Patents

Literature

194 results about "Silicon disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon sulfide is the inorganic compound with the formula SiS₂. Like silicon dioxide, this material is polymeric, but it adopts a 1-dimensional structure quite different from the usual forms of SiO₂.

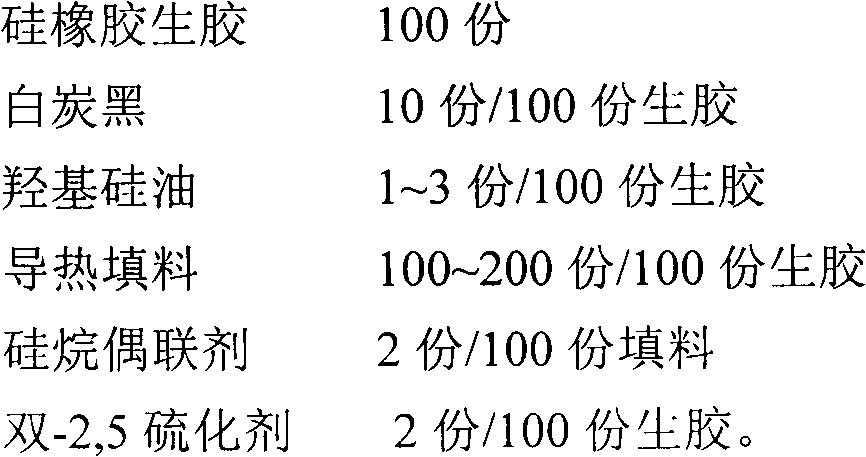

Mixed filling type thermal conductive silicone rubber composite and preparation method thereof

InactiveCN102220006APacked tightlyHigh thermal conductivityHeat-exchange elementsPolymer scienceVulcanization

The invention discloses a preparation method of a mixed filling type thermal conductive silicone rubber composite. Raw materials comprises the following components, by mass, 100 parts of raw silicone rubber, 10 parts of white carbon black, 1 to 3 parts of hydroxy silicone oil, 100 to 200 parts of a thermal conductive filler, 2 to 4 parts of a silane coupling agent and 2 parts of a di-2,5-vulanizator. The preparation method comprises the following steps: adding raw silicone rubber to a double roller mill; adding white carbon black, the thermal conductive filler, the silane coupling agent and hydroxy silicone oil according to a formula design after roller packaging; adding a peroxide vulcanizer after repeatedly and uniformly mixing; mixing uniformly to obtain mixed silicone rubber; putting in a die and carrying out first-stage vulcanization after cold pressing mold filling; and putting a molded sample in an air blasting drier and carrying out second-stage vulcanization to obtain a finished product. In the present invention, mixed particles of SiC and AlN are employed to fill high temperature vulcanized silicon rubber, effective thermal conductive net chains are formed in silicone rubber matrixes, so the obtained heat-conducting silicone rubber composite material has a good heat conducting performance.

Owner:TIANJIN UNIV

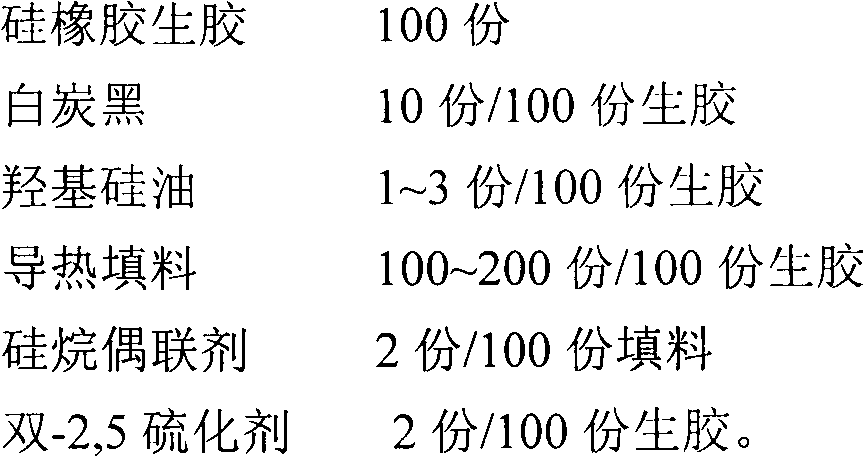

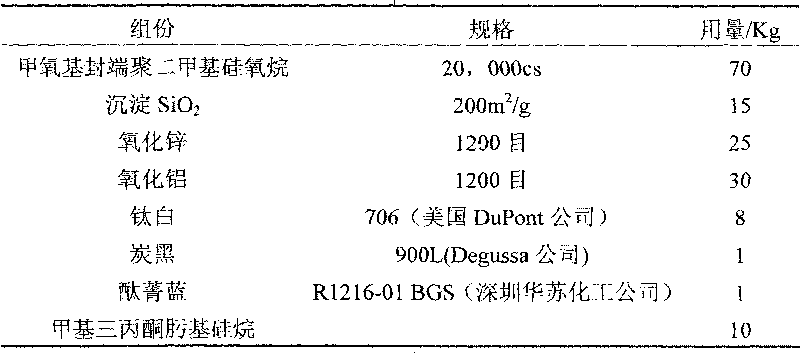

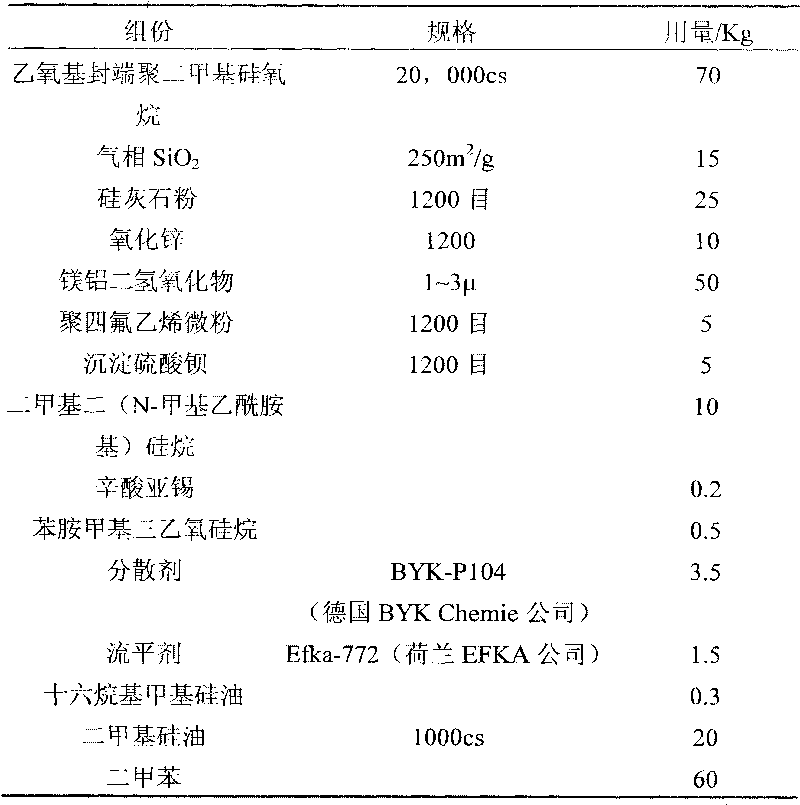

Elastic anti-corrosion coating

InactiveCN101747835AGood weather resistanceImprove water resistanceAnti-corrosive paintsRoom temperatureSolvent

The invention relates to an elastic anti-corrosion coating, which is a room-temperature silicon sulfide-based functional compound with high property. The formula of the coating comprises(in part by weight): 30 to 70 parts of polyorganosiloxane, 1 to 80 parts of pigments and fillers, 30 to 10 parts of crosslinking agent, 1 to 10 parts of auxiliary agent and 10 to 80 parts of thinning agent. The elastic anti-corrosion coating has high weathering resistance, water resistance, acid resistance, solvent resistance and oil resistance and alkali resistance; the paint film can be desirably adhered onto glass, ceramics, steel structural members, concrete, various resin primers and the like, and the paint film is good in elasticity and hydrophobicity and high in tensile strength and breaking elongation, can be widely used for the corrosion prevention of bridges, tanks and various steel structural members and the corrosion and leakage protection of ground, drainage channels and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

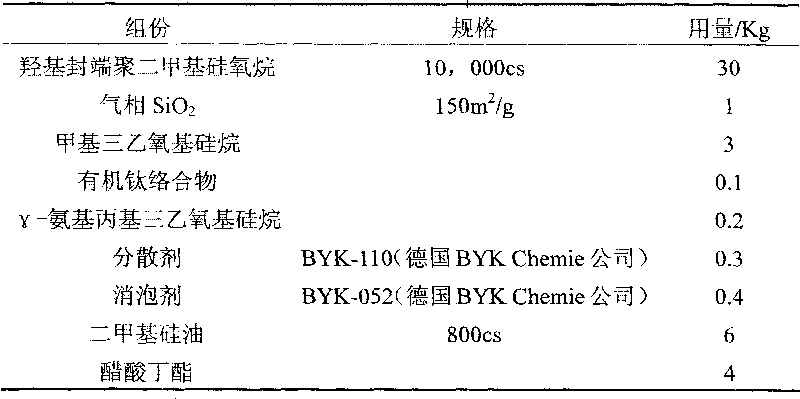

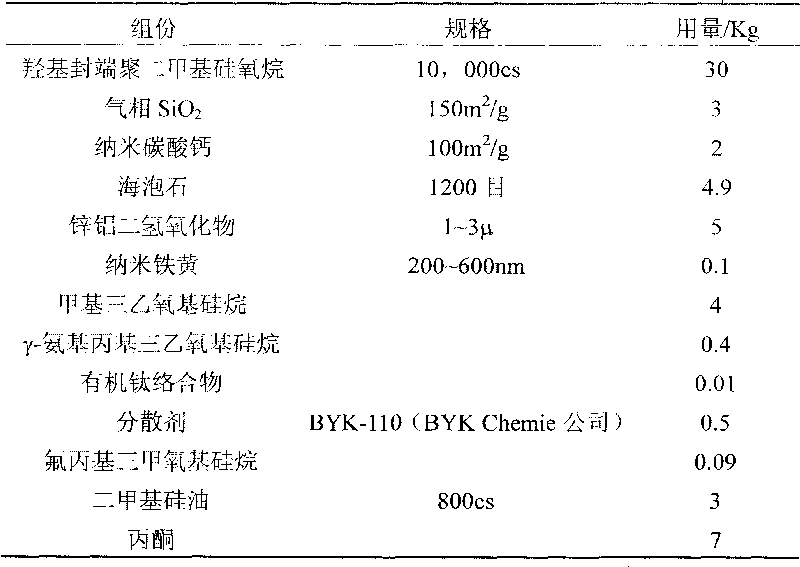

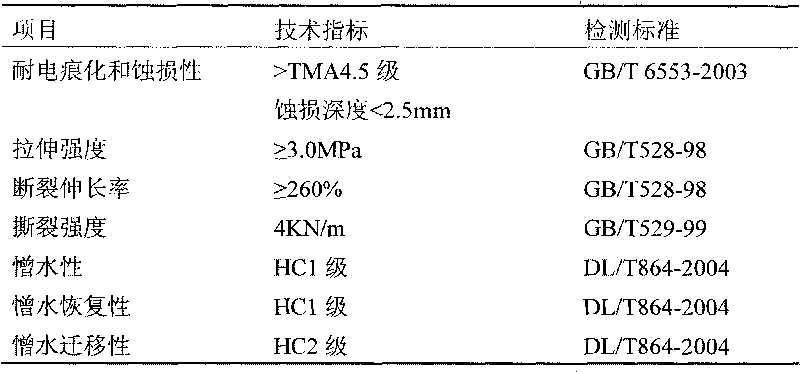

Tracking-proof corrosion-proof room temperature silicon disulfide rubber composite

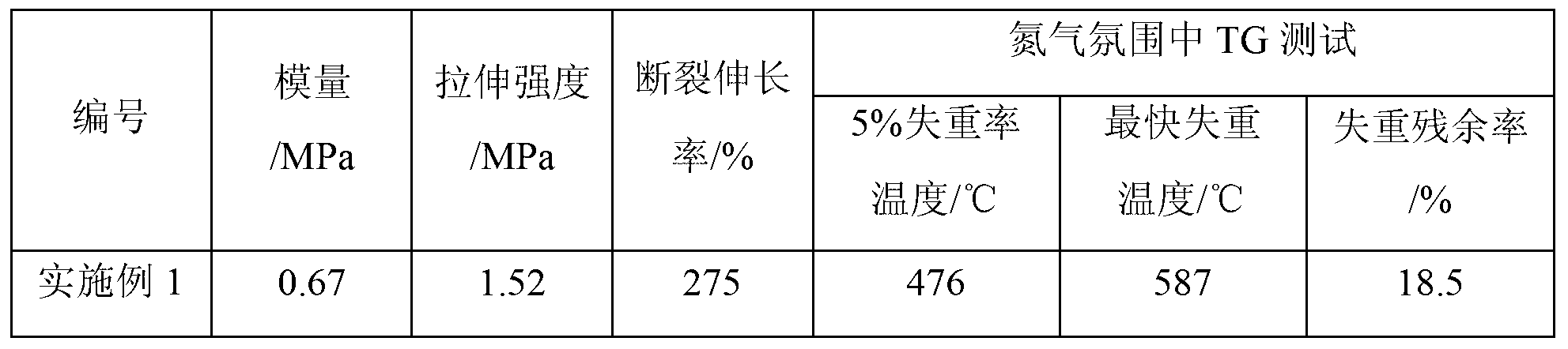

ActiveCN101747630AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsCoatingsRoom temperatureDiluent

The invention relates to a tracking-proof corrosion-proof room temperature silicon disulfide rubber composite which has the following formula: 30-70 parts of polysiloxane by weight, 5-40 parts of reinforced filler by weight, 10-70 parts of electric corrosion resistance stabilizer by weight, 5-15 parts of auxiliary agent by weight and 10-80 parts of diluent by weight. The tracking-proof corrosion-proof room temperature silicon disulfide rubber composite provided by the invention has favourable tracking-proof corrosion-proof performance, has higher tensile strength, breaking elongation and tearing strength as well as favourable surface hydrophobicity, hydrophobicity transference and hydrophobicity restoration and is a functional composite capable of effectively preventing and curing pollution flashover.

