Method and system for improving surface hydrophobicity of contaminated silicon sulfide rubber product

A vulcanized silicone rubber and hydrophobic technology, applied in electrical components, insulators, circuits, etc., can solve the problems of surface hydrophobic migration and difficult migration of surface hydrophobicity of vulcanized silicone rubber products, to ensure normal operation, convenient use, system simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The realization of the purpose of the present invention, functional characteristics and advantages will be further described in conjunction with the embodiments and with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

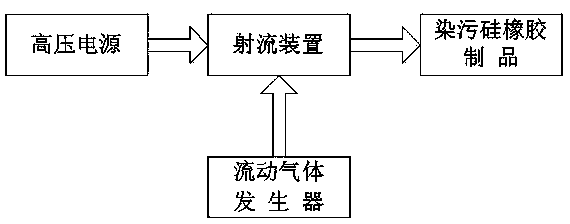

[0028] refer to figure 1 , the system for improving the hydrophobicity of the surface of stained vulcanized silicone rubber products includes a high-voltage power supply, a jet device and a flow gas generator.

[0029] The jet device includes a jet tube, a high-voltage electrode and a low-voltage electrode. The jet tube has a nozzle and an air inlet. Atmospheric pressure low-temperature plasma is ejected from the nozzle. The jet tube can be a quartz glass tube, a polytetrafluoroethylene tube or a metal tube, etc. The high-voltage electrode and the low-voltage electrode can have a variety of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com