Composite powder and preparing method thereof

A technology of composite powder and mixed gas, applied in the direction of coating, etc., can solve the problems of poor bonding force between oxide and metal matrix, non-uniformity, non-dense, etc., and achieve the effect of dense structure, controllable thickness and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

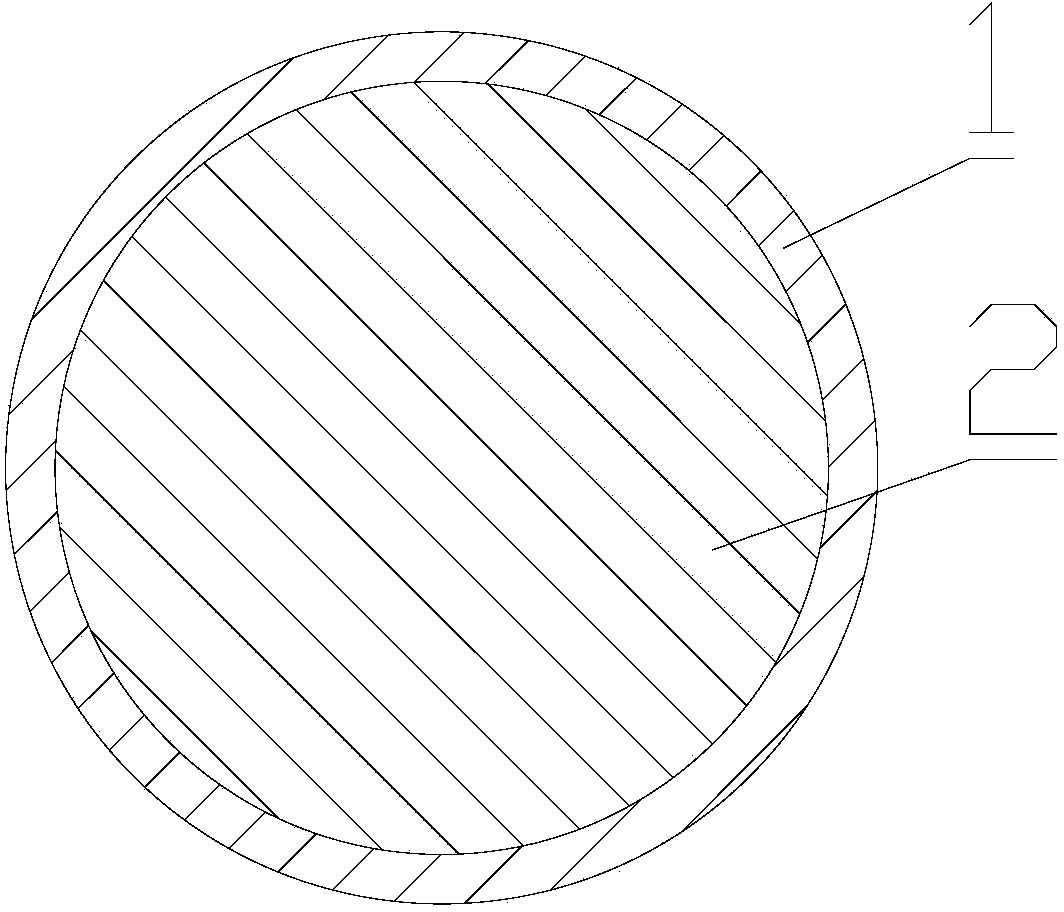

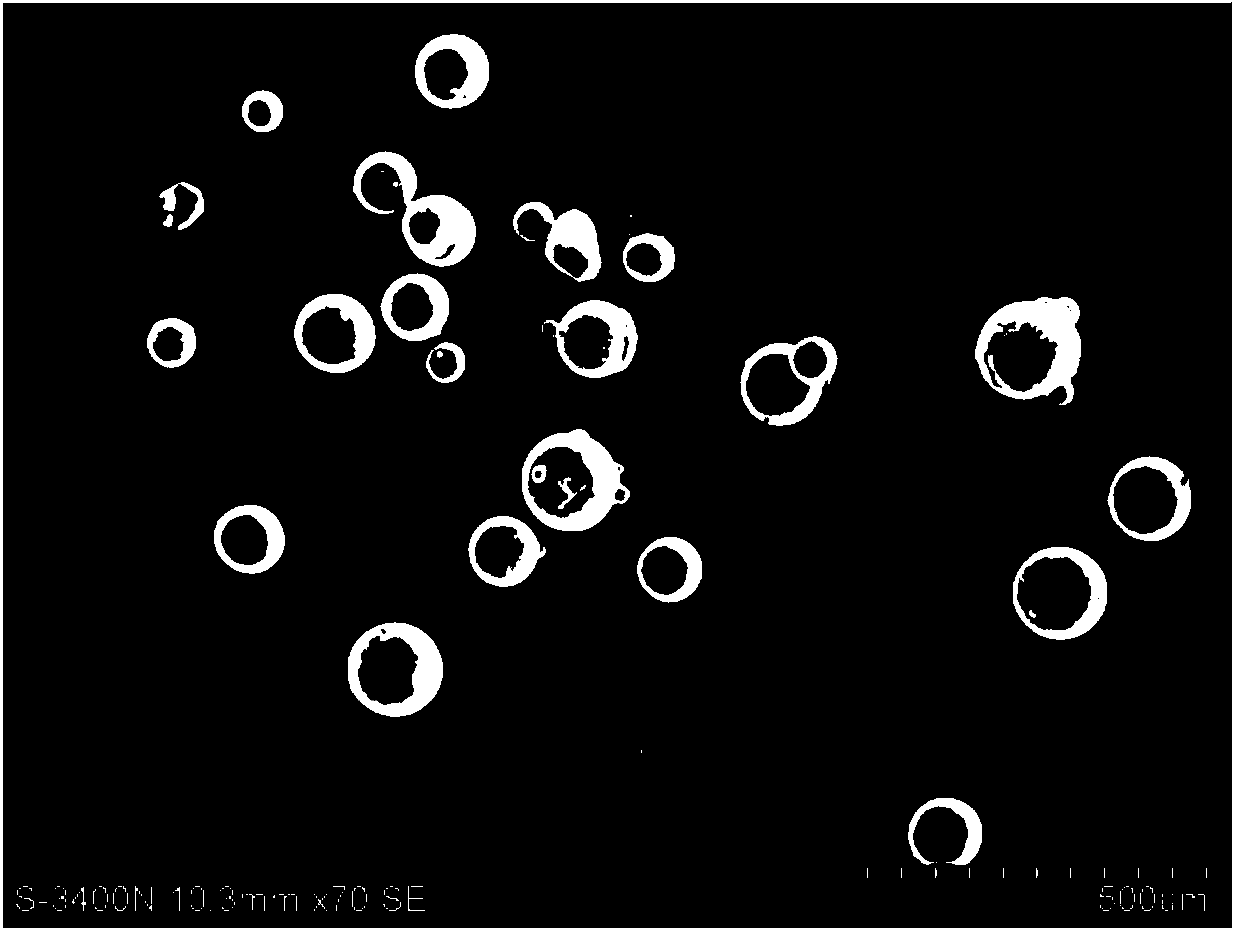

[0032] In this example, pure metal aluminum is used as the raw material. First, the raw material is heated and melted. The superheat of the molten aluminum is 100°C. The gas is sprayed and atomized, the mixed gas is a mixed gas of argon and oxygen, the volume percentage of oxygen is 10%, and the injection pressure is 1MPa during injection to obtain a composite powder. The cross-sectional view is as follows figure 1 As shown in the figure, the inner layer is the metal layer 2, and the outer layer is the oxide layer 1. The obtained composite powder is adhered with a conductive adhesive and analyzed by a scanning electron microscope, as shown in figure 2 shown.

[0033] From figure 1 and figure 2 It can be seen from the figure that the obtained aluminum powder is in a regular spherical shape, the sphericity is approximately equal to 1.0, and the particle size is between 50 and 100 μm.

