Method for producing rare-earth dry powder seed coating agent

A production method and rare earth technology, applied in the agricultural field, can solve the problems of difficulty in popularization and application, easy stratification, poor suspension, etc., and achieve the effects of improving the agricultural ecological environment, not easy to stratify, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

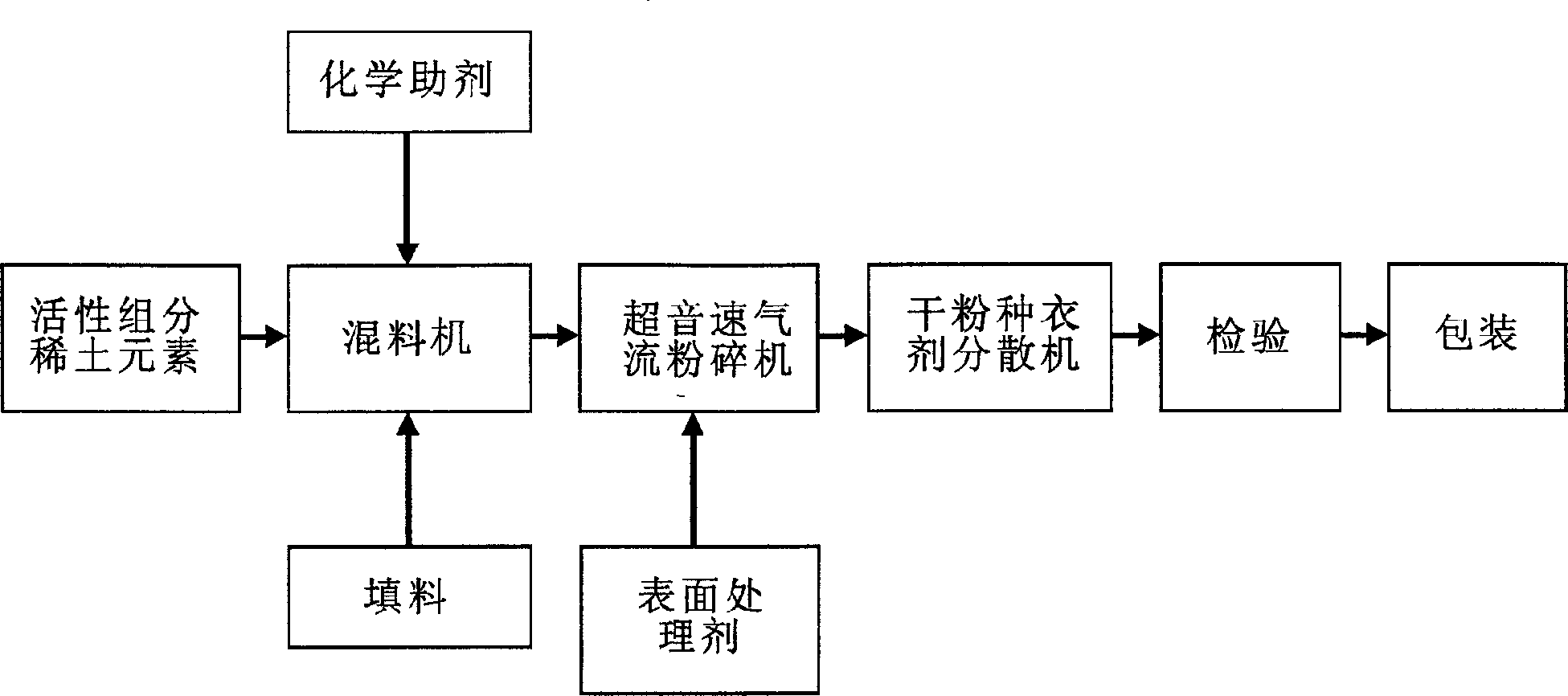

Image

Examples

Embodiment 1

[0017] First take the active components: complexed rare earth: 0.1%, tebuconazole: 2.4%, sodium hexametaphosphate: 5.6%, potassium dihydrogen phosphate: 11.2%; take chemical additives: polymer instant resin selection Acrylic acid: 6.2%, polyvinylpyrrolidone: 2.4%, hydroxyethyl cellulose: 1.7%, polyethylene glycol: 5.4%, zinc dodecylbenzenesulfonate: 2.8%, ten Calcium hexaalkylbenzenesulfonate: 3.4%; filler: dimethyl silicon defoamer: 2.4%, organic bentonite: 17.2%, attapulgite soil: 6.3%, humic acid organic soil: 4.2%, the warning color is: 8.2%;

[0018] Put the three components into the mixer and mix them evenly at a temperature of 12.5°C. Rotational speed: 90 rpm, mixing time 1.25 hours. The above-mentioned mixture that has been uniformly mixed by the mixer is put into a supersonic jet mill for crushing, and an interface agent and a surface treatment agent are added at the same time: sodium methylene bis-naphthalene sulfonate: 6.7%, methylene dimethyl Sodium naphthalene ...

Embodiment 2

[0019] Embodiment two: first take active component: complex rare earth: 0.4% tebuconazole: 2.1%, sodium hexametaphosphate: 5.5%, potassium dihydrogen phosphate: 11.0%; take chemical auxiliary agent: polymer Acrylic acid for instant resin: 6.0%, polyvinylpyrrolidone: 2.0%, hydroxyethyl cellulose: 1.5%, polyethylene glycol: 6.0%, zinc dodecylbenzenesulfonate: 3.5% %, calcium cetyl benzene sulfonate: 4.0%; filler: dimethyl silicon defoamer: 3.0%, organic bentonite: 17.1%, attapulgite soil: 6.0%, organic humic acid Soil: 4.0%, warning color: 8.0%;

[0020] Put the three components into the mixer and mix them evenly at a temperature of 10°C. Rotational speed: 80 rpm, mixing time is 1 hour. The above-mentioned mixture that has been uniformly mixed by the mixer is put into a supersonic jet mill for crushing, and an interface agent and a surface treatment agent are added at the same time: sodium methylene bis-naphthalene sulfonate: 6.5%, methylene dimethyl Sodium naphthalene sulfon...

Embodiment 3

[0021] Embodiment three: first take active component: complexed rare earth: 0.1%, tebuconazole: 3.0%, sodium hexametaphosphate: 6.0%, potassium dihydrogen phosphate: 11.5%; take chemical auxiliary agent: high Molecular instant resin selection of acrylic acid: 6.2%, polyvinylpyrrolidone: 3.0%, hydroxyethyl cellulose: 2.0%, polyethylene glycol: 5.0%, zinc dodecylbenzenesulfonate: 2.5%, calcium cetyl benzene sulfonate: 3.0%; filler: dimethyl silicon defoamer: 2.0%, organic bentonite: 17.0%, attapulgite: 6.0%, humic acid Organic soil: 4.0%, warning color: 8.3%;

[0022] Put the three components into the mixer and mix them evenly at a temperature of 15°C. The rotation speed was 100 rpm and the mixing time was 1.5 hours. The above-mentioned mixture that has been uniformly mixed by the mixer is put into a supersonic jet mill for crushing, and an interface agent and a surface treatment agent are added at the same time: sodium methylene bis-naphthalene sulfonate: 6.5%, methylene dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com