Patents

Literature

48results about How to "Excellent compression set resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

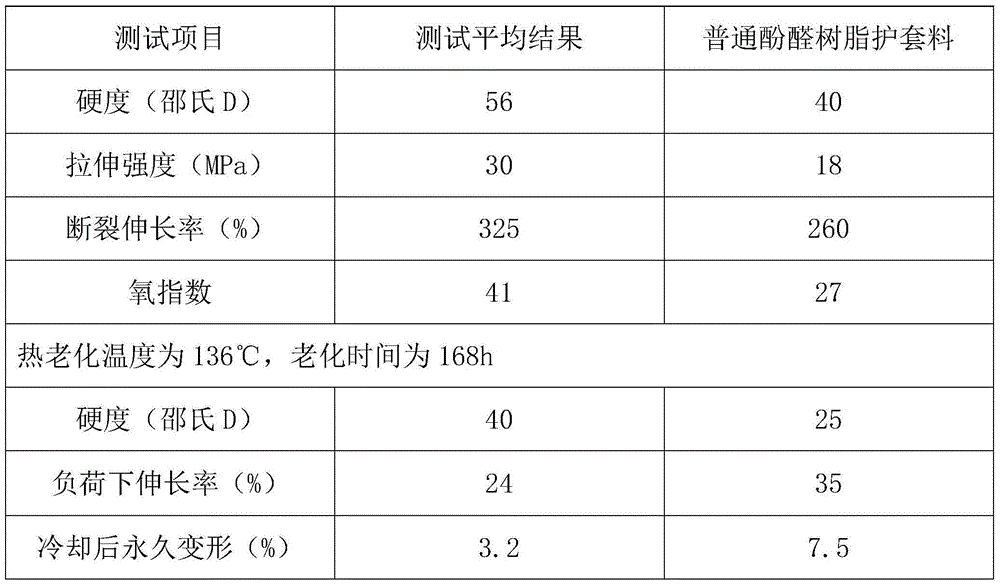

Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

InactiveCN101921437AChange natureImprove naturePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenThermoplastic elastomer

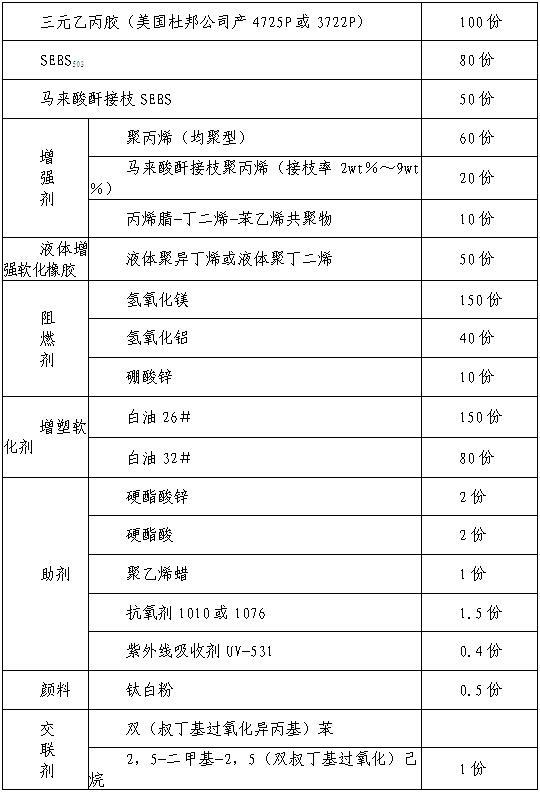

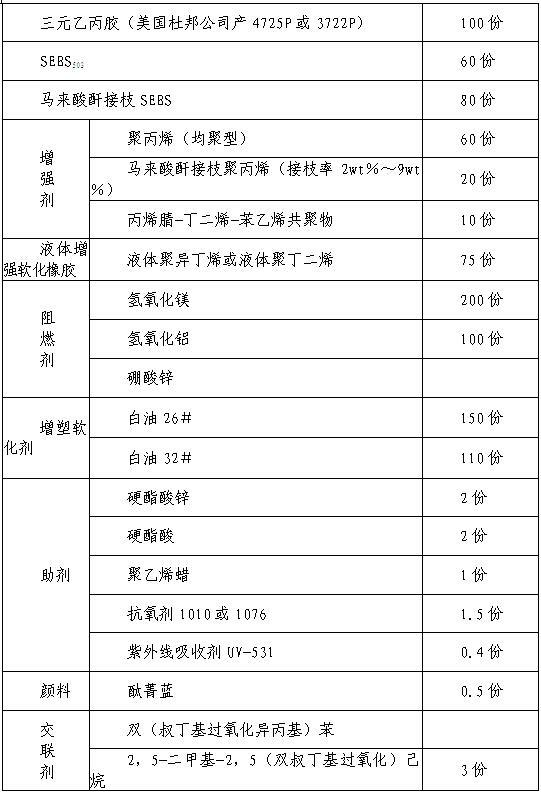

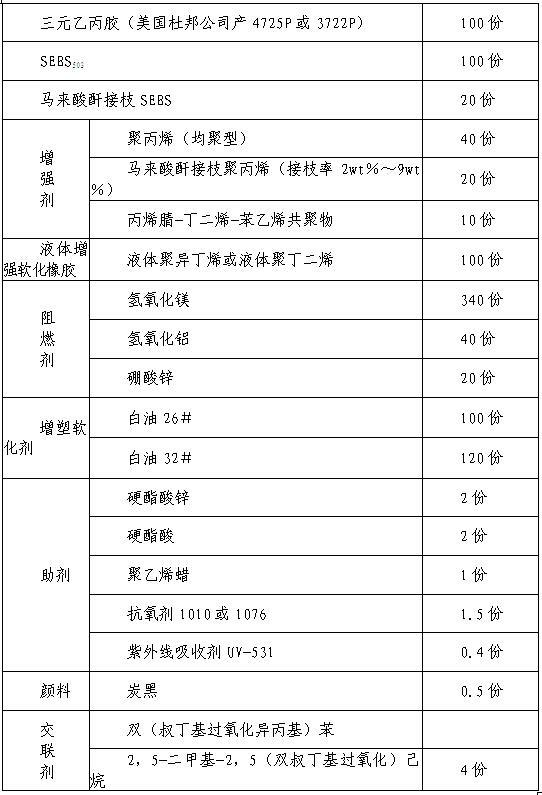

The invention discloses a low smoke zero halogen thermoplastic elastomer flame-retardant cable material which comprises the following components in weight ratio: 100 parts of ethylene-propylene diene monomer rubber, 50-200 parts of SEBS503 and / or maleic anhydride grafted SEBS, 55-100 parts of reinforcing agent, 100-300 parts of plasticizing and softening agent, 0-5 parts of pigment, 8-12 parts of auxiliary agent, 1-4 parts of cross-linking agent, 150-550 parts of flame retardant agent and 40-150 parts of liquid reinforcing and softening rubber. The preparation method of the material comprises the following steps of: firstly, mixing, plasticating, cooling and granulating the SEBS 503 and / or maleic anhydride grafted SEBS, the plasticizing and softening agent, the reinforcing agent, the pigment and the ethylene-propylene diene monomer rubber particles to prepare thermoplastic elastomer master batch; then, mixing the thermoplastic elastomer master batch with the auxiliary agent, the flame retardant agent and the liquid reinforcing and softening rubber, adding into a mixer, and stirring uniformly; and finally, mixing, plasticating, cooling and granulating to obtain a finished product. The product does not contain halogen, has excellent flame retarding efficacy and is not embrittled and hardened under the low temperature condition of subzero 40 DEG C. The preparation method has simple equipment and technology and does not have any three wastes discharge or environmental pollution.

Owner:天龙伟业线缆有限公司 +1

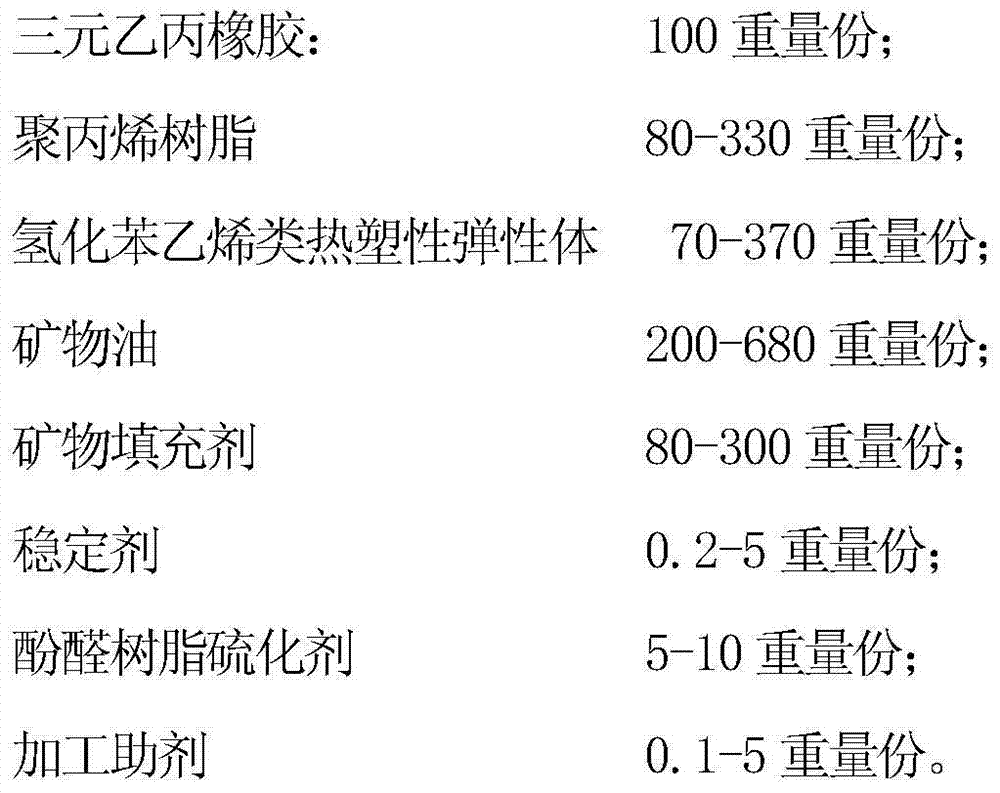

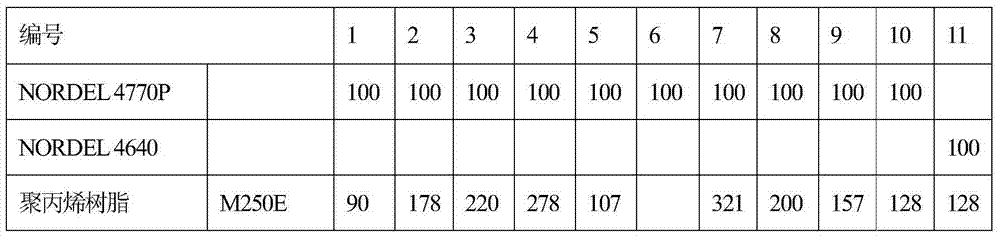

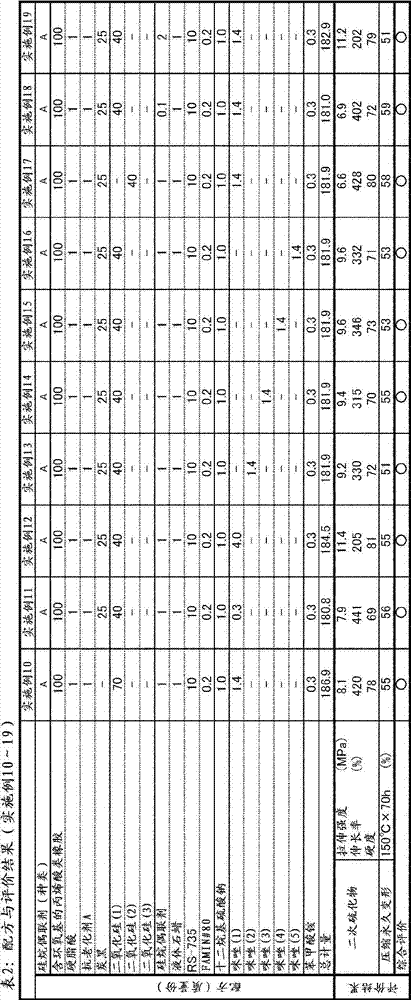

Thermoplastic vulcanizate elastomer composition and preparation method thereof

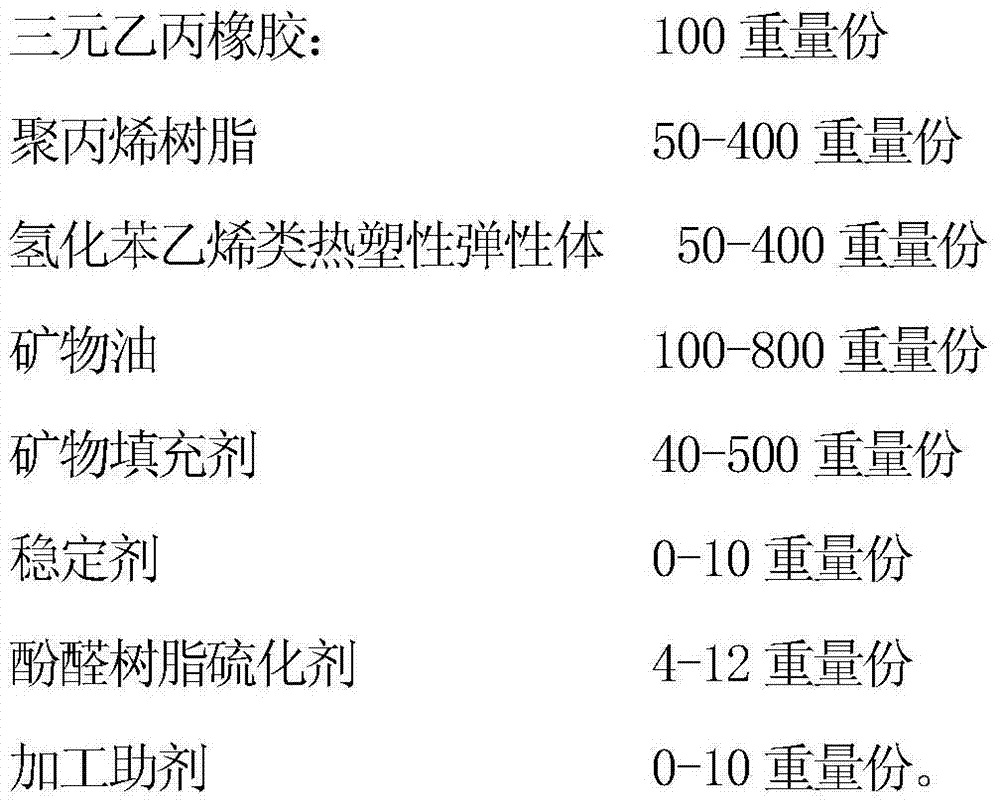

The invention discloses a thermoplastic vulcanizate elastomer composition and a preparation method thereof. The composition comprises the following components in parts by weight: 100 parts of ethylene-propylene-diene monomer rubber, 50-400 parts of polypropylene resin, 50-400 parts of a hydrogenated styrenic thermoplastic elastomer, 100-800 parts of mineral oil, 40-500 parts of a mineral filling agent, 0-10 parts of a stabilizer, 4-12 parts of a phenolic resin vulcanizing agent and 0-10 parts of processing aids. Compared with traditional TPV, the thermoplastic vulcanizate elastomer composition remains the characteristic of low compression set and is improved in term of fluidity and therefore the appearance of an injection molded surface is improved. The thermoplastic vulcanizate elastomer composition has hardness which is adjustable between 30A-55D, has soft and smooth handfeel, has damping and denoising effects and can meet the requirements of fields such as machinery, autos and electronics and electric products.