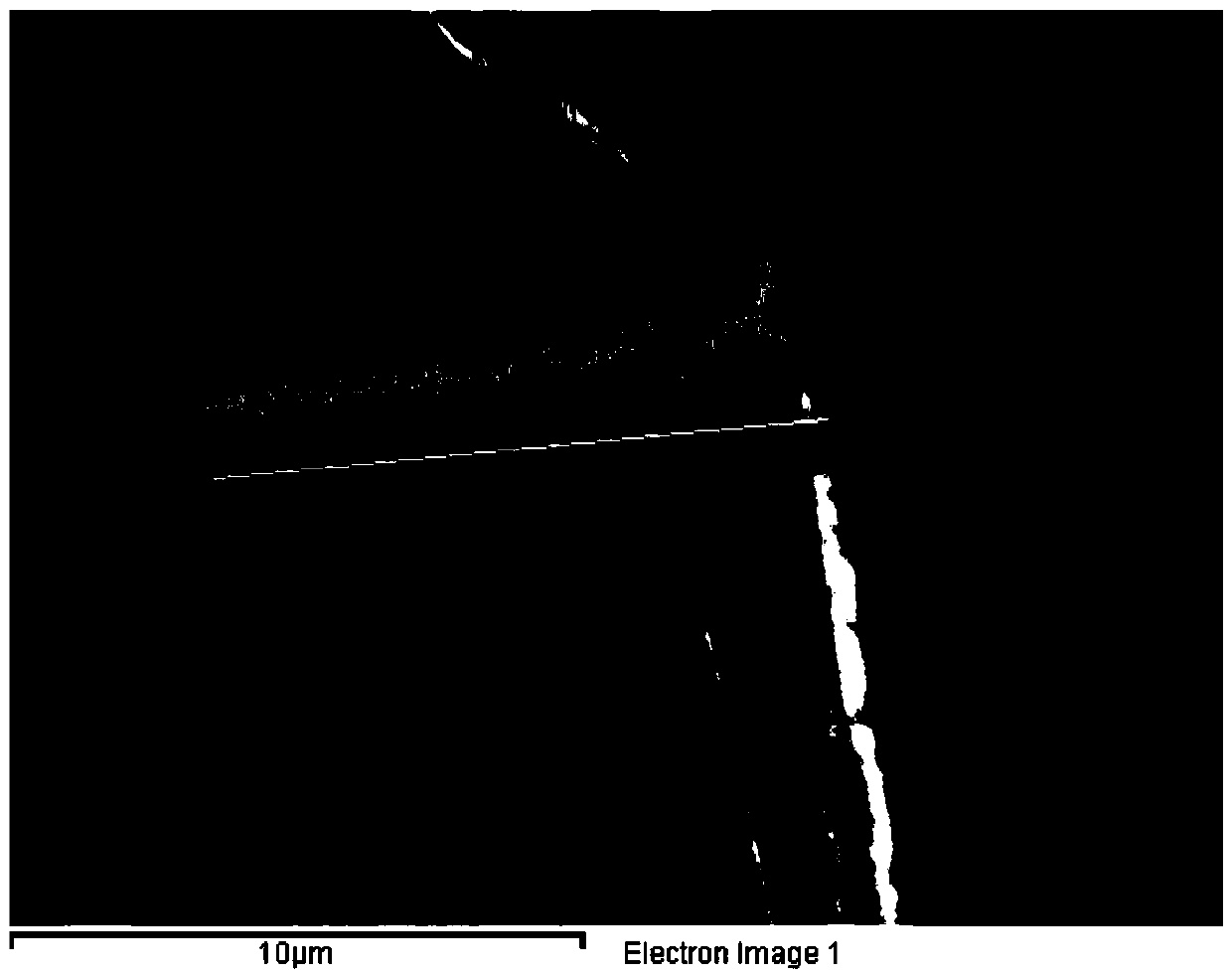

[0034] The obtained powder is analyzed with an X-ray energy spectrometer, and a line scan...

Embodiment 2

[0036] In this embodiment, pure metal copper is used as the raw material, the superheat of the molten metal is 150°C, the mixed gas is argon and oxygen, and the volume percentage of oxygen is 80%, and the injection pressure is 1.5 MPa, and the rest are the same as in Embodiment 1. The cross-sectional view of the composite powder is obtained as Figure 6 As shown in the figure, the inner layer is a metal layer 2, and the outer layer is an oxide layer 1, and the oxide layer is obviously thicker than that in Example 1. The composite powder is spherical, the sphericity is approximately equal to 1.01, and the particle size is between 80 and 120 μm.

Embodiment 3

[0038]In this example, pure metal iron is used as the raw material, the superheat of the molten metal is 200°C, the heating temperature of the intermediate insulation bag and the catheter tube is 1100°C, the mixed gas is argon and oxygen, the volume percentage of oxygen is 50%, and the injection pressure is 2.0 MPa, all the other are identical with embodiment 1. A composite powder is obtained, the inner layer is a metal layer, and the outer layer is an oxide layer. The composite powder is in a regular spherical shape with a sphericity of approximately 1.0 and a particle size between 70 and 120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com