SnO2/ZnO nanocomposite and preparation method thereof

A nanocomposite material and nanorod technology, applied in the field of SnO2/ZnO nanocomposite material and its preparation, can solve the problems of limited material properties and applications, cumbersome preparation process, chaotic and disordered ZnO hetero-nano branch structure, etc. Effects of lifetime and carrier concentration, simple process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Pour 1.4mol / L NaOH solution into 0.1mol / L Zn(CH 3 COOH) 2 2H 2 O solution (volume ratio is 1:1), after fully stirring to obtain the precursor solution, move 30ml of the precursor solution into the TFM-lined reaction kettle (the volume of the lining is 100ml), seal it and place it under a microwave power of 400W After the reaction, the reaction product was centrifuged and washed several times with deionized water until the pH of the filtrate = 7, and then the obtained product was dried in an oven at 60 °C to obtain ZnO The nanorod has a length of 5-10 μm and a diameter of about 0.5-1 μm.

[0032] Step 2, the SnCl of 0.05mol / L 4 ·5H 2 O solution is dripped in the NaOH solution of 0.3mol / L, after the titration is finished, add the ZnO nanorod prepared in step 1 of 0.01mol / L and keep stirring for 30min (the molar ratio of the three is [SnCl 4 ]:[NaOH]:[ZnO]=5:30:1) to obtain the precursor solution, take 30ml of the precursor solution and move it into the reacti...

Embodiment 2

[0035] Step 1: Same as Embodiment 1.

[0036] Step two: the SnCl of 0.1mol / L 4 ·5H 2 The O solution was dripped into the 0.9mol / L NaOH solution dropwise, and after the titration was completed, 0.02mol / L of ZnO was added and continued to stir for 30min (the molar ratio of the three was [SnCl 4 ]:[NaOH]:[ZnO]=5:45:1) to obtain the precursor solution, take 30ml of the precursor solution and move it into the reaction kettle of the TFM lining (the volume of the lining is 100ml), and place it in a microwave power of 400W After the reaction, the reaction product was centrifuged and washed with deionized water for several times until the pH of the filtrate = 7, and then the obtained product was dried in an oven at 60°C. Get SnO 2 / ZnO nanocomposites.