Owner:SINOTEX INVESTMENT & DEV CO LTD

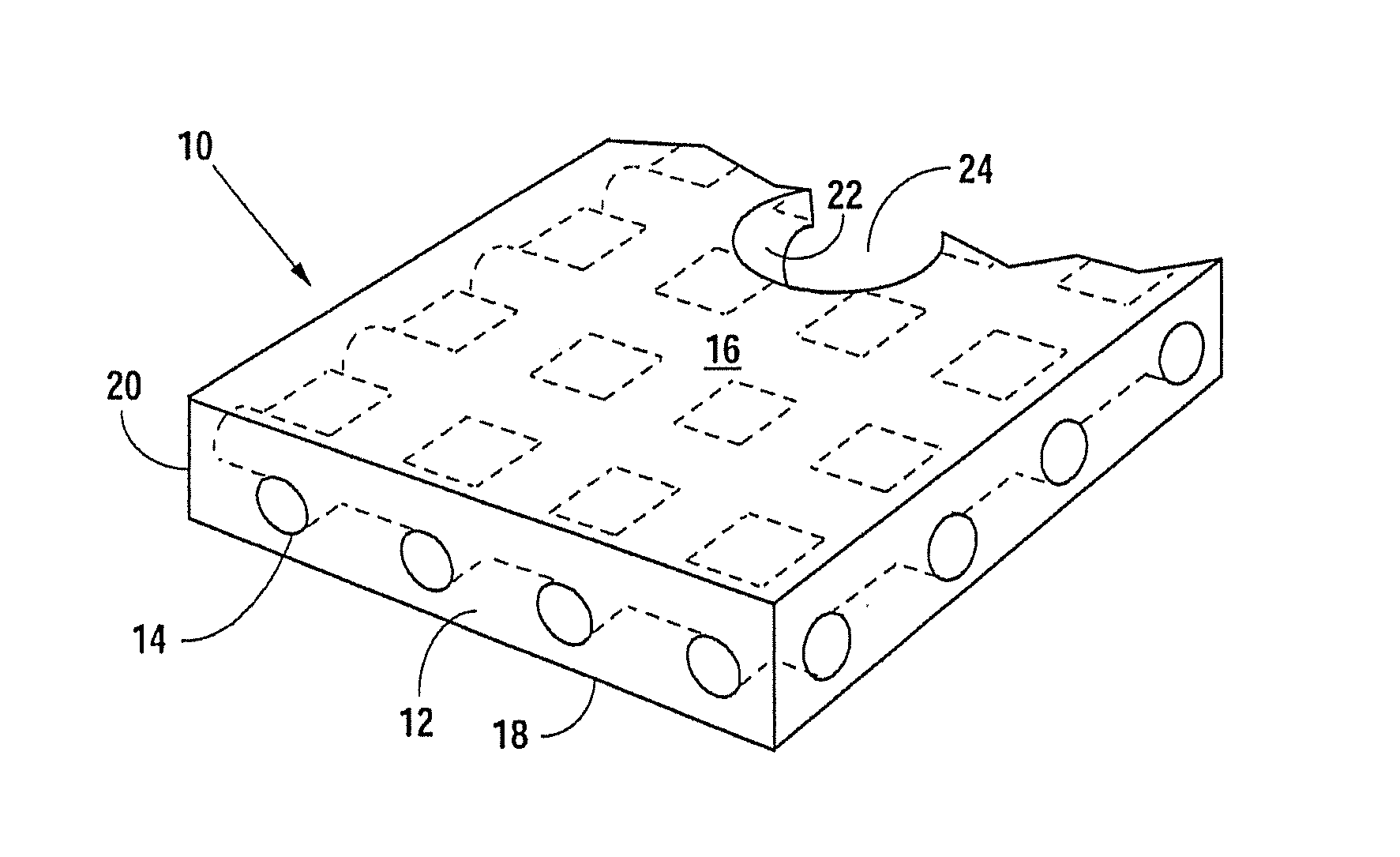

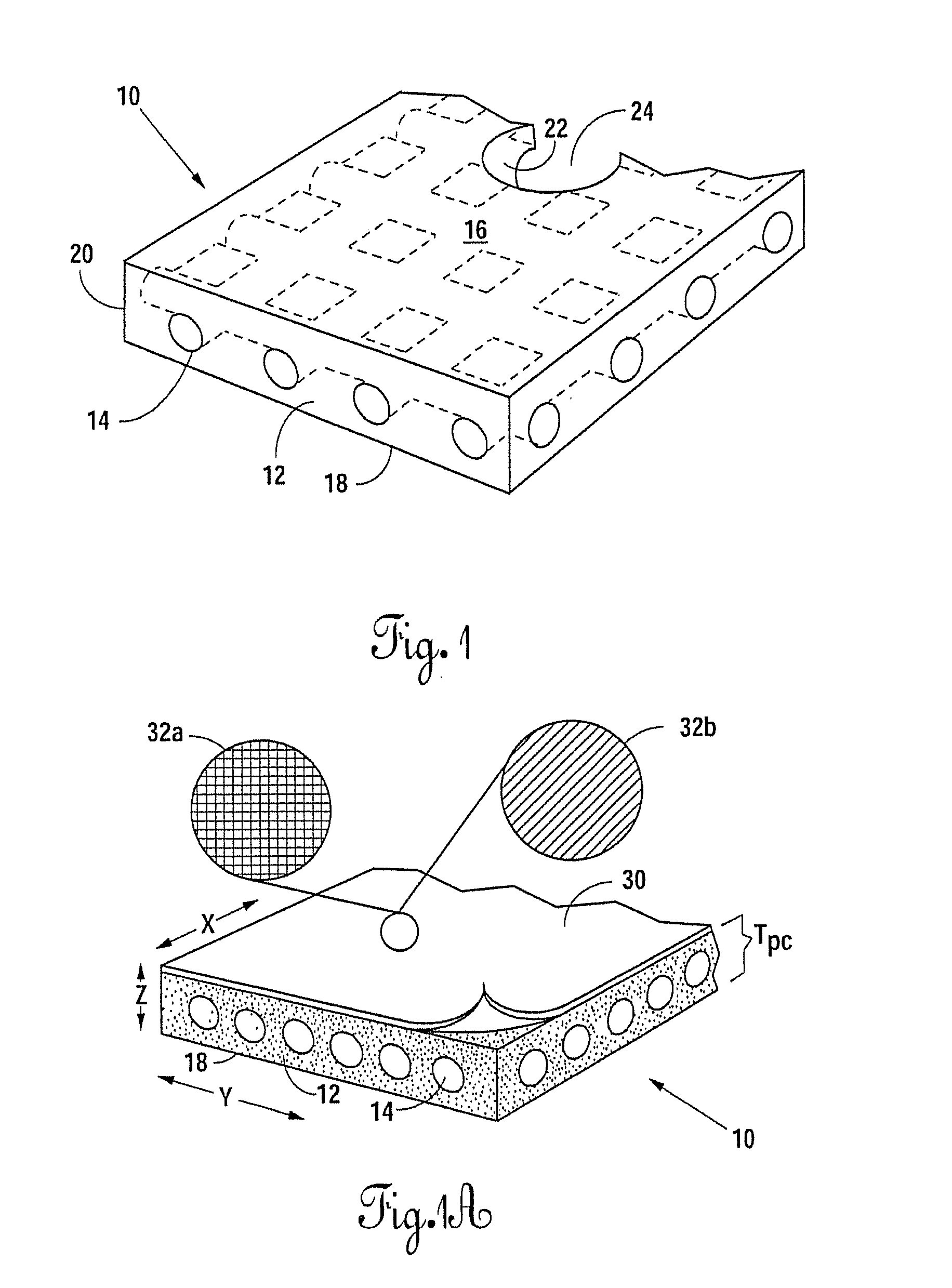

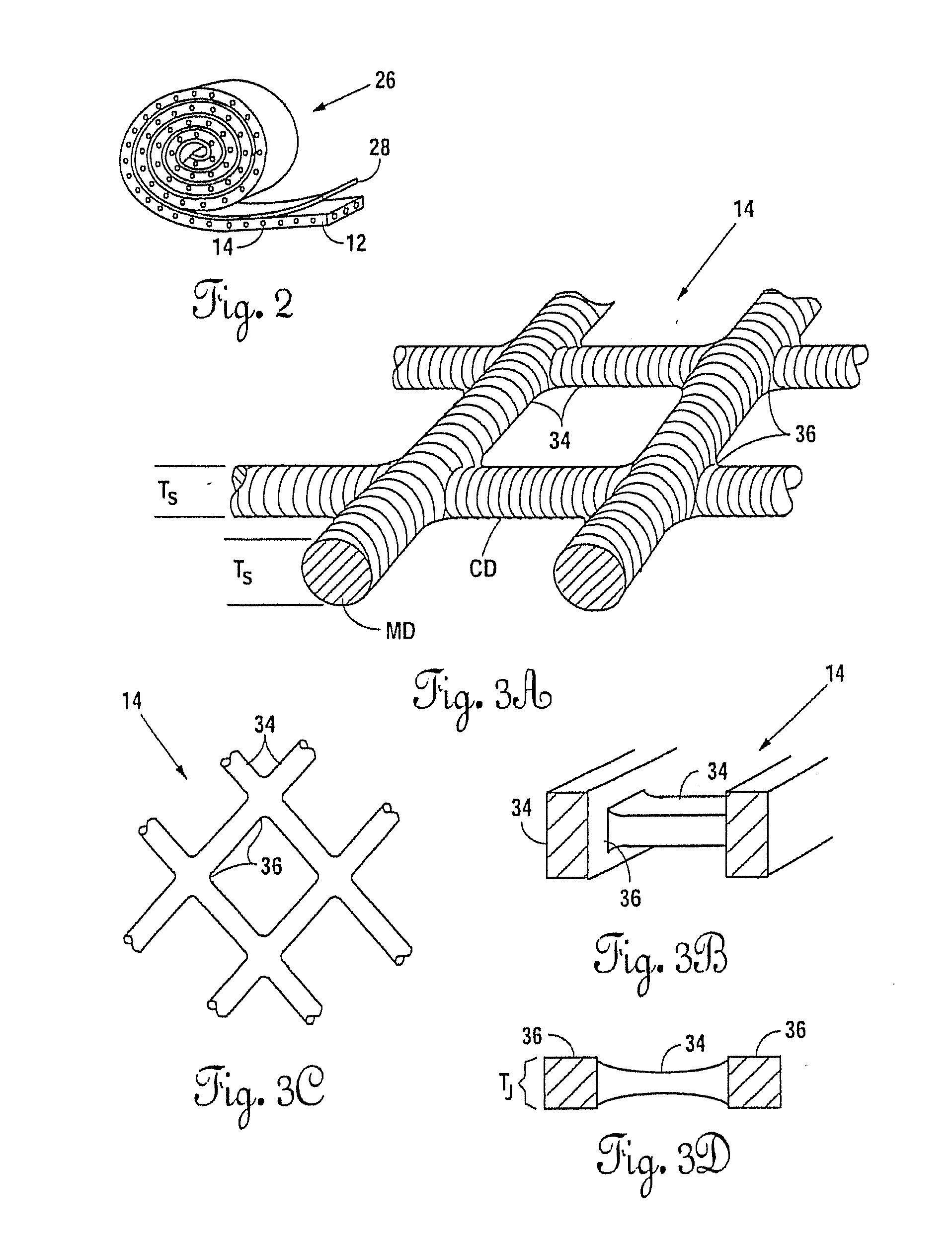

Elastomeric gel body gasket having a substantially incompressible skeleton, a method of making and using the same

ActiveUS20160131259A1Excellent compression set resistanceExcellent torque retentionFuselage framesEngine sealsEngineeringAir bubble

Gaskets, including aircraft gaskets, are disclosed, the gaskets having an elastomeric gel body and substantially incompressible skeletons. The bodies may be pliable and deformable and, in one example, may be comprised of a two-part chemically cured polyurethane that sets up as a gel after mixing with the web so that it is fully integral with the web and so that there is substantially no air bubbles or air pockets left in the web. The web may be a regular shaped web and made of nylon.

Owner:THE PATENT WELL LLC

Thermoplastic elastomer material for secondary overmolding and preparation method of thermoplastic elastomer material

The invention relates to a thermoplastic elastomer material for secondary overmolding and a preparation method of the thermoplastic elastomer material. The thermoplastic elastomer material for secondary overmolding is prepared from the following components in parts by mass: 55 to 95 parts of segmented copolymer, 2 to 35 parts of mineral oil, 5 to 40 parts of ethylene propylene diene terpolymer-polypropylene alloy thermoplastic elastomer, 1 to 20 parts of maleic anhydride-grafted polymer and 5 to 20 parts of mineral filler, wherein the segmented copolymer is selected from at least one of a styrene-ethylene-butadiene-styrene block copolymerized elastomer, a styrene-butadiene-styrene block copolymer and a styrene-butadiene block copolymer. The thermoplastic elastomer material for secondary overmolding is higher in stripping strength.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

Heat resistant, wear-resistant and tear-resistant cable sheath

InactiveCN105131614AGood dispersionImprove solubilityRubber insulatorsInsulated cablesFiberWear resistant

The invention discloses a heat resistant, wear-resistant and tear-resistant cable sheath. The heat resistant, wear-resistant and tear-resistant cable sheath is prepared, by weight, 20-30 parts of modified phenolic resin, 30-40 parts of epichlorohydrin rubber, 40-50 parts of boron-silicon rubber, 0.4-0.6 part of 3,6,9-triethyl-3,6,9-trimethyl-1,4,7-triperoxynonane, 2-4 parts of sulphur, 1-1.5 parts of accelerant MZ, 0.8-1.3 parts of accelerator TMTD, 3-4 parts of zinc oxide, 0.5-1 part of zinc carbonate, 1-2 parts of magnesium oxide, 20-40 parts of talcum powder, 20-25 parts of montmorillonite, 20-30 parts of kaolin, 2-4 parts of jute fiber, 1-1.5 parts of silane coupling agent, 2-5 parts of chlorinated paraffins, 1-2 parts of dimethyl phthalate, 1-2 parts of antioxidant 8PPD and 0.8-1.4 parts of antioxidant BLE. The heat resistant, wear-resistant and tear-resistant cable sheath has excellent wear resistance, tear resistance, weather resistance and flame resistance.

Owner:ANHUI HONGHAI CABLE

High-abrasion resistance and high temperature-resistant cable sheath material

InactiveCN105086034AIncrease polarityGood compatibilityRubber insulatorsInsulated cablesCalcium silicateEpoxy

The invention discloses a high-abrasion resistance and high temperature-resistant cable sheath material, which is prepared from the following raw materials in parts by weight: 25 to 35 parts of modified phenolic resin, 25 to 35 parts of carboxylic-acrylonitrile-butadiene rubber, 30 to 50 parts of epichlorohydrin rubber, 0.8 to 1.4 parts of 1,1-bis-( tertiary butyl peroxide)-3,3,5-trimethyl-cyclohexane, 0.2 to 0.4 part of brimstone powder, 0.5 to 0.8 part of accelerator TMTM, 1.2 to 1.5 parts of accelerator CZ, 10 to 20 parts of magnesium oxide, 30 to 35 parts of furnace black, 20 to 30 parts of sea-foam stone powder, 10 to 20 parts of calcium metasilicate, 1 to 3 parts of trimellitic acid-3-(n-octyl n-decyl adipate), 4 to 5 parts of epoxy-cottonseed butyl oleate, 1 to 3 parts of antiager DFC-34 and 0.5 to 1.5 parts of antiager MBZ. The high-abrasion resistance and high temperature-resistant cable sheath material disclosed by the invention has excellent high temperature resistance and abrasion resistance and is high in stability and long in service life.

