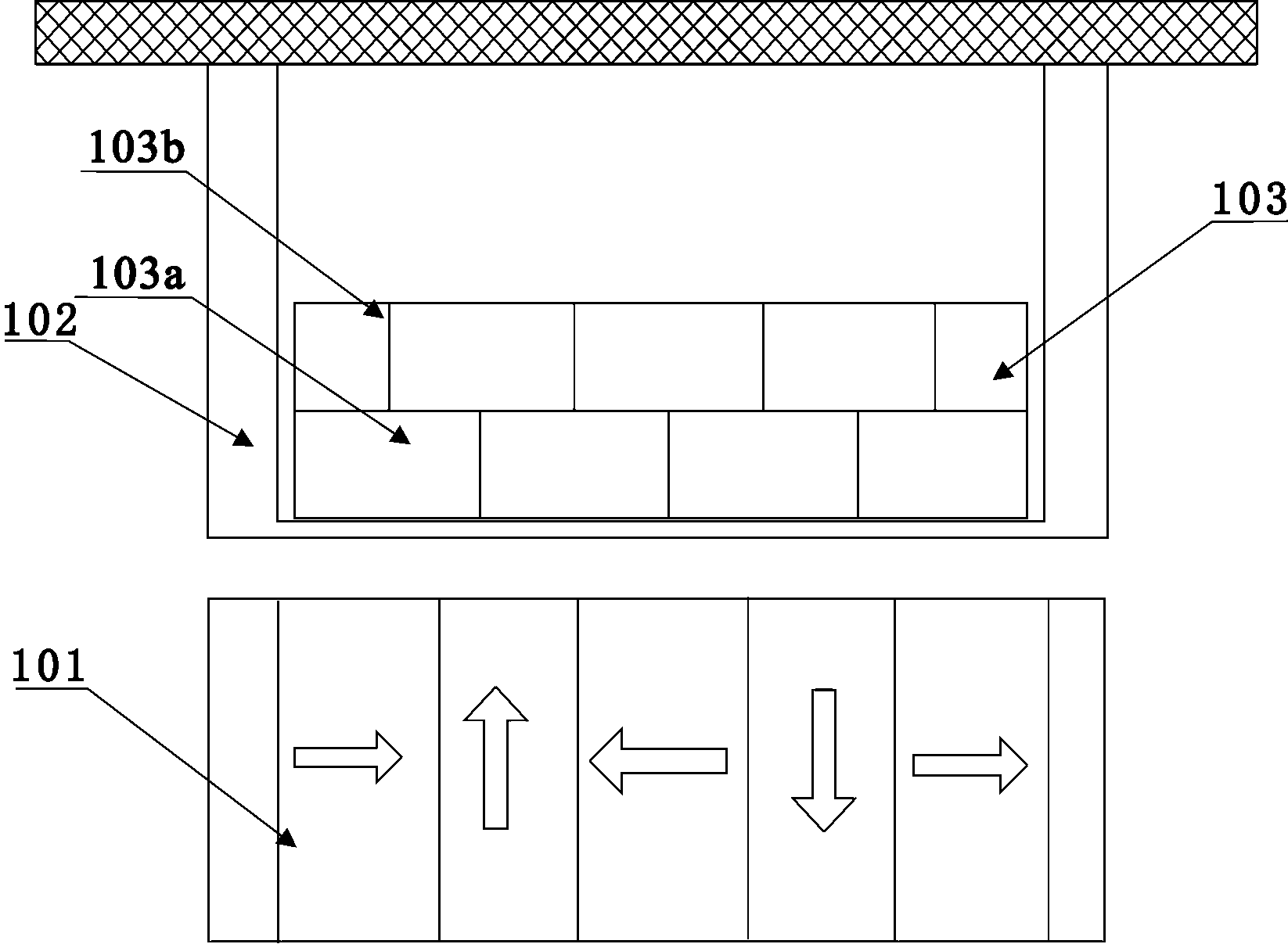

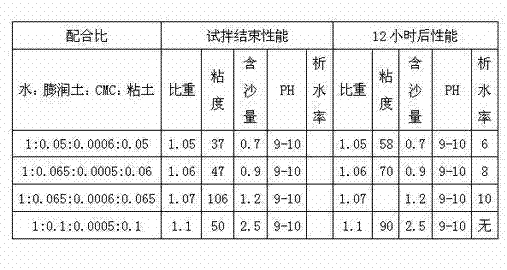

Vehicle double-layer high-temperature superconductor magnetic suspension system

InactiveCN102700431AGood buffGood suspensionElectric propulsionElectrical conductorCarrying capacity

The invention discloses a vehicle double-layer high-temperature superconductor magnetic suspension system, which is characterized by comprising a track and a low-temperature container, wherein the track is made of permanent magnet, a magnetic flux gathering material and the like; the low-temperature container is fixedly arranged in a vehicle body frame; and a high-temperature superconductor layer is fixedly arranged in the low-temperature container and is designed into two layers which are formed by overlapping a lower layer block 103a and an upper layer block 103b. According to the vehicle double-layer high-temperature superconductor magnetic suspension system, by additionally arranging the upper superconductor layer, the aim of simultaneously increasing the suspension force and the guidance force performance of the original single-layer suspension layer can be fulfilled; and the vehicle double-layer high-temperature superconductor magnetic suspension system can be used for optimizing the conventional single-layer high-temperature superconductive magnetic suspension system and improving the load carrying capacity and the stability performance of a superconducting maglev train.

Owner:SOUTHWEST JIAOTONG UNIV

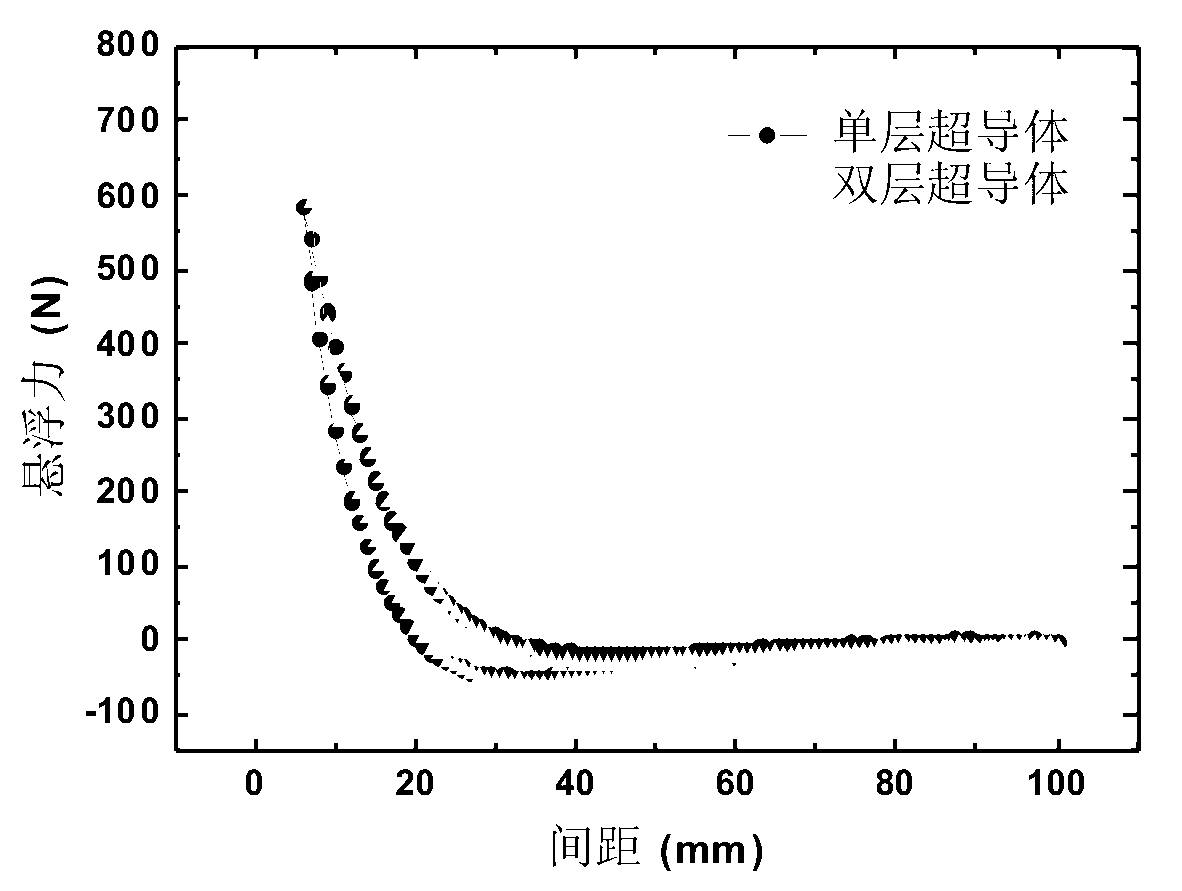

Construction slurry for rotary pile drilling

InactiveCN102226077ARich and stableEnrich and perfect mechanicsDrilling compositionSlurry wallSodium Bentonite

The invention discloses a type of construction slurry for rotary pile drilling. The slurry is a type of compound slurry comprising water, bentonite, hydroxypropyl methyl cellulose solution, clay and soda ash. The construction slurry provided by the present invention can be widely applied in fields of well drilling, rotary pile drilling, and underground diaphragm wall. During a preparing process, the slurry can be mixed quickly and well. The slurry also has advantages of high efficiency, low pollution, low energy consumption and low cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

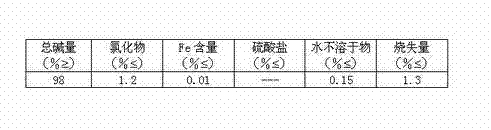

Attapulgite clay suspension agent

InactiveCN101987929AGood dispersionImprove suspension abilityCosmetic preparationsToilet preparationsSuspending AgentsSolvent

The invention discloses an attapulgite clay suspension agent, which mainly comprises attapulgite clay, other clays, chitosan and alkyl quaternary ammonium salt which serve as raw materials. The attapulgite clay suspension agent has the characteristics of high dispersibility and suspending power in water, has high dispersibility and suspension property in an ethanol solvent, and can be used as a suspended anti-settling agent, a thickening agent, a rheological aid and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

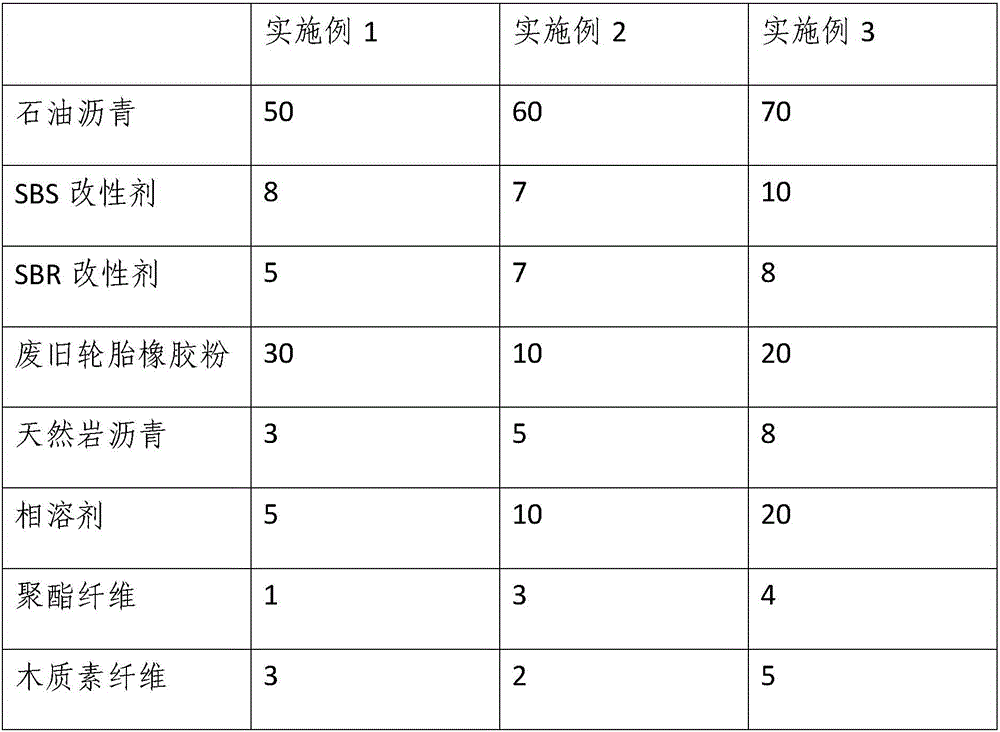

Environment-friendly type pavement heating sealant material as well as preparation method and application thereof

InactiveCN106147257AImprove adhesionFully elasticIn situ pavingsBuilding insulationsCross-linkPolyester

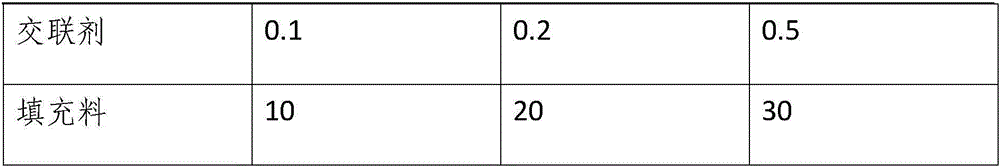

The invention relates to a pavement crack repairing material, in particular to an environment-friendly type pavement heating sealant material which is characterized by being prepared from the following raw materials in parts by weight: 50-70 parts of petroleum asphalt, 7-10 parts of an SBS modifier, 5-8 parts of an SBR modifier, 10-30 parts of waste tire rubber powder, 3-8 parts of natural rock asphalt, 5-20 parts of a phase solvent, 1-4 parts of polyester fiber, 2-5 parts of lignin fiber, 0.1-0.5 part of a cross-linking agent and 10-30 parts of a filling material. The environment-friendly type pavement heating sealant material is adopted for sealing and repairing cracks and joints of common roads, expressways and airfield runways, permeation and fusion of a sealant with an asphalt pavement at high temperature can be achieved, and the environment-friendly type pavement heating sealant material is sufficient in elasticity and free of over-flowing or tire adhesion; after being cooled, the environment-friendly type pavement heating sealant material is good in binding power, and can have elastic deformation along with expansion and shrinkage of cracks due to the relatively good elasticity.

