Plastic water pipe material and preparation method thereof

A water pipe and plastic technology, which is applied in the field of plastic water pipe materials and its preparation, can solve the problems of poor expansion and contraction performance, and achieve the effects of excellent expansion and contraction performance, good weather resistance, and improved tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

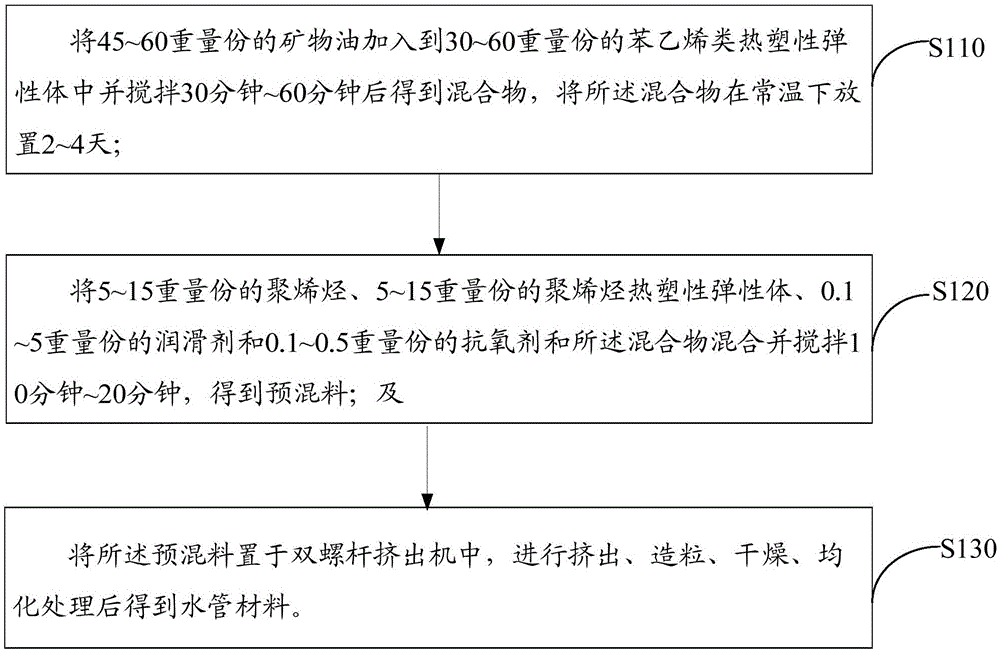

[0039] see figure 1 , the preparation method of plastic water pipe material of one embodiment, comprises the steps:

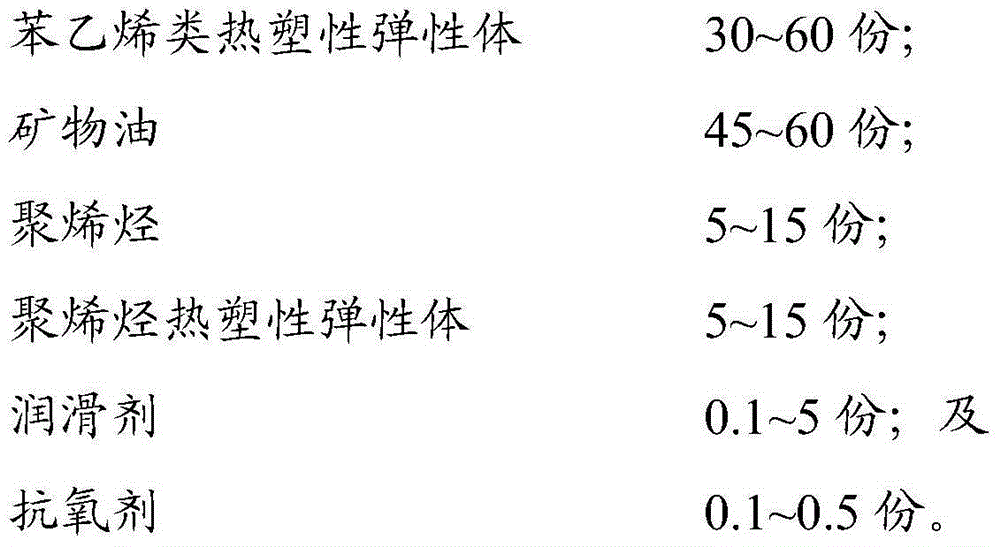

[0040] S110. Add 45-60 parts by weight of mineral oil to 30-60 parts by weight of styrene thermoplastic elastomer and stir for 30-60 minutes to obtain a mixture, and place the mixture at room temperature for 2-4 days.

[0041] The above-mentioned stirring device may be a horizontal mixer, and the mineral oil may be added in a spraying manner, so that the styrene thermoplastic elastomer is more evenly oiled.

[0042] S120, mixing 5-15 parts by weight of polyolefin, 5-15 parts by weight of polyolefin thermoplastic elastomer, 0.1-5 parts by weight of lubricant and 0.1-0.5 parts by weight of antioxidant with the mixture and stirring for 10 minutes to 20 minutes to obtain the premix.

[0043] Specifically, before mixing the above-mentioned raw materials, the above-mentioned raw materials need to be inspected to ensure that all the raw materials used are qualified....

Embodiment 1

[0054] Put 38 parts by weight of Yueyang Petrochemical SEBSYH503T into a horizontal mixer, uniformly add 51 parts by weight of mineral oil Karamay 500SN by spraying, and stir for 40 minutes to obtain a mixture, which is packaged and placed at room temperature for 4 days.

[0055] Put the mixture of 89 parts by weight into a horizontal mixer, add 6 parts by weight of ExxonMobil VistamaxxPOE3980, 5 parts by weight of Thailand Baolin PP1100NK, 0.15 parts by weight of Atmer1753, 0.1 parts by weight of antioxidant 168, 0.1 parts by weight Antioxidant 1076, stirred for 15 minutes to obtain a premix.

[0056] Pour the premixed material into the hopper of the co-rotating twin-screw extruder, shear and disperse through the co-rotating twin-screw, pelletize, pass through a vibrating sieve, blow dry, and cool to obtain the plastic water pipe material.

Embodiment 2

[0058] Put 35 parts by weight of Japanese Kuraray SEEPS4055 into a horizontal mixer, add 53 parts by weight of mineral oil KN4010 evenly by spraying, and stir for 50 minutes to obtain a mixture, which is packaged and placed at room temperature for 4 days.

[0059] Put 88 parts by weight of the mixture into a horizontal mixer, add 7 parts by weight of Borealis FB2230, 5 parts by weight of ExxonMobil PP7373, 0.2 parts by weight of Atmer1753, 0.15 parts by weight of antioxidant 168, 0.15 parts by weight of antioxidant Oxygen 1076, stirred for 14 minutes to obtain a premix.

[0060] Pour the premixed material into the hopper of the co-rotating twin-screw extruder, shear and disperse through the co-rotating twin-screw, pelletize, pass through a vibrating sieve, blow dry, and cool to obtain the plastic water pipe material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com