Owner:ANHUI HONGHAI CABLE

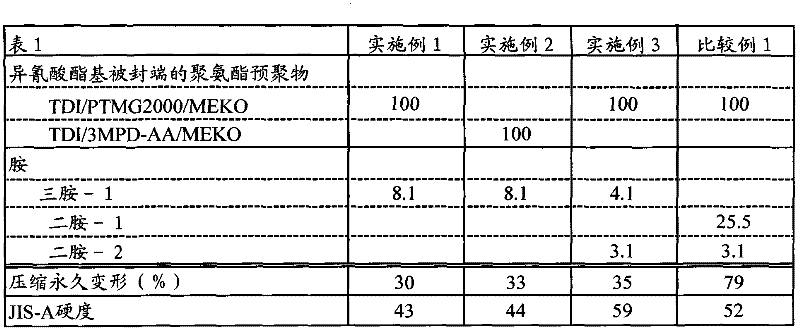

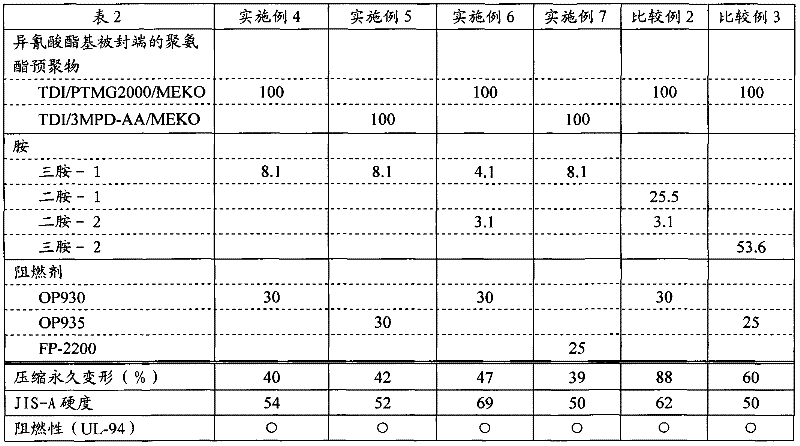

Heat-curable polyurethane resin composition and urethane elastomer molded article using the same

The invention aims at providing a heat-curable polyurethane resin composition and a urethane elastomer molded article using the same advantaged by excellent compression set resistance performance and low hardness. The invention relates to a heat-curable polyurethane resin composition and a urethane elastomer molded article using the same, which are characterized in that, the heat-curable polyurethane resin composition comprises a polyurethane prepolymer (1) with an isocyanate group terminated and a triamine with an amine equivalent of 50-350, the polyurethane prepolymer is obtained via polyhydric alcohol (A), polyisocyanates (B), and terminating agents (C) as necessary raw materials.

Owner:DAINIPPON INK & CHEM INC

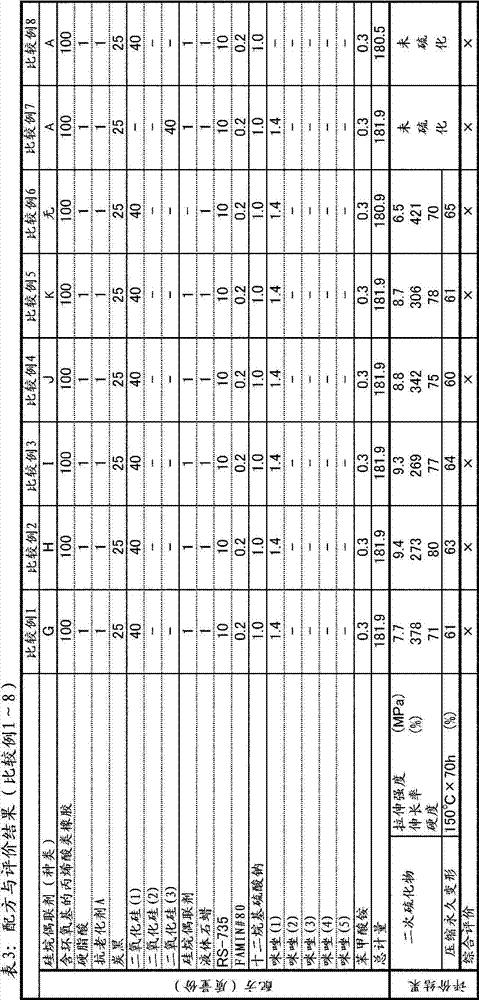

Acrylic rubber composition, vulcanizate, hose part, and sealing part

ActiveCN102959004AIncreased process safetyFull mechanical propertiesEngine sealsPolymer scienceVulcanization

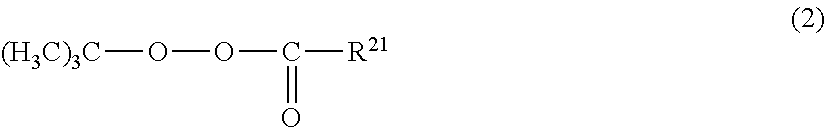

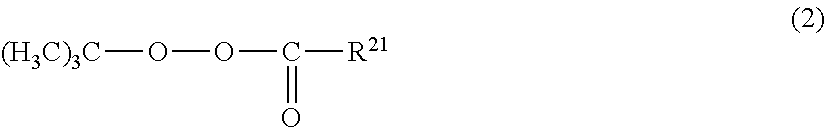

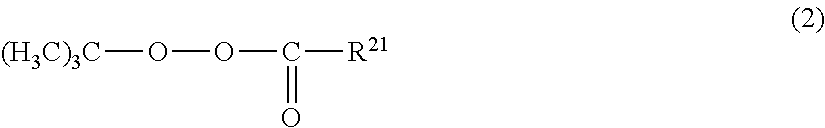

Disclosed is an acrylic rubber composition which has high processing safety and, after being subjected to secondary vulcanization (hot-air vulcanization), has sufficient mechanical properties and excellent permanent compression strain resistance. Also disclosed is a vulcanizate thereof. The acrylic rubber composition comprises (A) an epoxy group-containing acrylic rubber, (B) an imidazole compound represented by general formula (1), (C) silica, and (D) a silane coupling agent represented by general formula (2). Such an acrylic rubber composition has excellent mechanical properties such as permanent compression strain resistance and hardness.

Owner:DENKA CO LTD

High wear-resistant high-tenacity rubber sealing element

The invention discloses a high wear-resistant high-tenacity rubber sealing element which comprises the following raw materials in parts by weight: 30-50 parts of epichlorohydrin rubber, 12-20 parts of methyl vinyl silicone rubber, 20-30 parts of nitrile rubber, 6-12 parts of kieselguhr, 4-8 parts of calcium carbonate, 2-4 parts of magnesium oxide, 12-16 parts of bismuth oxide, 10-20 parts of barium metaborate, 8-16 parts of a glass bead, 4-8 parts of modified aupoz fiber, 2-4 parts of a dimethyl silicone polymer, 3-6 parts of methylphenyldiethoxysilane, 4-8 parts of an epoxidized fatty acid methyl ester, 1-3 parts of magnesium stearate, 2-4 parts of diisononyl phthalate, 0.4-1 part of triallylisocyanurate, 2-4 parts of zinc diacrylate and 1.5-3 parts of dicumyl peroxide. The high wear-resistant high-tenacity rubber sealing element not only has excellent wear resistance and tenacity, but also has very good high temperature resistance, and meanwhile, the sealing element is difficult to age and long in service life.

Owner:安徽亚兰密封件股份有限公司

High-flame-retardance and high-toughness expandable polystyrene

The invention discloses high-flame-retardance and high-toughness expandable polystyrene which comprises the following raw materials in parts by weight: 95-105 parts of styrene, 20-30 parts of ethylene-propylene-diene monomer rubber, 25-35 parts of polyethylene, 150-170 parts of water, 0.3-0.4 parts of dibenzoyl peroxide, 0.05-0.1 parts of tert-butyl peroxybenzoate, 0.2-0.3 parts of dicumyl peroxide, 2-5 parts of nano calcium silicate, 0.02-0.04 part of a silane coupling agent KH560, 2-4 parts of polyvinyl alcohol, 1-3 parts of cellulose ether, 2-8 parts of nekal, 0.05-0.15 parts of a defoamer, 0.2-0.5 parts of an antioxidant, 0.4-1.2 parts of a flame retardant and 7-12 parts of a foamer. The high-flame-retardance and high-toughness expandable polystyrene disclosed by the invention is excellent in flame-retardant and heat-resistant performance, good in toughness and excellent in impact resistance.

Owner:芜湖市京桥精密智造有限公司

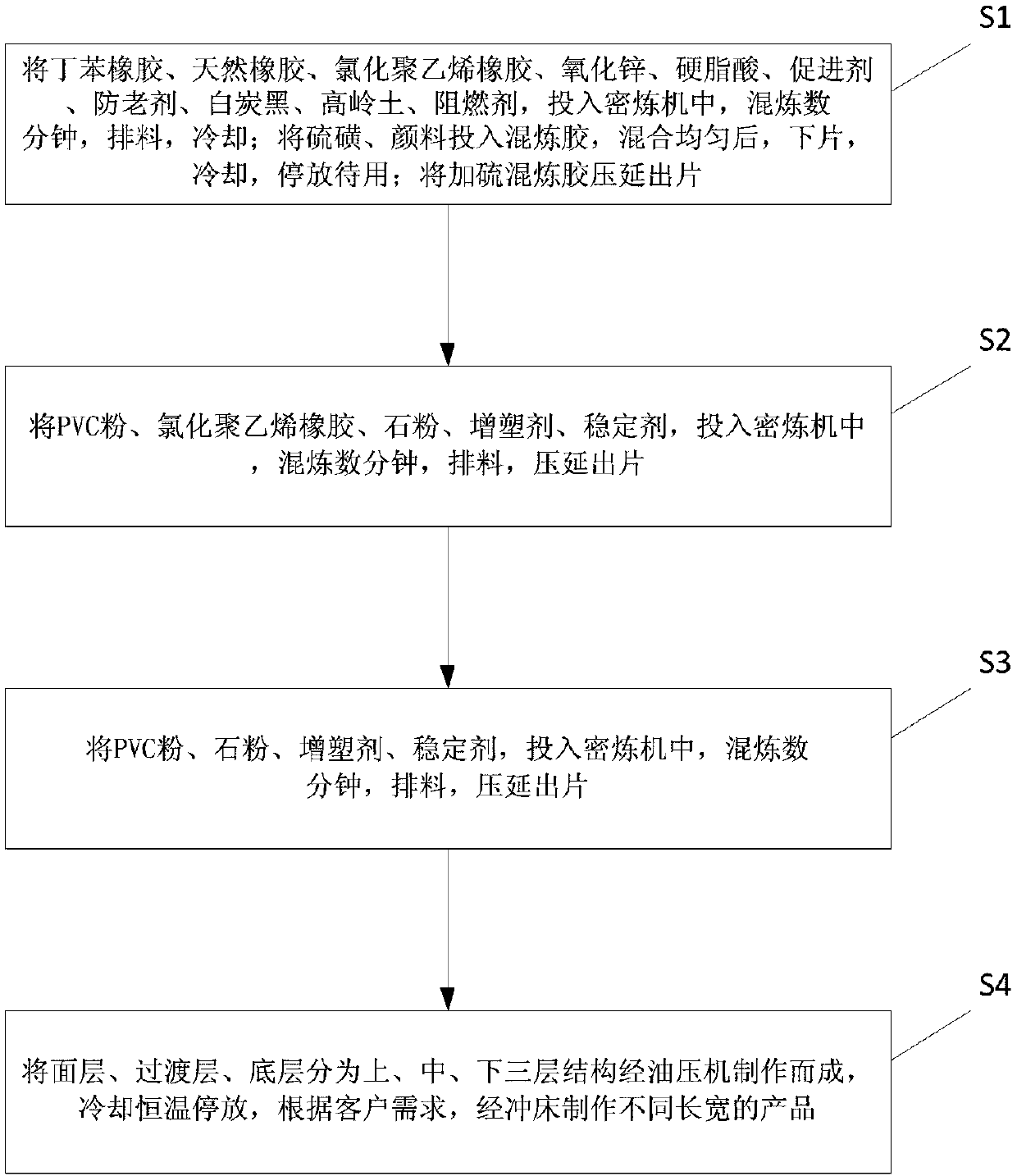

Improved rubber composite environment-friendly rubber floor and manufacturing method

InactiveCN107584836AIncrease elasticityExcellent compression set resistanceSynthetic resin layered productsLaminationSurface layerAging resistance

The invention discloses an improved rubber composite environment-friendly rubber floor and a manufacturing method. The composite environment-friendly rubber floor comprises a surface layer, a transition layer and a bottom layer in sequence from top to bottom, wherein the surface layer, the transition layer and the bottom layer are laminated together through high temperature. The surface layer is vulcanized rubber and has the advantages of good elasticity, compression deformation resistance, ageing resistance, wearing resistance, slipping resistance and the like; the bottom layer is a PVC (Polyvinyl Chloride) floor and has the advantages that the bottom layer has a firm structure, is durable, has stable performance and low price and the like; the transition layer is a mixture of plastic andrubber and can be used for effectively improving the adhering force of the surface layer and the bottom layer, is not influenced by external temperature and is not delaminated; the defect that the product environment assessment of a composite structure of an environment-friendly PVC floor and an environment-friendly rubber floor, which are adhered by adopting glue, in the current market does notreach standards is overcome; the environment-friendly rubber floor meets various environment-friendly performance indexes.