Owner:山东高速物资储运有限公司

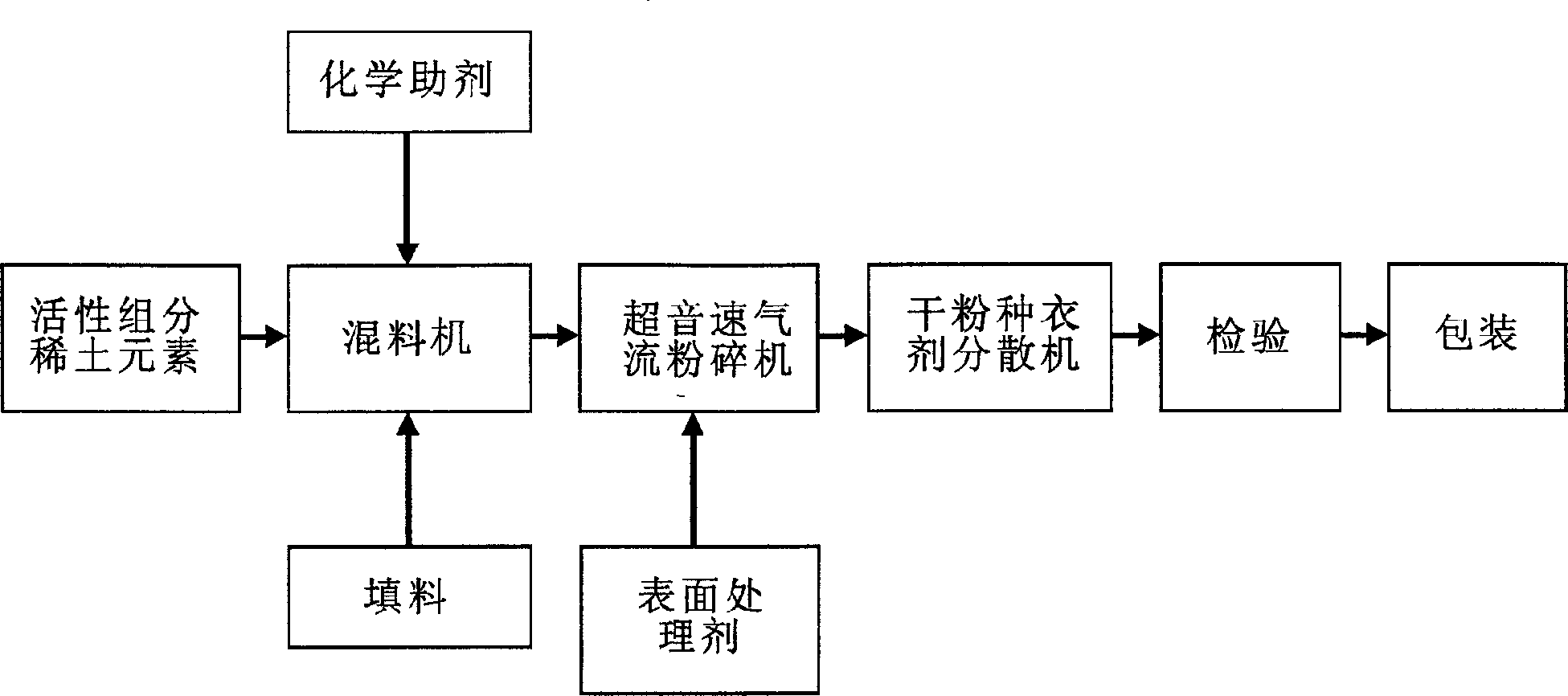

Method for producing rare-earth dry powder seed coating agent

InactiveCN1775034AImprove suspension abilityNot easy to fall offBiocideAnimal repellantsRare earthFilm-forming agent

The present invention relates to a production method of dry powder seed dressing agent for coating wheat, barley, maize, cotton, rice, forest wood and grass seeds. It selects and uses quick-dissolving resin with reticular structure as film-forming agent, uses the porous material with strong adsorptivity, light weight and good disintegrating property as pesticide carrier filling material, mixes them, adds interfacial agent and surfactant and makes the processes of pulverization, dispersion and detection so as to obtain the invented finished product.

Owner:江苏优科植物保护有限公司

High-temperature-resistant saturated brine drilling fluid and preparation method thereof

ActiveCN103275681AStrong anti-pollutionEnhanced inhibitory effectDrilling compositionSalt resistanceDiluent

The invention discloses a high-temperature-resistant saturated brine drilling fluid and a preparation method thereof. The drilling fluid contains 100 parts by weight of water, 2-5 parts by weight of salt resistant soil, 1-3 parts by weight of sepiolite, 10-15 parts by weight of a high temperature and salt resistant fluid loss agent, 1-2 parts of a high temperature and salt resistant diluent, 0.5-2 parts by weight of a high temperature resistant stabilizer, and 35 parts by weight of sodium chloride. The preparation method of the drilling fluid comprises the following steps: respectively adding the salt resistant oil and sepiolite to water, stirring for 20min, ageing for 24h, sequentially adding the high temperature and salt resistant fluid loss agent, the high temperature and salt resistant diluent, the high temperature resistant stabilizer and sodium chloride, and stirring under a speed of 8000r / min to obtain the drilling fluid. The materials of the drilling fluid are convenient to use, can be directly mixed with water, and is stirred for drilling. The drilling fluid has the advantages of good rheological property, strong inhibition performance, realization of the salt resistance saturation in the high temperature environment, realization of the HTHP fluid loss of below 35mL, and benefiting for the hole wall stability and the drill safety.

Owner:BEIJING INST OF EXPLORATION ENG

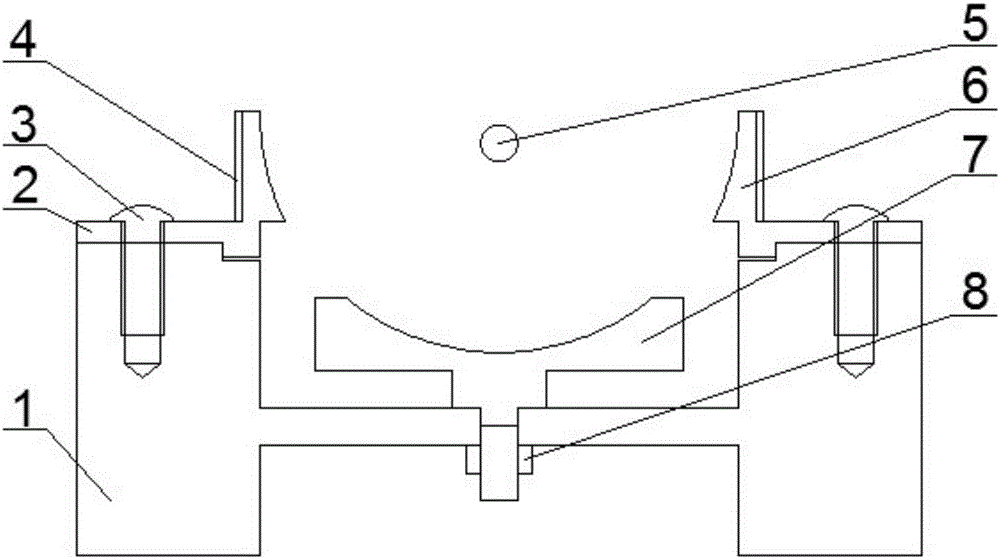

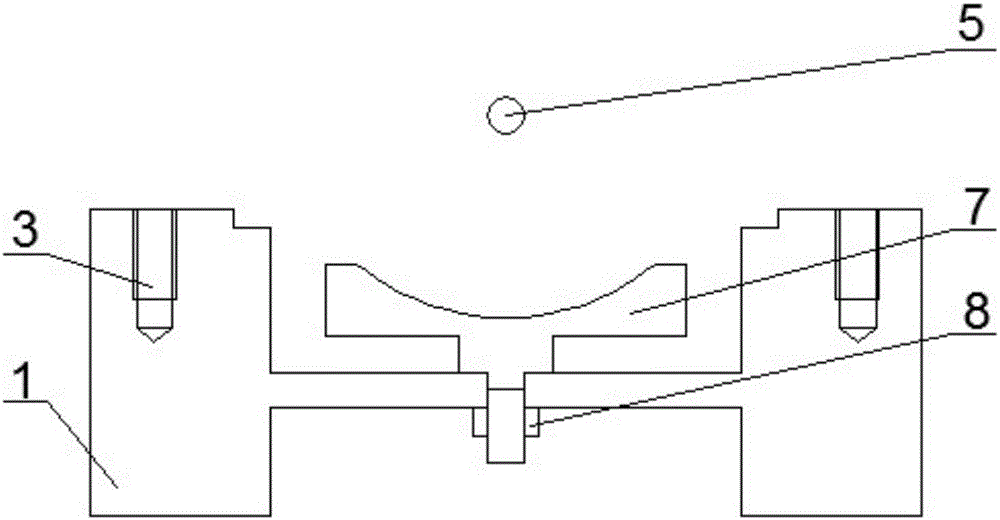

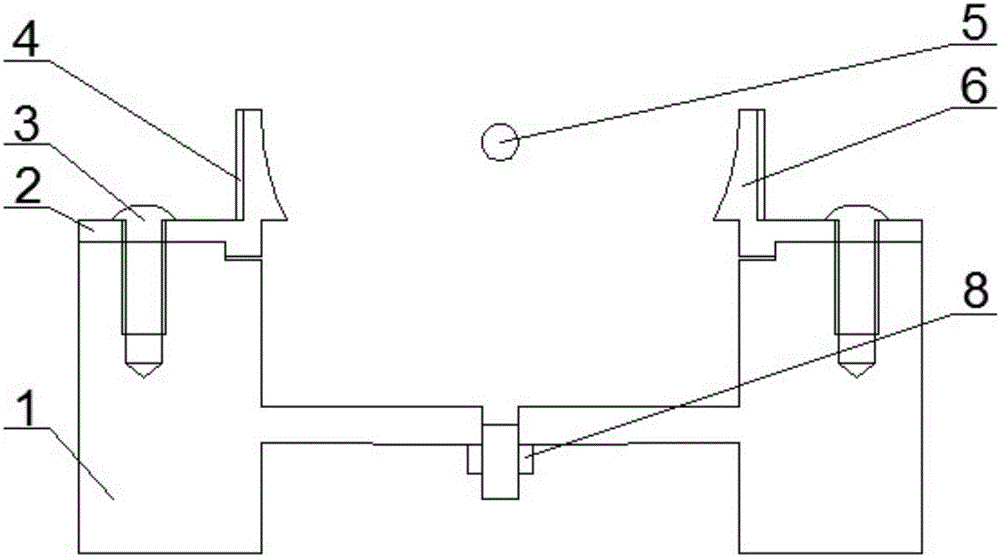

Device for realizing particle suspension and rotation

ActiveCN106391435AImprove suspension abilityReduce the impactMechanical vibrations separationUltrasonic machiningUltrasonic generator

The invention belongs to the technical field of ultrasonic machining equipment, and particularly relates to a device for realizing particle suspension and rotation. The device comprises a base, a shell, an ultrasonic generator and an ultrasonic reflection end, wherein the shell is arranged on the base; a piezoelectric ceramic piece unit is arranged on the outer surface of the shell; the ultrasonic reflection end is arranged in the shell; and the ultrasonic generator is arranged over the ultrasonic reflection end. According to the device for realizing particle suspension and rotation based on acoustic suspension and a rotary sound field, particle suspension and rotation are realized through ultrasonic standing wave suspension and rotary traveling waves generated by ultrasonic traveling waves.