Owner:CHINA ELECTRIC POWER RES INST +3

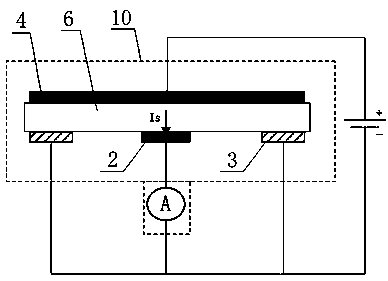

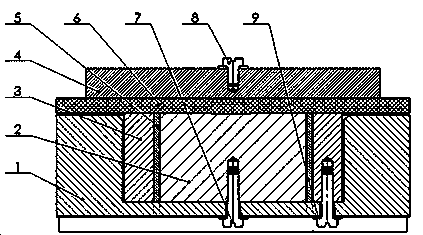

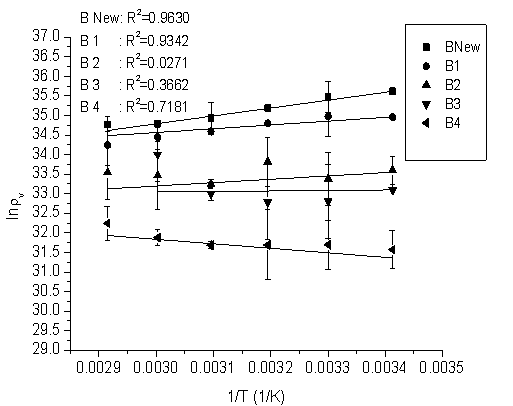

Evaluation method of aging degree of operational composite insulator

InactiveCN104062527AImprove accuracyGuaranteed uptimeElectrical testingComposite insulatorsVulcanization

An evaluation method of the aging degree of an operational composite insulator comprises the steps of firstly utilizing a three-electrode volume resistivity test device to measure the volume resistivity of a round-slice high-temperature silicon sulfide rubber sampler which is cut from the surface of the net-hanging operational composite insulator at different temperatures, plotting a curve, calculating the linear fitting R2 of the curve, and finally comprehensively determining the aging degree of the composite insulator according to the change situation of the linear fitting R2 of the curve and the volume resistivity of the round-slice high-temperature silicon sulfide rubber sampler. According to the present invention, the aging degree of the composite insulator is determined comprehensively according to the change situation of the linear fitting R2 of the curve and the volume resistivity of the round-slice high-temperature silicon sulfide rubber sampler, so that the operation is simple and convenient, and the accuracy of the evaluation result is improved, and accordingly, the reliable operation of a high voltage power transmission line is guaranteed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

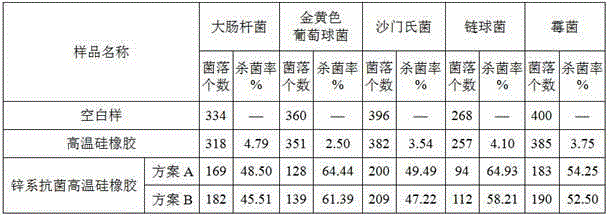

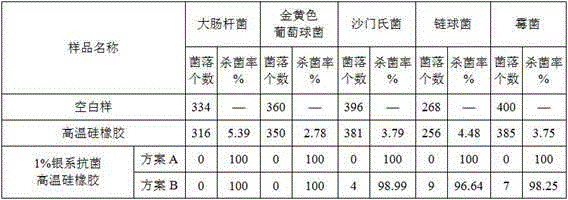

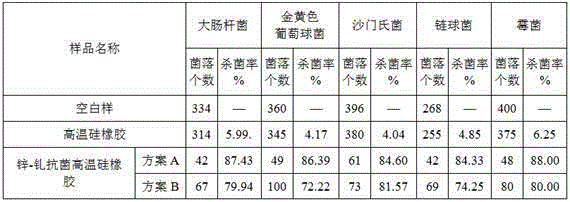

Preparation method of antibiosis high temperature silicone rubber

ActiveCN105238056AStrong antibacterial broad spectrumHigh antibacterial broad spectrumPolymer scienceTemperature resistance

The invention discloses a preparation method of antibiosis high temperature silicone rubber. The method comprises the following steps: adhering antibiosis ions to a white carbon black carrier through a sol-gel technology to obtain antibiosis gel; and adding corresponding high temperature silicone rubber raw rubber, fully mixing, and vulcanizing to prepare a high temperature silicone rubber material with antibiosis ability, or directly adding high temperature silicon sulfide rubber, fully fusing, and curing to obtain the silicone rubber material with antibiosis ability. The antibiosis high temperature silicone rubber prepared in the invention has the advantages of high temperature resistance, enhancement of the mechanical performances of silicone rubber, high antibiosis, strong antibiosis broad spectrum activity, high sterilization rate, no generation of drug resistance, safety to human bodies and environment, wide uses, and facilitation of the large-scale quantitative production of the future market.

Owner:KUNMING UNIV OF SCI & TECH

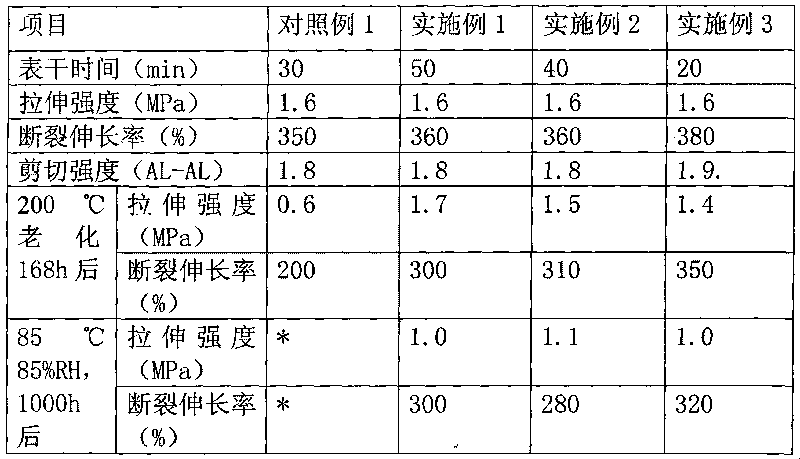

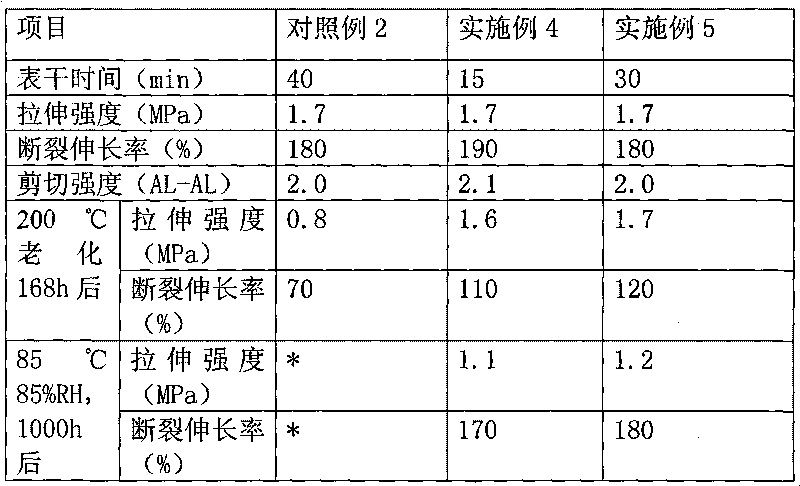

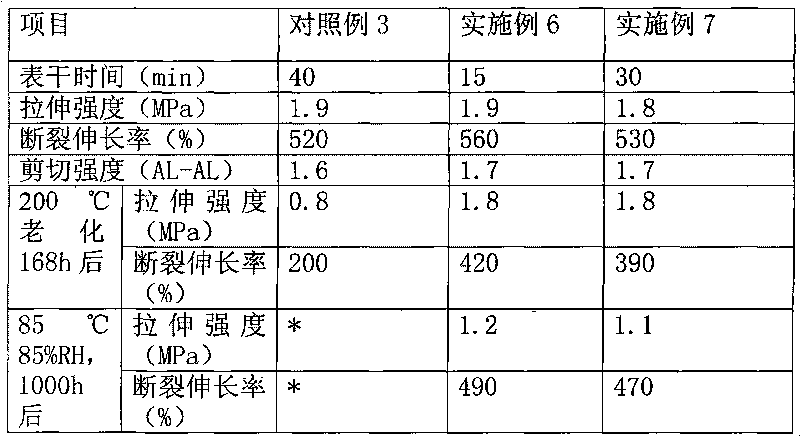

Bi-component room temperature vulcanizing silicone rubber for photovoltaic component

InactiveCN101717582AImprove the shortcomings of poor aging resistanceExcellent outdoor aging resistanceOther chemical processesAdhesivesThermal ageingNitrogen gas

The invention discloses a bi-component room temperature vulcanizing silicone rubber for a photovoltaic component, which comprises an A component and a B component. During use, the A component and the B component are uniformly coated on a work piece according to proportion through a bi-component glue spreader. The bi-component room temperature vulcanizing silicone rubber is characterized in that: the A component is prepared by grinding the following raw materials in part by weight: 100 parts of hydroxyl-terminated dimethyl silicone polymer, 20 to 50 parts of plasticizer, 60 to 100 parts of stuffing and 6 to 10 parts of thixotropic agent through a three-roll grinder; the B component is prepared by mixing the following raw materials in part by weight: 5 to 10 parts of cross-linking agent, 0.2 to 1.5 parts of compound catalyst, 1 to 2 parts of adhesion agent and 0.5 to 1.5 parts of catalyst carrier under the protection of nitrogen. The invention overcomes the shortcomings of poor aging resistance of the room temperature vulcanizing silicone rubber catalyzed by conventional organotin, and has characteristics of excellent outdoor aging resistance, good adhesiveness, fast curing speed, no reversion after the curing and no color change; the invention greatly improves the high temperature resistance and the damp-heat aging resistance, and can meet the requirement on the process procedure by controlling the curing speed.

Owner:YANTAI DARBOND TECH

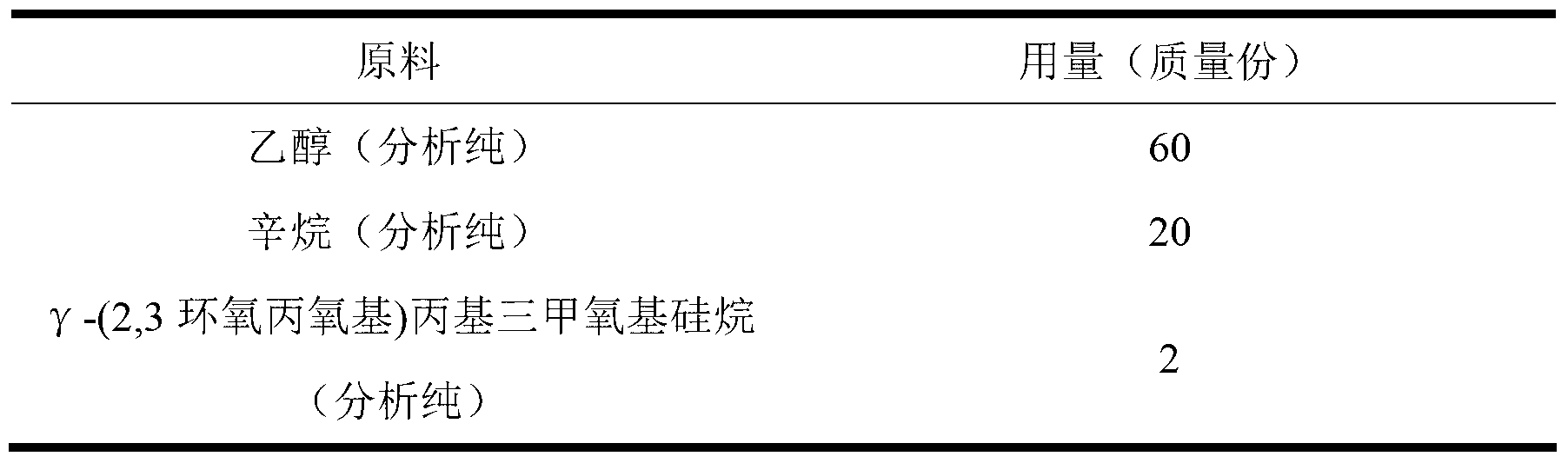

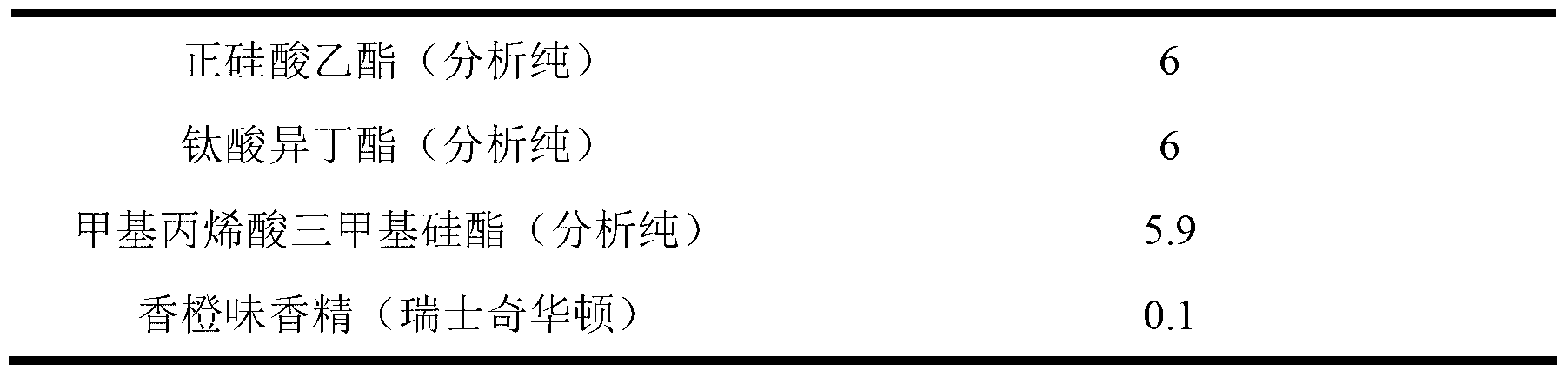

Primer coating for single-component room-temperature vulcanized silicone rubber and preparation method thereof

The invention discloses a primer coating for single-component room-temperature vulcanized silicone rubber. The primer coating is composed of the following components: A, 0.01-20 parts by weight of at least one of the following materials: polysiloxane, silane coupling agent, silicate ester, titanate and silicon resin; B, 10.00-85.00 parts by weight of organic solvent; and C, 0.01-1.20 parts by weight of essence. The preparation method of the primer coating for the single-component room-temperature vulcanized silicone rubber comprises the following steps of: A) evenly mixing the component A with the component C; 2) adding the component B and evenly mixing the mixture; and 3) filtering. The primer coating provided by the invention is directly applied to a substrate to be bonded in use and the process of applying glue can be performed in 20-45 seconds. The primer coating prepared by the method provided by the invention is capable of achieving the 100% cohesive failure of the single-component room-temperature vulcanized silicone rubber when the single-component room-temperature vulcanized silicone rubber is bonded with a plurality of kinds of surfaces; and as a result, the adhesion of the substrate with the single-component room-temperature vulcanized silicone rubber is enhanced.