Owner:秦力环保建材科技(东莞)有限公司

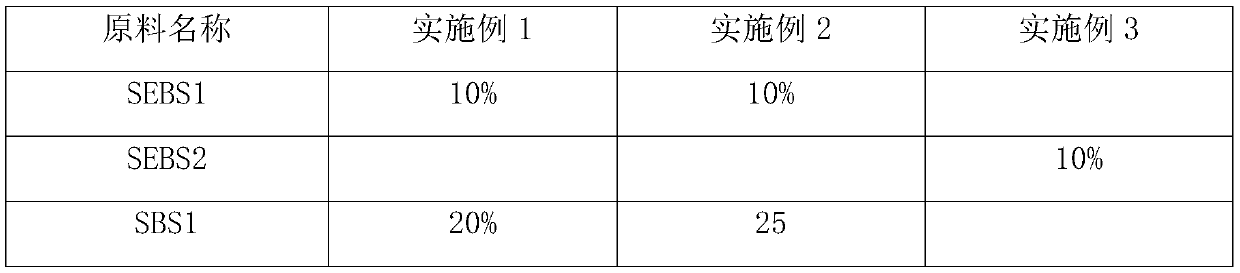

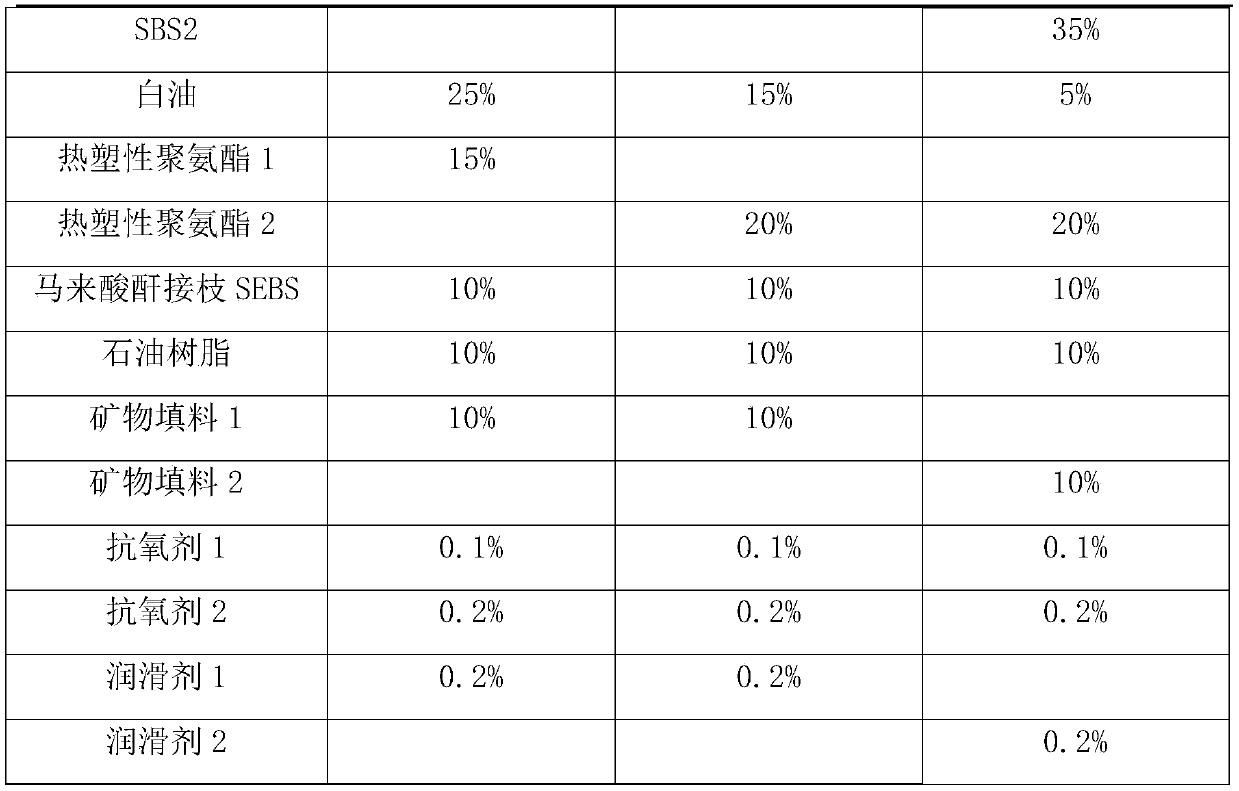

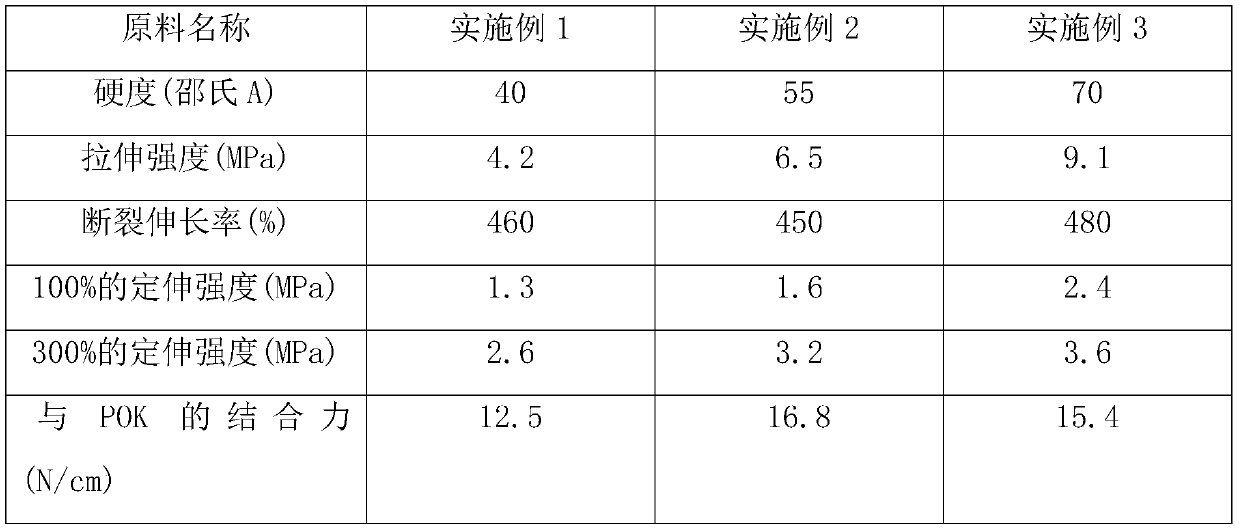

Thermoplastic elastomer material for secondary overmolding with polyketone material and preparation method thereof

The invention discloses a thermoplastic elastomer material for secondary overmolding with a polyketone material and a preparation method thereof. The thermoplastic elastomer material is prepared fromthe following raw materials in percentage by weight: 10-30% of SEBS, 20-40% of SBS, 15-35% of white oil, 10-30% of thermoplastic polyurethane, 5-10% of maleic anhydride grafted SEBS, 5-10% of petroleum resin, 5-10% of a mineral filler, 0.1 to 0.5% of an antioxidant and 0.1-0.5% of a lubricant. The invention also provides a preparation method of the thermoplastic elastomer material. The preparationmethod comprises the following steps: uniformly mixing the above components with above percentages by weight in a high-speed stirrer, and carrying out melt extrusion granulation by using a twin-screwextruder to obtain the thermoplastic elastomer material. The thermoplastic elastomer material has Shore hardness of 40-80 A, high tensile strength, high elongation at break which is larger than 500%,excellent temperature resistance and a thermal deformation temperature of 70 DEG C or above.

Owner:SHANGHAI GAOXINKE PLASTIC PROD

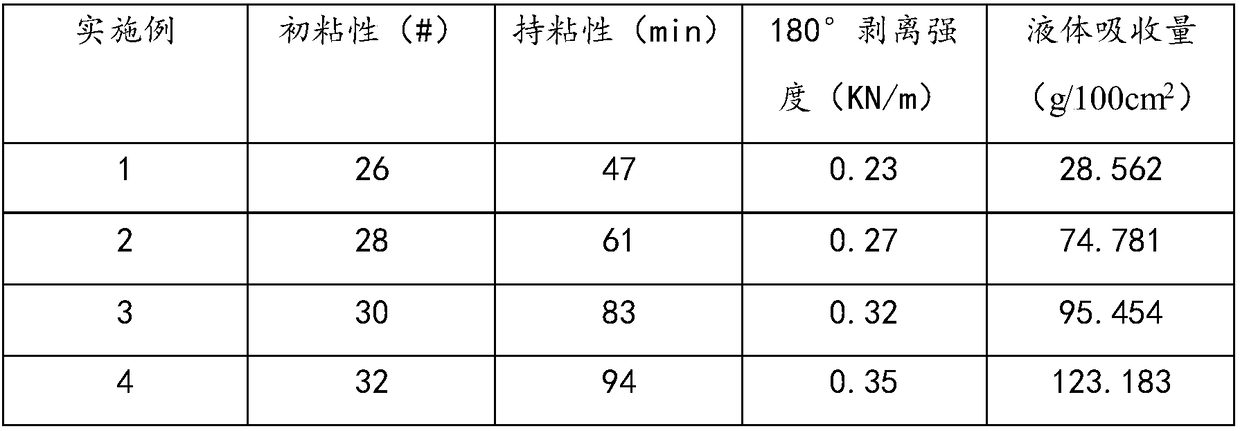

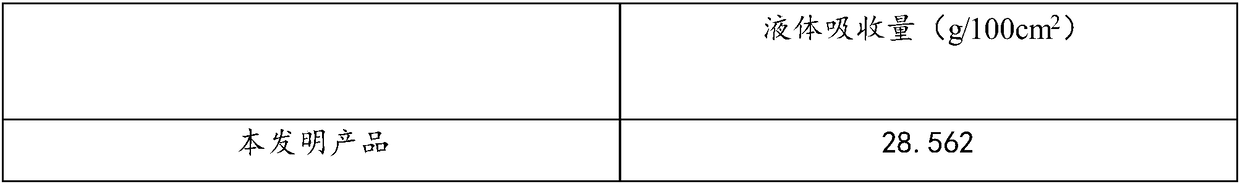

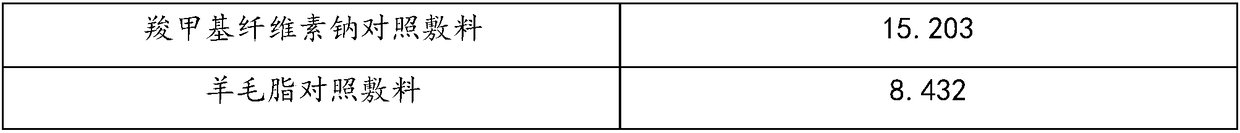

Hydrocolloid and hydrocolloid dressing and preparation method thereof

ActiveCN108339145AGood weather resistanceImprove heat resistanceAbsorbent padsBandagesCarboxymethyl celluloseWound dressing

The invention relates to the technical field of medical materials, and discloses a hydrocolloid and a hydrocolloid dressing and a preparation method thereof. The hydrocolloid includes a thermoplasticelastomer, sodium carboxymethyl cellulose, lanolin, sodium hyaluronate, and liquid paraffin. The lanolin and the sodium carboxymethyl cellulose and the like are added to the hydrocolloid to significantly increase the liquid absorbing property, so that the hydrocolloid can be applied to a highly-exudative wound dressing, and the problem that seepage of a traditional hydrocolloid dressing is easy toleak to cause damage to the surrounding skin can be avoided.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

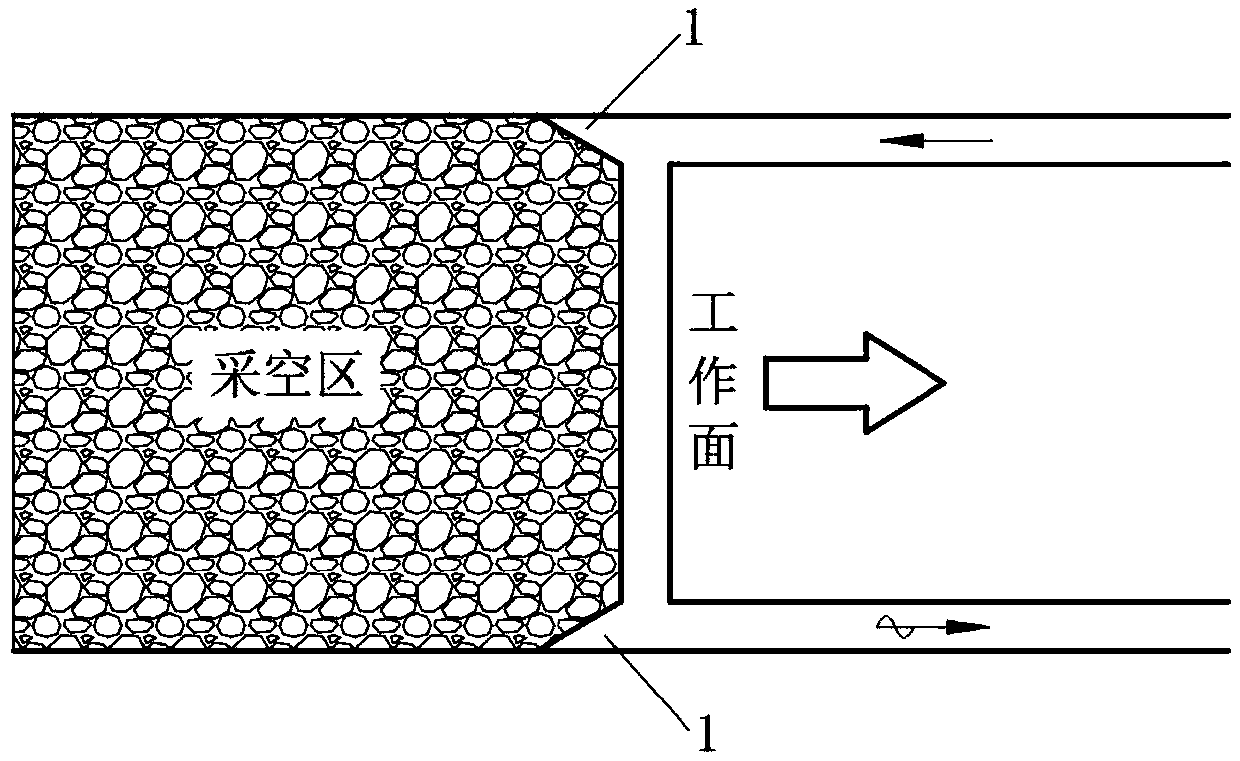

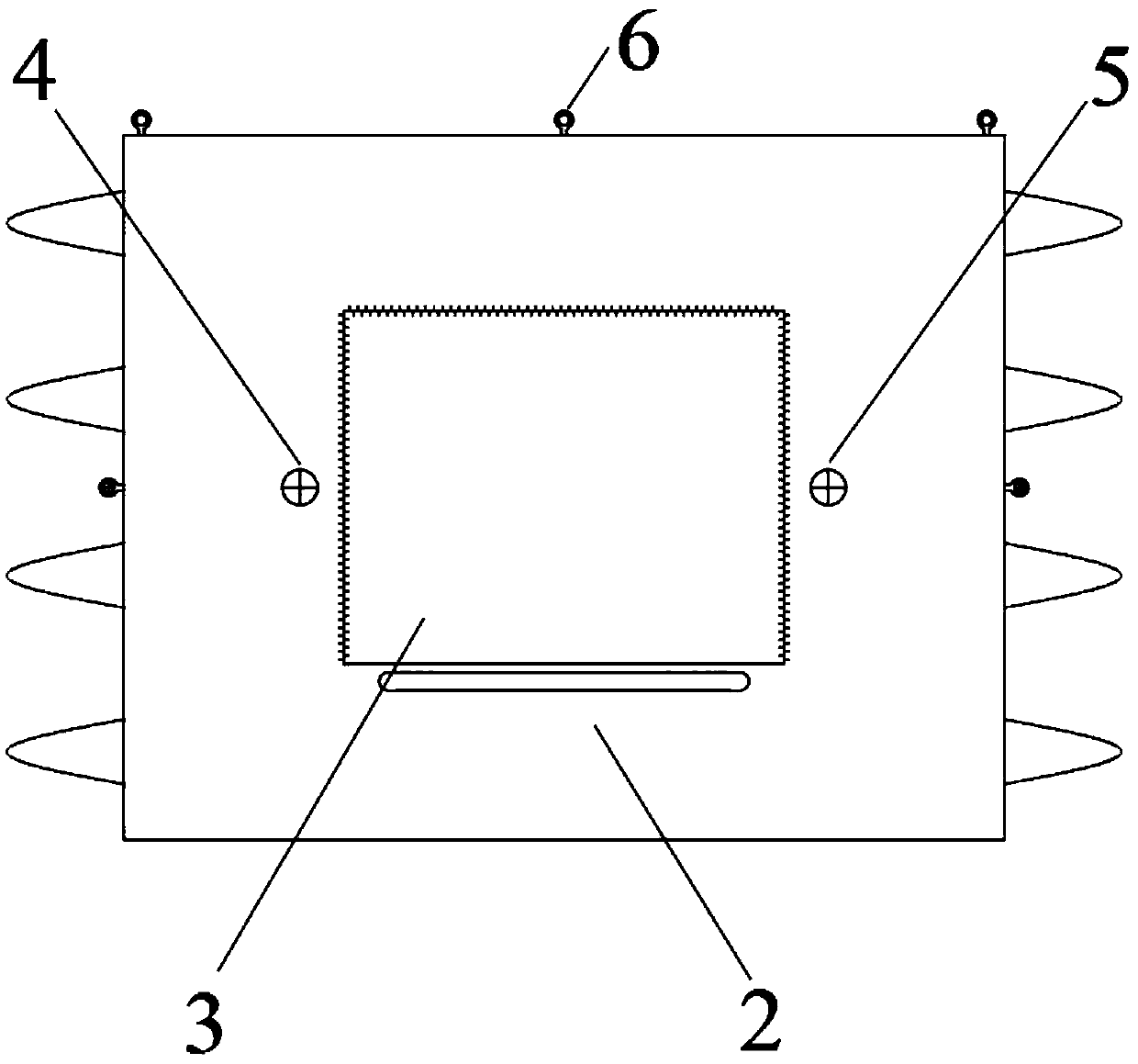

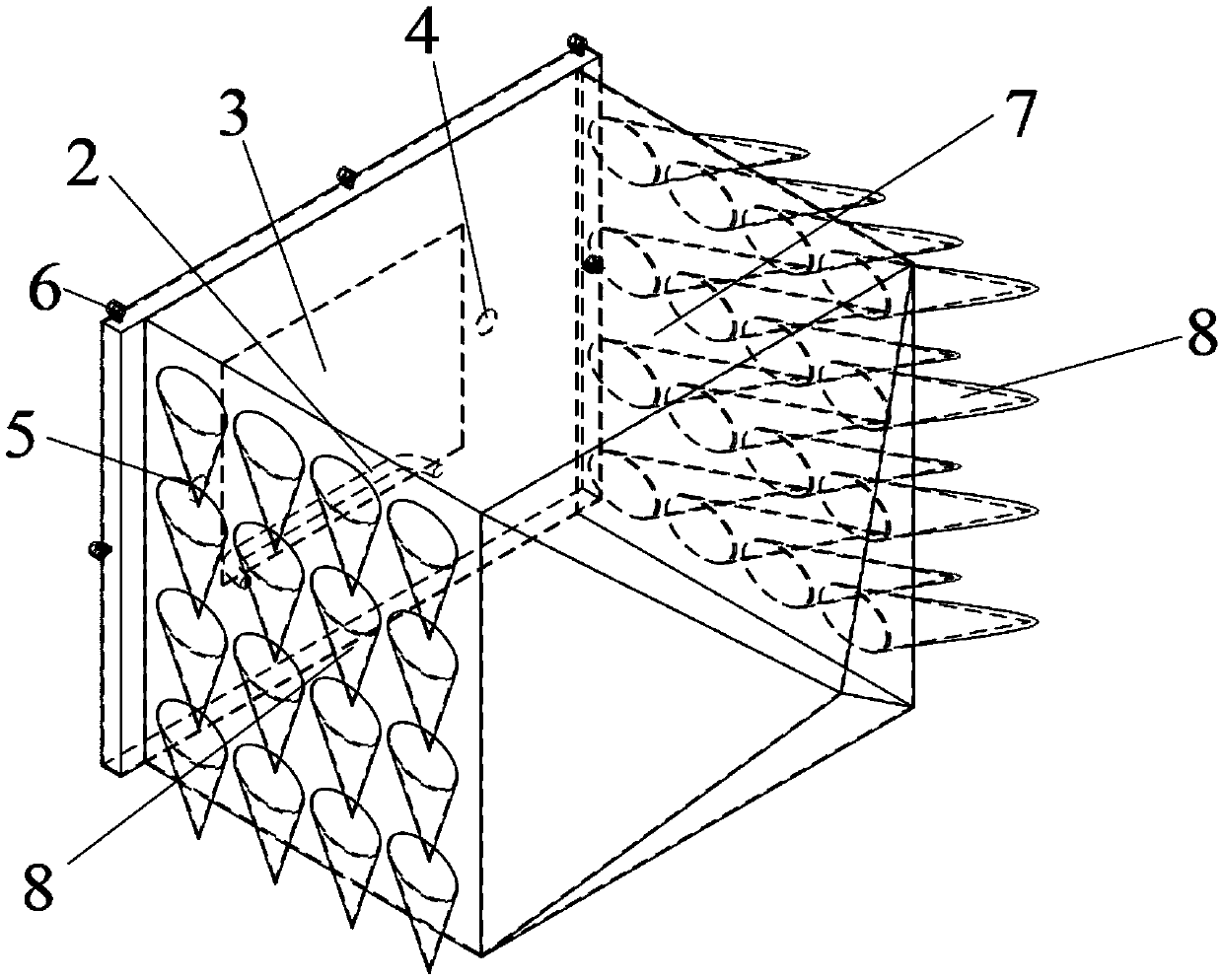

Fully mechanized mining surface end airbag type air leakage rapidly blocking device