Owner:HANGZHOU DIANZI UNIV

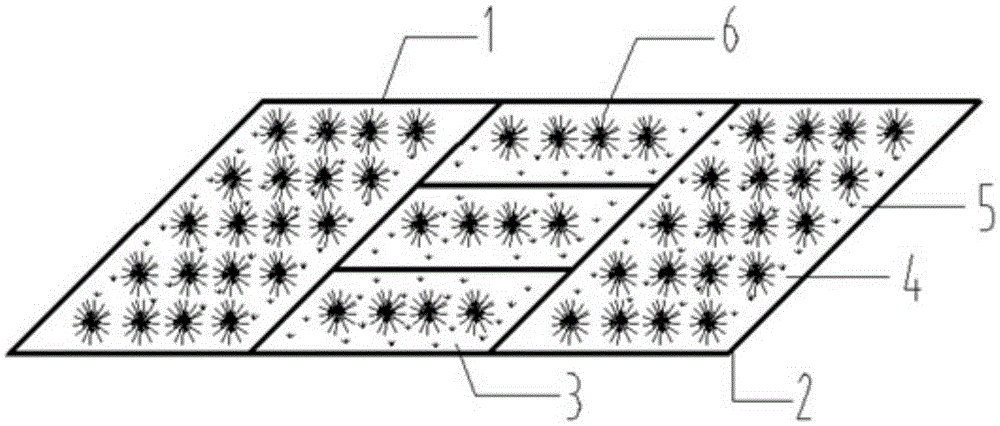

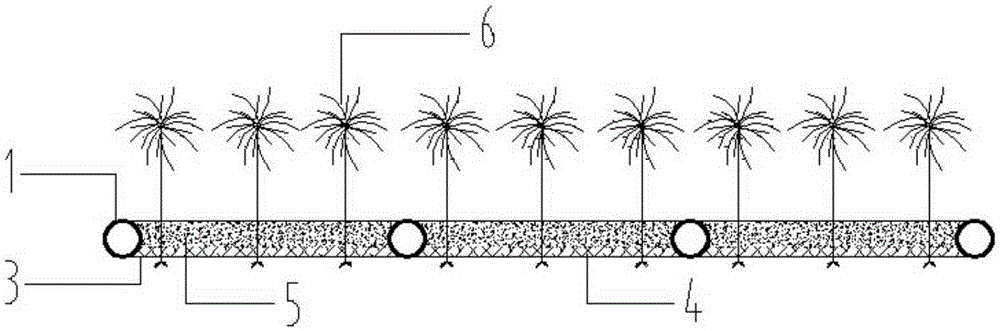

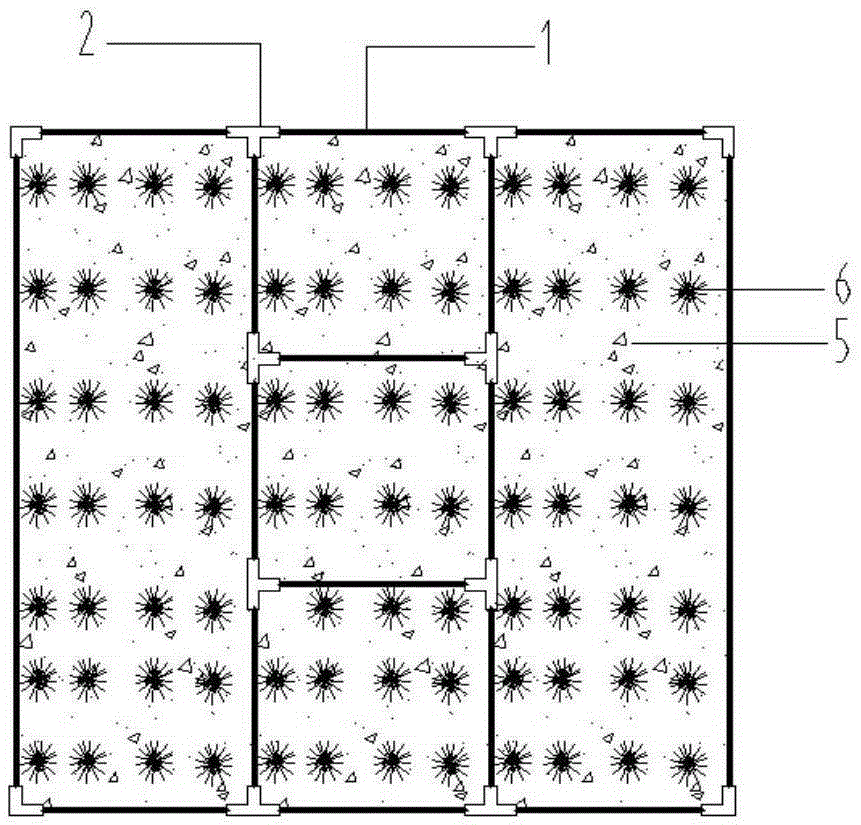

Ecological floating bed for oil-polluted water remediation

ActiveCN105293709AImprove water purification effectImprove adsorption capacityWater contaminantsBiological water/sewage treatmentPlant rootsNonwoven fabric

The invention discloses an ecological floating bed for oil-polluted water remediation. The main frame of the ecological floating bed comprises multiple assembled casing supports. Joints of the casing supports of the main frame are connected to matched PVC casing pipe joints and the joint openings are sealed by silica gel. A modified TiO2 photocatalytic material is carried by waste polyurethane foamed plastic recovered and recycled by an alcoholysis method so that the casing supports are prepared. The bottom of the main frame is wrapped by a non-woven fabric. Wrapped parts of the non-woven fabric and the main frame are tightened by a nylon rope. In each unit, a certain amount of a bottom filler layer and an upper filler layer are uniformly laid. Crops are planted in the upper filler layer. The paddy rice sprout on a floating bed can fully absorb redundant nitrogen and phosphor in water so that plant growth is promoted, the plant roots can promote floating bed bottom microbe growth so that floating bed water purification effects are improved, and the modified fly ash and the non-woven fabric have strong adsorptivity. The floating bed has three technology advantages and improves oil pollutant adsorption degradability and cleaning effects.

Owner:HOHAI UNIV

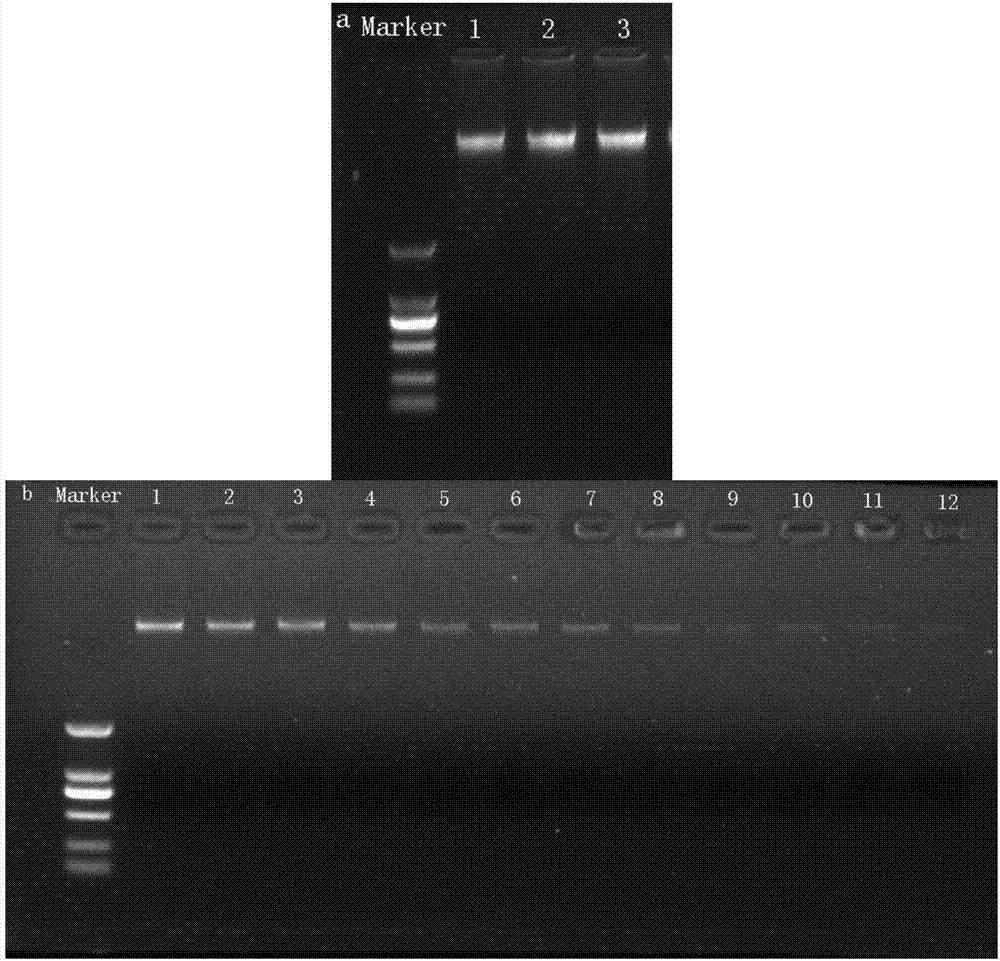

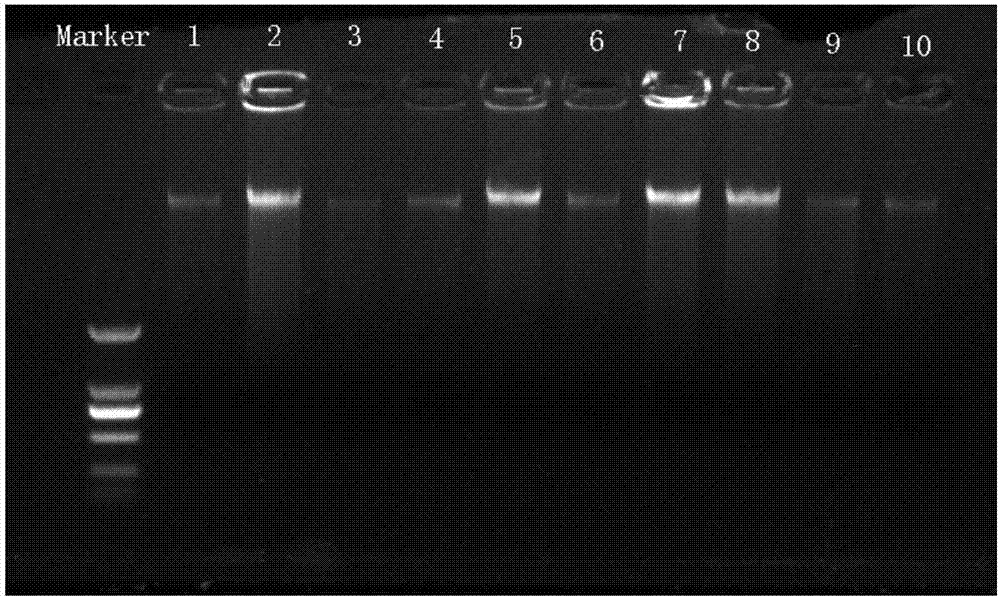

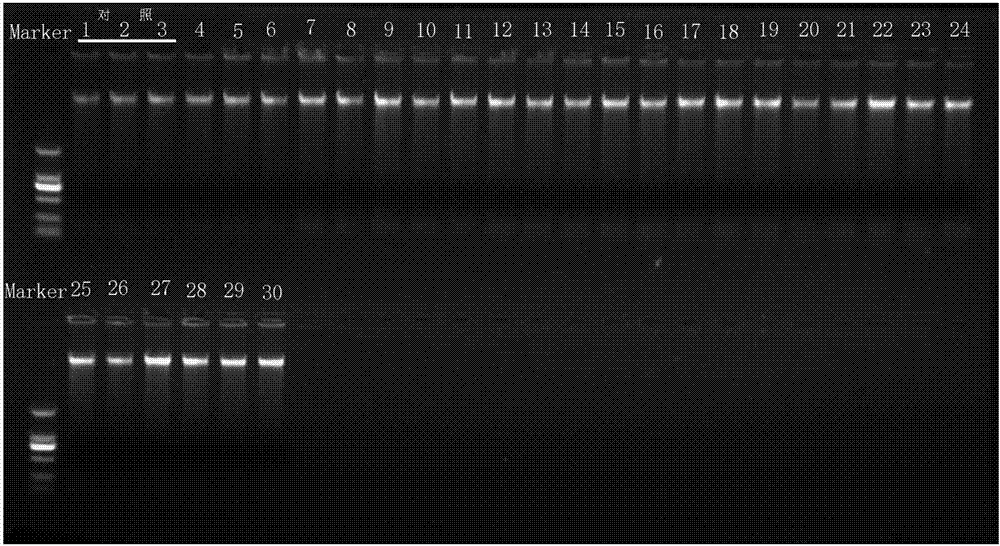

Kit for extracting genome DNA of oral sample based on magnetic bead method and application method of kit

InactiveCN107058286AConvenient collectionDNA extraction with high purityDNA preparationBiologySaliva

The invention discloses a kit for extracting genome DNA of an oral sample based on a magnetic bead method and an application method of the kit. The kit comprises a preservation liquid, a protease K solution, a lysate, a magnetic bead dispersion liquid, a cleaning liquid I, a cleaning liquid II and an eluent. The kit is simple and convenient to operate, and the work efficiency of extracting saliva or swab genome DNA can be greatly improved; and saliva does not need to be pretreated, and a saliva or swab sample can be split by adopting the lysate directly, and the magnetic bead dispersion liquid is added to be combined with the genome DNA, so that the extraction yield of nucleic acid is high and the kit is suitable for a high-throughput experiment.