Owner:SHENZHEN XINYA NEW MATERIALS CO LTD

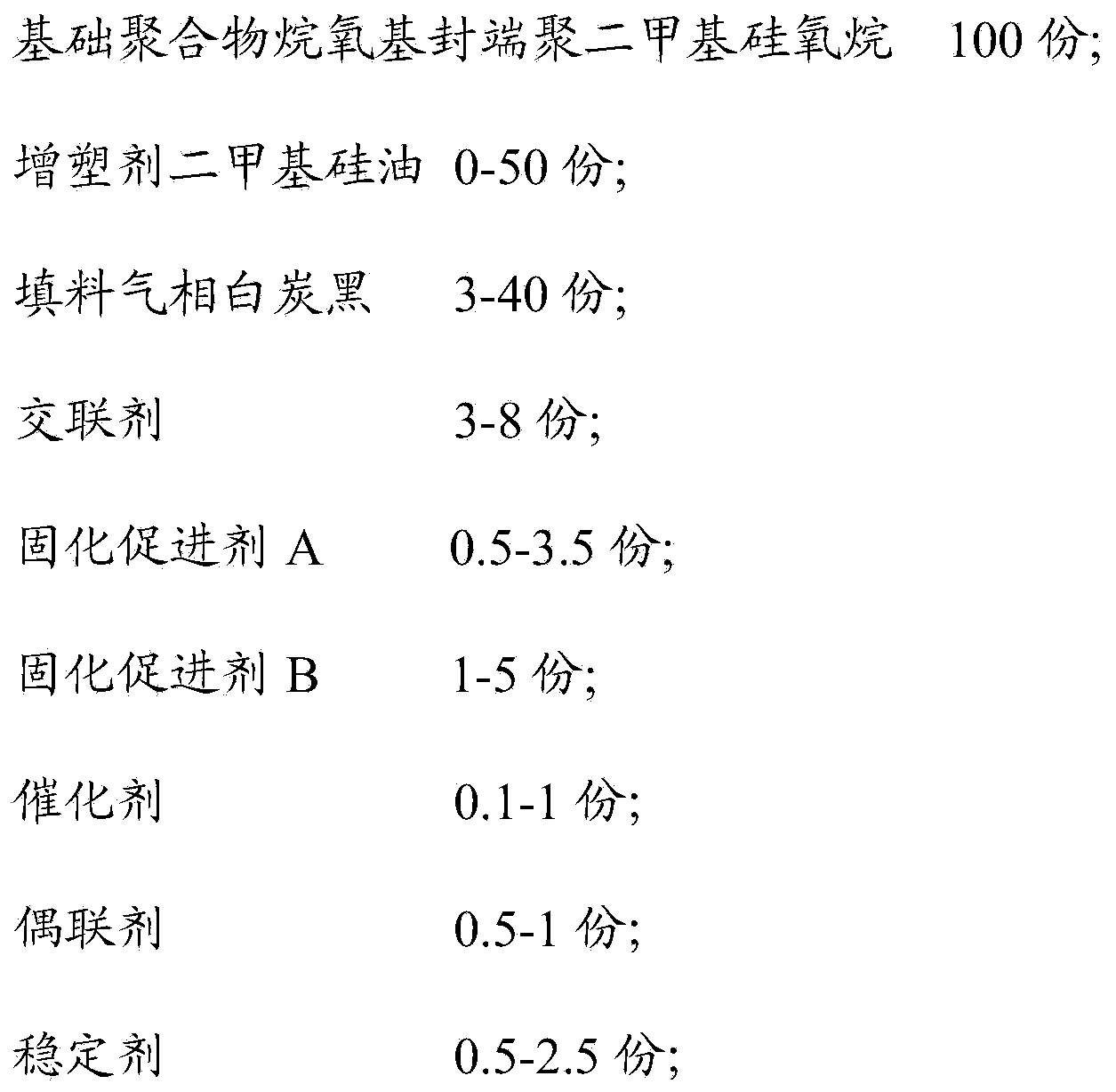

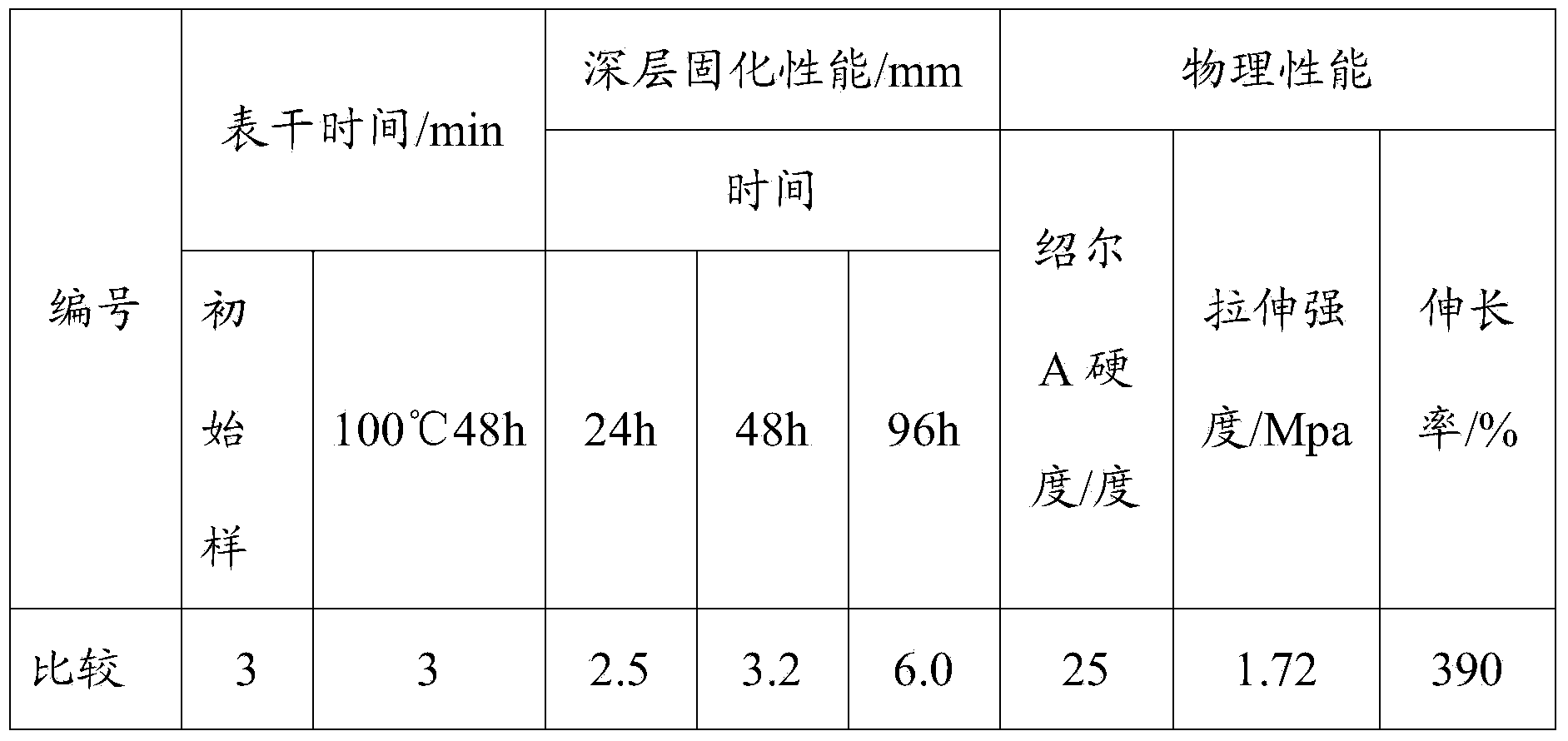

Preparation method of fast curing dealcoholization type transparent room-temperature silicon sulfide rubber

ActiveCN103725009AFast vulcanizationImprove sealingNon-macromolecular adhesive additivesMacromolecular adhesive additivesAcetic acidAlcohol

The invention relates to a preparation method of a fast curing dealcoholization type transparent room-temperature silicon sulfide rubber. According to the preparation method disclosed by the invention, a water-absorbing material and an air permeable material are respectively added into a dealcoholization type transparent room-temperature silicon sulfide sealant, and the whole curing performance is improved. With the adoption of the preparation method, by adsorbing moisture in air by virtue of the water-absorbing material, absorption of a system to the moisture of a reactant is improved; by adding the air permeable material, capillary apertures and channels are formed in a dense structure of a crosslinking product, the moisture of the reactant is facilitated to enter, methyl alcohol as a product is facilitated to be released, the crosslinking speed is accelerated, the curing speed of an alcohol type transparent adhesive reaches the curing speed of an acetic acid type silicone sealant, and the curing speed of the existing silicone rubber is increased by 30-60 percent.

Owner:湖北环宇化工有限公司

Sealing material of organic silicon sulfided at room temp. and preparation process thereof

InactiveCN1597828AIncrease elasticityGood adhesionOther chemical processesCross-linkRoom temperature

The invention is a room-temperature sulfurized organic-silicon sealing material, and comprise hydroxyl-capped poly-organic oxosilane 100 shares, filling 5-200 shares, chain extender 1-15 shares, cross-linked curing agent 1-20 shares, catalyst 0.01-5 shares, and tackifier 0.1-20 shares, mixing the above components at high vacuum. Its advantages are strong elastic retractility and rupture elongation above 800%; good bonding property and good adhesion to concrete, etc.

Owner:ZHEJIANG UNIV

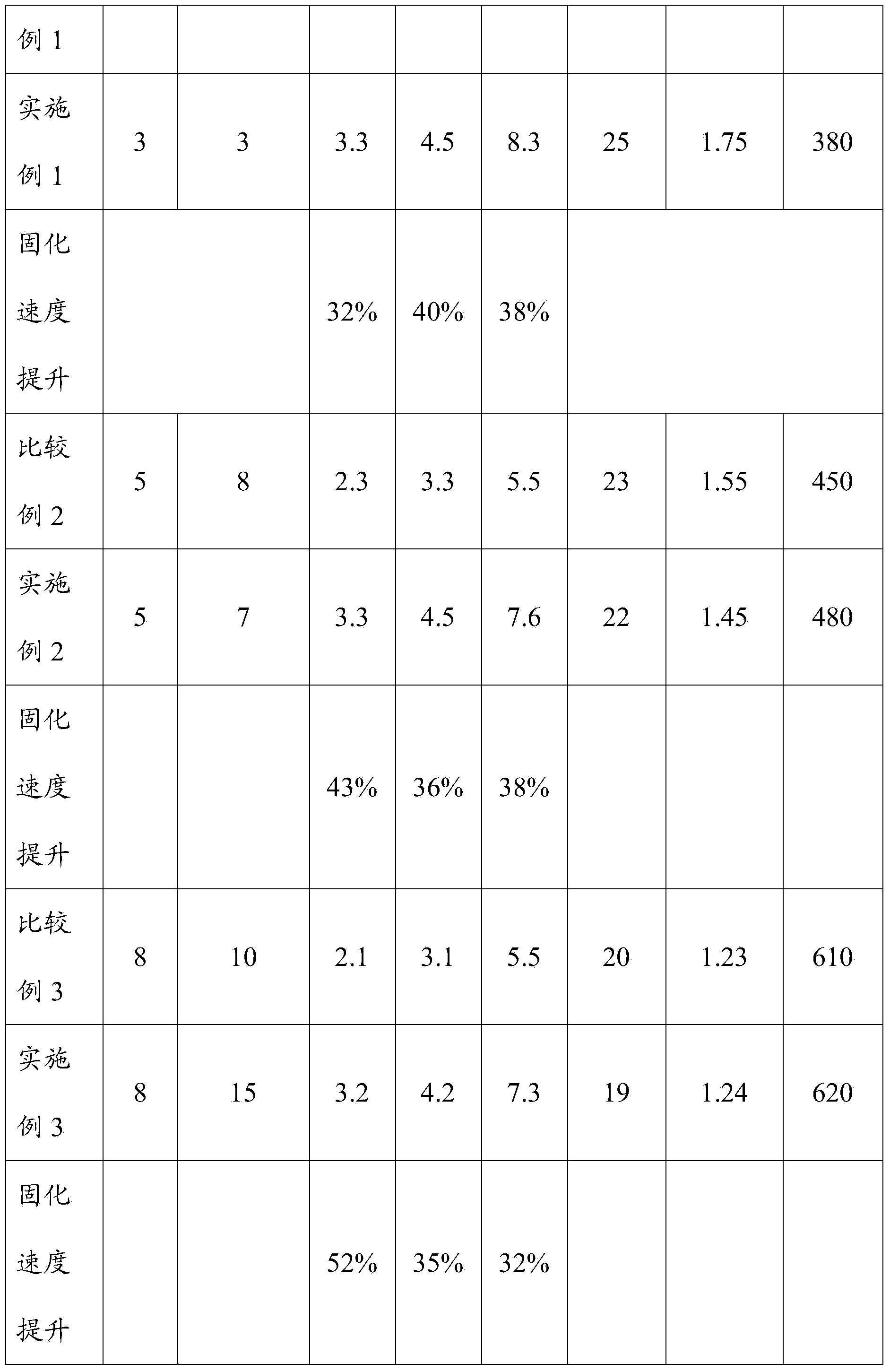

Novel alkoxy silane based POSS (polyhedral oligomeric silsesquioxanes) as well as preparation method and application thereof

ActiveCN103288867AImprove mechanical propertiesImprove thermal performanceSilicon organic compoundsChemical industrySilanes

The invention discloses novel alkoxy silane based POSS (polyhedral oligomeric silsesquioxanes) as well as a preparation method and application thereof, belonging to the fields of chemical industry and organic polymer materials. The POSS has a general molecular formula of SixOyR1nR2x-m-nR3m, wherein x is 8, 10 or 12, y=1.5x, n=0-(x-1), m=1-x, m+n is less than or equal to x, and m and n are integers. The preparation method comprises the following steps of: taking POSS raw materials, and performing a hydrosilation reaction on the POSS raw materials and hydrogen-containing silane under the action of a hydrosilation catalyst to obtain a target product. According to the preparation method, an alkoxy silane base is introduced into the POSS, and radicals including Si-OH, Si-H, Si-OR and the like in the alkoxy silane base and a polysiloxane system are used for reacting to form a Si-O-Si bond, so that the alkoxy silane based POSS can obviously promote mechanical properties and thermal properties of silicon resin and silicon rubber when added into condensed type silicon resin and room temperature vulcanized silicon rubber.

Owner:武汉绿凯科技有限公司

Method for preparing low-molecular-weight hydroxyl silicone oil

ActiveCN101570601AThe degree of polymerization is controllableNo pollution in the processIon-exchange resinSilicon disulfide

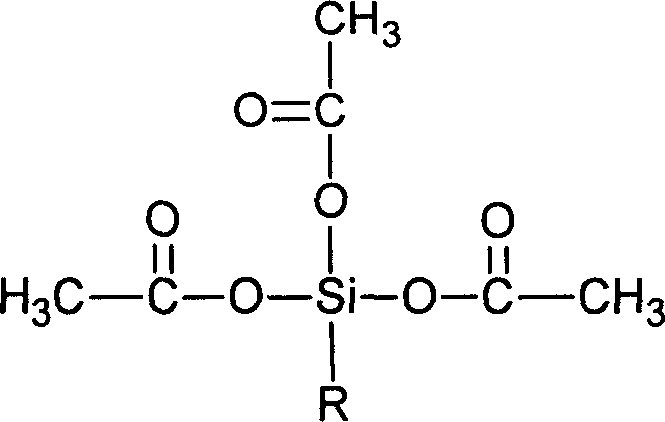

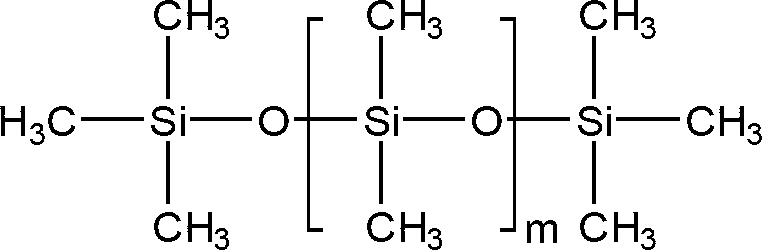

The invention relates to a method for preparing low-molecular-weight hydroxyl silicone oil, which comprises the following steps: adopting hexamethyl-cyclotrisiloxane as a raw material and perfluoro-sulfonate ion-exchange resin as a catalyst; reacting the materials at a temperature of between 50 and 70 DEG C for 1 to 2 hours in the presence of water and a solvent; filtering the mixture to remove the perfluoro-sulfonate ion-exchange resin; and vacuumizing the mixture at a temperature of between 20 and 80 DEG C and under a pressure of between 10 and 20 KPa and extracting out the solvent to obtain the low-molecular-weight hydroxyl silicone oil. The general formula of the hexamethyl-cyclotrisiloxane is (R2SiO)3, wherein R is Me; the dosage of the perfluoro-sulfonate ion-exchange resin is 1 to 10 percent of the weight of the hexamethyl-cyclotrisiloxane; the solvent is methanol, acetone or tetrahydrofuran; the molar ratio of the dosage of the water to the dosage of the hexamethyl-cyclotrisiloxane is 1.1-1.2:1; and the molar ratio of the dosage of the solvent to the dosage of the hexamethyl-cyclotrisiloxane is 1-5:1. The low-molecular-weight hydroxyl silicone oil is used as a silicon rubber structural control agent, an isolation paper coating, a mold releasing agent and room temperature silicon sulfide rubber; and the process is simple, the degree of polymerization is easy to control, and no environmental pollution exists.

Owner:PETROCHINA CO LTD

Low cost room temperature silicon sulfide rubber composition

Disclosed is a low cost room temperature vulcanized silicone rubber composition, wherein the constituents include (by weight portions): oligomeric polydimethylsiloxanol 80-120, cross linking agent 2-15, catalyst 0.005-0.1, filling material 3-100, addition agent 10-100.

