Tracking-proof corrosion-proof room temperature silicon disulfide rubber composite

A silicone rubber composition and room temperature vulcanization technology, applied in the field of materials, can solve the problems of reducing the use effect and service life of anti-pollution flashover, and achieve the effects of excellent tear strength, high tensile strength, and pollution flashover prevention and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

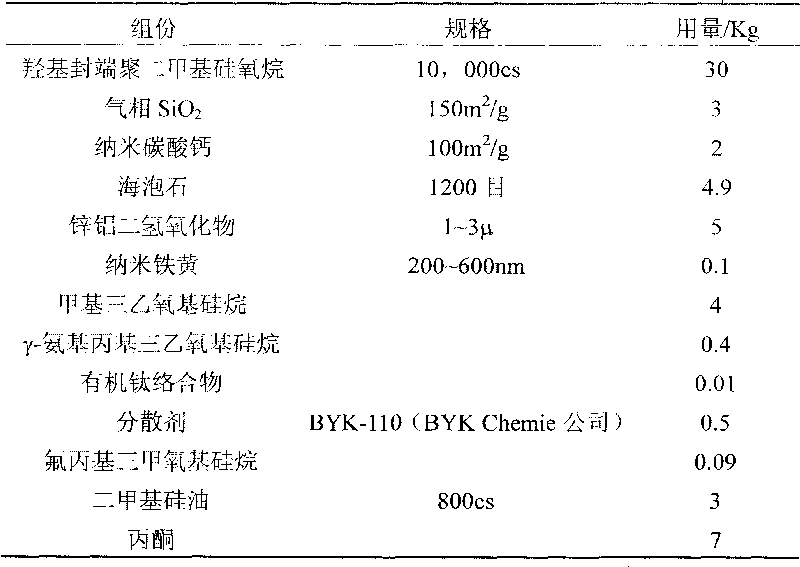

[0046] The formula and properties of the first tracking and corrosion resistant room temperature vulcanized silicone rubber composition provided by the present invention are listed in Table 1 and Table 2.

[0047] Table 1. Formula of high resistance to tracking and erosion room temperature vulcanized silicone rubber composition

[0048]

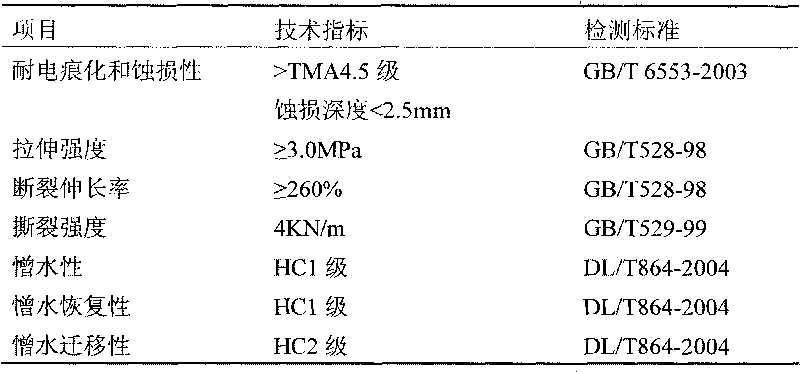

[0049] Table 2. Performance test

[0050]

Embodiment 2

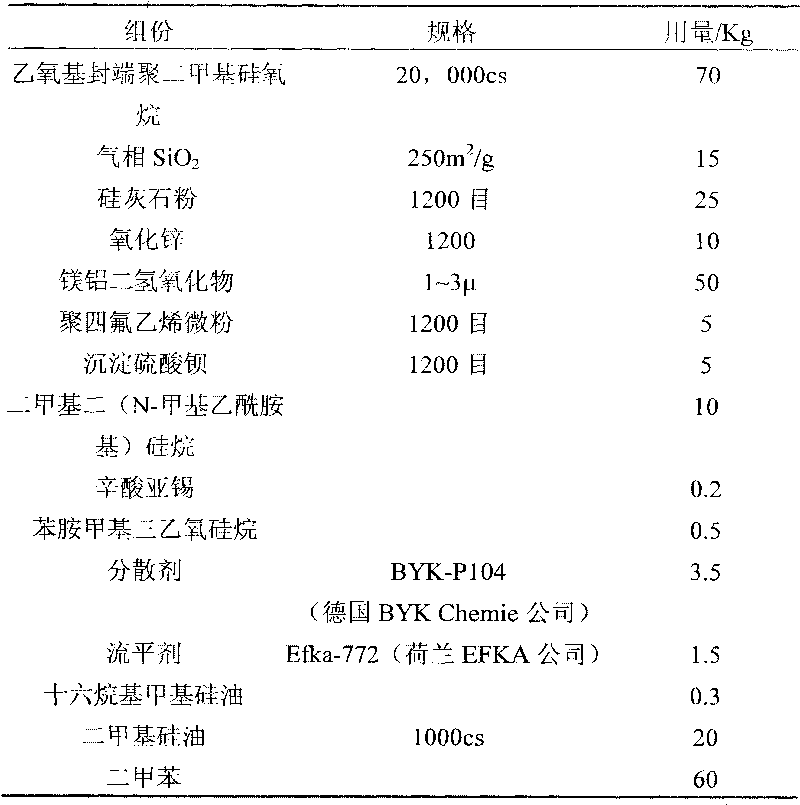

[0052] The formula and properties of the second tracking and corrosion resistant room temperature vulcanized silicone rubber composition provided by the present invention are listed in Table 3 and Table 4.

[0053] Table 3. Formulation

[0054]

[0055] Table 4. Performance test

[0056]

[0057]

Embodiment 3

[0059] The formula and properties of the third tracking and corrosion resistant room temperature vulcanized silicone rubber composition provided by the present invention are listed in Table 5 and Table 6.

[0060] Table 5. Recipe

[0061]

[0062] Table 6. Performance test

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com