Owner:SUZHOU ENRICHING BIOTECH CO LTD

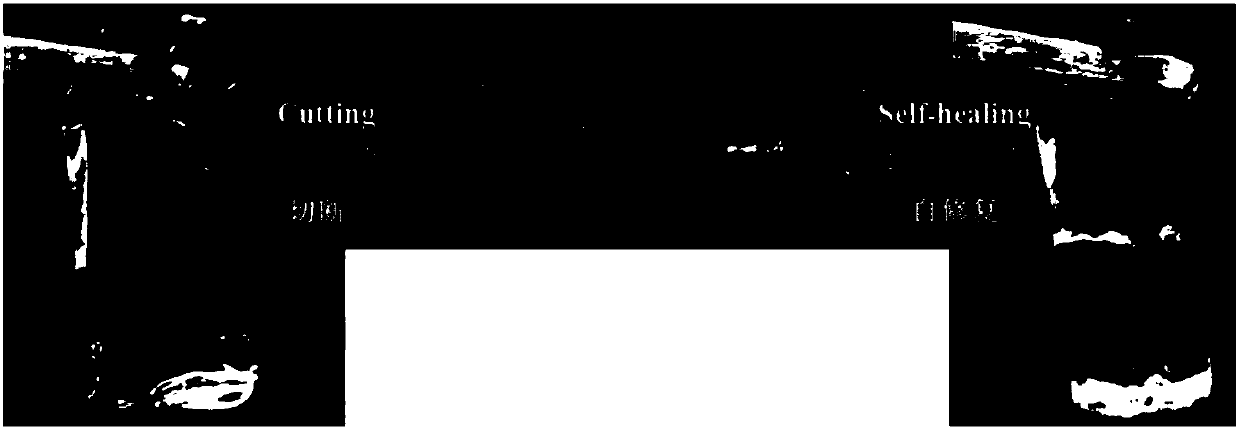

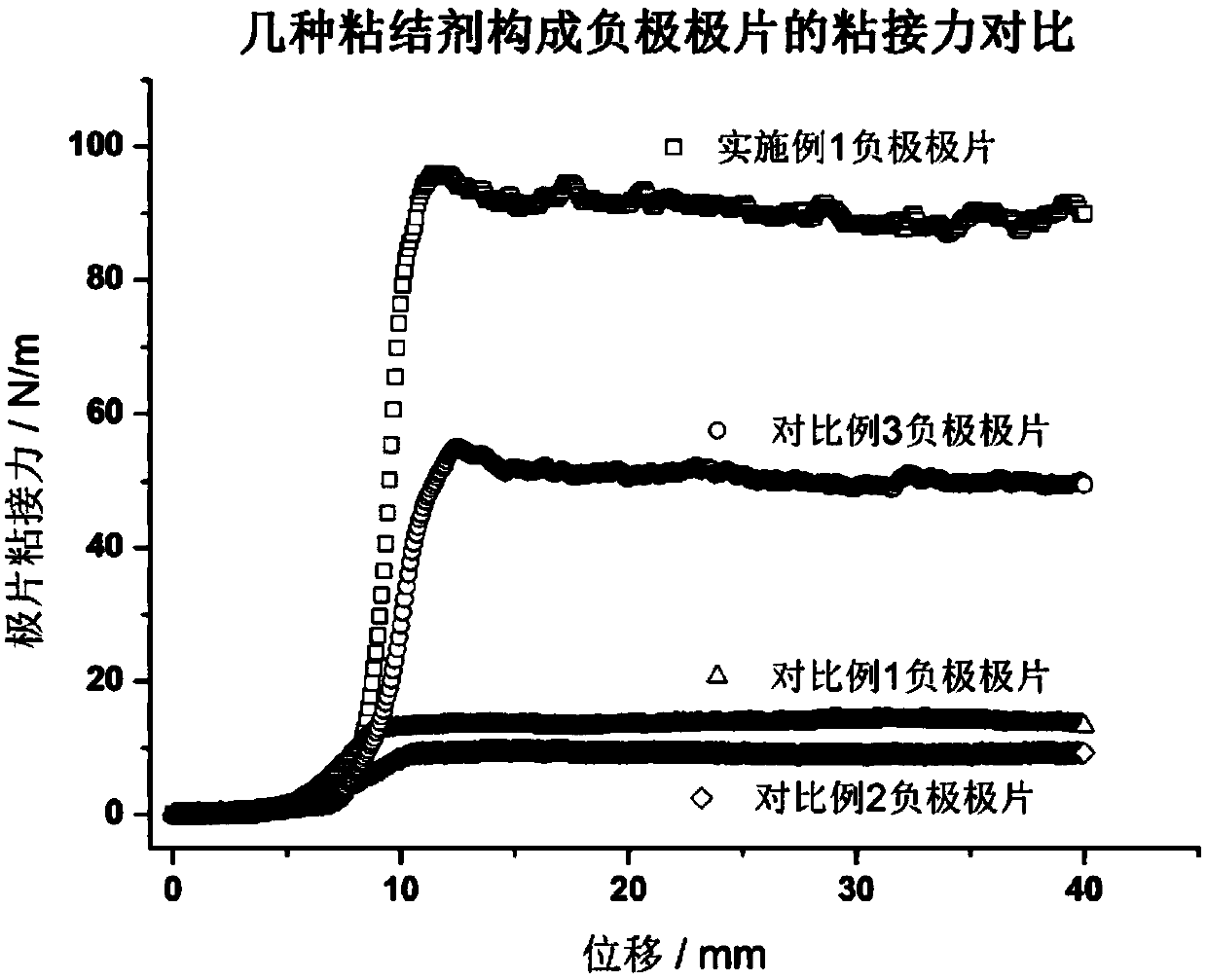

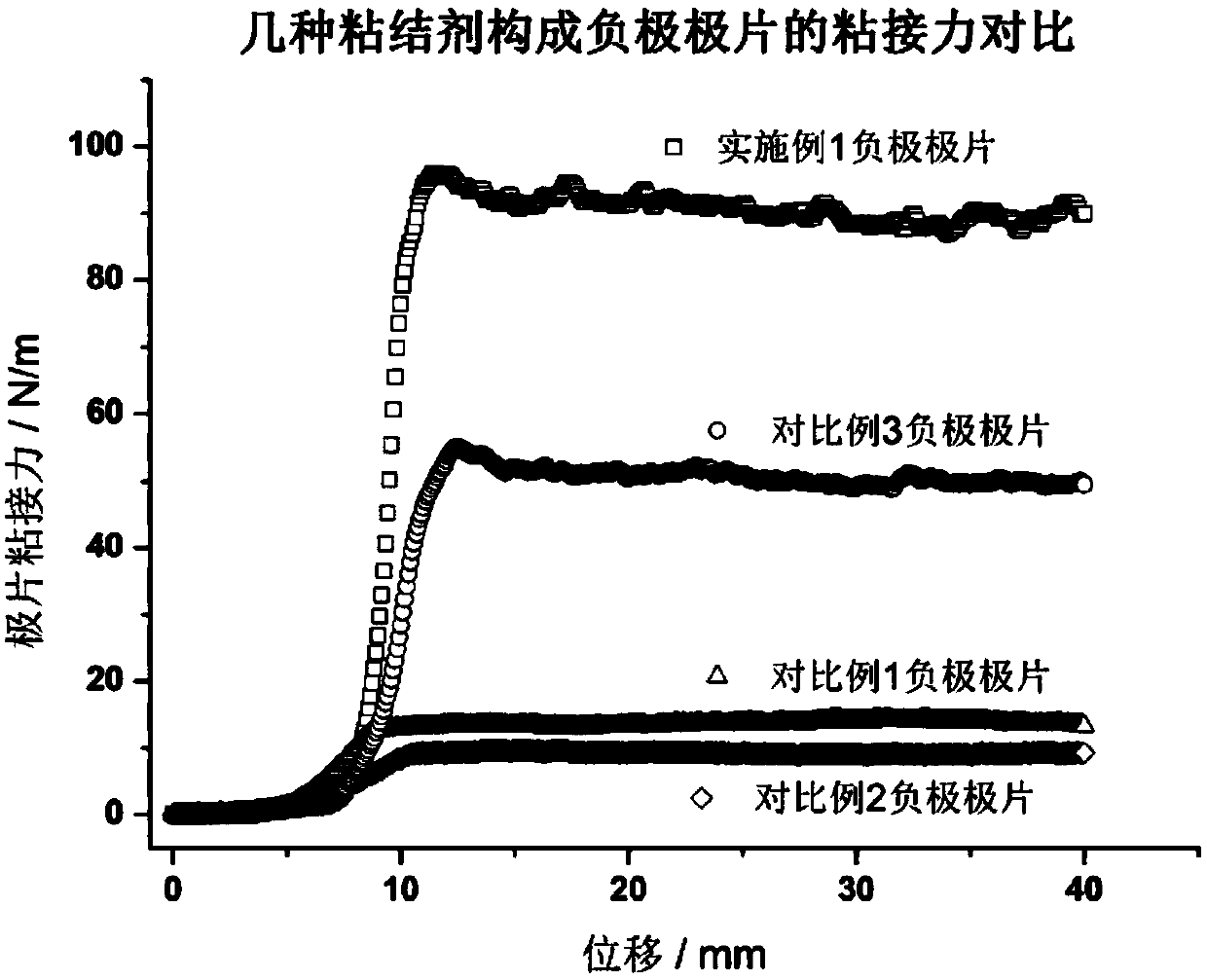

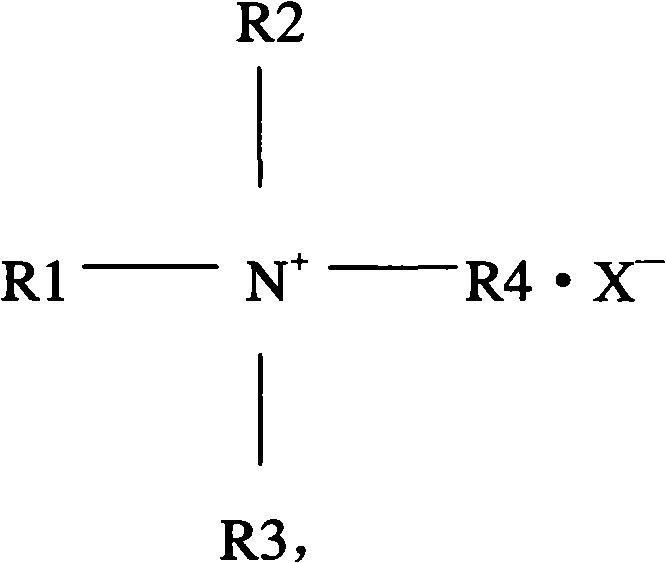

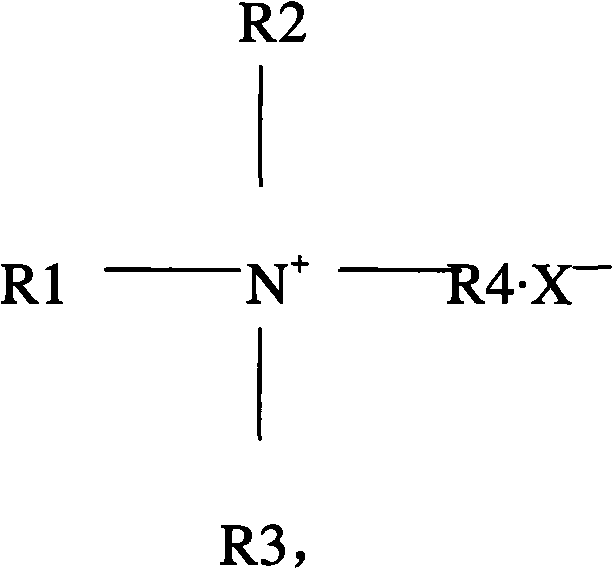

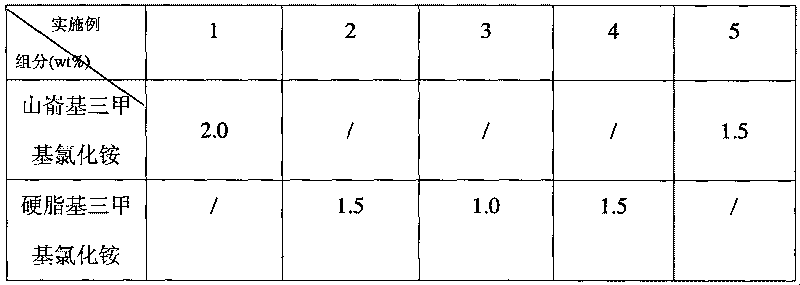

Aqueous binder and secondary battery

ActiveCN109957360ASimple structureEasy to prepareCell electrodesAmide/imide polymer adhesivesPolymer chemistrySelf repair

The invention discloses an aqueous binder and a secondary battery. The binder has self-repairing capability and is a polymer containing at least two kinds of monomeric units, wherein one monomer simultaneously contains a sulfonic group and an amido group, and the other monomer contains an alcohol ester group or / and a carboxylate radical. The number-average molecular weight of the polymer is greater than or equal to 200,000 preferably. The invention further relates to the secondary battery. The secondary battery comprises a positive pole piece, a negative pole piece, a barrier film and an electrolyte, wherein at least one of the positive pole piece, the negative pole piece and the barrier film (preferably the negative pole piece) contains the binder disclosed by the invention. Compared withbinders in the prior art, the binder disclosed by the invention has the advantages that the electrochemical stability is high, the binding capacity is high, the mechanical properties are good, the cycle life of the secondary battery can be remarkably prolonged, and the cycle expansion of the secondary battery can be remarkably lowered. Therefore, the binder material has a very good application prospect in the secondary battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Preparation method of activated organic attapulgite for coating

The invention discloses a preparation method of activated organic attapulgite for a coating. The method comprises the following steps: burning attapulgite raw ore at 420-450 DEG C for 2-3 hours after purifying by a hydrochloric acid; adding calcium lignosulphonate, jade powder and the like, adding water to pulp after grinding; adding span-80, sodium hexametaphosphate and the like; ultrasonically dispersing, stirring in a water bath, centrifugally separating, washing and baking; evenly mixing with nano-silica sol after burning at 860-920 DEG C for 1-2 hours; adding polyvinylpyrrolidone, hydroxyethyl cellulose, sodium polyacrylate, n-butyl acetate and the like; jordaning, filtering, baking and sieving, so as to obtain the activated organic attapulgite for the coating. The attapulgite prepared by the method is strong in dispersity, good in rheological property, small in precipitation coefficient and good in suspension property, and simultaneously has strong adsorbability and mildew resistance. Poisonous gases in various coatings can be effectively adsorbed, the coating can be prevented from mildewing, and improvement of the quality of a waterproof coating is facilitated.