Owner:GUANGZHOU GBS HIGH TECH & IND

Dealcoholization type room-temperature silicon sulfide rubber composite

ActiveCN102898839AImprove stabilityShorten drying timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkPolymer science

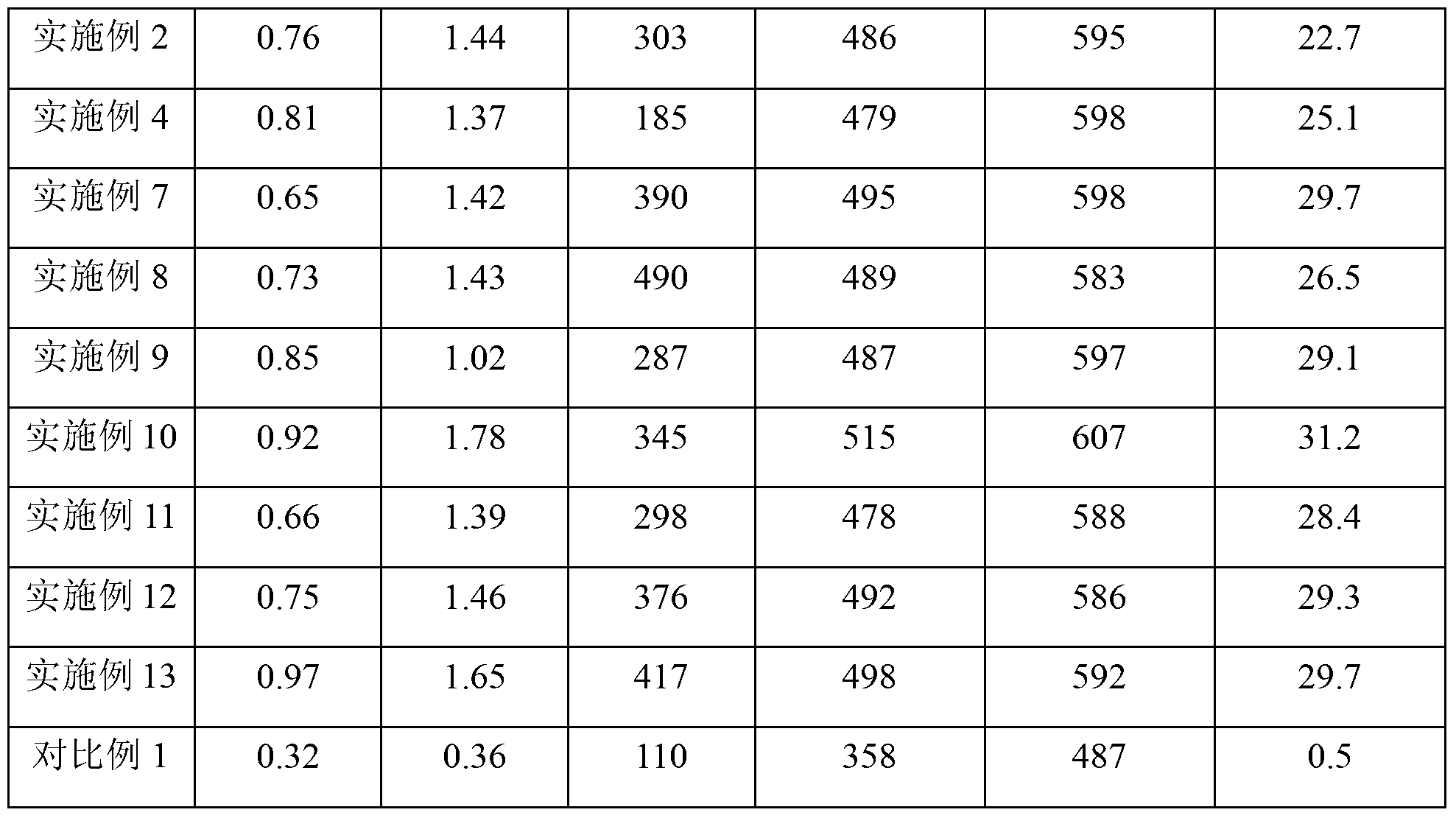

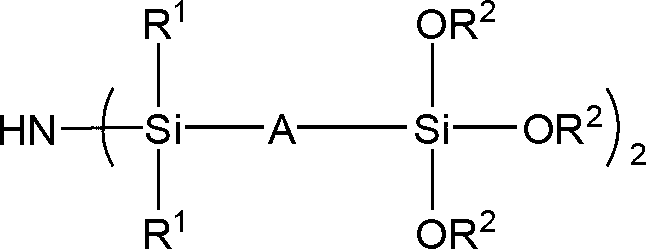

The invention relates to a dealcoholization type room-temperature silicon sulfide rubber composite. The dealcoholization type room-temperature silicon sulfide rubber composite contains poly-diorganosiloxane of which the two molecular ends are hydroxyl groups, silazane shown in the formula in the specification, a titanium chelate catalyst, a cross-linking agent, formic acid, ethanedioic acid and / or monocarboxylic acid or polybasic carboxylic acid containing 3 to 5 carbon atoms, and a filling material, wherein in the formula, the definitions of A, R1 and R2 are described in the specification.

Owner:GUANGZHOU HUITIAN FINE CHEM

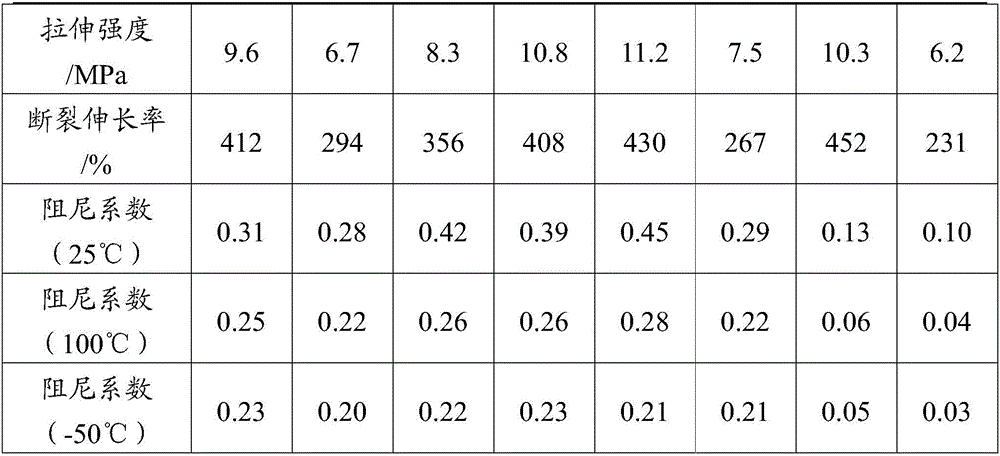

High-damping high-temperature silicon sulfide rubber and preparation method and application thereof

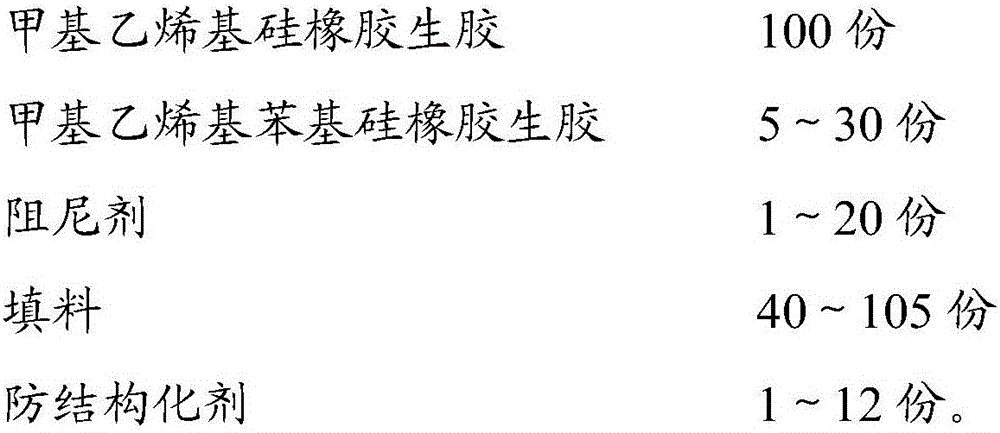

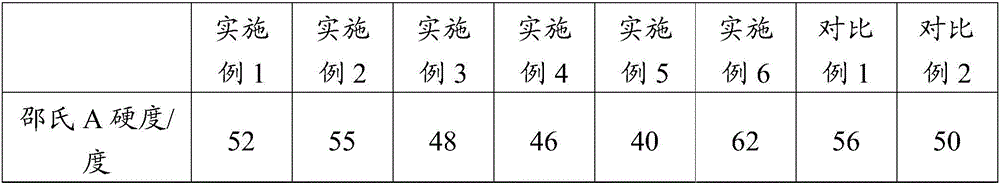

The invention relates to high-damping high-temperature silicon sulfide rubber and a preparation method and application thereof. The high-damping high-temperature silicon sulfide rubber is prepared from, by mass, 100 parts of a vulcanizing-agent-free mixed material and 0.5-3 parts of a vulcanizing agent. The vulcanizing-agent-free mixed material is prepared from, by mass, 100 parts of raw methyl vinyl silicone rubber, 5-30 parts of raw polymethylvinylphenylsiloxane rubber, 1-20 parts of a damping agent, 40-105 parts of filler and 1-12 parts of an anti-structuring agent. The damping coefficient of the high-damping high-temperature silicon sulfide rubber in the temperature range of 50-100 DEG C is larger than or equal to 0.2, stable damping and vibration-reducing performance can be kept in the wide temperature range, quality of prepared finished products is improved, and the high-damping high-temperature silicon sulfide rubber can be widely used in the wide-temperature-range fields such as automobiles, rail transit locomotives, ships, food and aerospace.