ActiveCN109653796AGood plugging effectIncrease elasticityMining devicesDust removalSpontaneous combustionHeat resistance

The invention belongs to the technical field of coal mining and discloses a fully mechanized mining surface end airbag type air leakage rapidly blocking device. According to the fully mechanized mining surface end airbag type air leakage rapidly blocking device, an airbag is made of thermoplastic rubber (TPR), which is an SEBS-based (saturated styrene-butylene-styrene-based) modified material andhas high anti-ageing performance, so that the airbag can be plastic and high in elasticity and mean while achieve good thermal resistance, compressive deformation resistance and excellent mechanical performance; the inflating structure of the airbag is composed of two parts, namely a front main airbag and a side auxiliary airbag, wherein the main airbag can fill up a relatively regular large-areafree space, and the auxiliary airbag can fill up a narrow space complicated in structure to ensure the blocking effects of the fully mechanized mining surface end airbag type air leakage rapidly blocking device. The fully mechanized mining surface end airbag type air leakage rapidly blocking device solves the problem of spontaneous combustion of residual coal in goafs which is caused by air leakage and the upper end and the lower end of a fully mechanized mining surface.

Owner:SHANDONG UNIV OF SCI & TECH

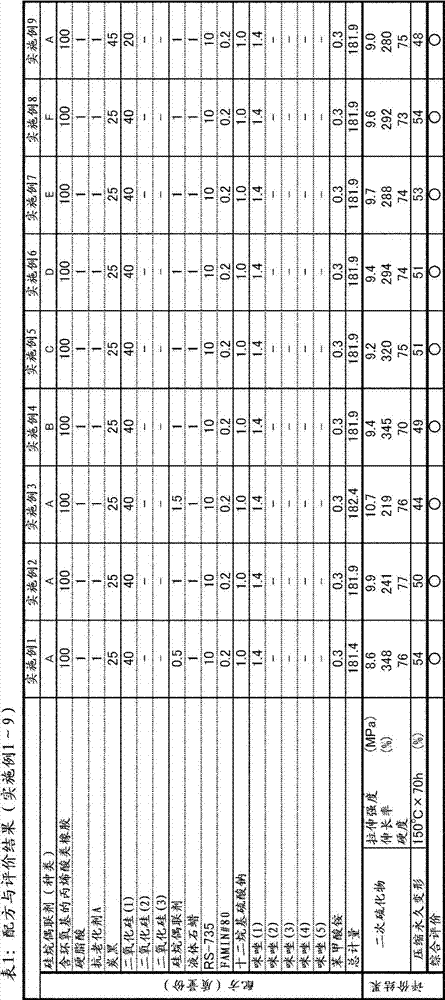

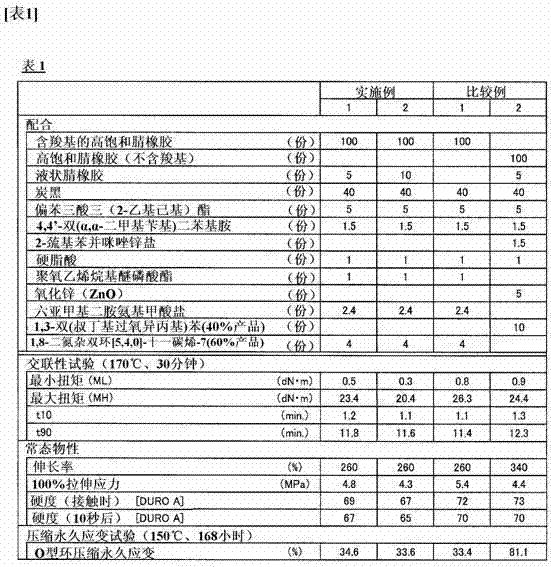

Crosslinkable rubber composition and crosslinked rubber

ActiveCN104583298AExcellent compression set resistanceOther chemical processesVehicle sealing arrangementsNitrile rubberPolymer chemistry

Provided is a crosslinkable rubber composition which contains (A) a carboxyl group-containing nitrile rubber that has an iodine number of 120 or less, (B) a polyamine crosslinking agent and (C) a specific basic crosslinking accelerator. In this connection, the basic crosslinking accelerator (C) is preferably dicyclopentyl amine or dicyclohexyl amine.

Owner:ZEON CORP

Cable protective sheath material

The invention discloses a cable protective sheath material. The cable protective sheath material is prepared from the following raw materials in parts by weight: 25 to 35 parts of modified phenol-formaldehyde resin, 25 to 35 parts of carboxyl nitrile butadiene rubber, 30 to 50 parts of chlorohydrine rubber, 0.8 to 1.4 parts of 1,1-bi-(tert-butylperoxyl)-3,3,5-trimethyl-cyclohexane, 0.2 to 0.4 part of sulfur powder, 0.5 to 0.8 part of an accelerant TMTM (Tetramethyl Thiuram Monosulfide), 1.2 to 1.5 parts of an accelerant TZ, 10 to 20 parts of magnesium oxide, 30 to 35 parts of furnace carbon black, 20 to 30 parts of sepiolite powder, 10 to 20 parts of calcium silicate, 1 to 3 parts of tri(n-octyl n-decyl) trimellitate, 4 to 5 parts of epoxy cottonseed butyl oleate, 1 to 3 parts of an anti-ageing agent DFC-34 and 0.5 to 1.5 parts of an anti-ageing agent MBZ (Mebendazole). The high-wearing-resisting and high-temperature-resisting cable protective sheath material provided by the invention has excellent high temperature resistance and wearing resistance and has good stability and long service life.

Owner:重庆三峡电线电缆科技股份有限公司

Rubber composition and use thereof

InactiveCN102844370ASelf-adhesiveImprove heat resistanceEngine sealsOther chemical processesMethacrylatePolymer science

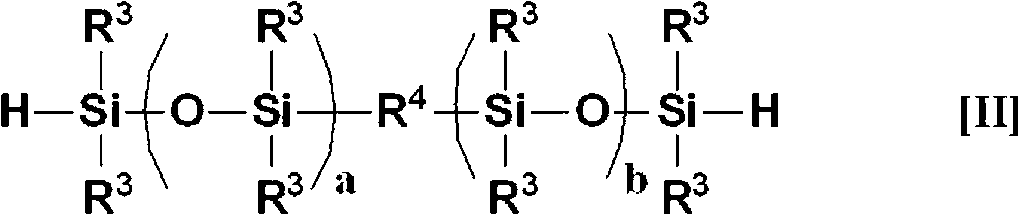

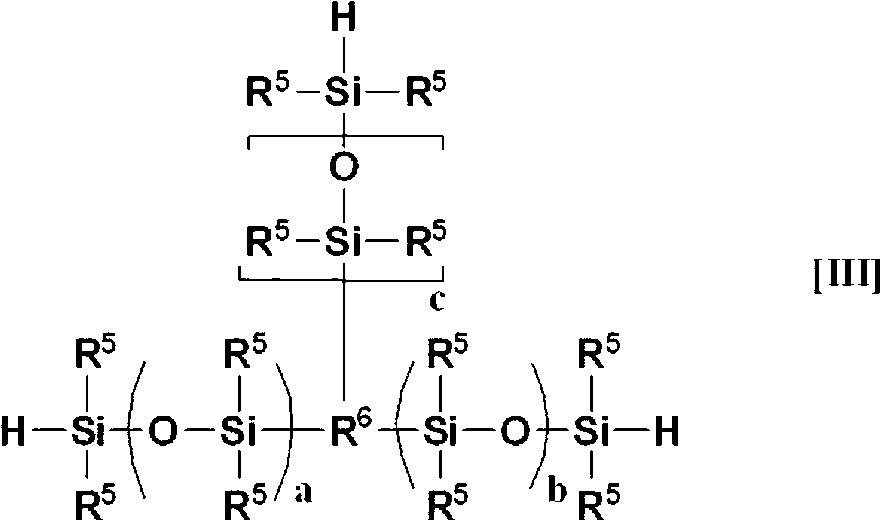

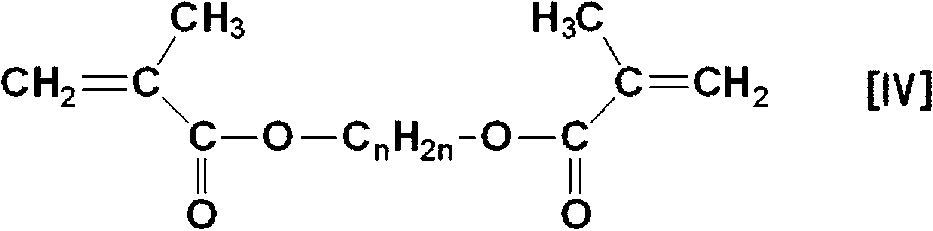

Provided is a rubber composition, which has excellent heat resistance, acid resistance, gas permeability resistance, and high-speed moldability, has low hardness and low counterforce, has excellent high-temperature compression set, and does not adhere to the metal of molds, etc. but is self-adhering with respect to organic resins. The rubber composition comprises: a predetermined ethylene / a-olefin / non-conjugated polyene copolymer [A]; a predetermined SiH group-containing compound [B-1] having two SiH groups per molecule and / or a predetermined SiH group-containing compound [B-2] having three SiH groups per molecule; and a predetermined methacrylic acid ester compound [C].

Owner:NOK CORP

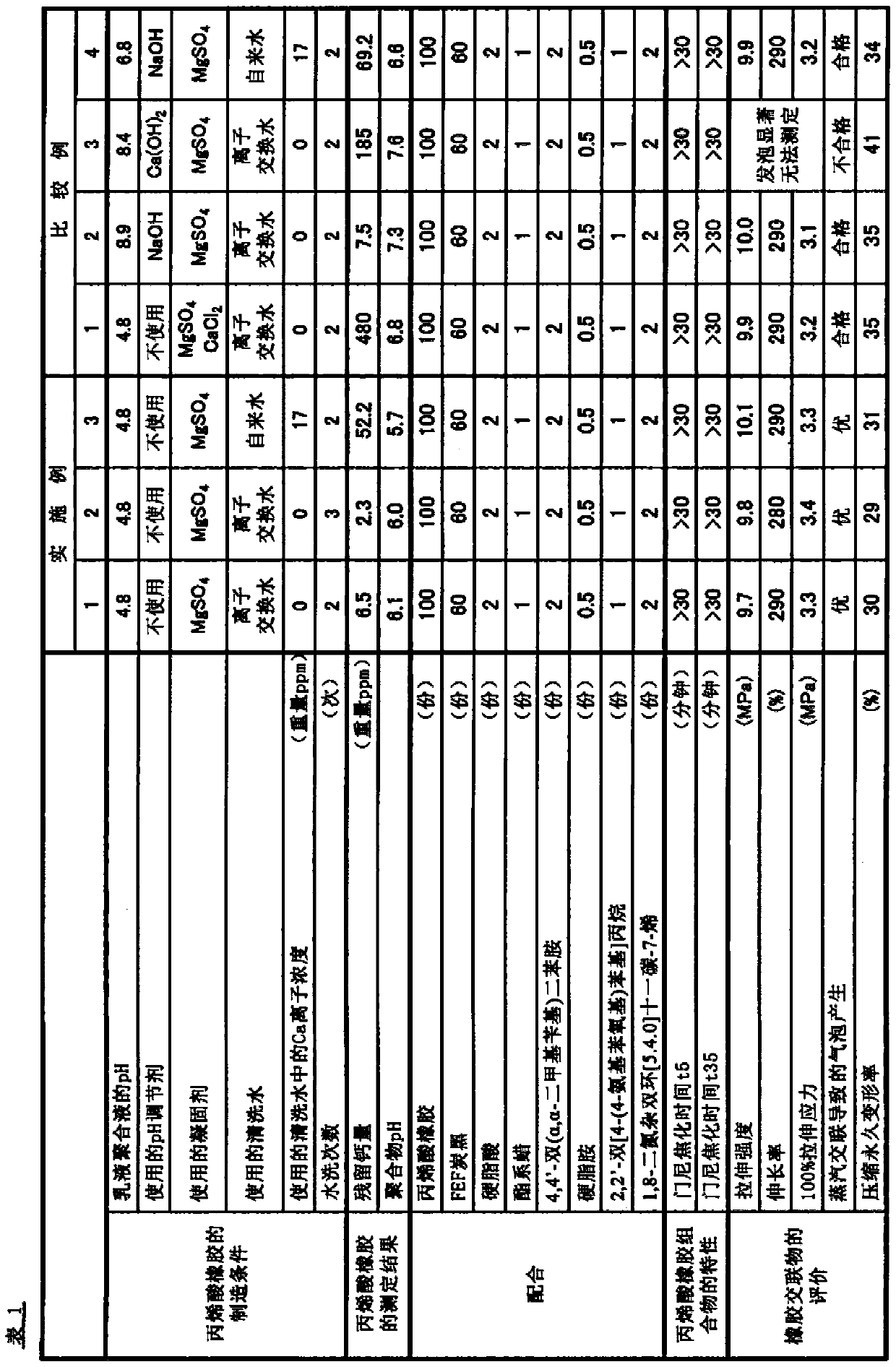

Acrylic rubber

InactiveCN110291118AGood physical propertiesExcellent compression set resistancePolymer scienceAcrylic rubber

Provided is an acrylic rubber which has a residual calcium content of 60 weight ppm or less and has a polymer pH of 7.0 or less, the acrylic rubber preferably containing carboxyl groups.