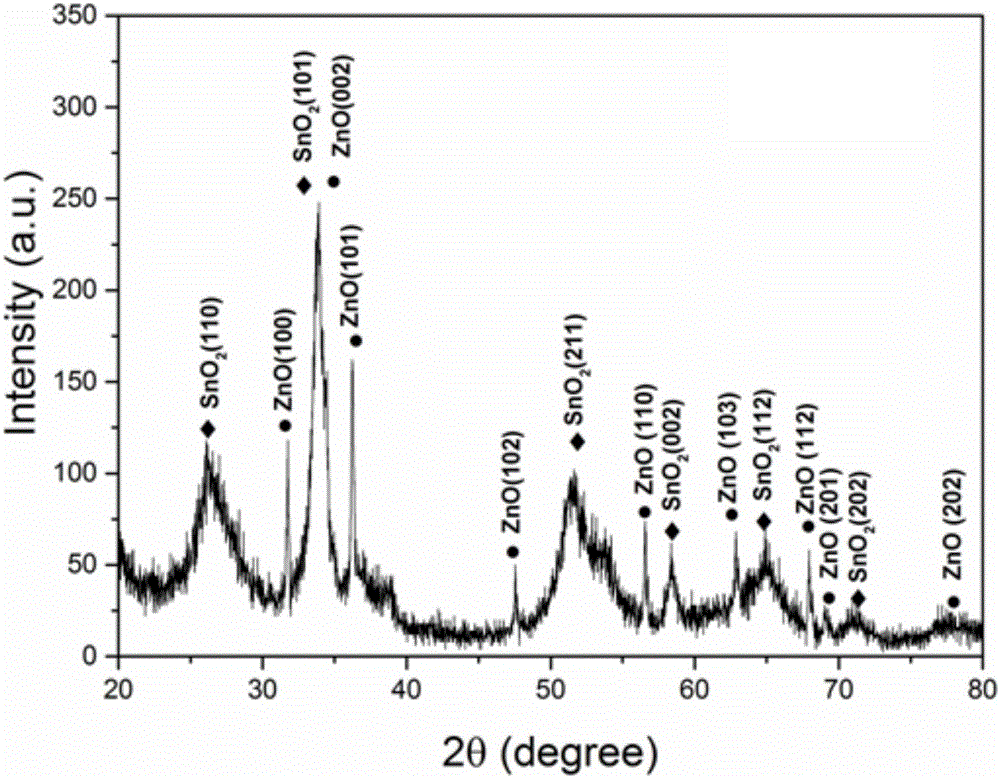

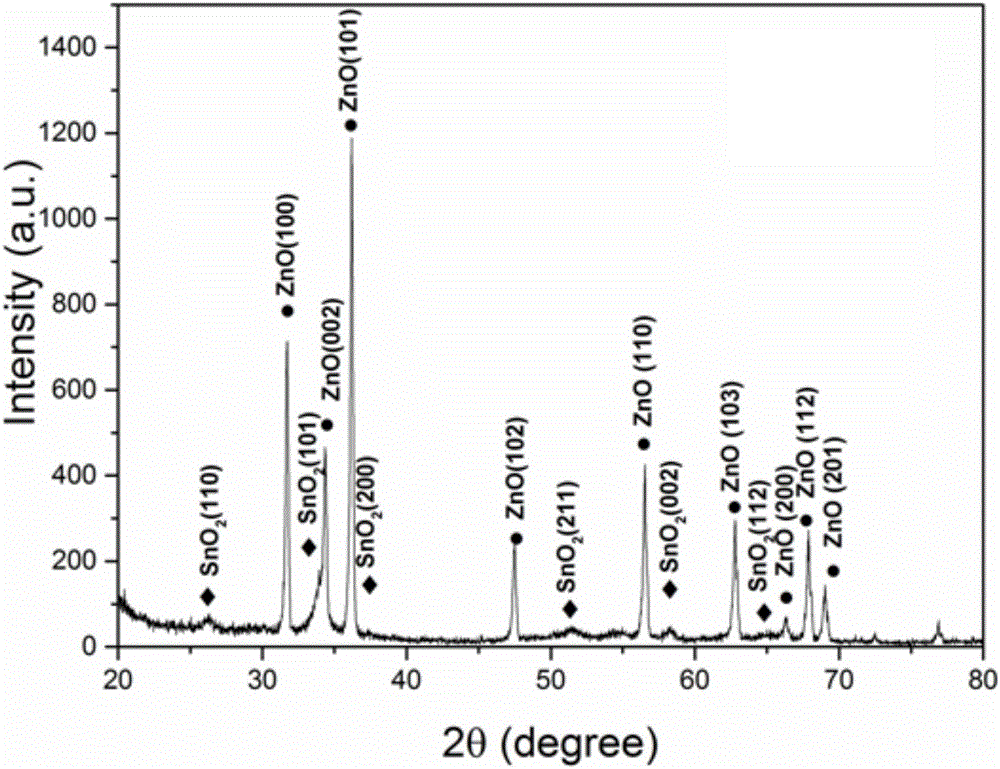

[0037] The X-ray diffraction pattern of the product is as figure 2 As shown in the scanning electron micrograph Figure 5 shown; figure 2 Illustrate that the product of embodiment two is SnO 2 / ZnO complex, Figure 5 Illustra...

Embodiment 3

[0039] Step 1: Same as Embodiment 1.

[0040] Step two: the SnCl of 0.3mol / L 4 ·5H 2 The O solution was dripped into the 1.8mol / L NaOH solution dropwise, and after the titration was completed, 0.05mol / L of ZnO was added and continued to stir for 30min (the molar ratio of the three was [SnCl 4 ]:[NaOH]:[ZnO]=6:36:1) to obtain the precursor solution, take 30ml of the precursor solution and move it into the reaction kettle of the TFM lining (the volume of the lining is 100ml), and place it in a microwave power of 400W After the reaction, the reaction product was centrifuged and washed with deionized water for several times until the pH of the filtrate = 7, and then the obtained product was dried in an oven at 60°C. Get SnO 2 / ZnO nanocomposites.

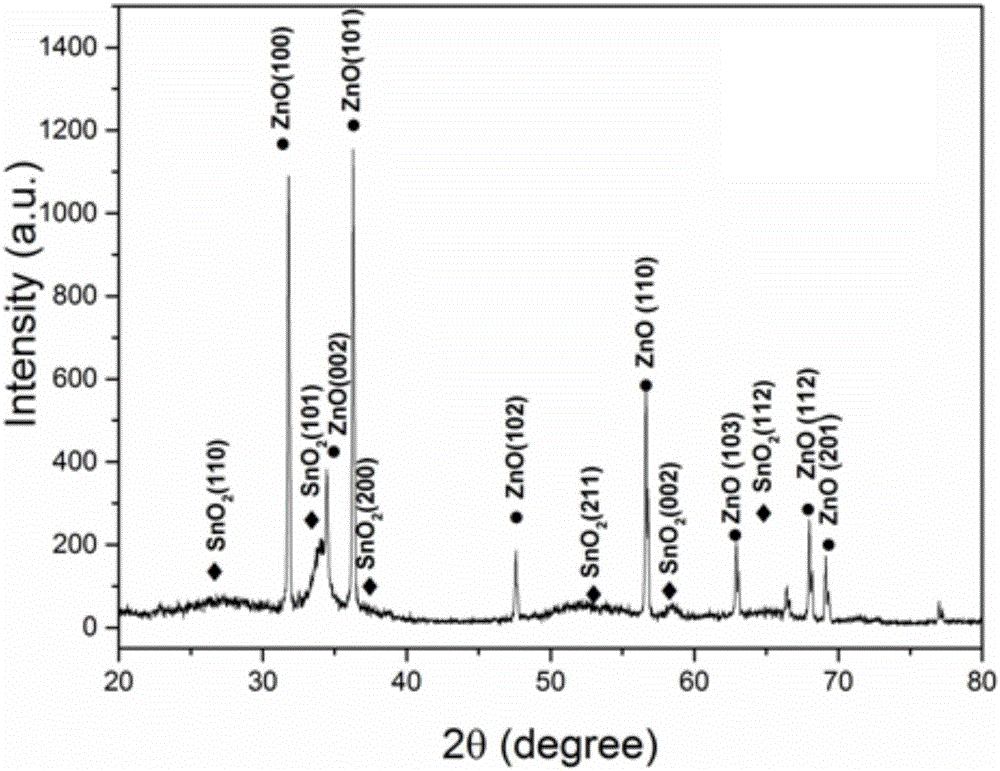

[0041] The X-ray diffraction pattern of the product is as image 3 As shown in the scanning electron micrograph Image 6 shown; image 3 Illustrate that the product of embodiment three is SnO 2 / ZnO complex, Image 6 Illustrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com