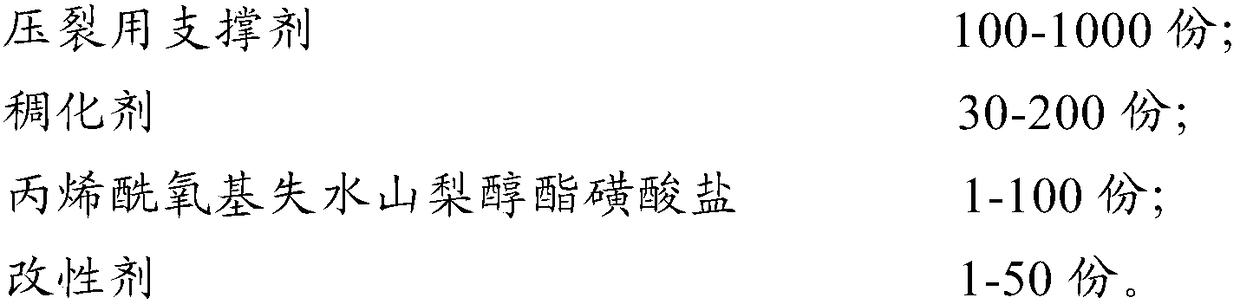

Self-suspending proppant for hydraulic fracturing and preparation method thereof

A hydraulic fracturing and proppant technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the fisheye phenomenon of thickeners, poor sand suspension ability, and affect the viscosity of base fluid, etc. problem, to achieve the effect of fluffy thickener, increased area, and increased steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. Preparation of acryloxy sorbitan sulfonate: add 400kg sorbitan monooleate, 70kg acrylic acid, 15kg p-toluenesulfonic acid as catalyst, 1kg hydroquinone in the reaction kettle, heat up to React at 80°C for 6 hours. Then add 140kg sodium sulfamate and continue to react for 2 hours for later use.

[0030] b. To clean the proppant, put 800kg of ceramsite proppant into the mixing tank, add a lot of water, and stir while washing.

[0031] c. Drain the water, add 50 kg of acryloxy sorbitan sulfonate prepared in step a, and stir evenly.

[0032] d. Raise the temperature to 60°C, add 100kg of polyacrylamide, and stir evenly.