Owner:ZEON CORP

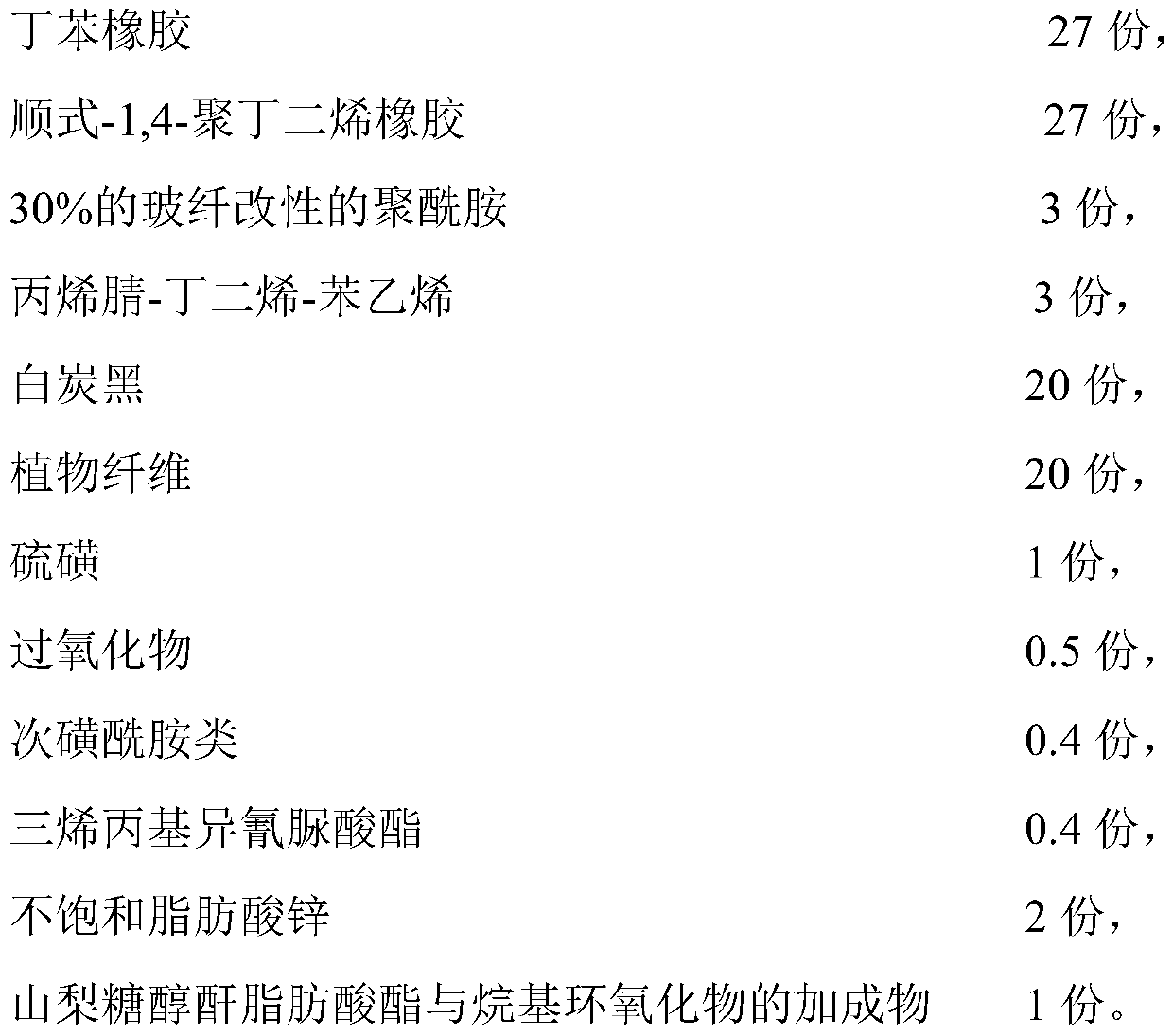

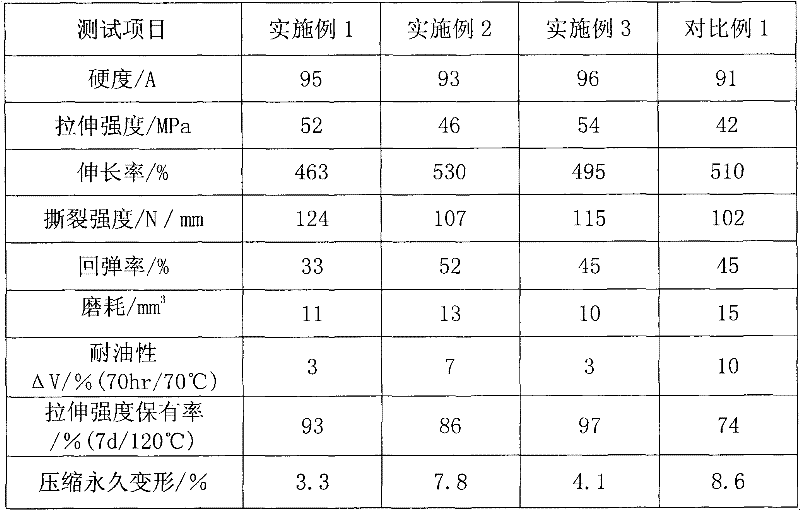

Plastic and rubber composite material and preparation method thereof

The invention discloses a plastic and rubber composite material which comprises the following components in parts by weight: 50-70 parts of a rubber plastic material, 25-45 parts of a filling agent, 1-5 parts of a vulcanizing agent, 0.1-1 part of an accelerant, 1-5 parts of an auxiliary agent and 1-6 parts of an active agent. An addition product of a natural surfactant sorbitan fatty acid ester with a compatibilization effect and an alkyl epoxide is added in an incompatible rubber / plastic polymer blend, and the addition product is also a dispersing agent, a phase dispersion-crosslinking synergistic effect is achieved, the dosage of the vulcanizing agent, the accelerant and the processing aid can be reduced by about 20% or above, the vulcanized composite material has good elasticity, compression deformation resistance, aging resistance and wear resistance, the cost is reduced and the competitive capacity is improved.

Owner:广东志达行新材料有限公司

High-toughness polyvinyl chloride tubular product

The invention discloses a high-toughness polyvinyl chloride pipe, the raw materials of which include by weight: 35-42 parts of polyvinyl chloride, 10-18 parts of polyurethane rubber, 20-30 parts of butyl rubber, and 20-30 parts of filling and reinforcing agent 1-2 parts of epoxidized soybean oil, 1-2 parts of magnesium stearate, 1-2 parts of triphenyl phosphate, 1.5-3 parts of compatibilizer, and 2-4 parts of crosslinking agent. The high-toughness polyvinyl chloride pipe provided by the invention has good toughness, high pressure resistance, high flexural strength, and excellent high-temperature stability.

Owner:ANHUI LANTONG TECH CO LTD

Casting polyurethane elastomer as well as preparation method and application thereof

ActiveCN101982479BImprove mechanical propertiesImprove heat resistanceEngine sealsShaft and bearingsPolyurethane elastomerPolyol

The invention discloses a casting polyurethane elastomer as well as a preparation method and an application thereof. The casting material is composed of a component A and a component B with a mass ratio of 100 / (8-12), wherein the component A is composed of TODI, macromolecule polyalcohol and a catalyst and the component B is composed of a diamine chain extender and a three-functionality micromolecule alcohol chain extender. The TODI and the macromolecule polyalcohol are added to a reactor to be stirred and mixed; then, a reaction is carried out on the mixture for 1.5-2.5 hours at a temperature of 75-95 DEG C to obtain a prepolymer; the prepolymer is heated to 70-90 DEG C, the chain extender component is heated to 110-130 DEG C, the prepolymer and the chain extender component are mixed, stirred, degassed and cast into a mould with a temperature of 90-120 DEG C; the mould is demoulded after 20-40 minutes of curing at a temperature of 90-120 DEG C; and the demoulded product is cured for 16-24 hours at a temperature of 90-110 DEG C. The elastomer is suitable to serve as a sealing element for a medium high-pressure hydraulic system, a sealing element for a pneumatic system and high-performance roller wheels and rubber covered rollers.

Owner:LIMING RES INST OF CHEM IND

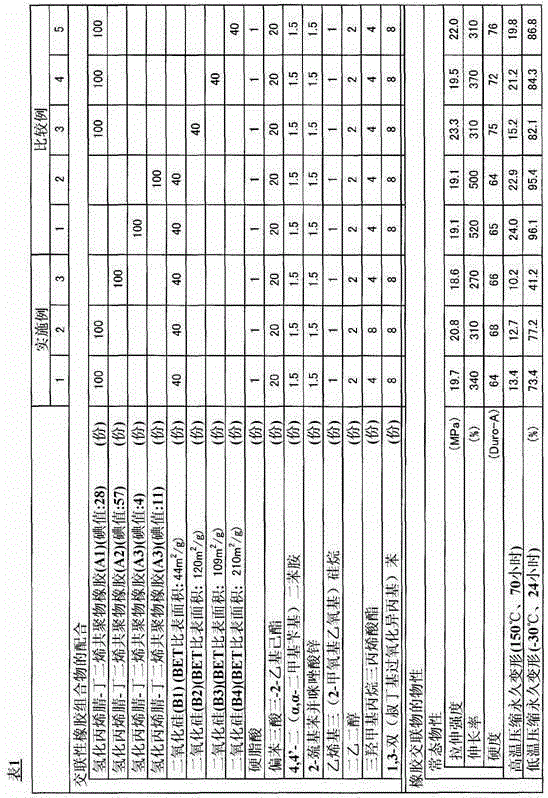

Nitrile copolymer rubber composition, crosslinkable rubber composition, and crosslinked rubber

The invention provides a nitrile copolymer rubber composition containing a nitrile copolymer rubber (A) having an iodine value of 20-80, and white carbon (B) having a specific surface area of 20-48 m2 / g. The invention provides a nitrile copolymer rubber composition that makes it possible to provide a crosslinked rubber having good normal physical properties as well as excellent compression set resistance under high-temperature and low-temperature conditions.

Owner:ZEON CORP

Medical rubber

InactiveUS20140045999A1Improve cleanlinessExcellent compression set resistanceSurgeryPharmaceutical containersPolymer scienceCompression set

The present invention provides a medical rubber having high cleanliness and excellent compression set resistance. The present invention relates to a medical rubber including an ethylene-propylene-diene rubber crosslinked by an organic peroxide having no aromatic ring structure.

Owner:SUMITOMO RUBBER IND LTD

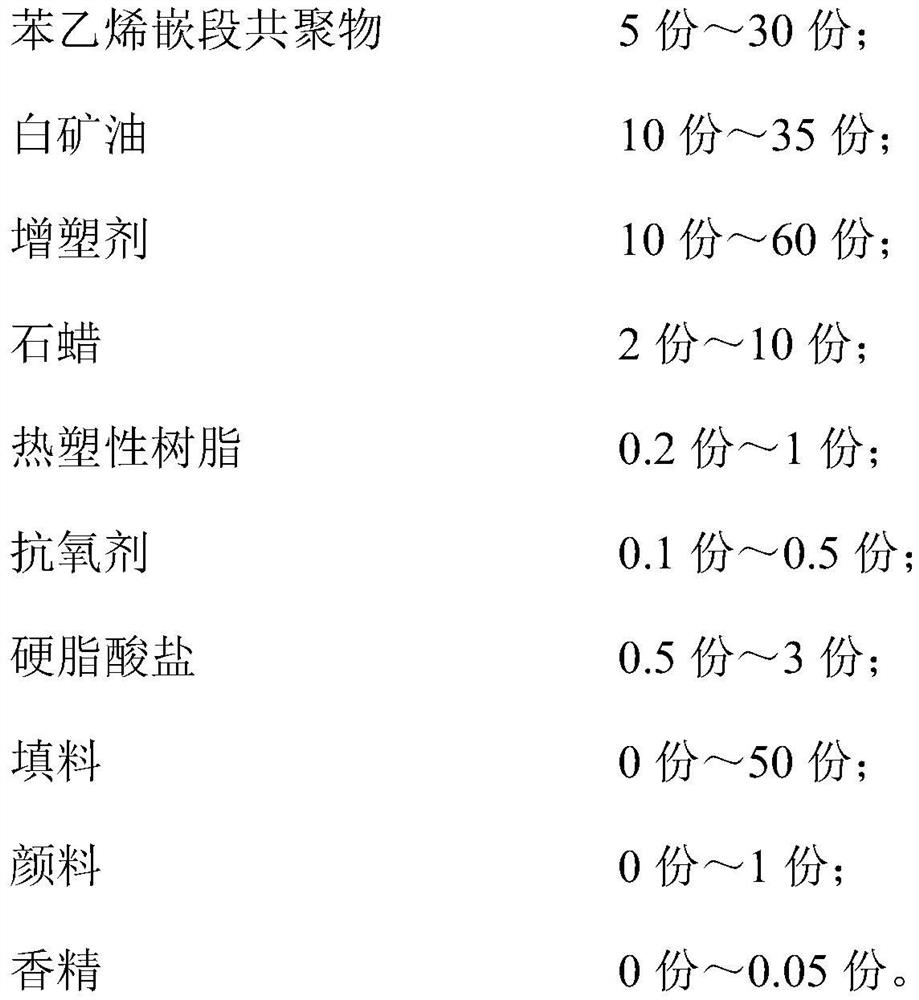

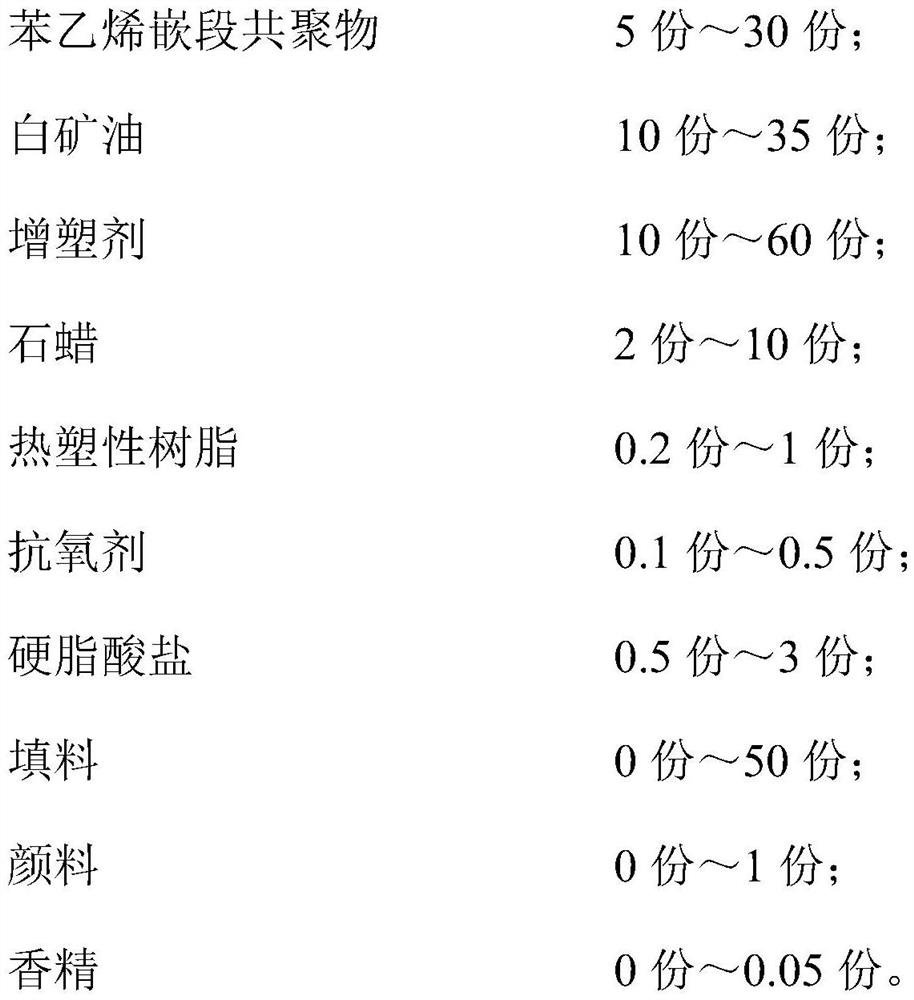

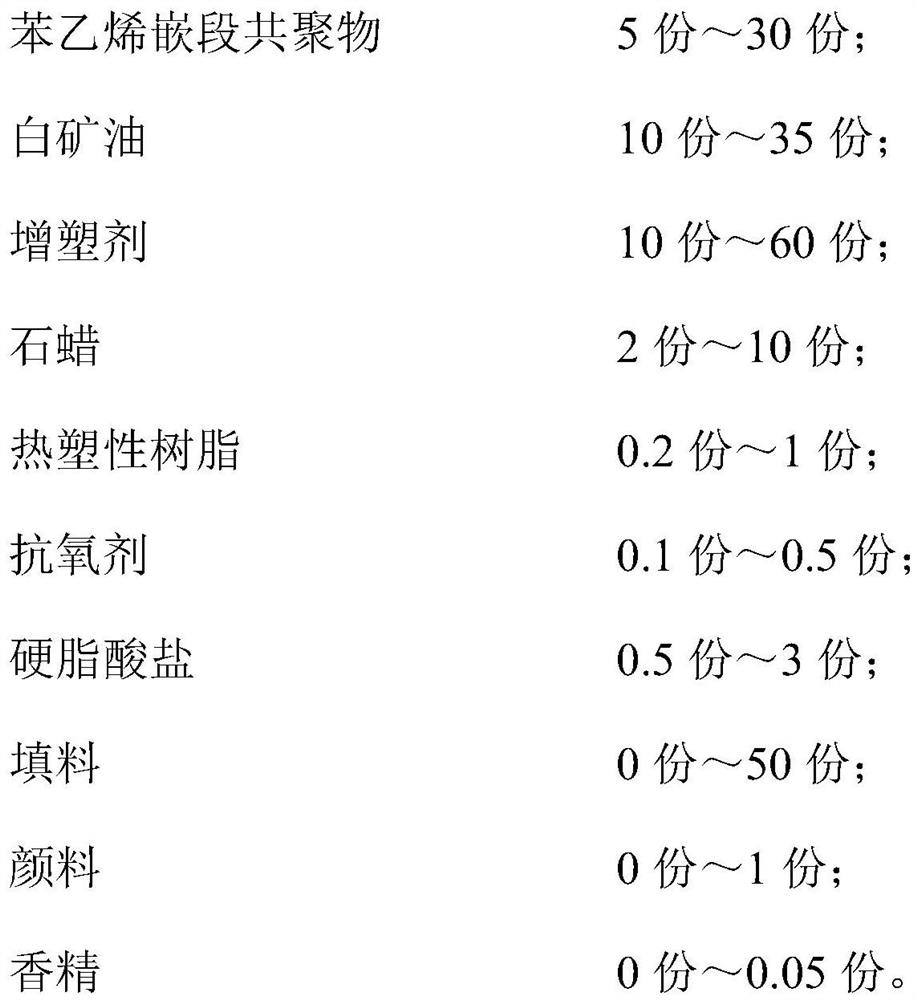

Thermoplastic elastomer composition as well as preparation method and application thereof