Owner:MINGGUANG TIANJIAO TECH DEV

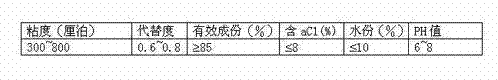

Hair care composition and preparation method thereof

ActiveCN101697940AImprove hair qualityIncrease viscosityCosmetic preparationsHair cosmeticsEmulsionMedicine

The invention discloses a hair care composition containing the following ingredients, by weight percent, of: 0.2-10.0% of cationic surfactant, 0.1-15.0% of high melting-point aliphatic compound, 0.2-8.0% of lower alkylol and water as the balance. The invention further discloses a preparation method of the hair care composition. The hair care composition can ameliorate hair quality, care hair, endow wet hair with excellent spreadability and smoothness, enhance softness and lubrication of dry hair and lower production cost. The preparation method of the hair care composition leads the composition to higher yield stress, emulsion suspension ability and electrolyte resistance.

Owner:广州市迪彩化妆品有限公司

Efficient glass polishing powder and preparation method thereof

ActiveCN102643614ANot easy to damageImprove suspension abilityPolishing compositions with abrasivesRare-earth elementDispersion stability

The invention relates to the technical field of a mixed rare-earth oxide and a preparation process thereof and particularly relates to efficient glass polishing powder and a preparation method thereof. The polishing powder comprises a rare-earth oxide, wherein the rare-earth oxide comprises a lanthanum oxide or a cerium oxide; and a crystal lattice of the rare-earth oxide contains a non-rare-earth element catalyst with a lower oxidation-reduction potential. The polishing powder further contains metal ions. The product disclosed by the invention has the advantages of strong suspension, difficulty of depositing, good dispersion stability, stable polishing effect, low surface defects and no scratches formed by polishing; the flattened polishing efficiency can be effectively improved and the polishing efficiency can reach to 1300 nanometers / minute; and damage to a polishing machine is not easy to cause.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

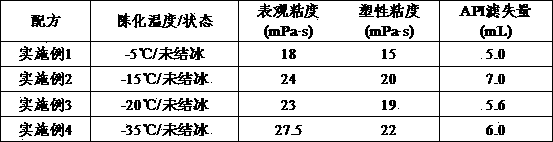

Ultra-low temperature resistant calcium-based low-solid drilling fluid for drilling in permafrost or severe cold areas

InactiveCN103834371AImprove rheologyWall protection effect is goodDrilling compositionPermafrostEngineering

The invention relates to ultra-low temperature resistant calcium-based low-solid drilling fluid for drilling in permafrost or severe cold areas. The ultra-low temperature resistant calcium-based low-solid drilling fluid is composed of 100 parts of water, 10-30 parts of calcium chloride, 1-10 parts of multifunctional complexing agent, 0.5-2.0 parts of viscosity reducer, 0.1-1.0 parts of filtrate reducer, 1-5 parts of lubricant and 1-3 parts of antifoaming agent. The drilling fluid provided by the invention has good rheological property in an ultra-low temperature environment and quite good wall protection capability and carrying ability, thereby providing a technical support for drilling constructions in permafrost and severe cold areas in winter of our country.

Owner:BEIJING INST OF EXPLORATION ENG +1

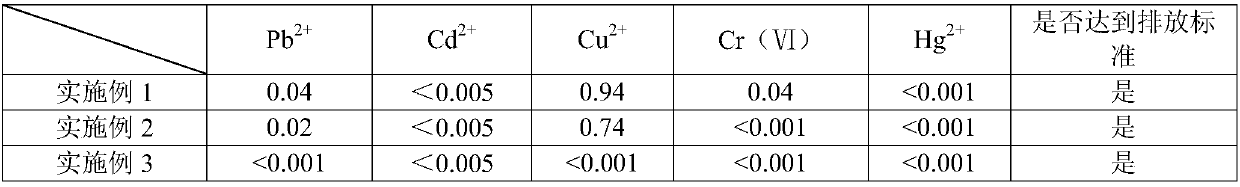

Spheroidal composite adsorbent for sewage treatment

ActiveCN109621921AHigh densityHigh mechanical strengthOther chemical processesWater contaminantsSorbentPolyacrylamide

The invention relates to the field of sewage treatment and aims to provide a spheroidal composite adsorbent for sewage treatment. The spheroidal composite adsorbent is prepared from 8-10 parts of lignin, 6-9 parts of sulfydryl modified polyacrylamide, 2-3 parts of sodium alginate, 30-40 parts of sulfydryl modified quartz sand and 20-30 parts of sepiolite. The spheroidal composite adsorbent has thefunctions of adsorbing and removing organic matter, suspended matter and heavy metals in sewage, and has the good removal effect on the heavy metals in the acidic sewage and has the integrated effectof adsorption, flocculation and sedimentation, the contents of COD, SS, lead, cadmium, copper and mercury in treated river channel sewage all reach the stipulations of national standard surface waterenvironmental quality standard GB3838-2002 of the People's Republic of China, and the removal rate of heavy metals in acid heavy-metal heavily polluted wastewater reaches 99% or above.

Owner:浙江省环境科技有限公司

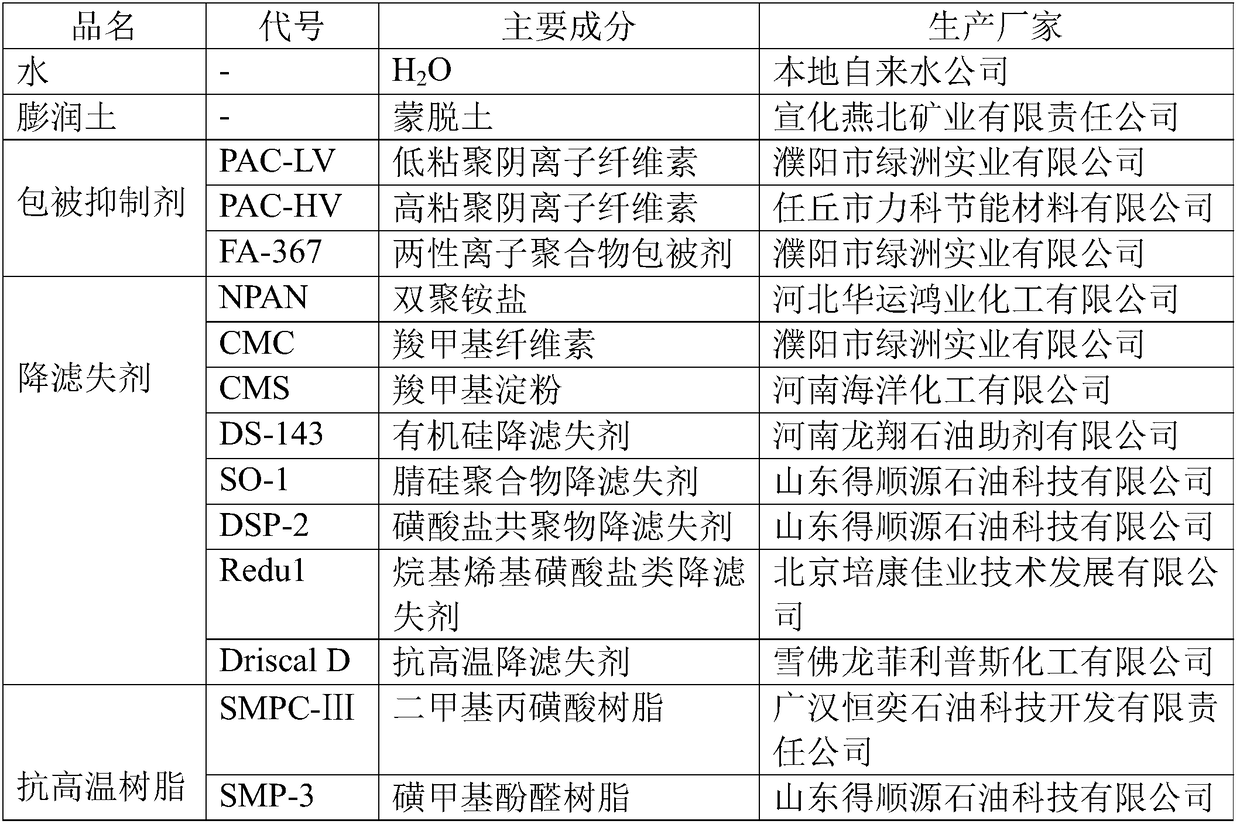

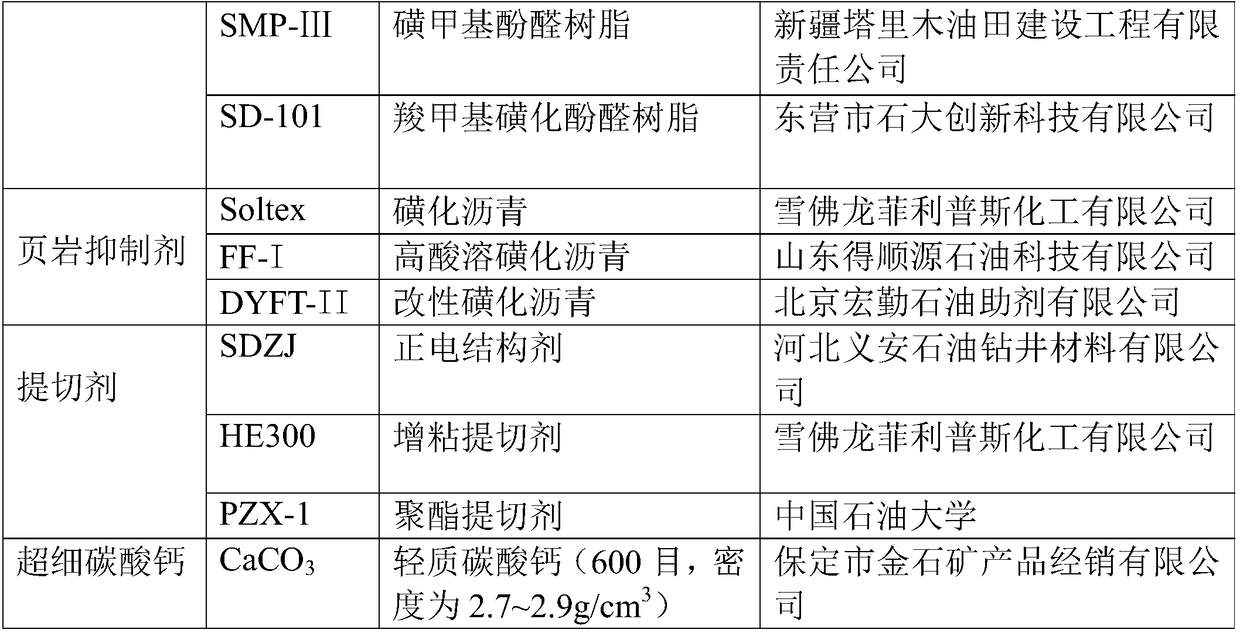

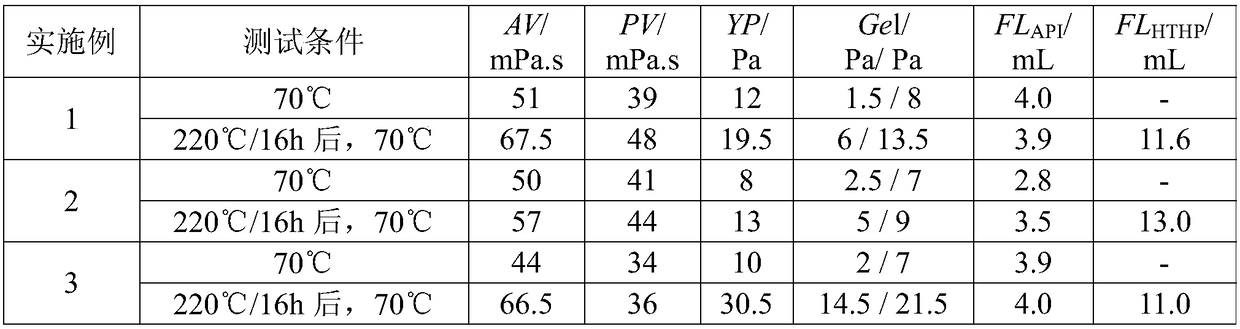

Low-solid phase ultrahigh-temperature water-based drilling fluid and preparation method thereof

ActiveCN108949127AReduce pollutionImprove suspension abilityDrilling compositionWater basedRoom temperature

The invention discloses a low-solid phase ultrahigh-temperature water-based drilling fluid which is prepared from the following components in parts by weight: 100 parts of solvent water, 3-4 parts ofbentonite, 1.8-2.2 parts of a coating inhibitor, 2.3-3.5 parts of a filtrate reducer, 2-2.5 parts of high-temperature resistant resin, 2-2.5 parts of a shale inhibitor, 1.5-2 parts of a stripping agent and 15-35 parts of ultrafine calcium carbonate. The preparation method is simple. The preparation method comprises the following steps: adding a certain amount of bentonite into the solvent water toprepare prehydrated bentonite slurry; then successively adding the coating inhibitor, the filtrate reducer, the high-temperature resistant resin, the shale inhibitor, the stripping agent and ultrafine calcium carbonate while performing high-speed electric stirring; and finally, carrying out hydration at room temperature for 24 hours to prepare the low-solid phase ultrahigh-temperature water-baseddrilling fluid. The low-solid phase ultrahigh-temperature water-based drilling fluid can resist a temperature high up to220 DEG C, the low-solid phase ultrahigh-temperature water-based drilling fluidis good in rheological property, rock carrying property and high in blocking inhibiting property, the problem of low density carrying stability is solved, the low-solid phase ultrahigh-temperature water-based drilling fluid is successfully applied in mounting and probing a 4X well, and a good field application effect is obtained.