Owner:GUANGZHOU BAIYUN CHEM IND

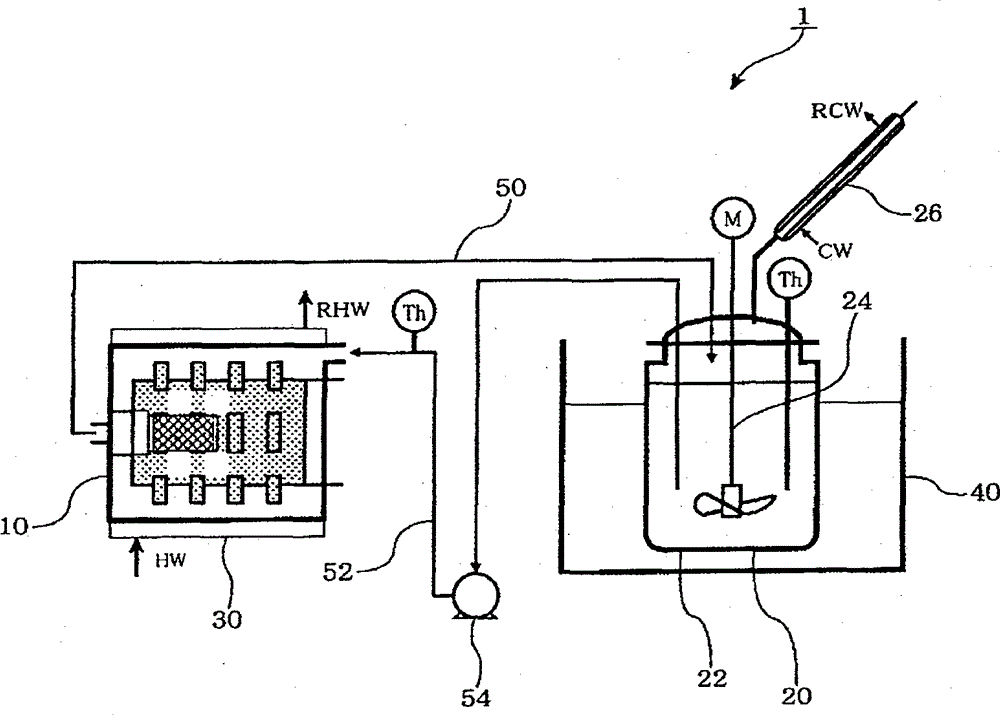

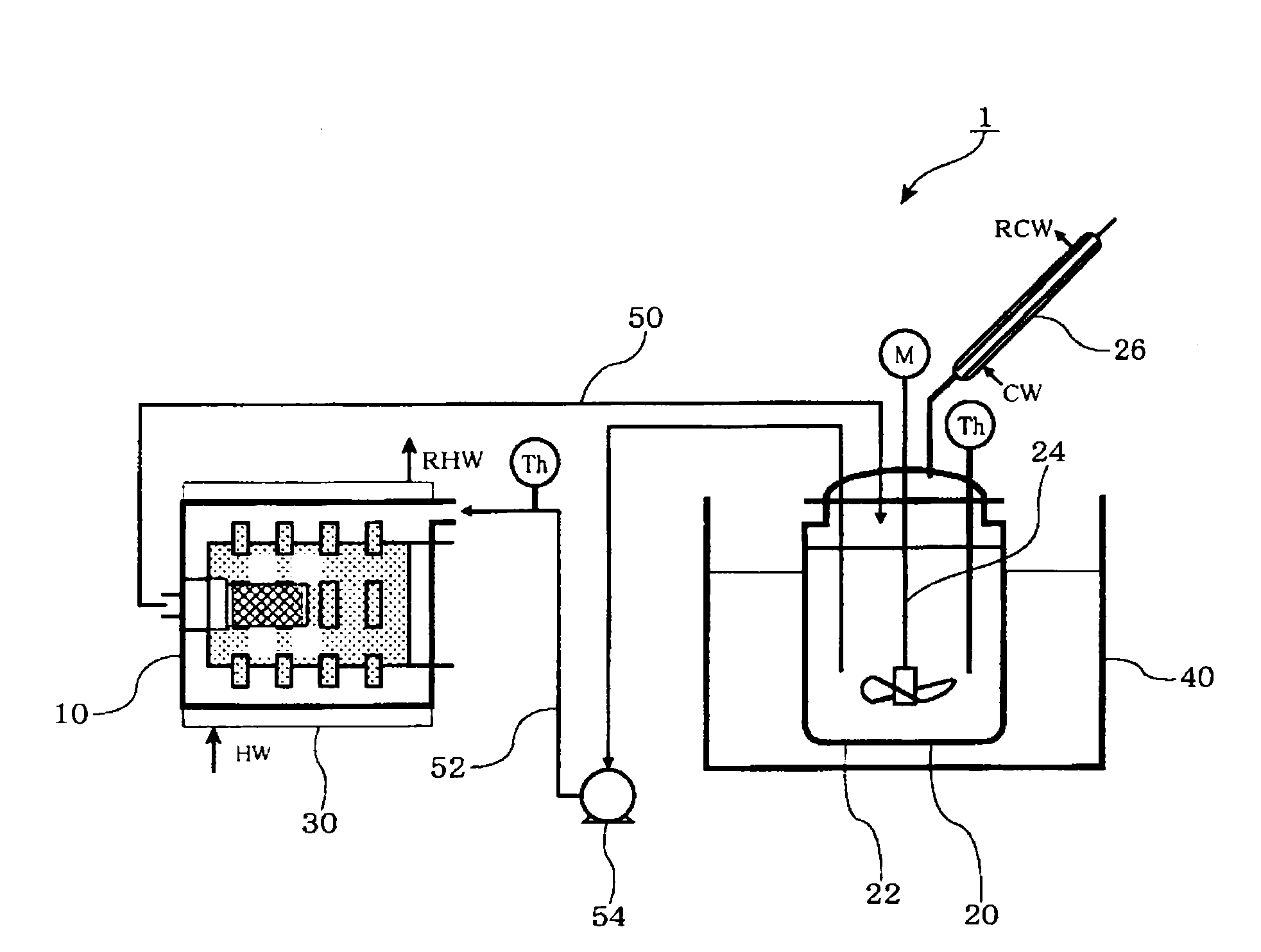

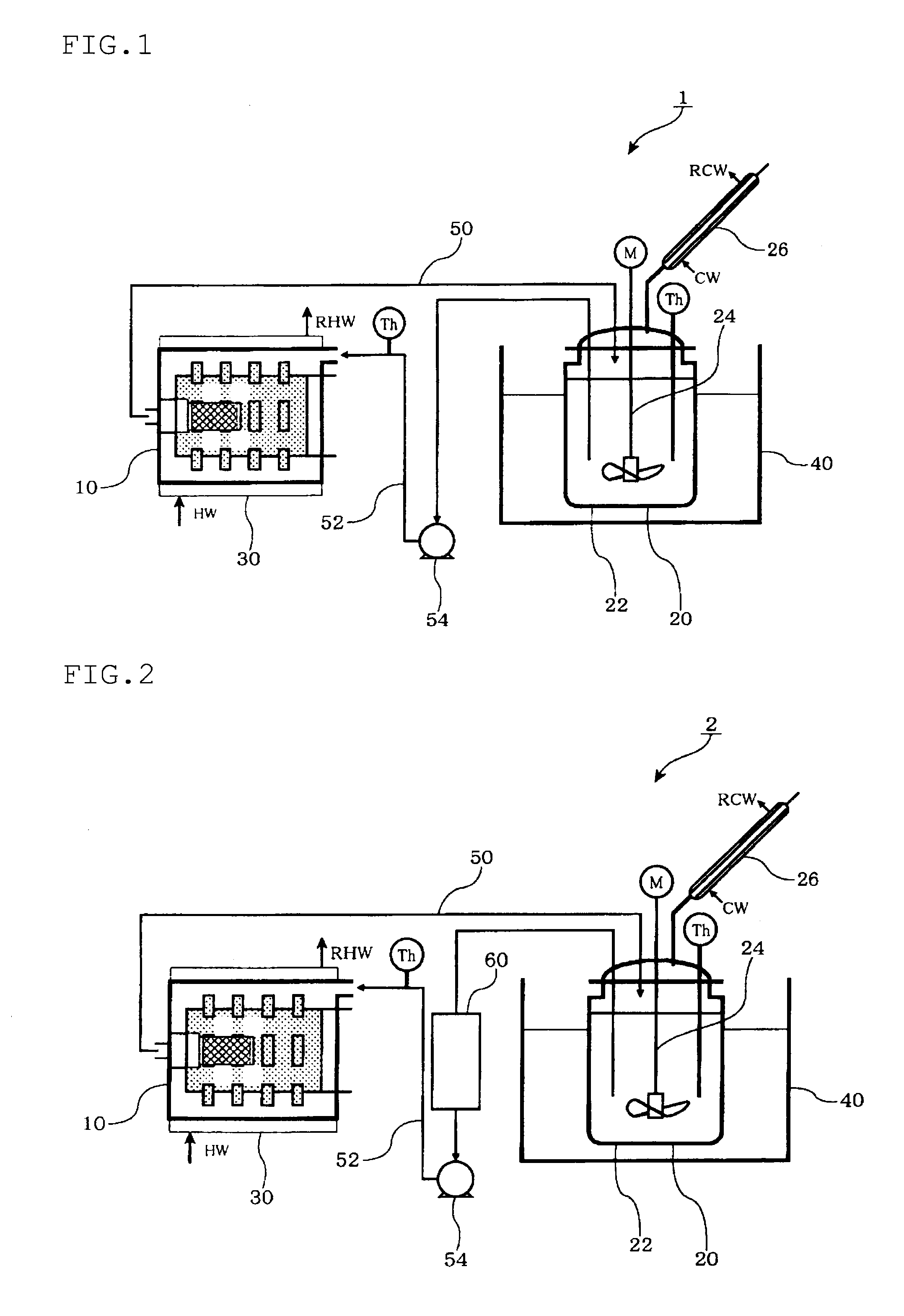

Method for producing lithium ion conductive solid electrolyte

ActiveUS20100200795A1Improve responseImprove solubilitySolid electrolytesOrganic electrolyte cellsPhysical chemistrySolvent

Owner:IDEMITSU KOSAN CO LTD

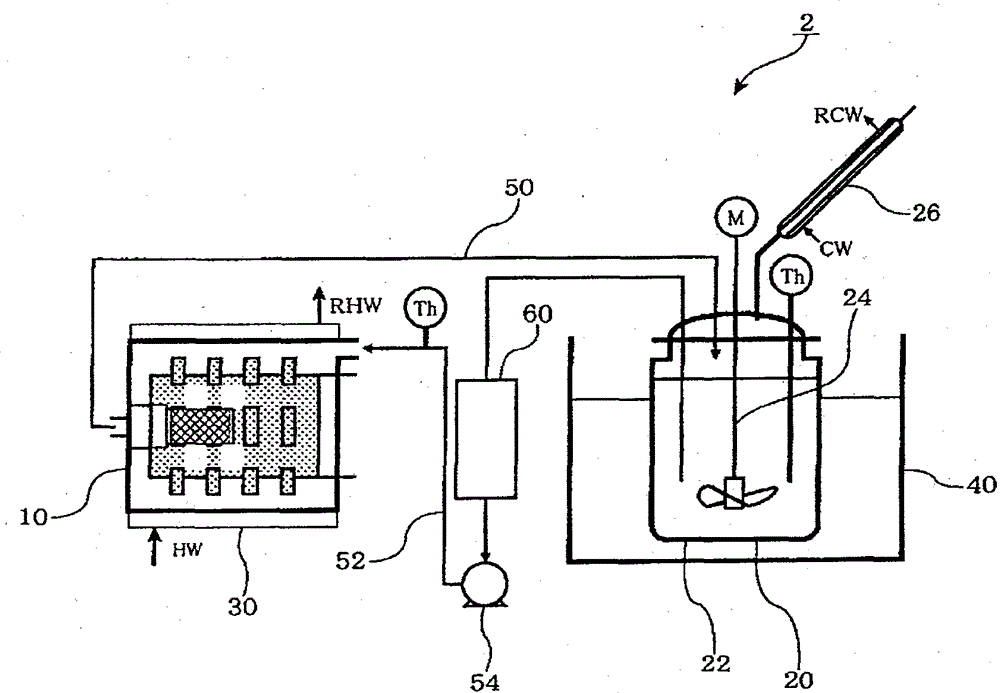

Method for producing ion-conductive substance, ion-conductive substance, crystallized ion-conductive substance, and cell

InactiveCN104412338AImprove yieldImprove work efficiencyNon-metal conductorsSolid electrolytesHalogenSolvent

Provided is a method for producing an ion-conductive substance from starting materials of: one or more types of compound selected from phosphorus sulfide, germanium sulfide, silicon sulfide, and boron sulfide; a sulfide of a metal element belonging to Group I or Group II of the periodic table; and a halogen compound represented by MwXx, and including a step for contact thereof within a solvent. (In the formula, M is Li, B, Na, K, Rb, Cs, Ca, Mg, Sr, Ba, Al, Si, P, S, Ge, As, Se, Sn, Sb, Te, Pb or Bi; w is 1 or 2; X is F, Cl, Br, or I; and x is any integer selected from 1 to 10 inclusive);.

Owner:IDEMITSU KOSAN CO LTD

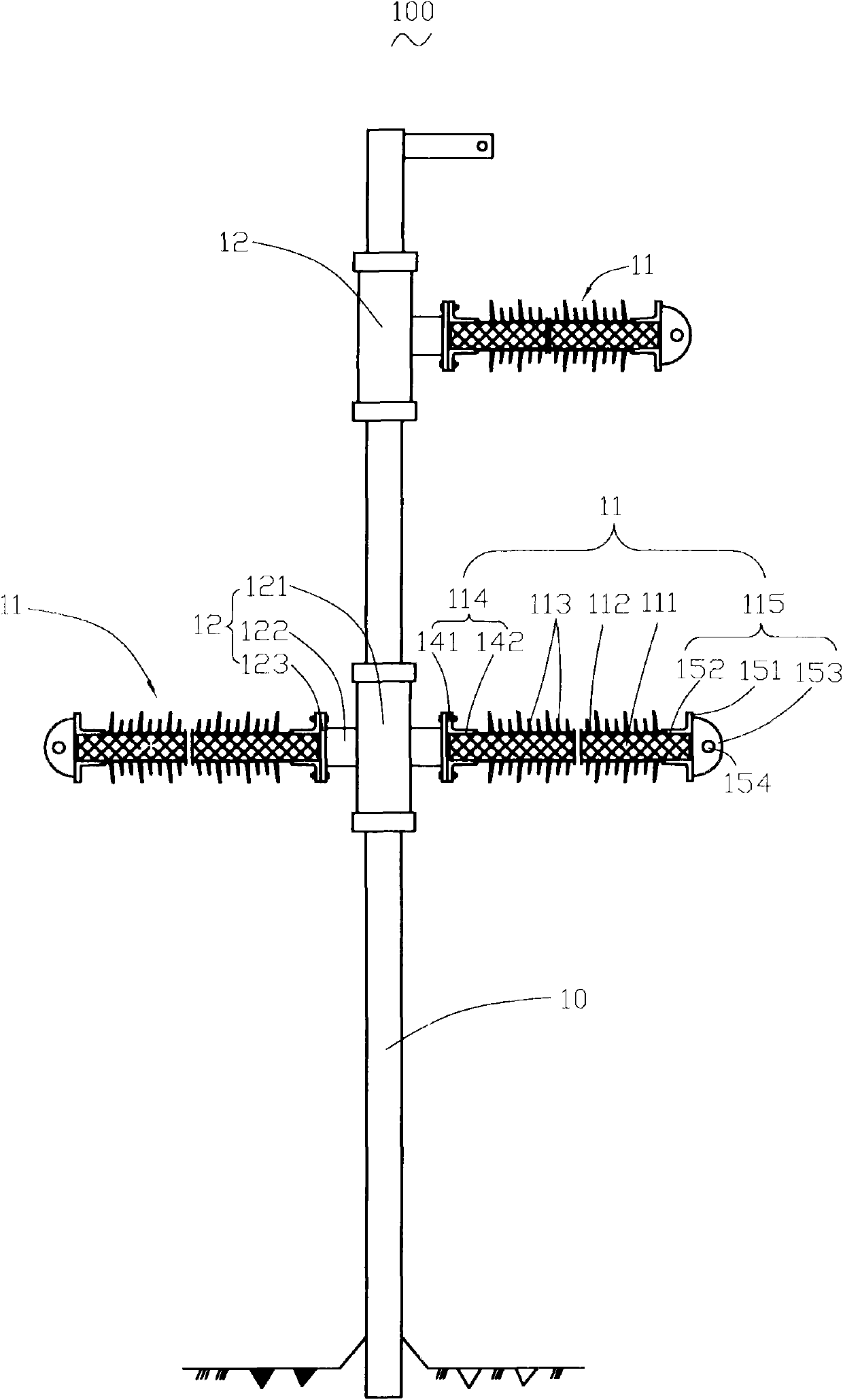

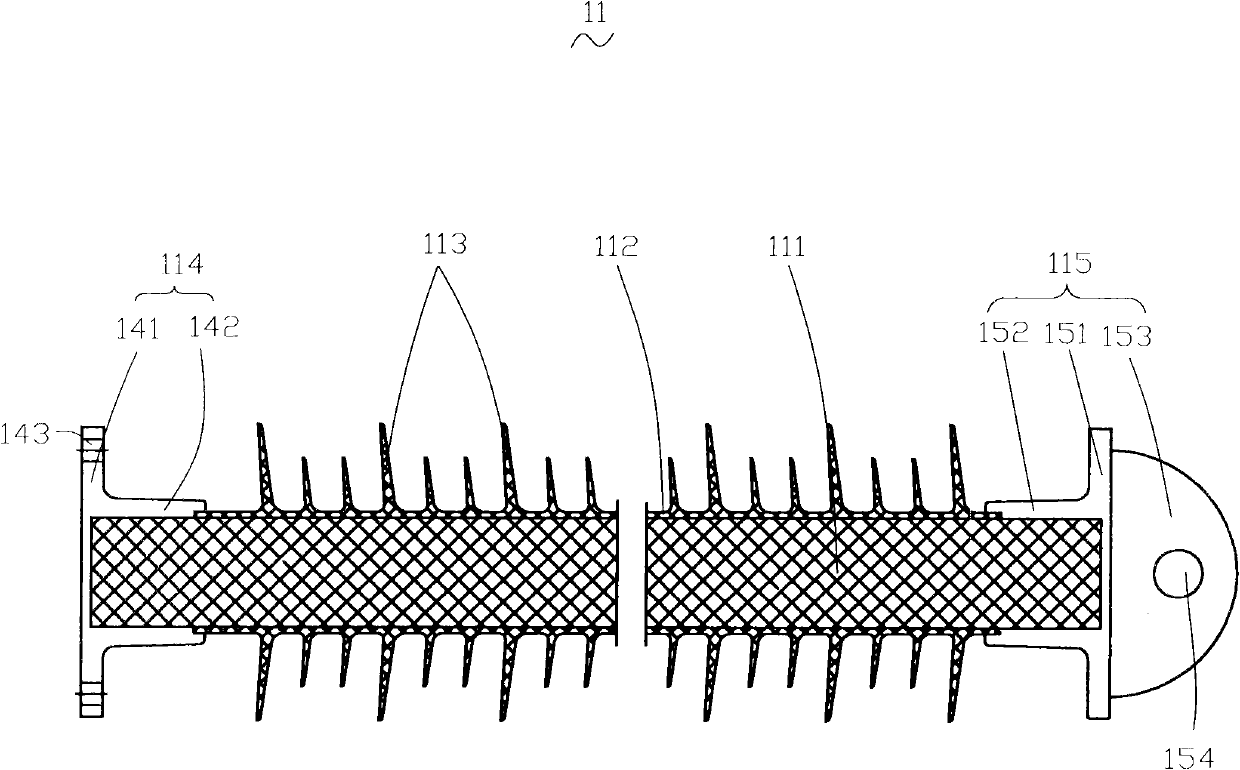

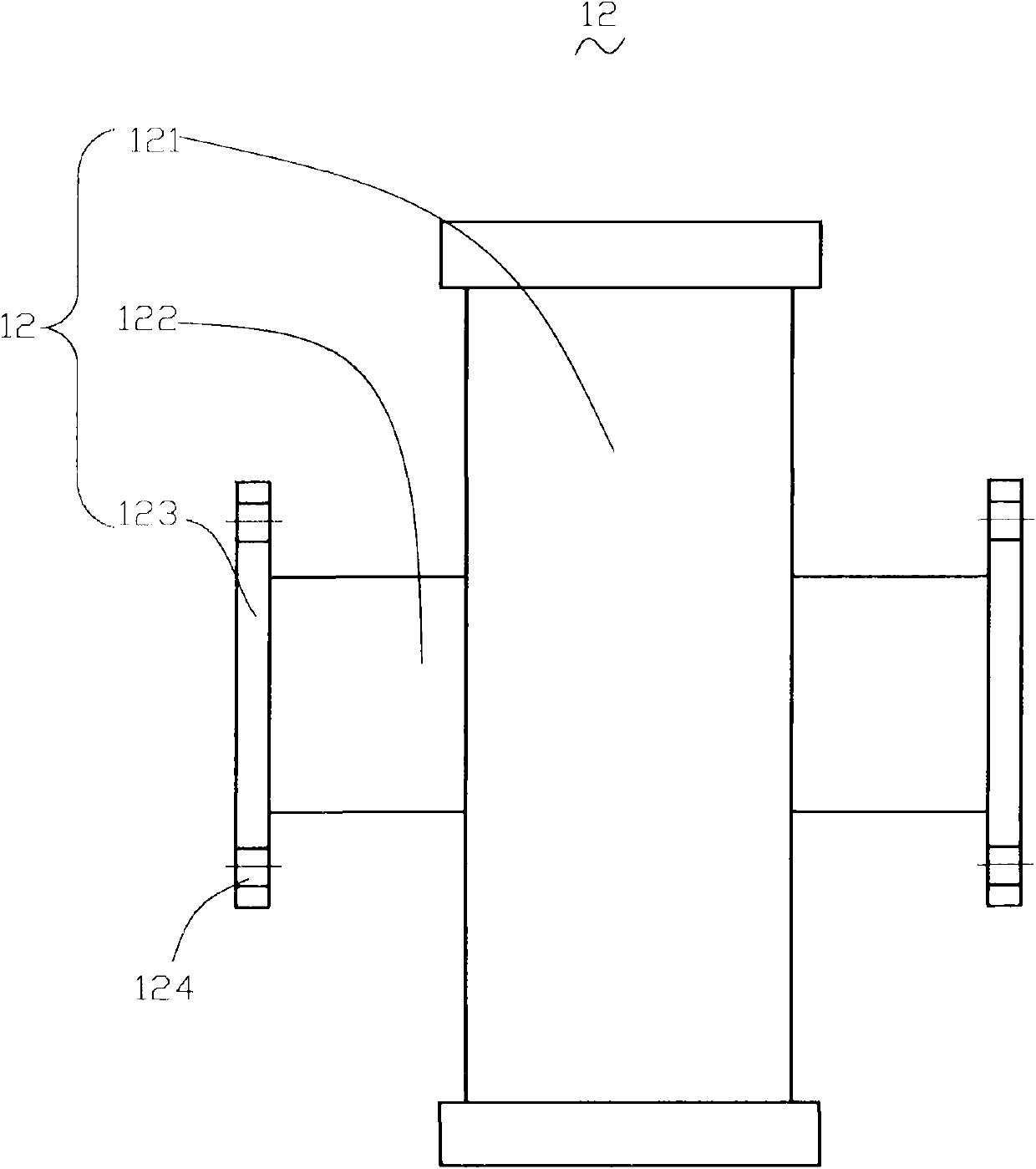

Composite insulating tower for power grid transmission line

InactiveCN102003098AReduce the overall heightLow costSuspension arrangements for electric cablesTowersYarnGlass fiber

