Nitrile copolymer rubber composition, crosslinkable rubber composition, and crosslinked rubber

A technology of rubber composition and nitrile copolymer, applied in the field of cross-linkable rubber composition and rubber cross-linked product, can solve the problem of insufficient compression set resistance, and achieve the effect of excellent compression set resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

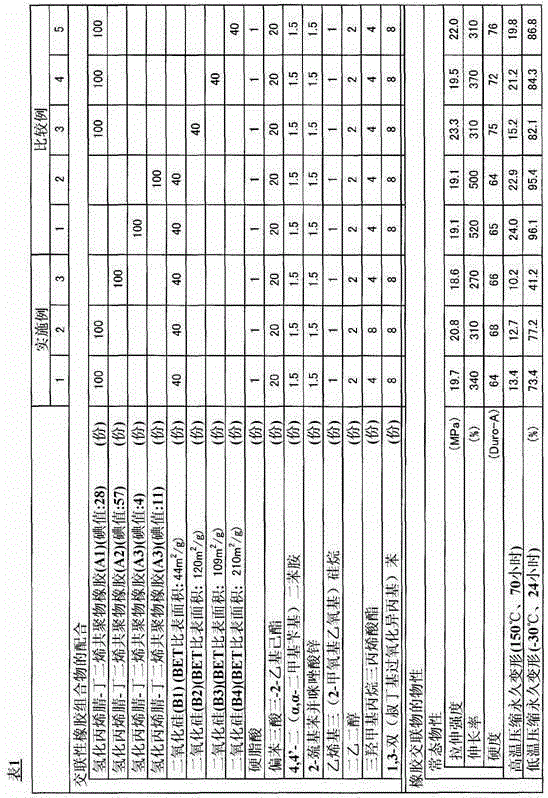

Embodiment 1

[0093] To 100 parts of hydrogenated acrylonitrile-butadiene copolymer rubber (A1) (trade name "Zetpol 2020", manufactured by ZEON CORPORATION, acrylonitrile content: 36% by weight, iodine value: 28) was added hardener using a Banbury mixer. 1 part of fatty acid, silica (B1) (trade name "Nipsil EL", manufactured by Tosoh Silica Corporation, BET specific surface area: 44m 2 / g) 40 parts, Tris-2-ethylhexyl trimellitate (trade name "Adeka サイザー C8", manufactured by ADEKA CORPORATION, plasticizer) 20 parts, 4,4'-bis(α,α-dimethyl Benzyl benzyl) diphenylamine (trade name "NocracCD", Ouchi Shinko Chemical Co., Ltd., antioxidant) 1.5 parts, 2-mercaptobenzimidazole zinc salt (trade name "NocracMBZ", Ouchi Shinko Chemical Co., Ltd., Antiaging agent) 1.5 parts, vinyl tris (2-methoxyethoxy) silane (trade name "Dynasilane VTMOEO", manufactured by Evonik Degussa GmbH, silane coupling agent (C) (vinyl silane coupling agent)) 1 part, 2 parts of diethylene glycol and 4 parts of trimethylolpropa...

Embodiment 2

[0096] Except changing the blending amount of trimethylolpropane triacrylate as a crosslinking auxiliary agent (E) from 4 parts to 8 parts, the same operation as in Example 1 was carried out to prepare a crosslinkable rubber composition and carry out Same rating. The results are shown in Table 1.

Embodiment 3

[0098] In addition to using 100 parts of hydrogenated acrylonitrile-butadiene copolymer rubber (A2) (trade name "Zetpol 2030L", manufactured by ZEONCORATION, acrylonitrile content: 36% by weight, iodine value: 57) instead of hydrogenated acrylonitrile-butadiene copolymer Except for 100 parts of synthetic rubber (A1) (trade name "Zetpol 2020", manufactured by ZEONCORATION, acrylonitrile content: 36% by weight, iodine value: 28), a cross-linkable rubber composition was prepared in the same manner as in Example 1. evaluation of. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com