Owner:CNPC BOHAI DRILLING ENG +1

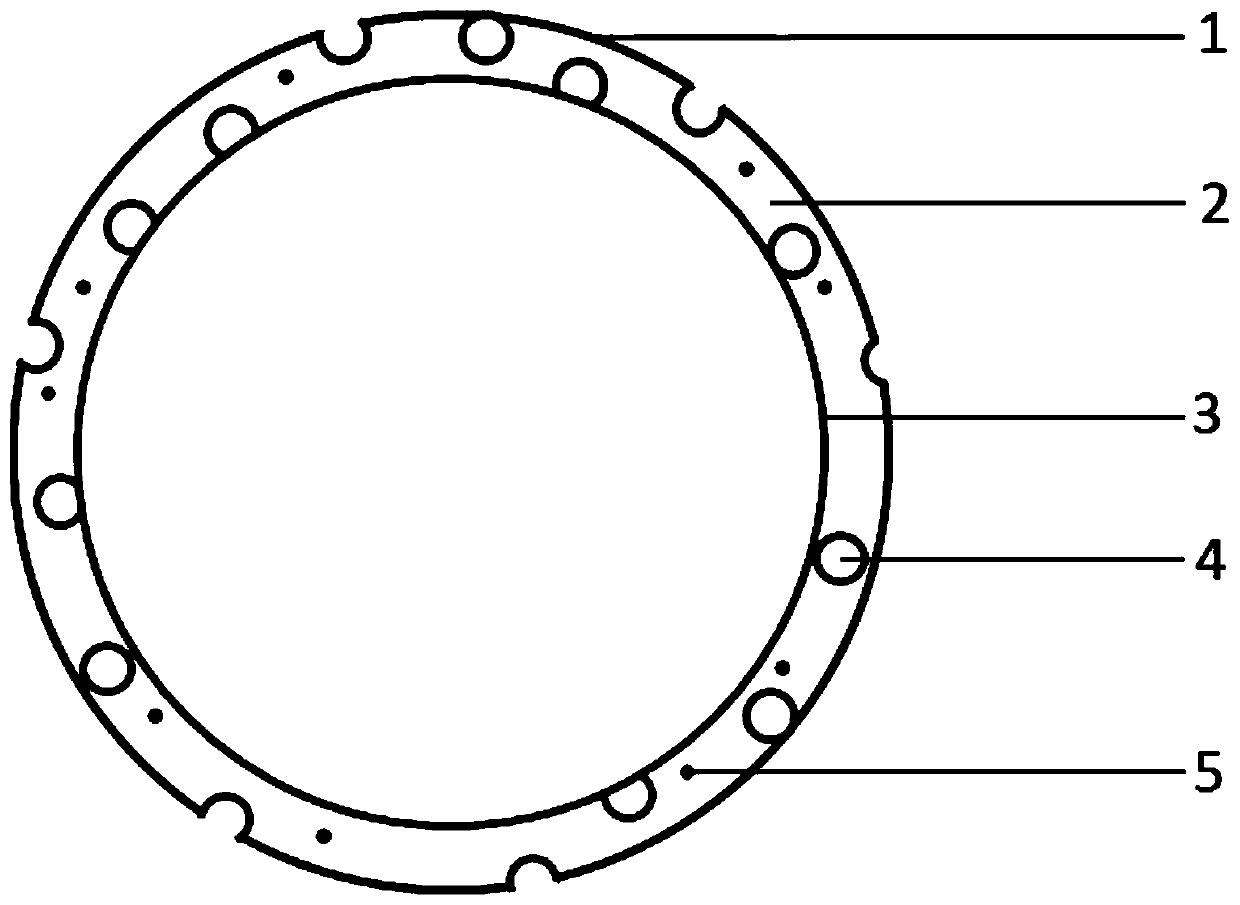

Self-suspension hydrofracturing coated proppant with targeting function as well as preparation and application

ActiveCN110746956AFirmly connectedGuarantee tight integrationFluid removalDrilling compositionNanoparticleMaterials science

The invention provides a self-suspension hydrofracturing coated proppant with a targeting function as well as preparation and application. The proppant comprises: A particles existing in the quantityof 70%-99.99% of total weight of the proppant and B a nanoparticle enhanced porous composite coating which coats the surfaces of particles and exists in the quantity of 0.01%-30% of total weight of the proppant, and the nanoparticle enhanced porous composite coating comprises nanoparticles (preferably, the weight of nanoparticles is 1%-50% (preferably, 10%-20%) of total weight of the nanoparticleenhanced porous composite coating) and a porous composite. Compared with a functional coated proppant produced by a traditional process, the method has the advantages that materials such as resin usedin the method come from industrial production, the nanoparticles are creatively added to improve performance of the proppant, and the method has more simplified operation process and more saved production cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing and constructing pipe die coating

ActiveCN102527925ALow gas productionHigh strengthFoundry mouldsFoundry coresSurface roughnessStock solution

The invention discloses a method for preparing and constructing a pipe die coating and belongs to the technical field of centrifugal casting pipes. The method for preparing the pipe die coating mainly comprises the following steps: preparing mud, preparing a stock solution, preparing a sizing liquid and preparing a final coating. The method for constructing the pipe die coating mainly comprises the following steps: heating a pipe die, cleaning the pipe die and spraying paint. The method for preparing and constructing the pipe die coating has the beneficial effect that the coating with lower gas forming amount, higher strength, stronger suspension property and better demoulding performance is successfully developed by optimizing a coating preparation process; the forming acceptability and appearance quality of the pipe are improved by optimizing a coating construction process; the forming acceptability of the pipe is maintained to be about 99.5%; and the surface roughness of the pipe is below gradient 25.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Modified attapulgite washing auxiliary detergent and preparation method thereof

InactiveCN104194972AIncreased interlayer voidsImprove adsorption capacityOrganic detergent compounding agentsSurface-active detergent compositionsFatty alcoholAmmonium nitrate

The invention discloses a modified attapulgite washing auxiliary detergent. The modified attapulgite washing auxiliary detergent is prepared from the following raw materials in parts by weight: 1-2 parts of ammonium carbonate, 2-3 parts of sodium carbonate, 1-2 parts of octadecyl dimethyl hydroxyethyl ammonium nitrate, 0.4-0.7 part of acetic acid, 3-5 parts of sodium bentonite, 1-2 parts of fatty alcohol-polyoxyethylene ether, 1-2 parts of disodium EDTA, 1-2 parts of trisodium citrate, 100-120 parts of attapulgite, a proper amount of water, 5-10 parts of additives and 20-30 parts of 2-3% hydrochloric acid solution. The interlayer space of the attapulgite is increased after the attapulgite is modified; the adsorption property is improved; the attapulgite is capable of well adsorbing calcium and magnesium ions, good in suspension property, high in resistance to recontamination and high in biodegradability; the attapulgite can replace sodium tripolyphosphate, so that the environmental pollution is reduced and the cost is reduced; by adding octadecyl dimethyl hydroxyethyl ammonium nitrate, the washing effect can be improved; meanwhile, the modified attapulgite washing auxiliary detergent has an anti-static function.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

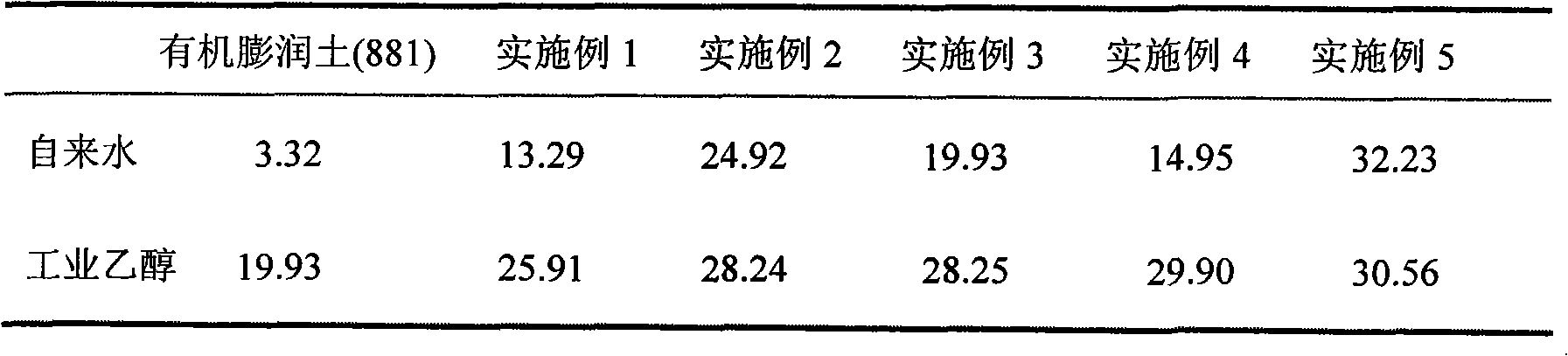

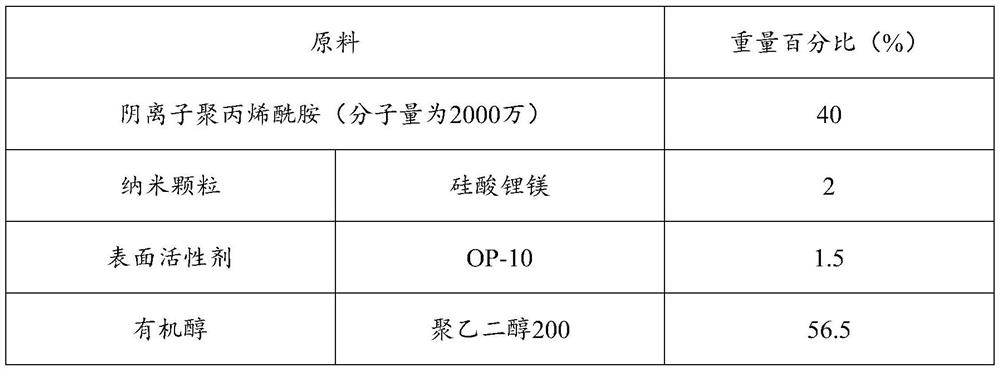

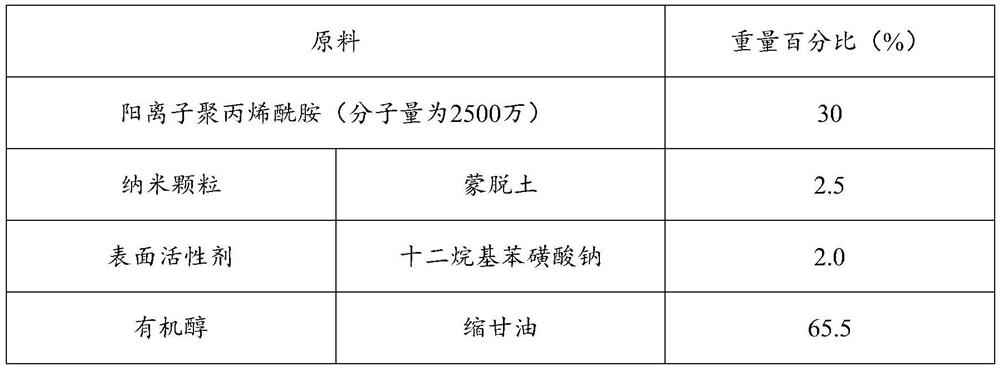

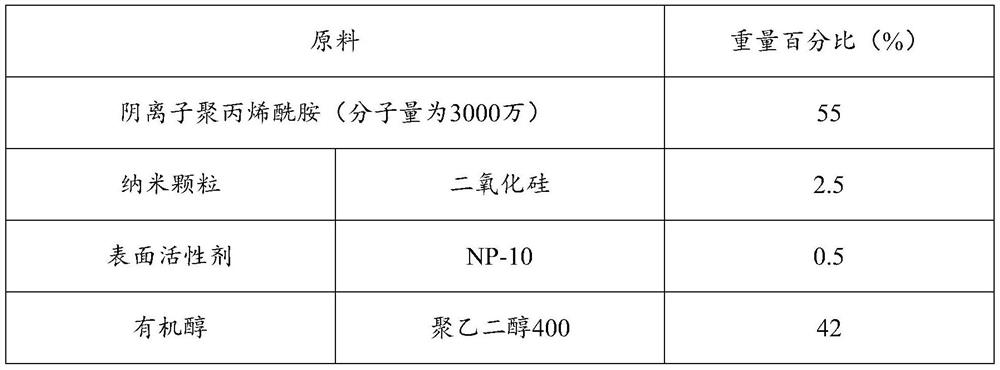

Alcohol-soluble slickwater system for fracturing as well as preparation method and application of alcohol-soluble slickwater system

ActiveCN112375557AImprove thixotropyImprove suspension abilityGeneral water supply conservationDrilling compositionAcid fracturingAlcohol

The invention discloses an alcohol-soluble slickwater system for fracturing as well as a preparation method and application of the alcohol-soluble slickwater system, and relates to the technical fieldof acid fracturing agents. The slickwater system is composed of the following components in percentage by weight: 20.0-60.0% of a polyacrylamide polymer, 0.5-4.0% of nano particles, 0.1-3% of a surfactant, and the balance of organic alcohol.

