Thermoplastic elastomer material for secondary overmolding and preparation method of thermoplastic elastomer material

A thermoplastic elastomer, secondary injection bonding technology, applied in the field of thermoplastic elastomer materials and their preparation, can solve the problems of insufficient coating, poor adhesion, low peel strength, etc., and achieve good interface compatibility and good elasticity , Improve the effect of peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

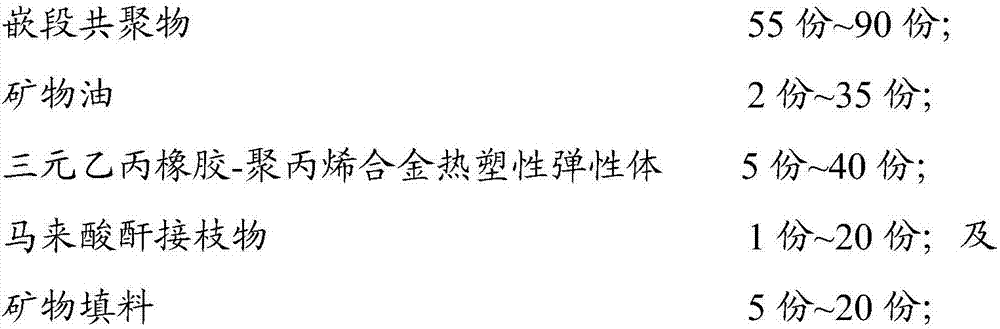

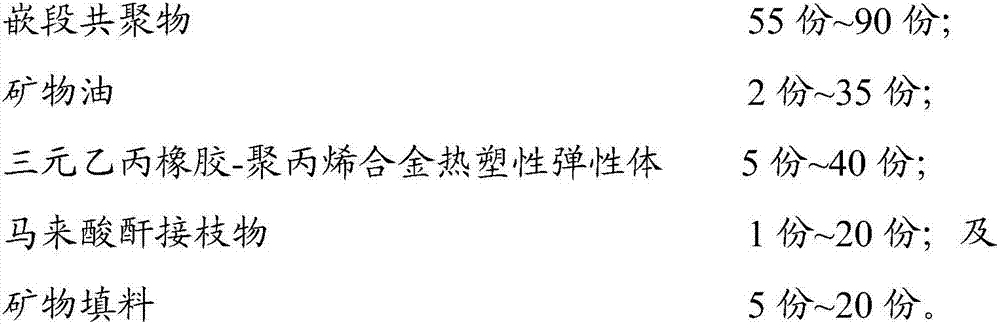

[0043] The above-mentioned preparation method for the thermoplastic elastomer material of secondary shot bonding, comprises the following steps:

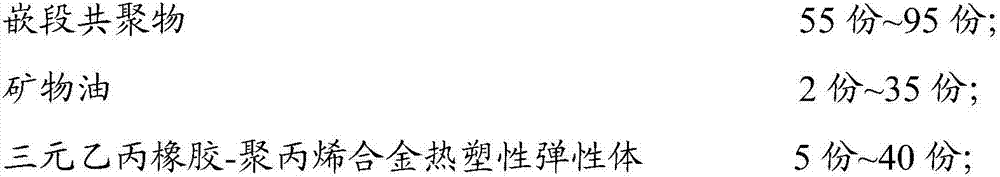

[0044] S110. In terms of parts by mass, 55-95 parts of block copolymer and 2-35 parts of mineral oil are evenly stirred, and left for at least 2 days to obtain the first mixture.

[0045] In one embodiment, the stirring is carried out in a horizontal mixer, and the stirring rate is 30r / min-120r / min.

[0046] In one of the embodiments, stirring is performed for 5 minutes to 15 minutes.

[0047] In one of the embodiments, it is placed for 2 to 4 days.

[0048] In one embodiment, 55-90 parts of block copolymer and 2-35 parts of mineral oil are mixed well and the package is sealed for at least 2 days.

[0049] S120. Stir and mix the first mixture with 5-40 parts of EPDM rubber-polypropylene alloy thermoplastic elastomer and 1-20 parts of maleic anhydride graft to obtain a second mixture.

[0050] In one embodiment, the stirring is ca...

Embodiment 1

[0063] Put 9 parts by weight of SEBS YH503T and 63 parts by weight of SBS PB5502 into a horizontal mixer, uniformly add 5 parts by weight of mineral oil 150N, stir for 10 minutes to obtain the first mixture, pack the first mixture, and place it for 2 days.

[0064] Put the first mixture into a horizontal mixer, add 5 parts by weight of EPDM rubber-polypropylene alloy thermoplastic elastomer GP610-55, and 13 parts by weight of thermoplastic styrene-butadiene rubber-maleic anhydride graft FG1901, stir 5 min to get the second mixture.

[0065] Add 5 parts by weight of heavy calcium carbonate, 0.1 part by weight of antioxidant 168, 0.05 part by weight of antioxidant 1076, and 0.15 part by weight of erucamide into the second mixture, stir for 10 minutes until uniformly mixed, and obtain a premix.

[0066] Put the premix in a co-rotating twin-screw extruder to extrude and pelletize to obtain a thermoplastic elastomer material for secondary shot bonding.

Embodiment 2

[0068] Put 50 parts by weight of SBS PB5502 and 10 parts by weight of SBS 3546 into a horizontal mixer, evenly add 2 parts by weight of mineral oil KNH4006, stir for 10 minutes to obtain the first mixture, pack the first mixture, and place it for 5 days.

[0069] Put the first mixture into a horizontal mixer, add 20 parts by weight of EPDM rubber-polypropylene alloy thermoplastic elastomer GP610-55, and 13 parts by weight of thermoplastic styrene-butadiene rubber-maleic anhydride graft FG1901, stir 5 min to get the second mixture.

[0070] Add 5 parts by weight of heavy calcium carbonate, 0.1 part by weight of antioxidant 168, 0.05 part by weight of antioxidant 1076, and 0.2 parts by weight of lubricant erucamide into the second mixture, stir for 10 minutes until uniformly mixed, and obtain a premix.

[0071] Pour the premix into the hopper of the co-rotating twin-screw extruder, shear and disperse through the co-rotating twin-screw, pelletize, pass through a vibrating sieve, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com