The invention relates to a composite insulating tower for a power grid transmission line, which comprises a main pole and at least one cross arm arranged on the main pole. The cross arm comprises an insulating rod and an umbrella body arranged on the outer side of the insulating rod. The umbrella body is made of silicon disulfide rubber. One end of the insulating rod is connected with the main pole. The other end of the insulating rod is connected with a hanging fitting. The hanging fitting extends along the axial direction of the cross arm and is used for arranging the transmission line or an insulator. The main pole and the insulating rod are formed by impregnating glass fiber yarns in a resin material. The composite insulating tower for the power grid transmission line comprises the main pole and the cross arm which are made of composite materials and serve as supporting parts of the transmission line, and a sheath and a shed are arranged on the outer side of the cross arm, so that the total height of the composite insulating tower for the power grid transmission line can be reduced without an insulator string or the insulator string shorter than the conventional insulator string to reduce the cost and the weight of the tower.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

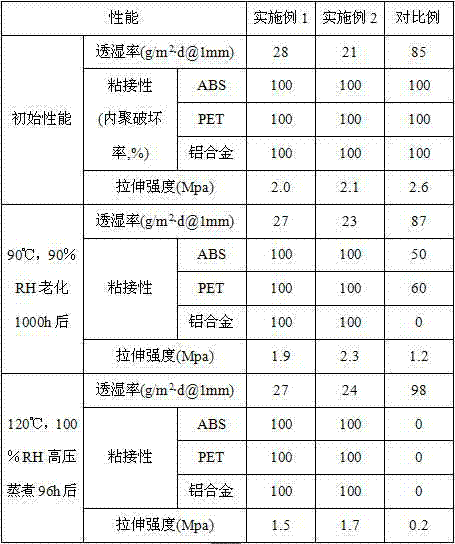

Low-moisture-permeability single-component dealcoholization type room-temperature silicon sulfide rubber sealing agent and preparation method thereof

ActiveCN104513645ALow moisture permeabilityReduce penetrationNon-macromolecular adhesive additivesPtru catalystVulcanization

The invention discloses a low-moisture-permeability single-component dealcoholization type room-temperature silicon sulfide rubber sealing agent and a preparation method thereof. The sealing agent consists of the components in parts by weight: 100 parts of alpha, omega-divinyl polydimethylsiloxane, 3-8 parts of hydrogen-based silane, 0.5-3 parts of a platinum catalyst, 3-10 parts of simethicone, 10-30 parts of silane-modified polyisobutylene, 3-8 parts of a crosslinking agent, 1-5 parts of a silane coupling agent, 50-150 parts of a reinforcement filler and 1-5 parts of a catalyst. Compared with conventional single-component dealcoholization type room-temperature silicon sulfide rubber, the sealing agent disclosed by the invention has improved sealing performance and is low in moisture permeability, and harm to a sealing component due to invasion of water vapor can be effectively prevented.

Owner:富乐(苏州)新材料有限公司

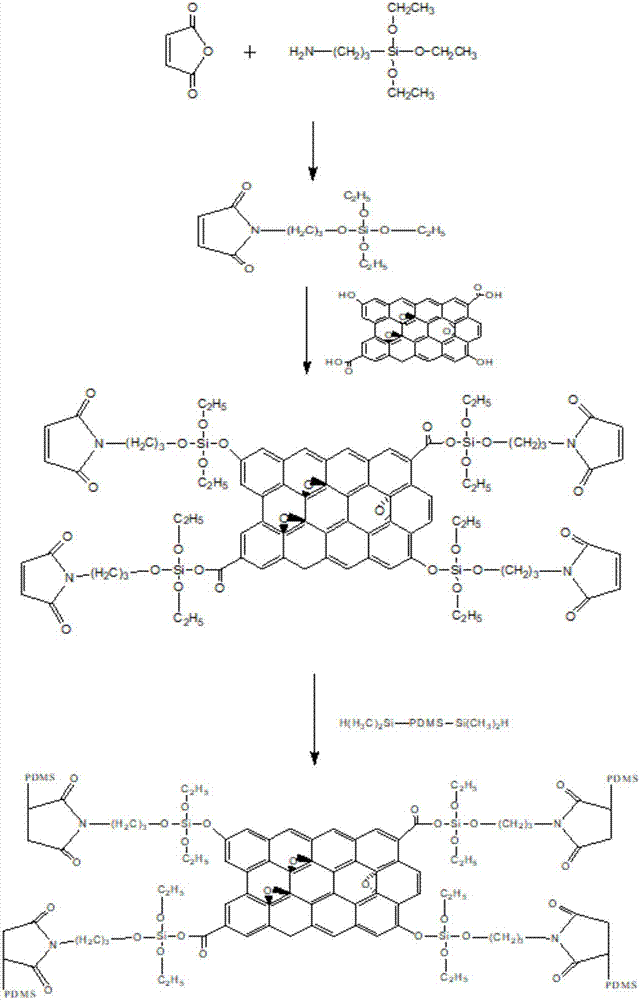

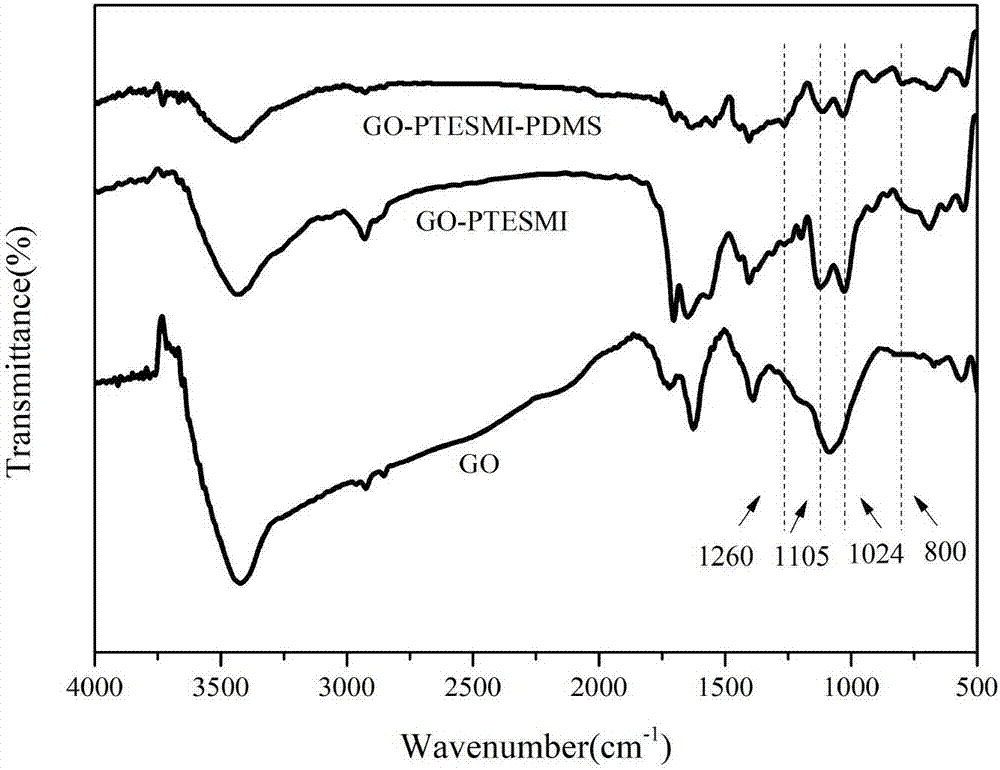

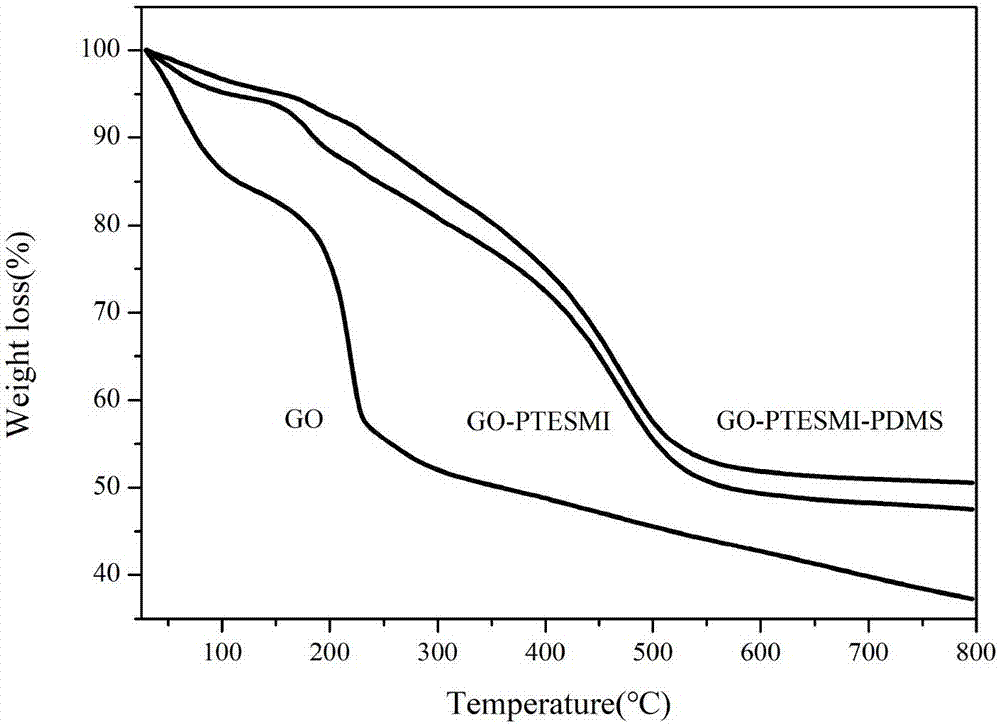

Functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and preparation method thereof

The invention discloses a functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and a preparation method thereof. The method comprises steps as follows: firstly, the surface of GO is grafted with maleimide siloxane, GO-PTESMI is obtained, then double bonds of maleimide on grafting chains in GO-PTESMI are subjected to a hydrosilation reaction with Si-H group terminated PDMS (polydimethylsiloxane) in a solution, and GO (functionalized GO) with surface linked with PDMS grafting chains containing imide groups is prepared; then the functionalized GO is dispersed in a dispersing agent uniformly, and the silicone rubber nanocomposite with different content of functionalized GO is prepared through solution blending. According to the invention, imide bonds and polysiloxane long chains are introduced to the surface of GO, so that interface interaction force and mechanical properties of the nanocompoiste can be improved simultaneously, and the RTV silicone rubber material with capacity of playing excellent performance of GO better is prepared.

Owner:FUJIAN NORMAL UNIV

Dual composition addition type room temperature silicon disulfide rubber containing phase transformation material

The invention discloses a dual composition addition type room temperature silicon disulfide rubber containing phase transformation material, comprising a basic composition and a catalyst composition with the volume ratio being 1:1; the basic composition comprises the following raw material components: 20-40% of methyl vinyl silicone oil, 0.5-3% of cross linking agent methyl silicone oil containinghydrogen, 0.01-0.5% of inhibitor, 1-10% of plasticizer, 30-60% of silicon dioxide premix filler, 3-15% of other filler, 1-5% of additive, and 0-5% of pigment; the catalyst composition comprises the following raw material components: 20-40% of methyl vinyl silica gel, methyl vinyl oxosilane coordination platinum complex catalyst, 1-10% of plasticizer, 30-60% of silicon dioxide premix filler, 3-15%of other filler, and 1-5% of additive. The invention ensures the room temperature vulcanization velocity of the dual composition addition type room temperature silicon disulfide rubber to maintain constant basically in a wider temperature range, is suitable for manufacturing dental impression and ear impression materials, heat insulation protection materials, curtains, vehicle seat cushions, drugpackage materials, cold-proof materials and the like.

Owner:合肥凯蒙新材料有限公司

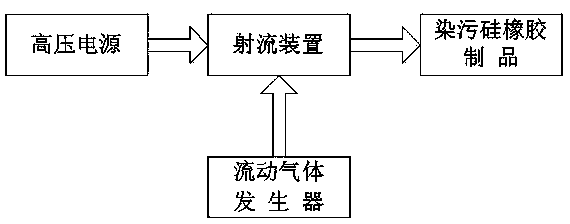

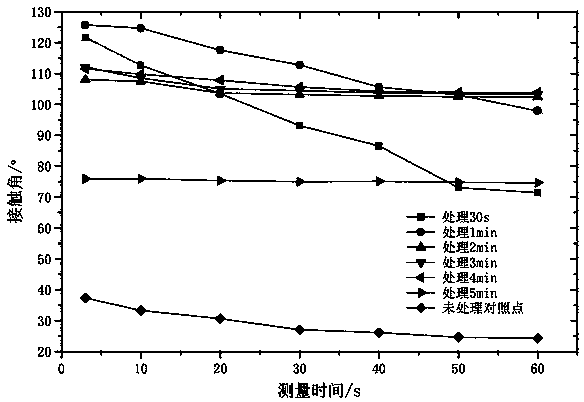

Method and system for improving surface hydrophobicity of contaminated silicon sulfide rubber product

ActiveCN103354141AMaintain pollution flashover voltageGuaranteed uptimeInsulatorsComposite insulatorsPolymer science

The invention provides a method for improving surface hydrophobicity of a contaminated silicon sulfide rubber product. The method includes steps of providing the silicon sulfide rubber product contaminated by dirt; and injecting atmospheric-pressure low-temperature plasma jet on the dirt on the surface of the product for conducting surface treatment. The atmospheric-pressure low-temperature plasma jet acts on the dirt on the surface of the silicon sulfide rubber product and enables hydrophobicity of the surface of the silicon sulfide rubber product to be transferred to the surface of the dirt, so that flashover voltage on the surface of the contaminated silicon sulfide rubber product is kept. The processing efficiency is high. Surface hydrophobicity of contaminated composite insulators, post insulators, insulating bushes and the like can be improved ideally. Therefore, the method for improving surface hydrophobicity of the contaminated silicon sulfide rubber product is suitable for popularization and application.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