Owner:四川川庆井下科技有限公司

Method for plug removal of triassic oil reservoir in nitrogen foam acidification mode

ActiveCN103541712ASelectiveIncrease water saturationFluid removalDrilling compositionNitrogenOil water

The invention relates to a method for plug removal of a triassic oil reservoir in a nitrogen foam acidification mode. The method comprises the steps that 3 steres of prepad fluid is injected in from a tool oil tube, a sliding sleeve matched steel ball is thrown, 12MPa pressure is applied to set a packer, and pressure is applied continuously to reach 16 MPa to open a sliding sleeve; the rest prepad fluid is squeezed into the triassis oil reservoir in the discharge capacity of 0.2-0.4m<3> / min from the tool oil tube, and nitrogen is mixed in the prepad fluid in the discharge capacity of 20m<3> / min; all working liquid is squeezed into the triassis oil reservoir from the tool oil tube in the discharge capacity of 0.2-0.4m<3> / min, and the nitrogen is mixed into the working liquid in the discharge capacity of 20m<3> / min; all prepad fluid is squeezed, and active water of the volume of the tool oil tube is squeezed; after 1 hour of shut-in reaction, open flow is controlled to be conducted. According to the method for the plug removal of the triassis oil reservoir in the nitrogen foam acidification mode, the reaction speed of foamed acid and rock is low, the loss of acid liquid is small, the penetration depth of the acid liquid can be better improved, and deep acidification is achieved; an oil-water layer can be selected, and temporary plug can be formed to a high permeability layer and a water layer so that the acid liquid can enter a low permeability layer and an oil layer; solid particles can be brought out of the ground.

Owner:PETROCHINA CO LTD

Polymer cement waterproof slurry prepared from superfine cement

The invention provides polymer cement waterproof slurry prepared from superfine cement, belonging to the field of building materials. The polymer cement waterproof slurry comprises powder and liquid, wherein the liquid contains 80-100 parts of styrene-acrylic emulsion, 1-3 parts of defoaming agent, 1-3 parts of preservative and 50-150 parts of water by weight; the powder contains 300-350 parts of superfine cement, 150-200 parts of calcium carbonate, 100-150 parts of quartz sand and 0.1-5 parts of aid by weight. The polymer cement waterproof slurry has the effects of avoiding the phenomenon of sand sedimentation and further densifying skeleton structures.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

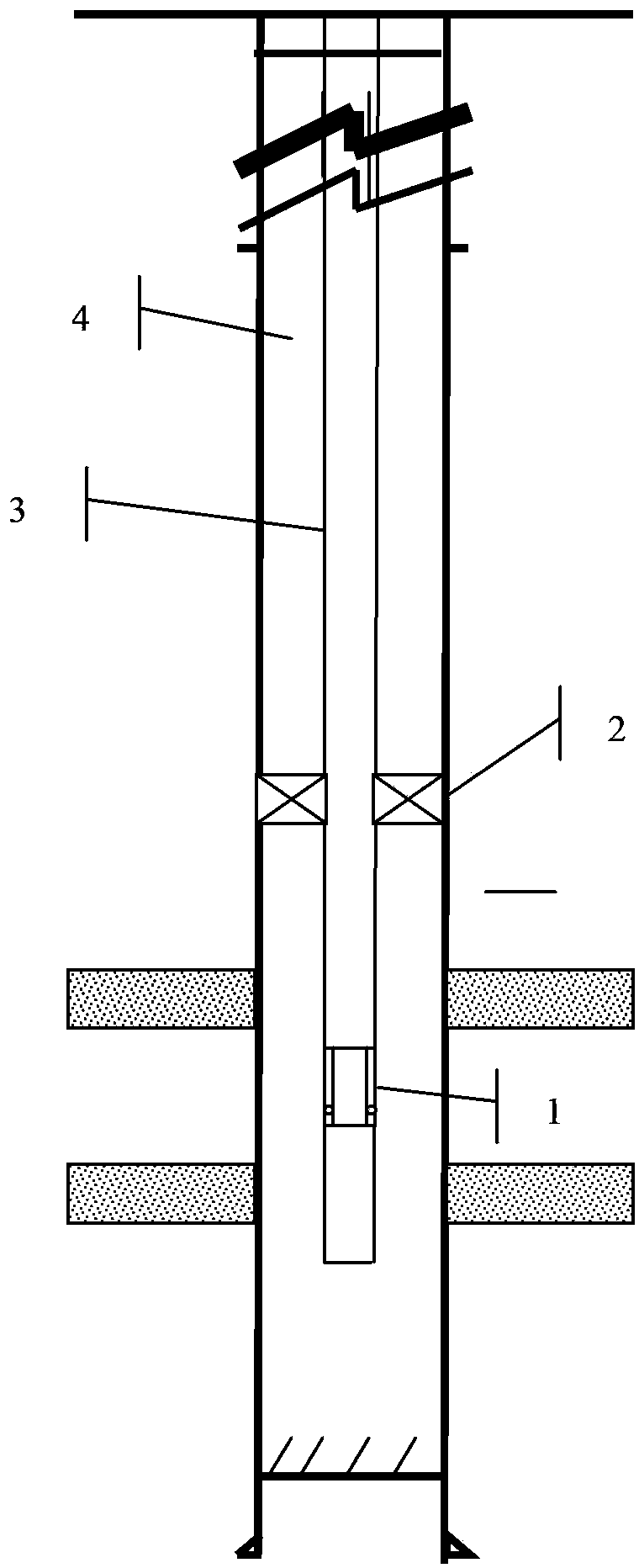

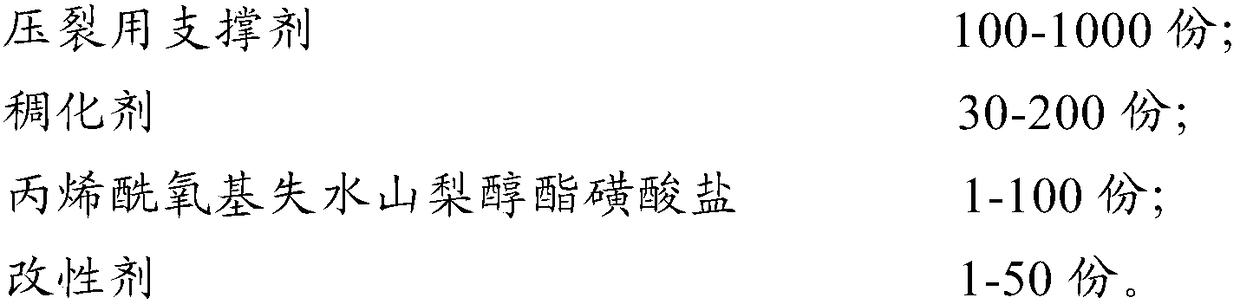

Self-suspending proppant for hydraulic fracturing and preparation method thereof

ActiveCN108424762ACover tightlyNot easy to fall offFluid removalDrilling compositionSulfonateDissolution

The invention discloses a self-suspending proppant for hydraulic fracturing and a preparation method thereof. The self-suspending proppant comprises the following components in parts by weight: 100-1000 parts of a fracturing proppant, 30-200 parts of a thickening agent, 1-100 parts of acryloxy sorbitan sulfonate and 1-50 parts of a modifier. Sulfonic acid groups on the acryloxy sorbitan sulfonateare adsorbed to the surface of the proppant, double bonds at the other end and active groups of the thickening agent are tightly connected under the action of chemical bonds, so that the surface of the proppant is uniformly coated with the thickening agent more tightly and the thickening agent is unlikely to fall off; meanwhile, the spacial steric hindrance of the thickening agent can be increased, the thickening agent is more fluffy, the contact area between the thickening agent and water during dissolution is increased, the dissolution speed of the thickening agent is higher, and a fisheye phenomenon is unlikely to form.