The invention relates to a thermoplastic elastomer composition as well as a preparation method and application thereof. The thermoplastic elastomer composition is prepared from the following raw materials in parts by weight: 5 parts to 30 parts of a styrene block copolymer, 10 parts to 35 parts of white mineral oil, and 10 parts to 60 parts of a plasticizer, wherein the content of polystyrene in the styrene block copolymer is 15%-45%; the number average molecular weight of the styrene block copolymer is 50000 g / mol to 300000 g / mol; and the kinematic viscosity of the white mineral oil at the temperature of 40 DEG C is 5 mPa*s to 180 mPa*s. The thermoplastic elastomer composition is soft in hand feeling, dry and comfortable in surface, not easy to mildew, stain-resistant, not easy to dry and solidify, good in rebound resilience and strong in bare-handed plasticity, can be stored for a long time, can be recycled and has a wide application prospect.

Owner:盛嘉伦橡塑(河源)有限公司 +1

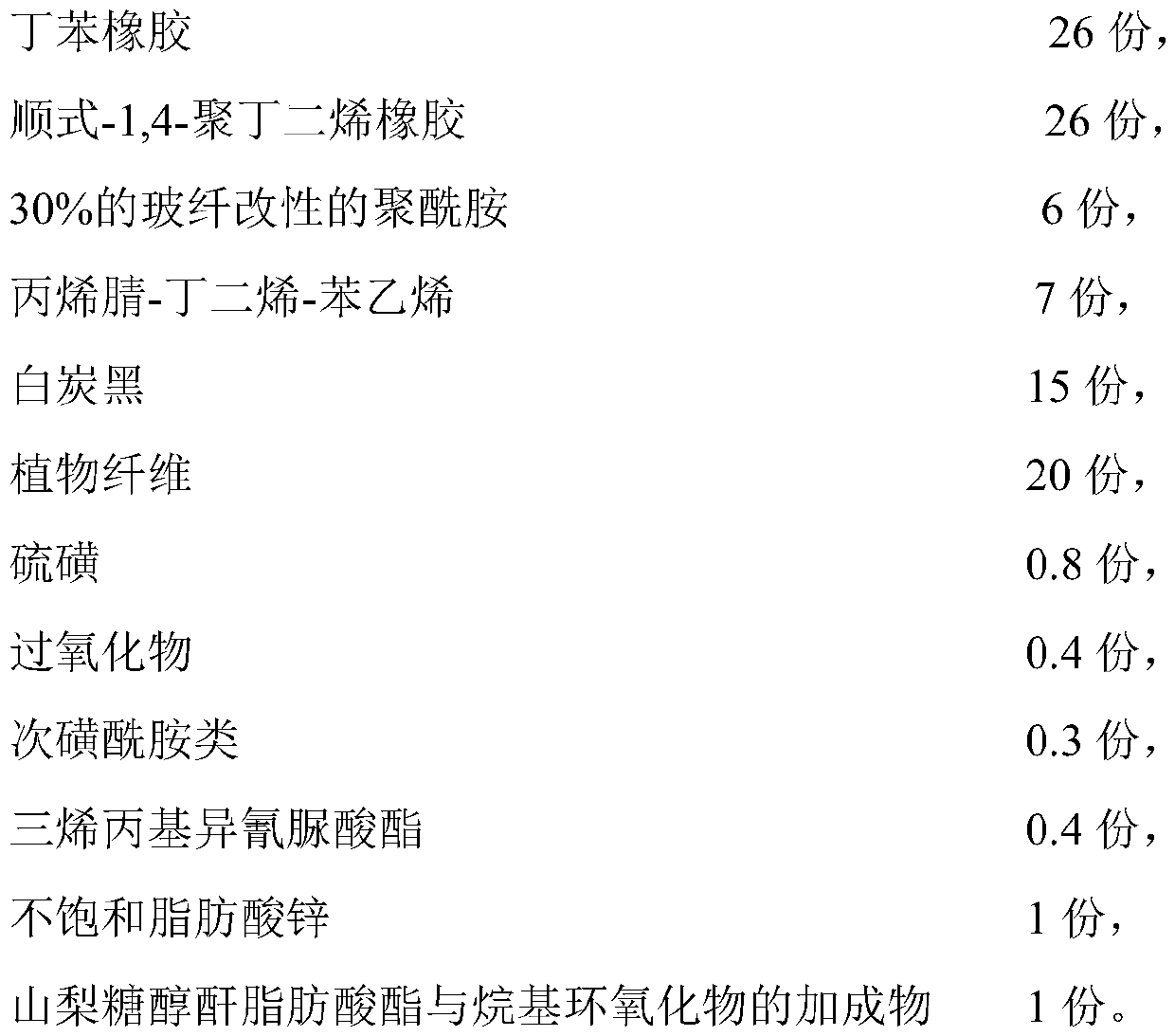

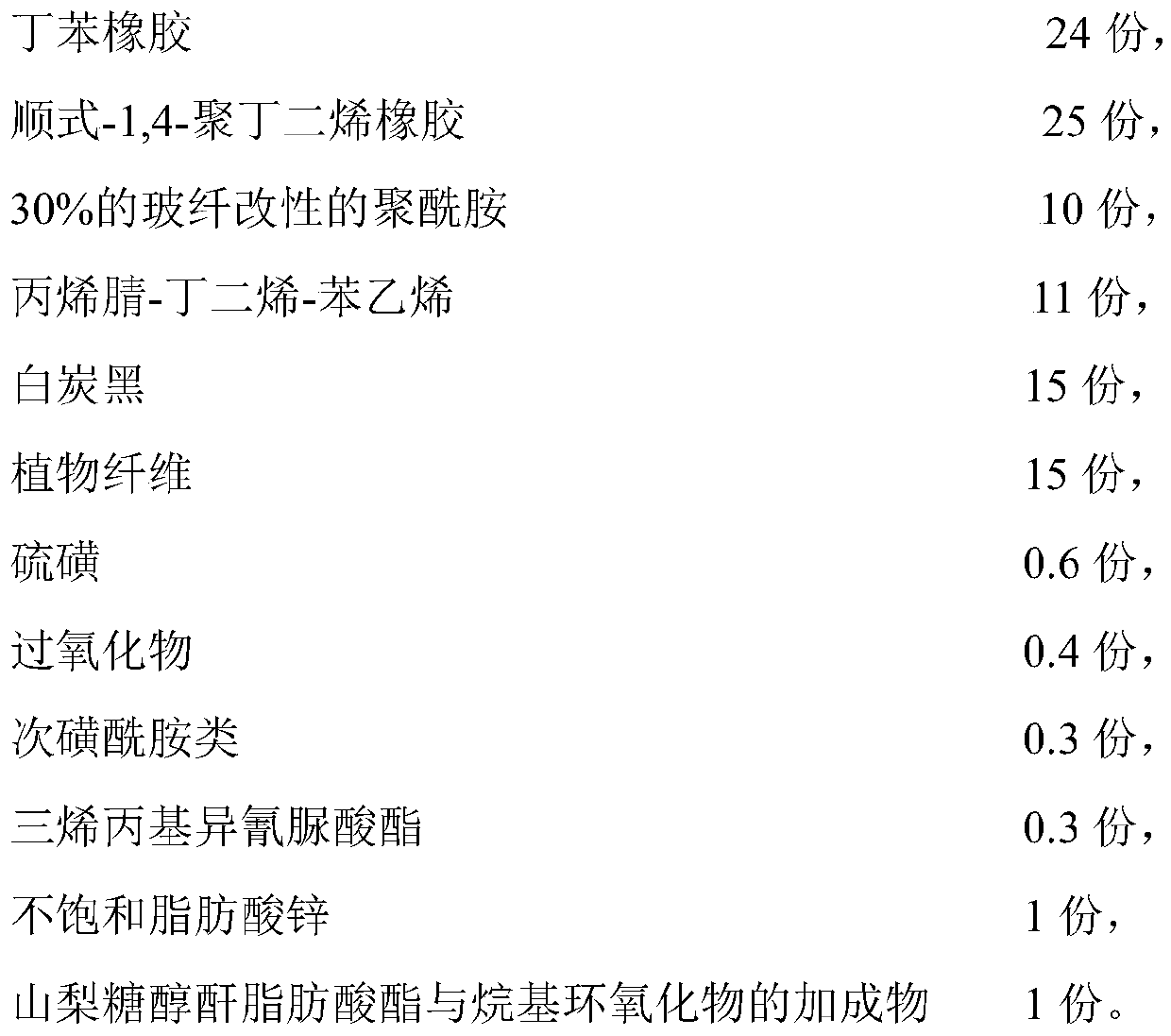

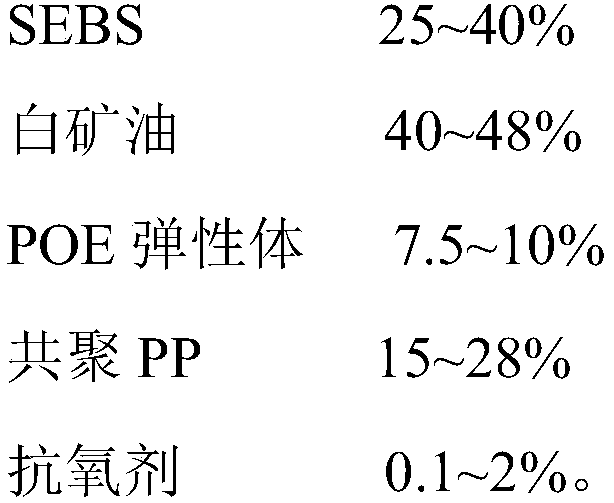

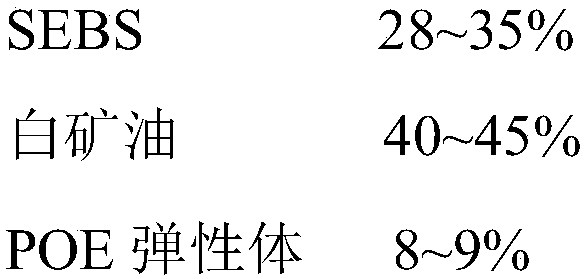

Novel rubber material of run-flat tire

InactiveCN109233183AHigh impact strengthHigh elongation at breakSpecial tyresElastomerRubber material

The invention relates to the field of rubber materials, in particular to a novel rubber material of a run-flat tire. The novel rubber material is prepared from the following raw materials by weight percent: 25 to 40 percent of SEBS, 40 to 48 percent of white mineral oil, 7.5 to 10 percent of POE elastomer, 15 to 28 percent of copolymer PP, and 0.1 to 2 percent of antioxidant. The invention provides the novel rubber material of the run-flat tire which is resistant to high temperature and aging.

Owner:东莞市塑高塑化科技有限公司

Nitrile rubber composition, and rubber cross-linked product

Provided is a nitrile rubber composition which contains: a carboxyl group-containing nitrile rubber (A); liquid nitrile rubber (B); and a polyamine cross-linking agent (C). The iodine value of the carboxyl group-containing nitrile rubber (A) in this nitrile rubber composition is preferably 120 or less. Furthermore, the carboxyl group-containing nitrile rubber (A) in this nitrile rubber composition preferably contains: 5-60 mass% of an α,β-ethylenically unsaturated nitrile monomer unit; 0.1-20 mass% of a carboxyl group-containing monomer unit; and 15-94.9 mass% of a conjugated diene monomer unit.

Owner:ZEON CORP

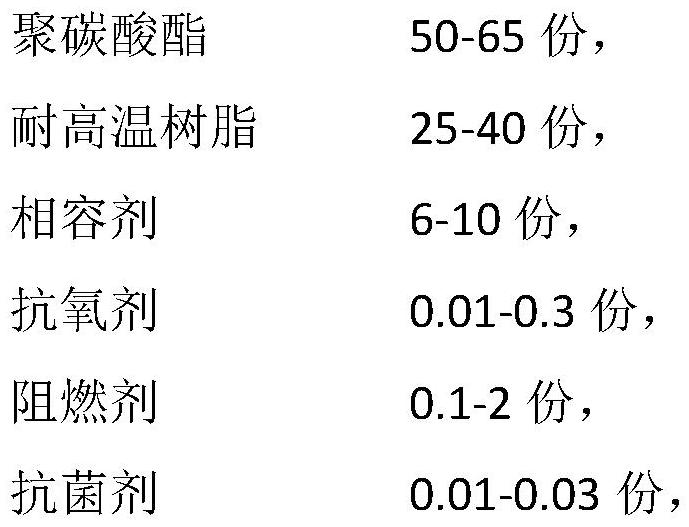

Protective eyeshade with cleaning-resistant, high-temperature-resistant, damp-heat-resistant and sterilizing composition

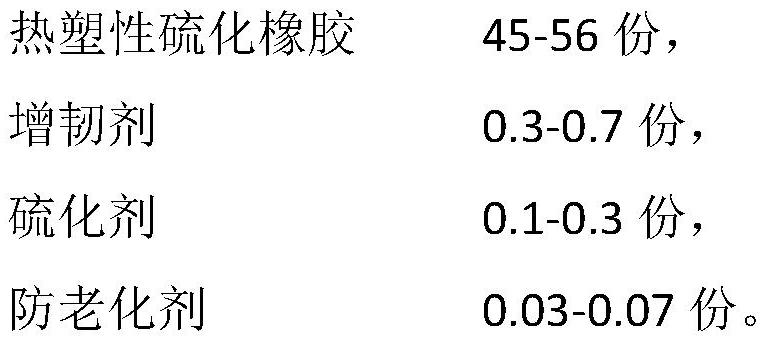

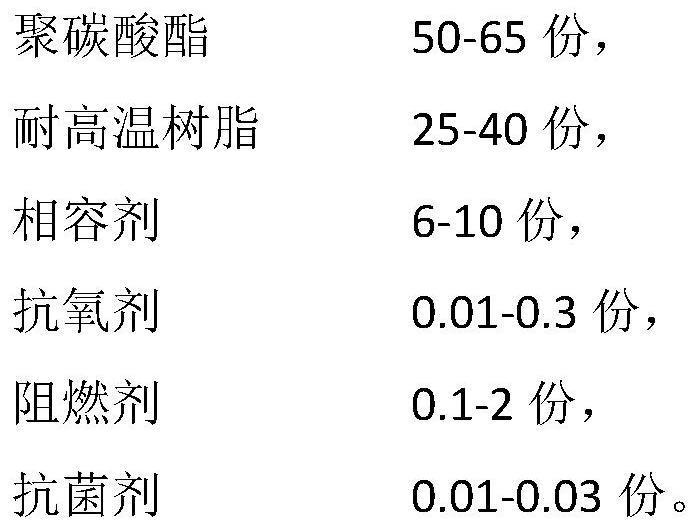

The invention provides a protective eyeshade with a cleaning-resistant, high-temperature-resistant, damp-heat-resistant and sterilizing composition. The protective eyeshade comprises a protective lens, an eyeshade frame and a fixing part. The protective lens is embedded into the eyeshade frame, the eyeshade frame and a woven tape are fixed together through the fixing part, the protective lens is composed of a modified polycarbonate composition, and the modified polycarbonate composition comprises polycarbonate, high-temperature-resistant resin, a compatilizer, an antioxidant, a flame retardantand an antibacterial agent. The eyeshade frame and the fixing part are both composed of a modified thermoplastic vulcanized rubber composition. The modified thermoplastic vulcanized rubber composition comprises thermoplastic vulcanized rubber, a flexibilizer, a vulcanizing agent and an anti-aging agent. The protective eyeshade is prepared from the modified polycarbonate composition and the modified thermoplastic vulcanized rubber composition so that the protective eyeshade has the characteristics of high temperature resistance, cleaning resistance, good impact resistance, high strength, goodantibacterial property, good flame retardant property, aging resistance and the like, has good elasticity and compression deformation resistance and can be repeatedly used.