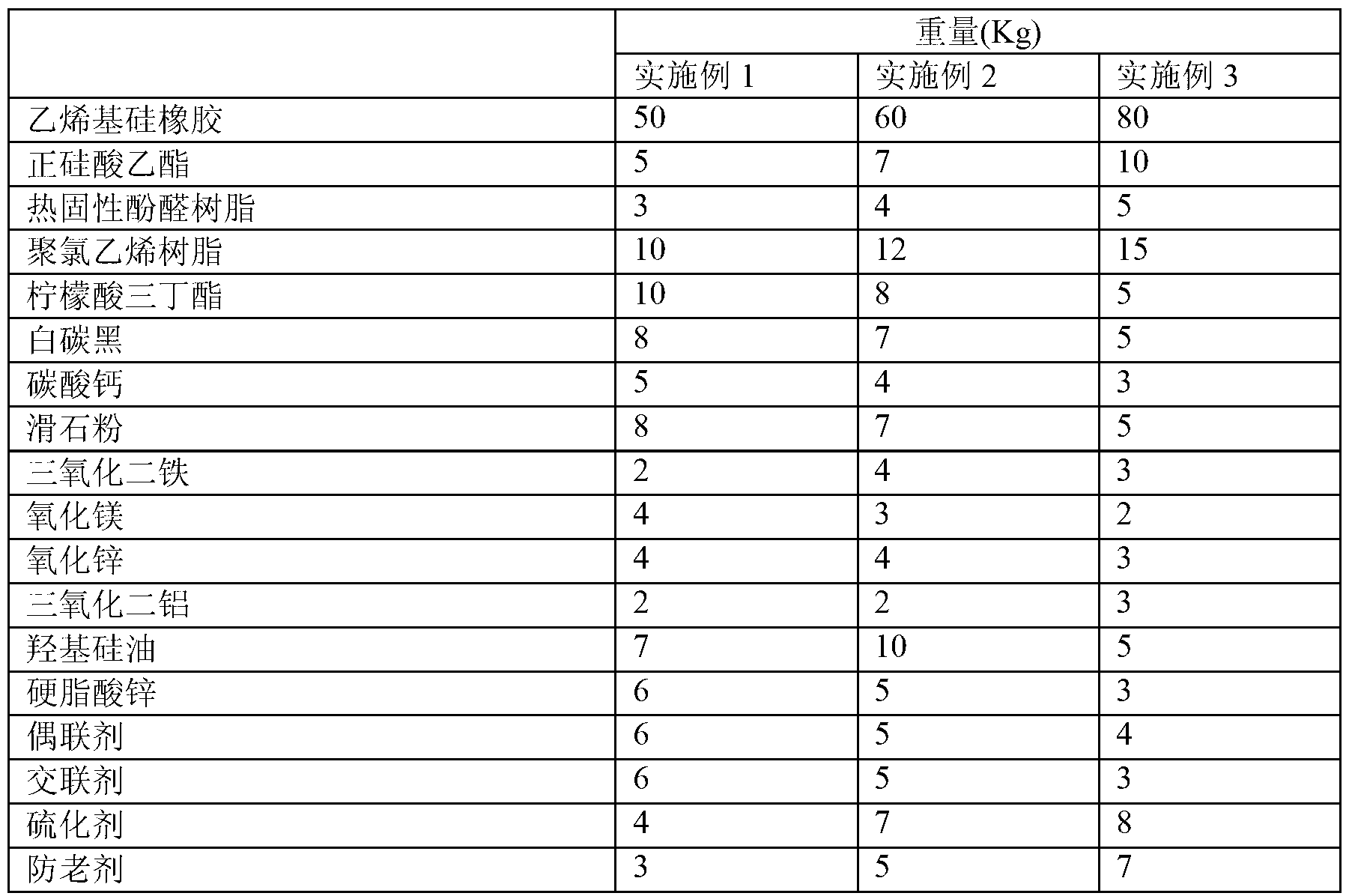

High temperature resistant silicon rubber and preparation method thereof

InactiveCN103265815AImprove mechanical propertiesImprove high temperature resistancePolyvinyl chlorideTemperature resistance

The invention provides a silicon rubber, particularly relates to a high temperature resistant silicon sulfide rubber and belongs to the technical field of polymer materials. The high temperature resistant silicon rubber comprises the following constituents in parts by weight: 50-80 parts of vinyl silicon rubber, 5-10 parts of ethyl orthosilicate, 3-5 parts of thermosetting phenol resin, 10-15 parts of polyvinyl chloride resin, 5-10 parts of tri-n-butyl citrate, 5-8 parts of white carbon black, 3-5 parts of calcium carbonate, 5-8 parts of talcum powder, 2-4 parts of iron trioxide, 2-4 parts of magnesium oxide, 3-4 parts of zinc oxide, 2-3 parts of aluminum oxide, 5-10 parts of hydroxyl silicone oil, 3-6 parts of zinc stearate, 4-6 parts of coupling agent, 3-6 parts of cross-linking agent, 4-8 parts of vulcanizing agent and 3-7 parts of anti-aging agent. The silicon rubber provided by the invention has better mechanical property and high temperature resistance, the hardness can be more than 70HA, the tensile strength can be more than 9.5MPa, the elongation can be more than 420%, and the thermal decomposition temperature can be more than 450 DEG C.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

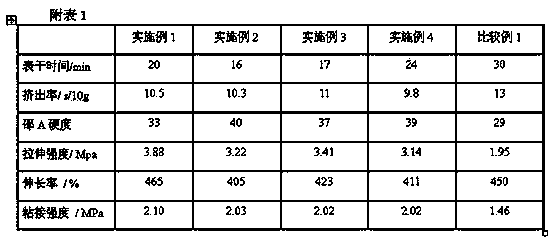

High-strength single-component room temperature vulcanized silicone rubber

InactiveCN103834353AHigh mechanical strengthSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceSealant

The invention discloses a high-strength single-component room temperature vulcanized silicone rubber, which belongs to the technical field of single-component room temperature vulcanized silicone rubber sealants, and mainly solves the problem that the tensile strength of organosilicone rubber in the prior art is low (less than 2MPa). The high-strength single-component room temperature vulcanized silicone rubber is mainly characterized by comprising (a) 100 parts of hydroxyl-terminated poly (dimethyl siloxane) polymer; (b) 90-150 parts of a reinforcing filler; (c) 4-10 parts of a thixotropic agent; (d) 15-33 parts of a silicone oil plasticizer; (e) 6-14 parts of a crosslinking agent; (f) 1.7-4 parts of a coupling agent; (g) 0-2.5 parts of a catalyst; and (h) 0.3-3 parts of a pigment. The tensile strength of the high-strength single-component room temperature vulcanized silicone rubber can reach above 3.0MPa, the elongation at break of is greater than 400%, the aluminum sheet, steel sheet adhesion force can reach 2.0Mpa, and the high-strength single-component room temperature vulcanized silicone rubber has the features of being simple in preparation process, low in cost, and easy to use.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

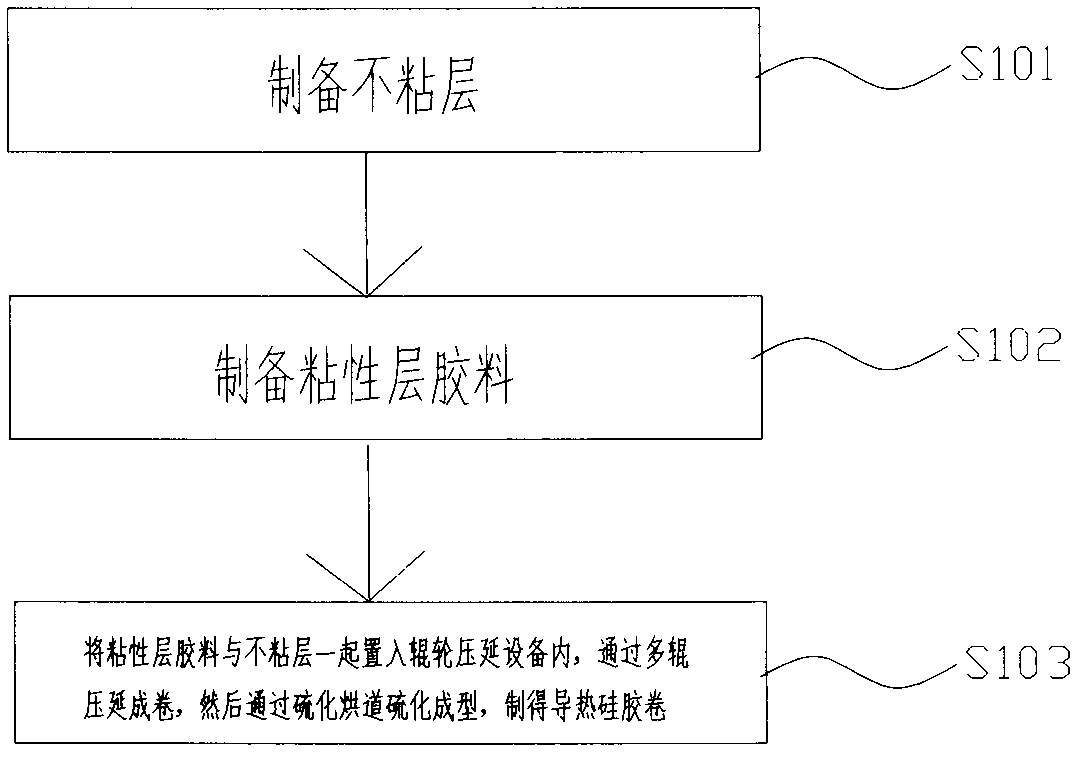

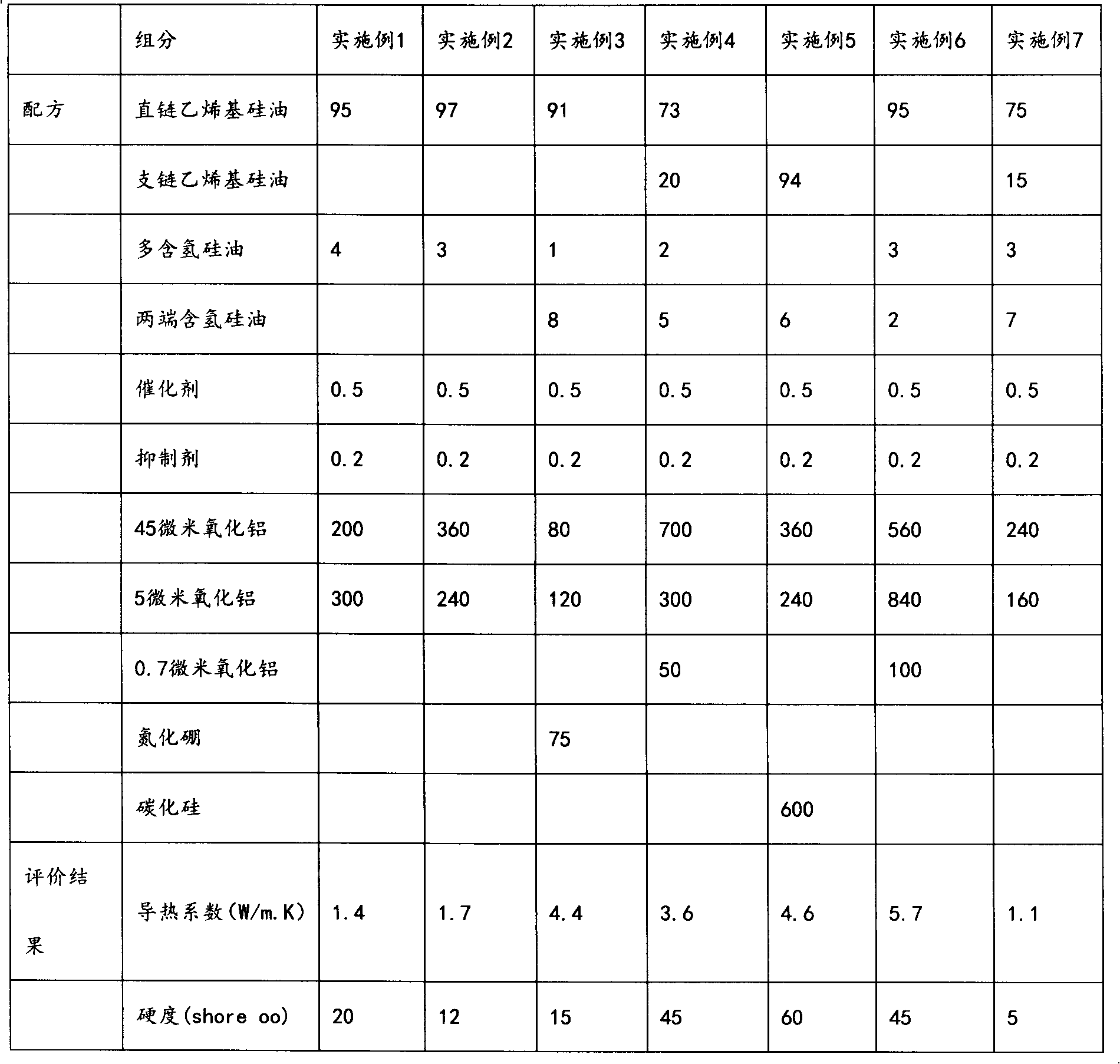

Heat-conducting siliconfilm and manufacturing method thereof

The invention relates to the technical field of heat-conducting siliconfilms, and discloses a heat-conducting siliconfilm and a manufacturing method of the heat-conducting siliconfilm. One surface of the heat-conducting siliconfilm is a viscous layer, the other surface of the heat-conducting siliconfilm is a non-viscous layer, the viscous layer comprises liquid state silicone, solid heat conduction powder and fire retardants, the non-viscous layer comprises high-temperature silicon disulfide rubber and solid heat conduction powder, and the high-temperature silicon disulfide rubber is rubber compound. When being used, the heat-conducting siliconfilm with the viscous layer at one surface and the non-viscous layer at the other surface is convenient to disassemble, the problem of non-uniform radiating of heterogeneous materials with different heat condition performances can not be worried when the siliconfilm is used, and as the heat amount is accumulated, the radiating effect of the siliconfilm is greatly enhanced. The coefficient of heat conductivity of the siliconfilm provided by the invention is more than 0.8W / m.K, and can reach more than 5W / m.K according to different types and quantities of the added solid heat conduction powder.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