Owner:TIANJIN XINXIANG PETROLEUM TECH CO LTD

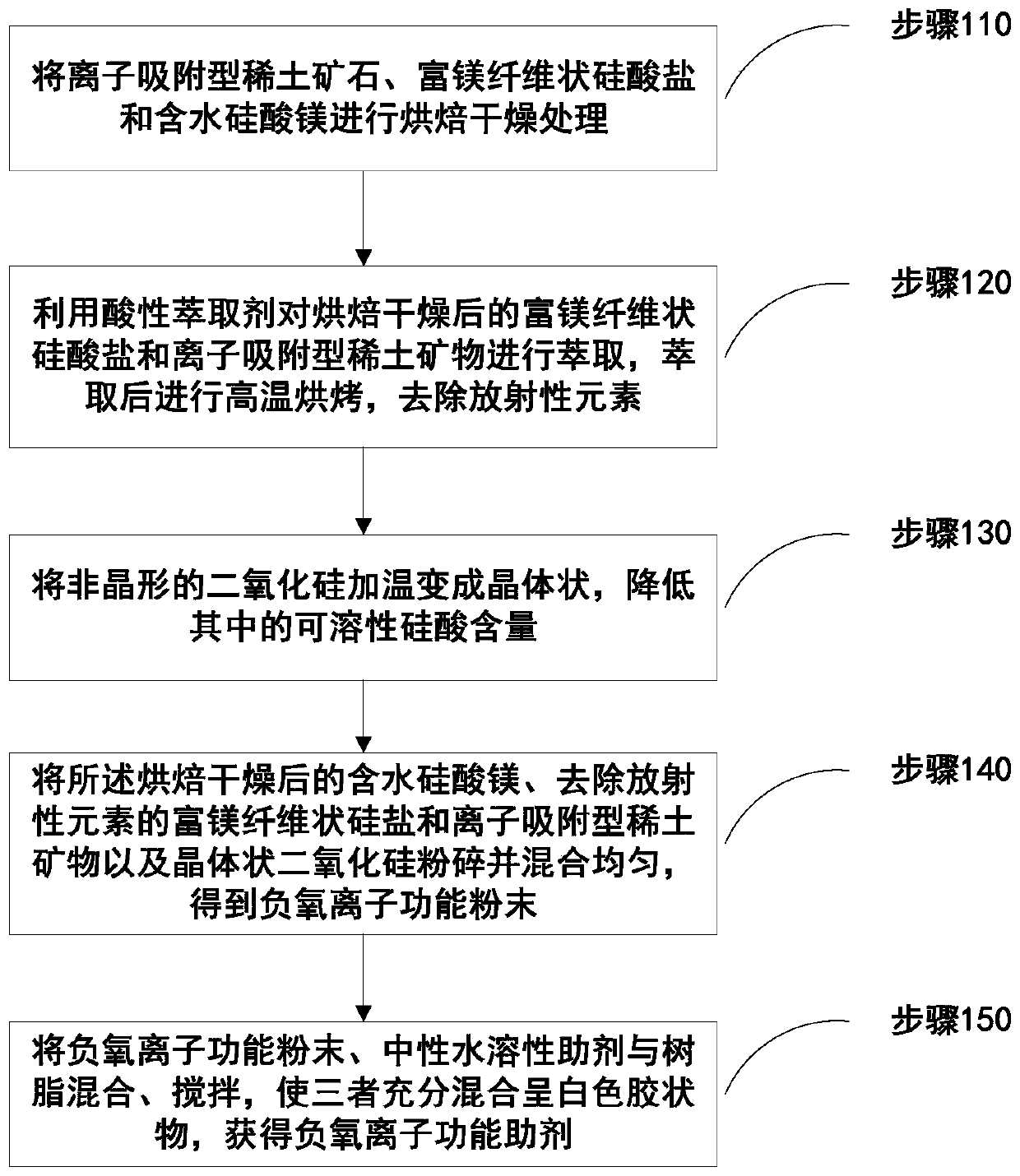

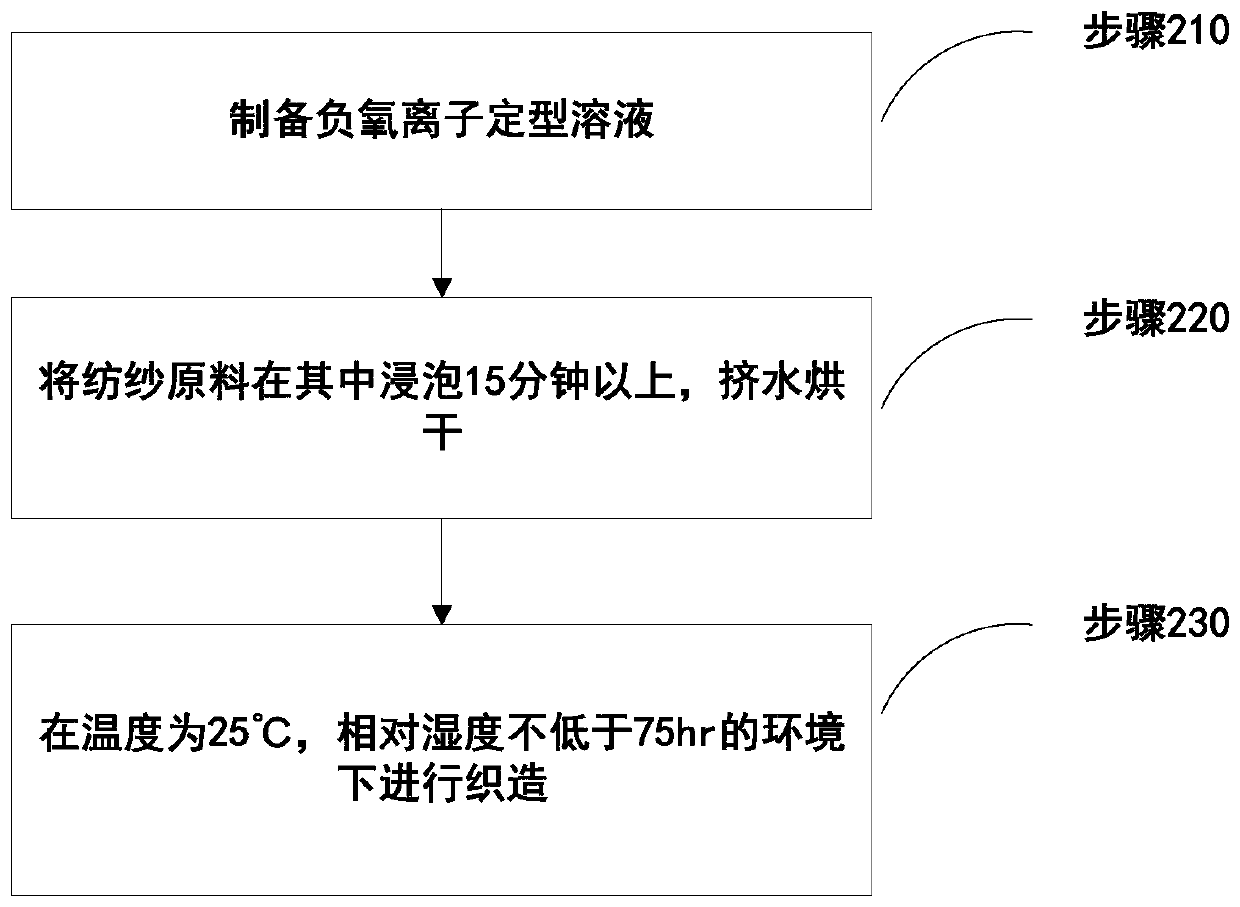

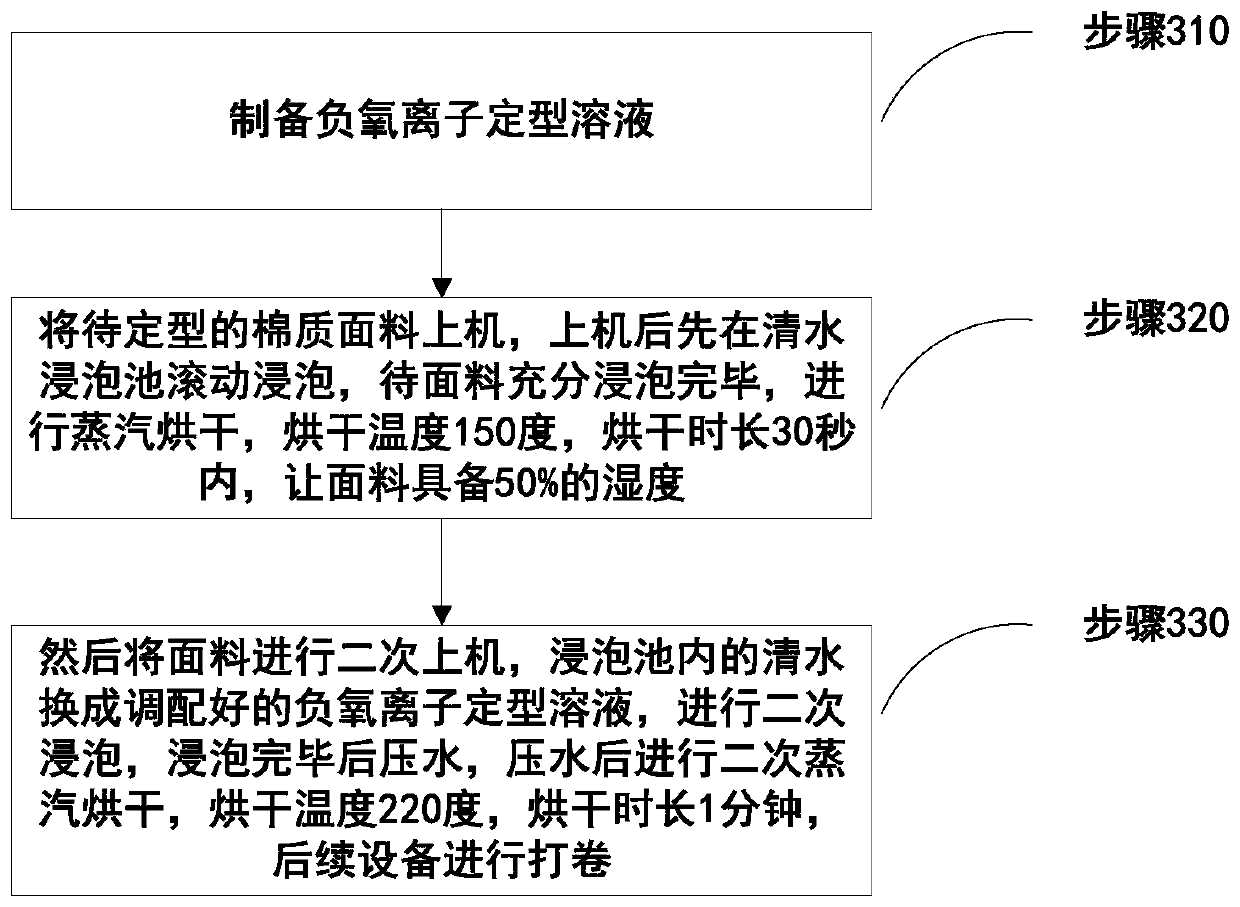

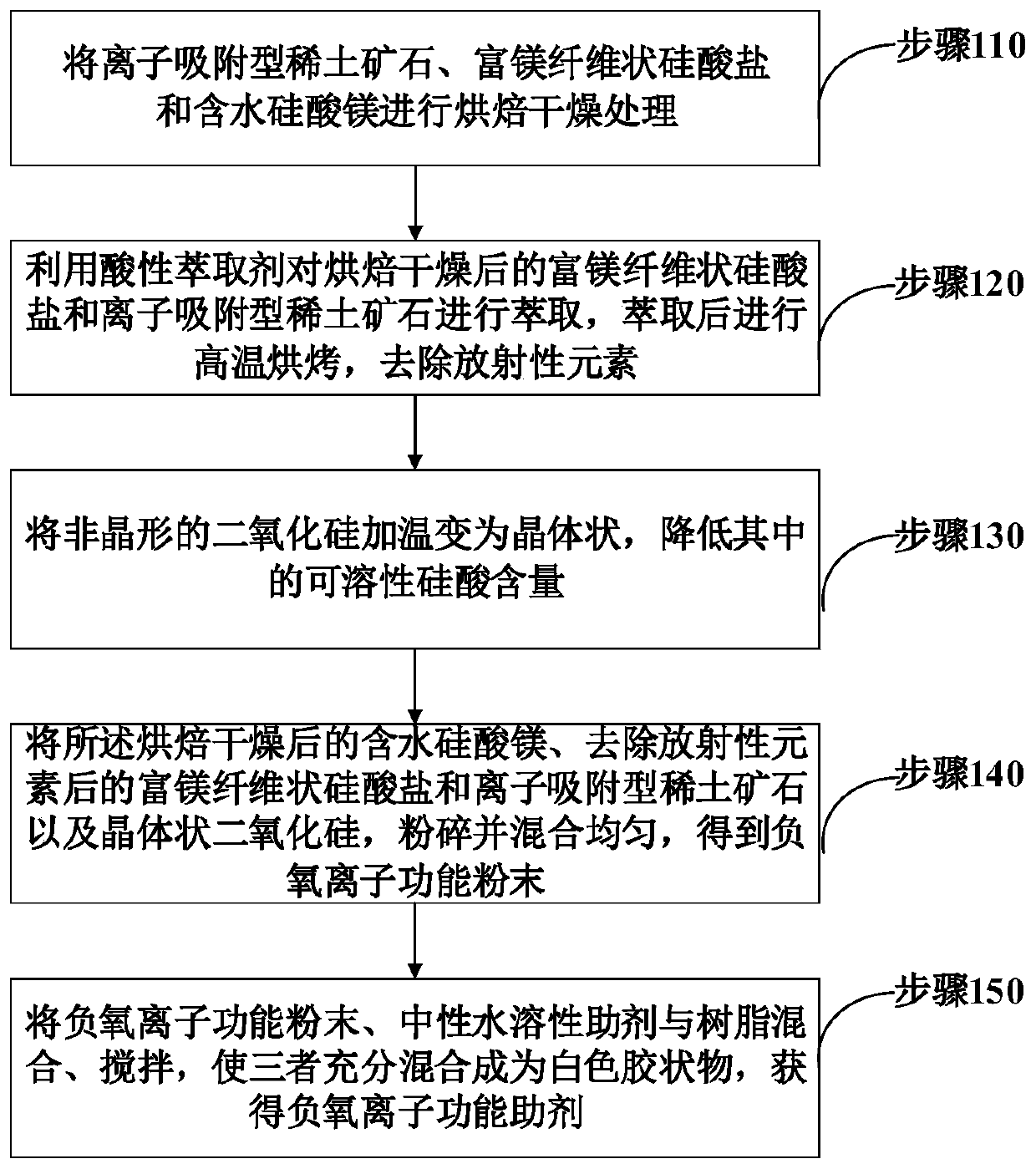

Purified cotton for inducing negative oxygen ions and preparing method of functional powder and aid of negative oxygen ions

The invention discloses purified cotton for inducing negative oxygen ions and a preparing method of a functional powder and aid of the negative oxygen ions. The preparing method of the negative oxygenion functional powder includes the following steps of baking and drying ion adsorption type rare earth ore, magnesium-rich fibrous silicate and hydrous magnesium silicate, extracting the baked and dried magnesium-rich fibrous silicate and ion adsorption type rare earth ore through an acidic extractant, conducting high-temperature baking after extracting to remove radioactive elements, heating amorphous silicon dioxide to reduce the content of soluble silicic acid in the amorphous silicon dioxide, and pulverizing and evenly mixing the hydrous magnesium silicate, magnesium-rich fibrous silicate, ion adsorption type rare earth ore and silicon dioxide to obtain the negative oxygen ion functional powder. The negative oxygen ion functional aid is low in raw material cost, the produced negativeoxygen iron purified cotton can ceaselessly induce the negative oxygen ions into the space through ionization, the inducing amount is 1200-2500 ions per square centimeter, the living space of people can be improved, and the air and environment are purified.

Owner:河北森雅环保新材料科技有限公司

Mullite/magnesia composite alcohol-base casting paint and production method thereof

InactiveCN104014726AImprove insulation effectImprove flame retardant performanceFoundry mouldsFoundry coresAlcoholMullite

The invention discloses mullite / magnesia composite alcohol-base casting paint. The mullite / magnesia composite alcohol-base casting paint is characterized by comprising the following raw materials in parts by weight: 65 to 85 arts of mullite, 20 to 30 parts of magnesia, 15 to 20 parts of expanded perlite, 1 to 3 parts of palygorskite clay, 3 to 6 parts of rosin, 0.5 to 0.8 part of magnesium hydroxide, 0.3 to 0.6 part of urea, 1 to 3 parts of rock wool leftovers, 12 to 15 parts of corn straw, 3 to 5 parts of phenolic resin, 4 to 6 parts of hexamine, 45 to 60 parts of ethanol and 3 to 6 parts of additives. The rock wool leftovers are used as a heat-preserving material, and other appropriate additives are also added, so that the prepared paint is high in heat preserving property, flame retardant property, adhesion property, coating property and suspension property. The paint also can prevent the paint from being oxidized, so that the surface of a casting is smooth and free from a sand hole and a crack.

Owner:郭菲

Negative oxygen ion inducing functional powder and auxiliary agent and preparation method thereof

The invention discloses a negative oxygen ion inducing functional powder and an auxiliary agent and a preparation method thereof. The preparation method of the negative oxygen ion inducing functionalpowder comprises the following steps: baking and drying ion adsorption type rare earth ores, magnesium-rich fibrous silicate and hydrous magnesium silicate; extracting the baked and dried magnesium-rich fibrous silicate and ion adsorption type rare earth ores by using an acidic extractant, and executing baking at high temperature after extraction to remove radioactive elements; heating amorphous silicon dioxide to reduce the content of soluble silicic acid in the amorphous silicon dioxide; crushing and evenly mixing the hydrous magnesium silicate, the magnesium-rich fibrous silicate, the ion adsorption type rare earth ores and the silicon dioxide to obtain the negative oxygen ion inducing functional powder. The raw material cost of the negative oxygen ion inducing functional additive is low, and the produced negative oxygen ion inducing functional powder can be added into different fabrics to continuously ionize and induce negative oxygen ions into a space, the induction amount is 1200-2500 / cm<3>, the living space of people can be improved, and air and environment can be purified.

Owner:河北森雅环保新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com