Owner:SHANGHAI JIABO CLOTHING SCI & TECH

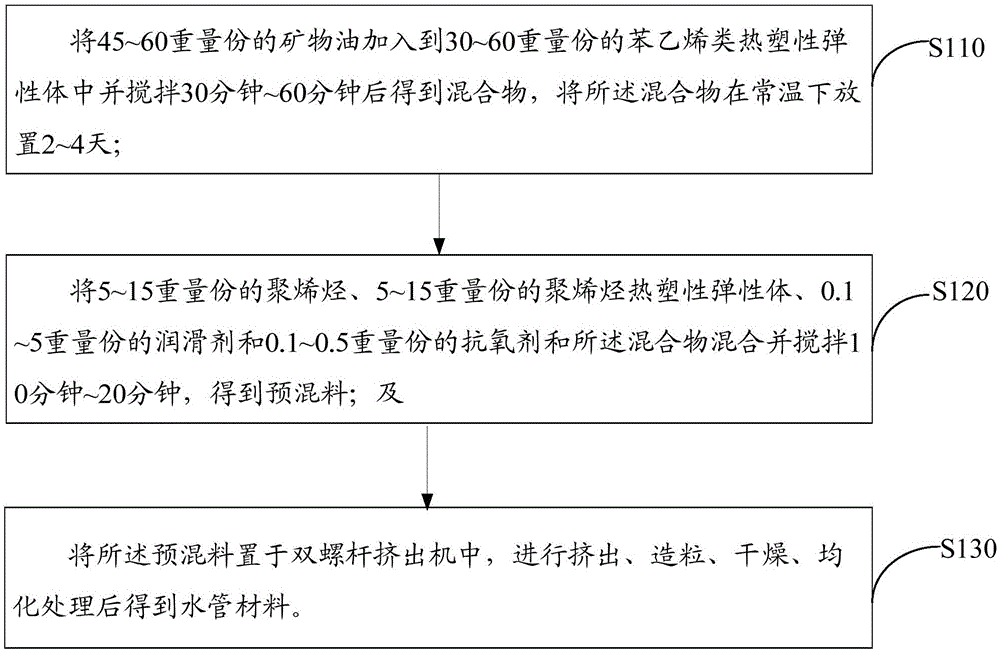

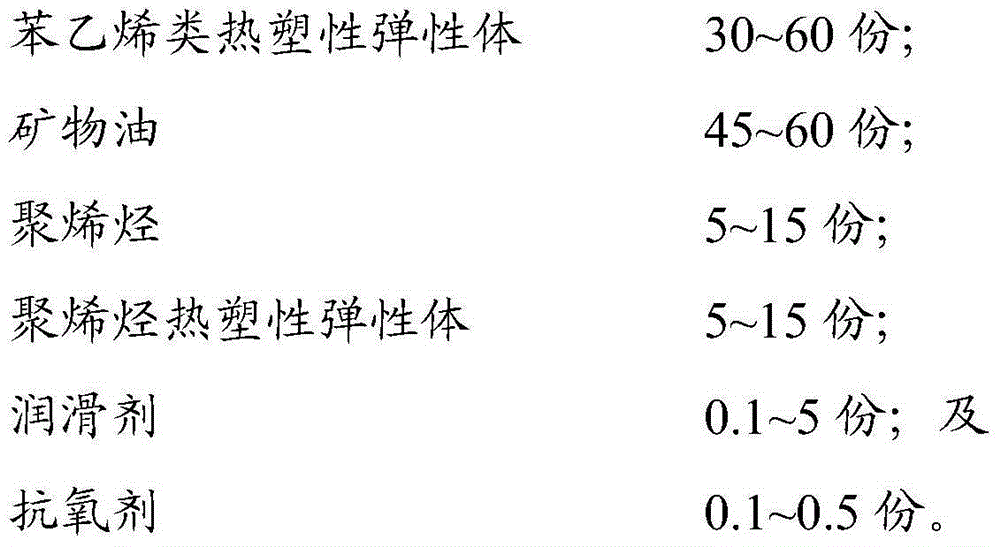

Plastic water pipe material and preparation method thereof

ActiveCN103772834BHigh tear strengthHigh tensile strengthRigid pipesPolyolefinThermoplastic elastomer

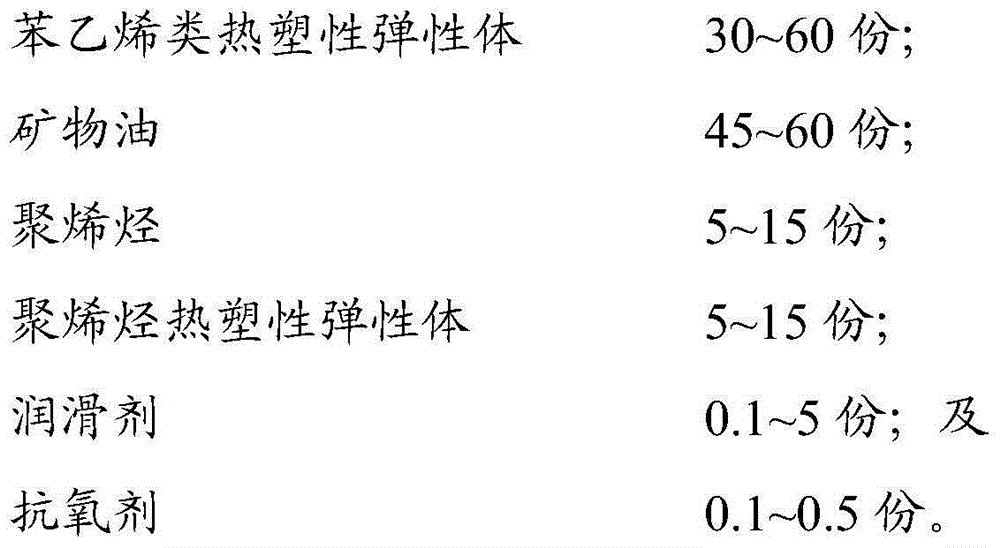

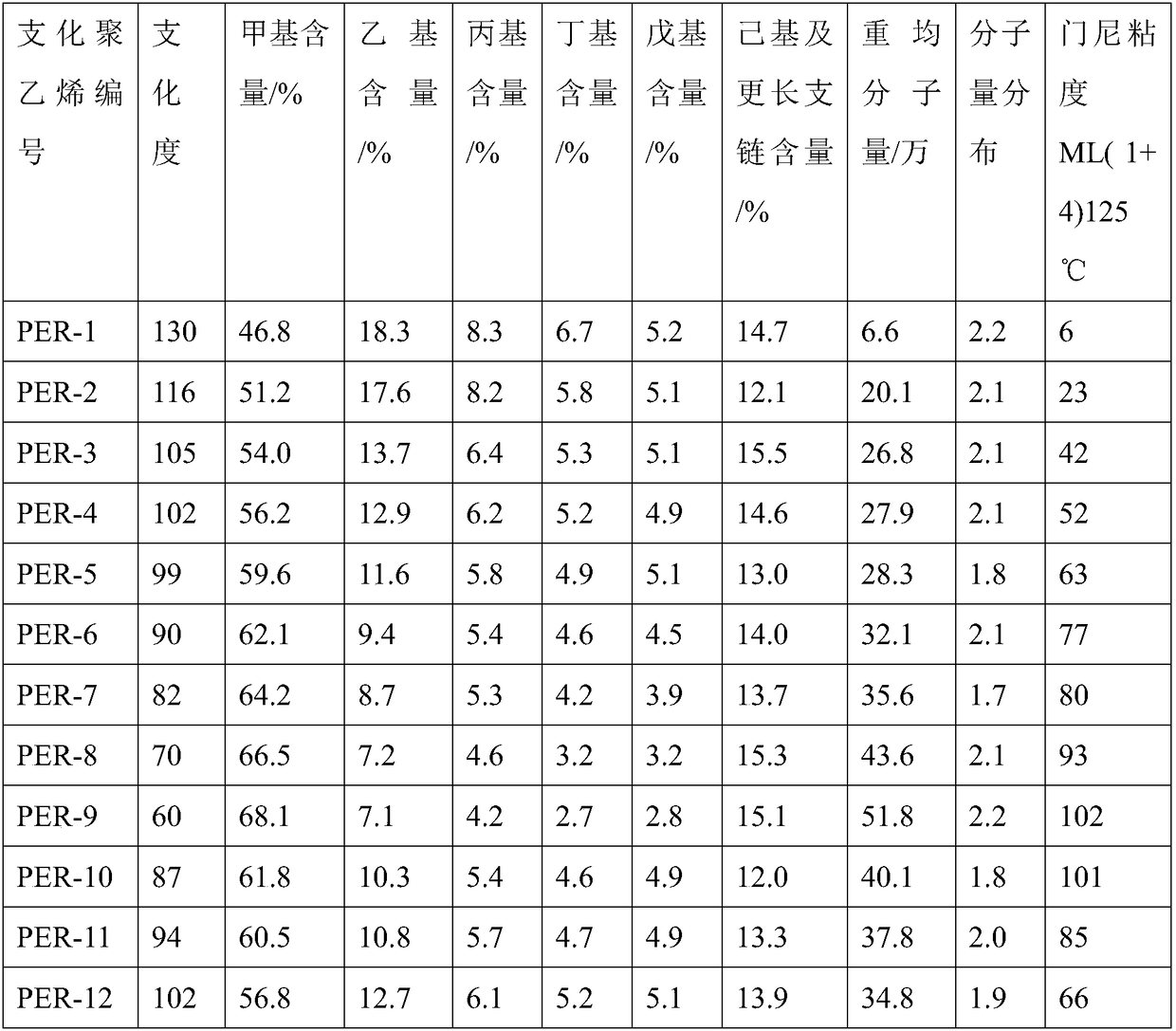

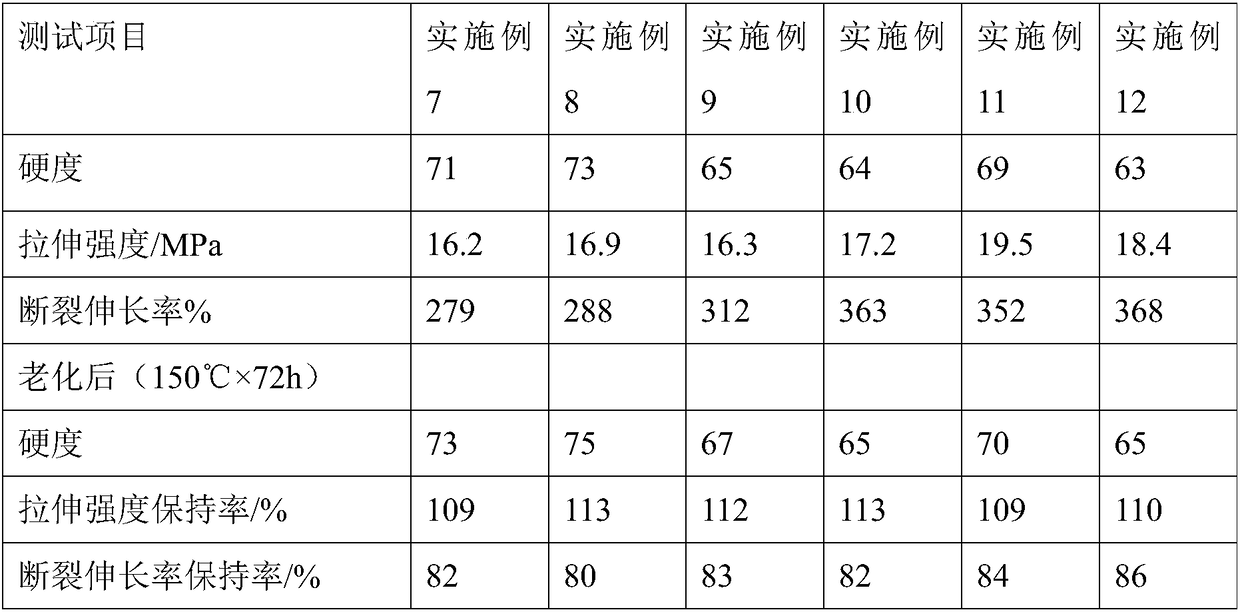

The invention relates to a plastic water pipe material. The plastic water pipe material comprises the following components in parts by weight: 30-60 parts of styrene thermoplastic elastomer, 45-60 parts of mineral oil, 5-15 parts of polyolefin, 5-15 parts of polyolefin thermoplastic elastomer, 0.1-5 parts of lubricant, and 0.1-0.5 part of antioxidant. The invention also provides a preparation method for the plastic water pipe material. The styrene thermoplastic elastomer is taken as base material, and is fully mixed with the polyolefin thermoplastic elastomer and other raw materials so as to obtain the plastic water pipe material, the styrene thermoplastic elastomer has good weather fastness, heat resistance and compression deformation resistance, the polyolefin thermoplastic elastomer has narrow relative molecular mass distribution and uniform short branched chain distribution, and the styrene thermoplastic elastomer and polyolefin thermoplastic elastomer are mixed with other materials, so that the product has good plasticity and is stably extruded, the tear strength, tensile strength and elongation at break of the plastic water pipe material are improved, and the plastic water pipe material has excellent elasticity.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

Rubber composition, processing method, application and method for producing high-strength rubber product

ActiveCN108314852AImprove mechanical propertiesExcellent compression set resistanceConveyorsGlovesCross-linkPolymer science

The invention discloses a rubber composition, a processing method, a product adopting the rubber composition and a production method. The rubber composition comprises a rubber matrix and necessary components, wherein the rubber matrix comprises the following components: branched polyethylene with the content a being greater than 0 and smaller than or equal to 100 parts, and ethyene-propylene rubber and ethylene propylene terpolymer with the content b being greater than or equal to 0 and smaller than 100 parts; the necessary components comprise the following components: 1 to 10 parts of a cross-linking agent, and 5 to 50 unsaturated carboxylic metal salt. The rubber composition has the benefits that the rubber composition can be applied to rubber products, such as insulating gloves, heat resistance conveying belts and rubber tubes, and the rubber products have excellent mechanical property.

Owner:HANGZHOU XINGLU TECH CO LTD +1

Highly saturated copolymer rubber containing nitrile group

ActiveCN102300882BGood physical propertiesExcellent compression set resistancePolymer scienceDicarboxylic acid

The invention provides highly saturated copolymer rubber containing nitrile groups, which has 5-60% by weight α, β-ethylenically unsaturated nitrile monomer unit (a), 0.1-20% by weight α , β-ethylenically unsaturated dicarboxylic acid monoester monomer unit (b), 11-50% by weight of an alkoxyalkyl group having 2-8 carbon atoms (meth)acrylic acid alkoxyalkyl ester The monomer unit (c), and 20-83.9% by weight of the conjugated diene monomer unit (d), and at least a part of the conjugated diene monomer unit (d) is hydrogenated.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com