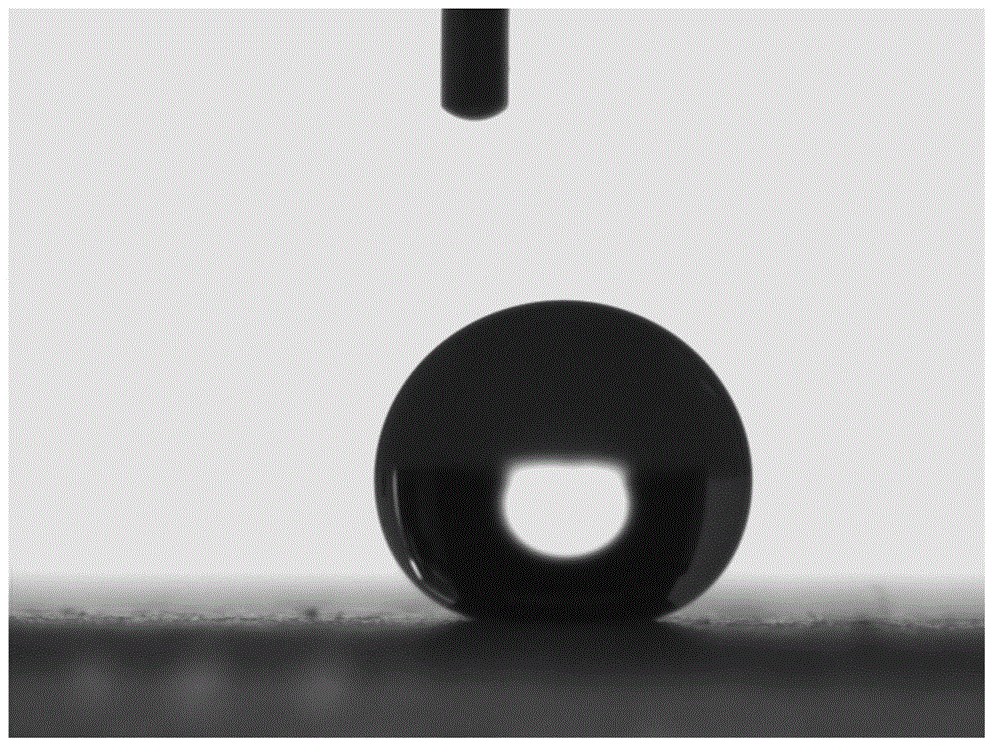

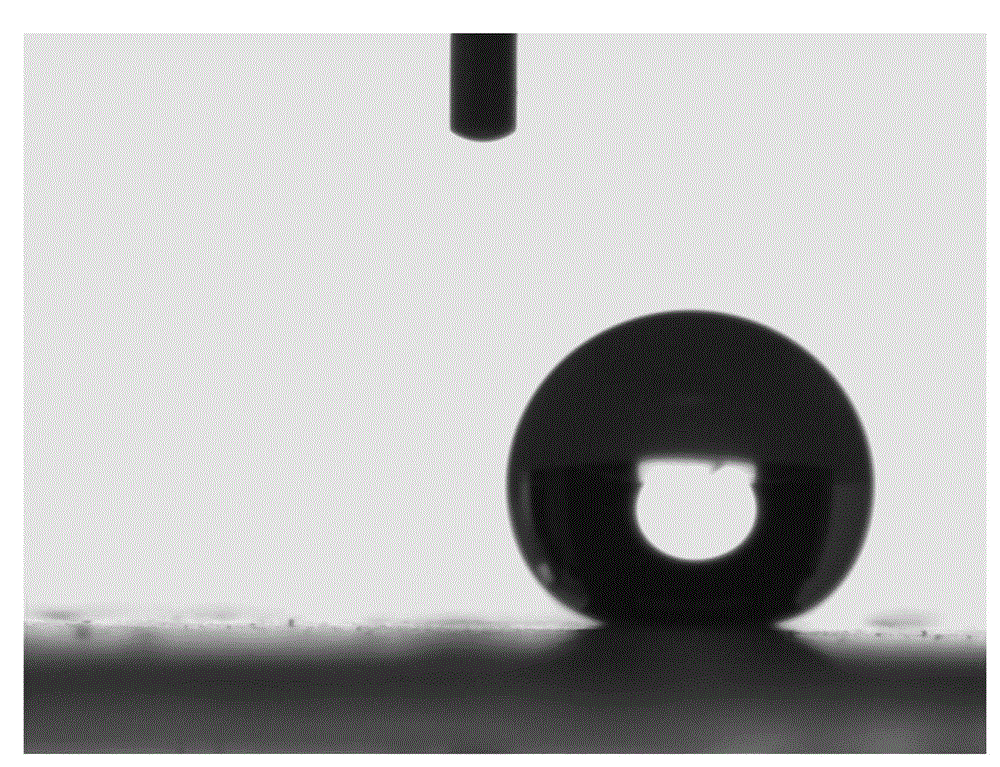

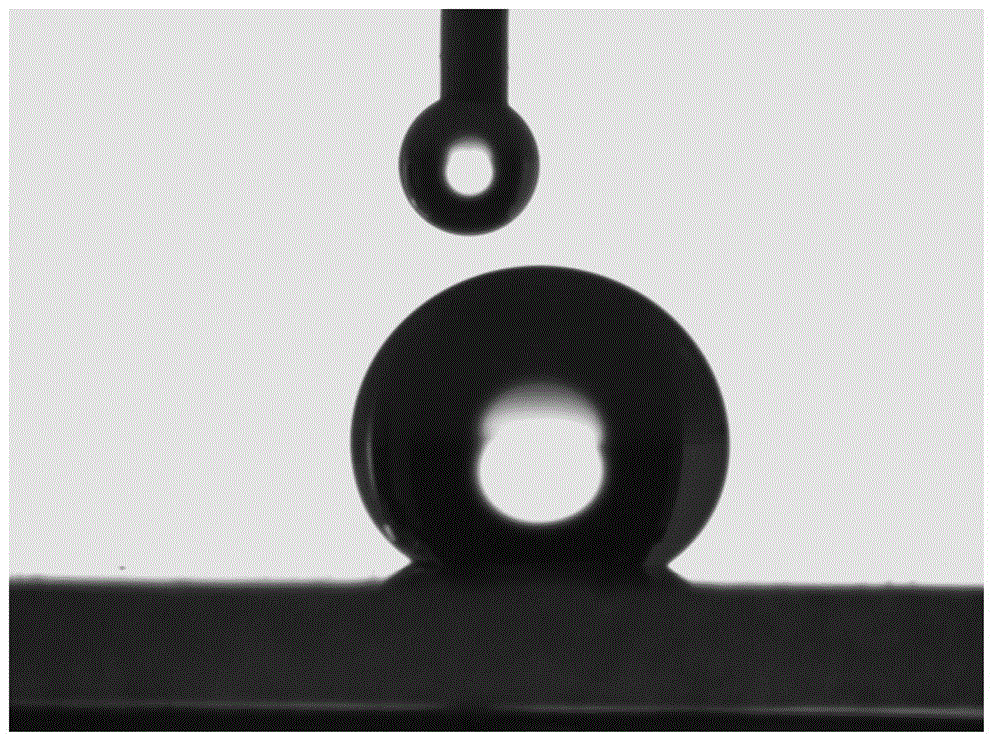

Superhydrophobic polypropylene film and preparation method thereof

The invention provides a super-hydrophobic polypropylene film and a preparation method thereof, belonging to the technical field of superhydrophobic film materials. The invention solves the problems of too high preparation cost, complex process, and the like in the traditional super-hydrophobic polypropylene film. The surface structure of the super-hydrophobic polypropylene film is similar to the surface structure of natural taro leaf. The preparation method for the super-hydrophobic polypropylene film comprises the following steps of: placing the fresh taro leaf into a casting mold, mixing and stirring liquid room temperature vulcanizing silicone rubber with a catalyst and a crosslinking agent thereof in proportions, pumping air bubbles in the mixture, and then pouring the mixture on the fresh taro leaf in the mold, and finally obtaining a vulcanized silicone rubber soft template after curing in an atmospheric environment at a room temperature. By casting polypropylene solution with the concentration of 1 to 100 mg / ml onto the vulcanized silicone rubber soft template, and then drying in the atmospheric environment at the room temperature and tearing off, the super-hydrophobic polypropylene film is obtained. The super-hydrophobic polypropylene film has the advantages of simple preparation process, good reproducibility, and very good industrial application prospect without needing any expensive equipment.

Owner:昌源集团有限公司

Inorganic solid electrolyte and lithium cell component

InactiveUS20060147806A1Improve ionic conductivityMaintain good propertiesElectrolytic capacitorsPhosphorus sulfur/selenium/tellurium compoundsMetallic lithiumPhysical chemistry

A sulfide-based inorganic solid electrolyte that suppresses the reaction between silicon sulfide and metallic lithium even when the electrolyte is in contact with metallic lithium, a method of forming the electrolyte, and a lithium battery's member and lithium secondary battery both incorporating the electrolyte. The electrolyte comprises Li, P, and S without containing Si. It is desirable that the oxygen content vary gradually from the electrolyte to the lithium-containing material at the boundary zone between the two members when analyzed by using an XPS having an analyzing chamber capable of maintaining a super-high vacuum less than 1.33×10−9 hPa and that the oxygen-containing layer on the surface of the lithium-containing material be removed nearly completely. The electrolyte can be formed such that at least part of the forming step is performed concurrently with the step for etching the surface of the substrate by irradiating the surface with inert-gas ions.

Owner:SUMITOMO ELECTRIC IND LTD

Method for producing ion-conductive substance, ion-conductive substance, crystallized ion-conductive substance, and cell

A method for producing an ionic conductive substance, including a step of contacting raw materials in a solvent, wherein the raw materials include: one or more compounds selected from phosphorus sulfide, germanium sulfide, silicon sulfide and boron sulfide; a sulfide of a metal element belonging to group I or group II of the periodic table; and a halogen compound represented by MwXx wherein M is Li, B, Na, K, Rb, Cs, Ca, Mg, Sr, Ba, Al, Si, P, S, Ge, As, Se, Sn, Sb, Te, Pb or Bi, w is 1 or 2, X is F, Cl, Br or I, and x is an arbitrary integer selected from 1 to 10.

Owner:IDEMITSU KOSAN CO LTD

Method for preparing natural rubber exhaust gasket for forming rubber shoes

InactiveCN101940386AImprove conduction abilityEffective isolationUpperBootlegsSurface layerRoom temperature

The invention discloses a method for preparing a natural rubber exhaust gasket for forming rubber shoes. The method comprises the following steps of: vulcanizing natural rubber to obtain a rubber body of the exhaust gasket; painting a layer of gasoline mucilage on the reverse side of interlock and drying; cutting the interlock and the rubber body of the exhaust gasket according to the shape requirements of the rubber gasket, placing the rubber body of the exhaust gasket on the side of the interlock painted with the gasoline mucilage, putting in a module and boiling in water for heating, and taking the rubber exhaust gasket out and cooling to obtain an exhaust gasket blank; and painting room-temperature silicon disulfide rubber on the interlock side of the exhaust gasket blank and standing at room temperature for more than 5 days to obtain the finished product. In the method, the high-elasticity vulcanized sponge rubber of the natural rubber is used as the substrate of the exhaust gasket, the elasticity and flexibility of the rubber body are adjusted by using a boiling and foaming process, the surface of the rubber substrate is enhanced due to the adoption of the high-elasticity interlock, the service life of the exhaust gasket is prolonged and the force transfer effect is improved; moreover, due to the room-temperature silicon disulfide rubber coating on the surface layer, the rubber components of the rubber shoes are effectively isolated and the original shape of the patterns of the rubber components of the rubber shoes is maintained.

Owner:JIHUA 3537 SHOE MAKING

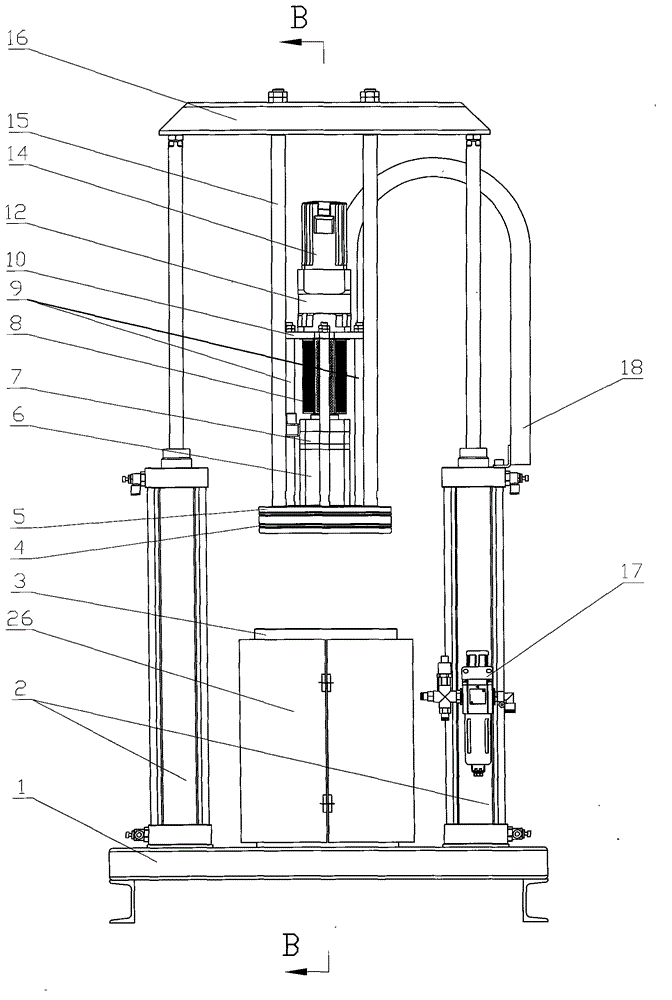

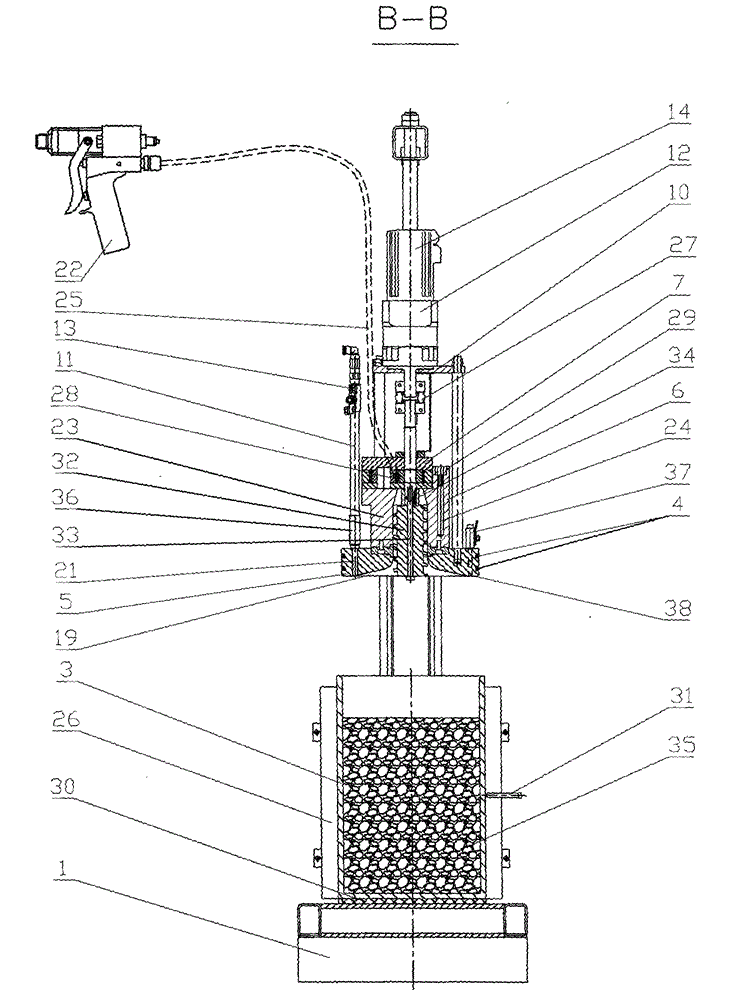

Combined adhesive supplying device using gear pump and screw pump

ActiveCN104454516AEasy to control metering deliveryAccurate metering and deliveryRotary/oscillating piston combinationsMachines/enginesGear pumpCoupling

The invention discloses a combined adhesive supplying device using a gear pump and a screw pump, and relates to a device for metering, conveying and supplying high-viscosity materials such as adhesive, polyurethane and hot-melt adhesive, in particular to a polyurethane metering, conveying and supplying device. The combined adhesive supplying device comprises a pedestal, cylinders, an adhesive barrel, a sealing ring, a gland, a screw pump, a gear pump, a fixing plate, a speed reducer, a servo motor, connecting rods, a cross beam and the like, wherein the screw pump comprises a pump body, a screw rod and a screw; the servo motor and the speed reducer are fixedly connected with a fixing plate sequentially; the gear pump is fixed on the screw pump; the lower end of a shaft of the gear pump is connected with the upper end of the screw rod through a shaft coupler A; a suction opening of the gear pump is positioned at an outlet end of the screw pump; an inlet end of the screw pump is positioned at a conical adhesive feeding opening of the gland. When the viscosity of the polyurethane or the adhesive is relatively high, metering and conveying can be easily controlled and metering is accurate; the combined adhesive supplying device can be also used for metering and conveying the polyurethane, the adhesive, the hot-melt adhesive, foam materials, grease, ink, silicon sulfide resin or other high-viscosity materials.

Owner:DALIAN HUAGONG INNOVATION TECH

Method for manufacturing mono-component water-dispersing room temperature dewatering silicon sulfide ketone seal gum

The present invention relates to a manufacturing method of single component water dispersivity room temperature evaporated sulfuration silicones sealing gum. The manufacturing method is characterized in that the method includes the steps as follows: wherein the raw materials are all parts by weight; 100 shares of anion hydroxide radical silicon oil, 1.5 to 6 shares of anion active agent, 0 to 6 shares of non-ion active agent and 60 to 150 shares of de-ionized water are processed in a high pressure viscolizer for one to three times, the mixture is added into a reaction kettle with a blender, and the mixture reacts for 24 to 72 hours under the temperature of 5 to 80 degree centigrade, then 0.5 to 20 shares of metal alkaline silicate or silica sol and 0.02 to 5 shares of stanniferous catalyzing compound are added for curing 2 to 3 days to get Alpha and Omega to (dihydroxy) dimer organic siloxane polymer latex; the latex, 0 to 5 shares of organic silicon resin acceptor, 50 to 180 shares of inorganic filler, 0.1 to 1 shares of thickening agent and 0.1 to 1 shares of foam killer are added into a kneader for evenly mixing to get single component water dispersivity room temperature evaporated sulfuration silicones sealing gum.

Owner:CHENGDU GUIBAO NEW MATERIAL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com