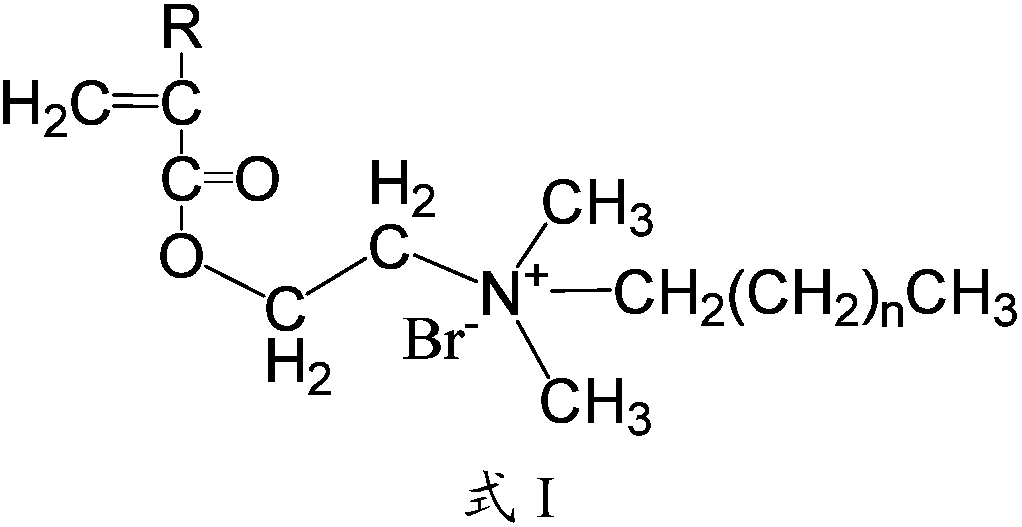

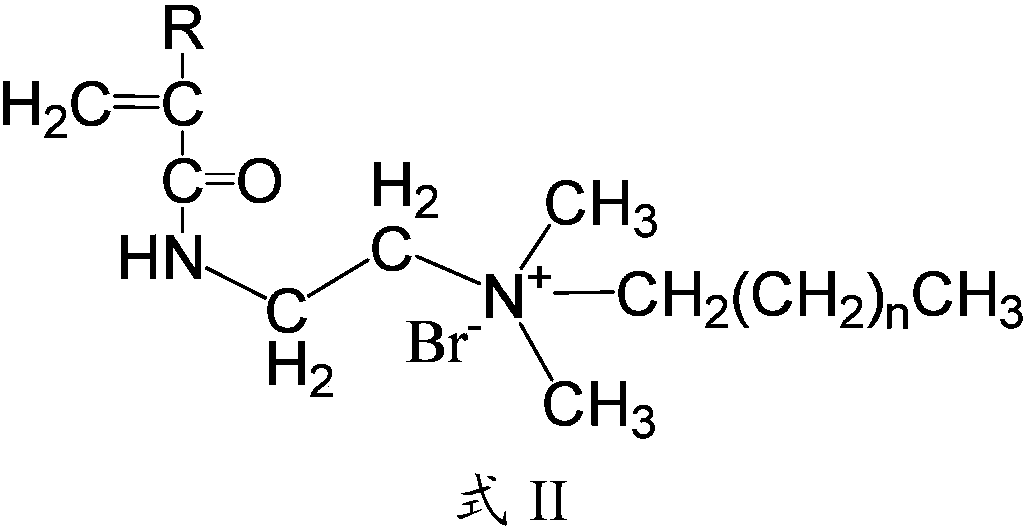

[0033] e. Add 20 kg of methacryloyloxyethyl hexadecyl ammonium bromide and continue to stir for 2 hours. The temperature is lowered, the material is discharged, and the finished self-suspending proppant for hydraulic fracturing is obtained.

Embodiment 2

[0035] a. prepare acryloyloxy sorbitan ester sulfonate: add 350kg sorbitan monostearate in reactor, 70kg acrylic acid, 15kg p-toluenesulfonic acid as catalyst, 1kg hydroquinone is heated up to React at 80°C for 6 hours. Then add 140kg sodium sulfamate and continue to react for 2 hours for later use.

[0036] b. To clean the proppant, put 1000kg of quartz sand proppant into the mixing tank, add a large amount of water, and stir while washing.

[0037] c. Drain the water, add 30 kg of acryloxy sorbitan sulfonate prepared in step (1), and stir evenly.

[0038] d. be warmed up to 60 degrees Celsius, add 150kg hydroxypropyl guar gum, and stir evenly.

[0039] e. Add 20 kg of acrylamide ethyl octadecyl ammonium bromide and continue stirring for 2 hours. The temperature is lowered, the material is discharged, and the finished self-suspending proppant for hydraulic fracturing is obtained.

Embodiment 3

[0041] a. Preparation of acryloyloxy sorbitan ester sulfonate: add 400kg sorbitan monopalmitate, 70kg acrylic acid, 15kg p-toluenesulfonic acid as catalyst, 1kg hydroquinone in the reaction kettle, heat up to React at 80°C for 6 hours. Then add 140kg sodium sulfamate and continue to react for 2 hours for later use.

[0042] b. To clean the proppant, put 1000kg of quartz sand proppant into the mixing tank, add a large amount of water, and stir while washing.

[0043] c. Drain the water, add 100 kg of acryloxy sorbitan sulfonate prepared in step (1), and stir evenly.

[0044] d. heat up to 60 degrees Celsius, add 200kg xanthan gum, and stir evenly.

[0045] e. Add 50 kg of methacrylamide ethyl octadecyl ammonium bromide and continue stirring for 2 hours. The temperature is lowered, the material is discharged, and the finished self-suspending proppant for hydraulic fracturing is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com