Heat-conducting siliconfilm and manufacturing method thereof

A manufacturing method and technology of heat-conducting silicon, which is applied to adhesives, film/sheet adhesives, etc., can solve the problems of different thermal conductivity between sticky and non-sticky surfaces, impractical configuration of fans, and inability to export them in a timely and effective manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

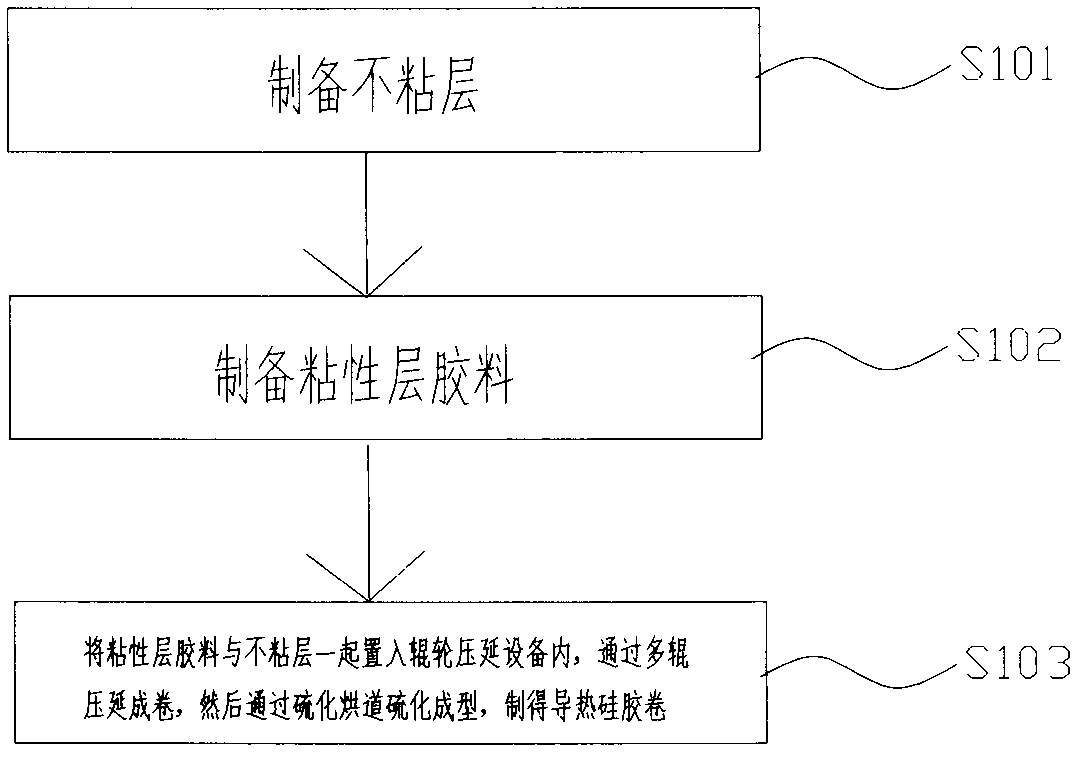

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

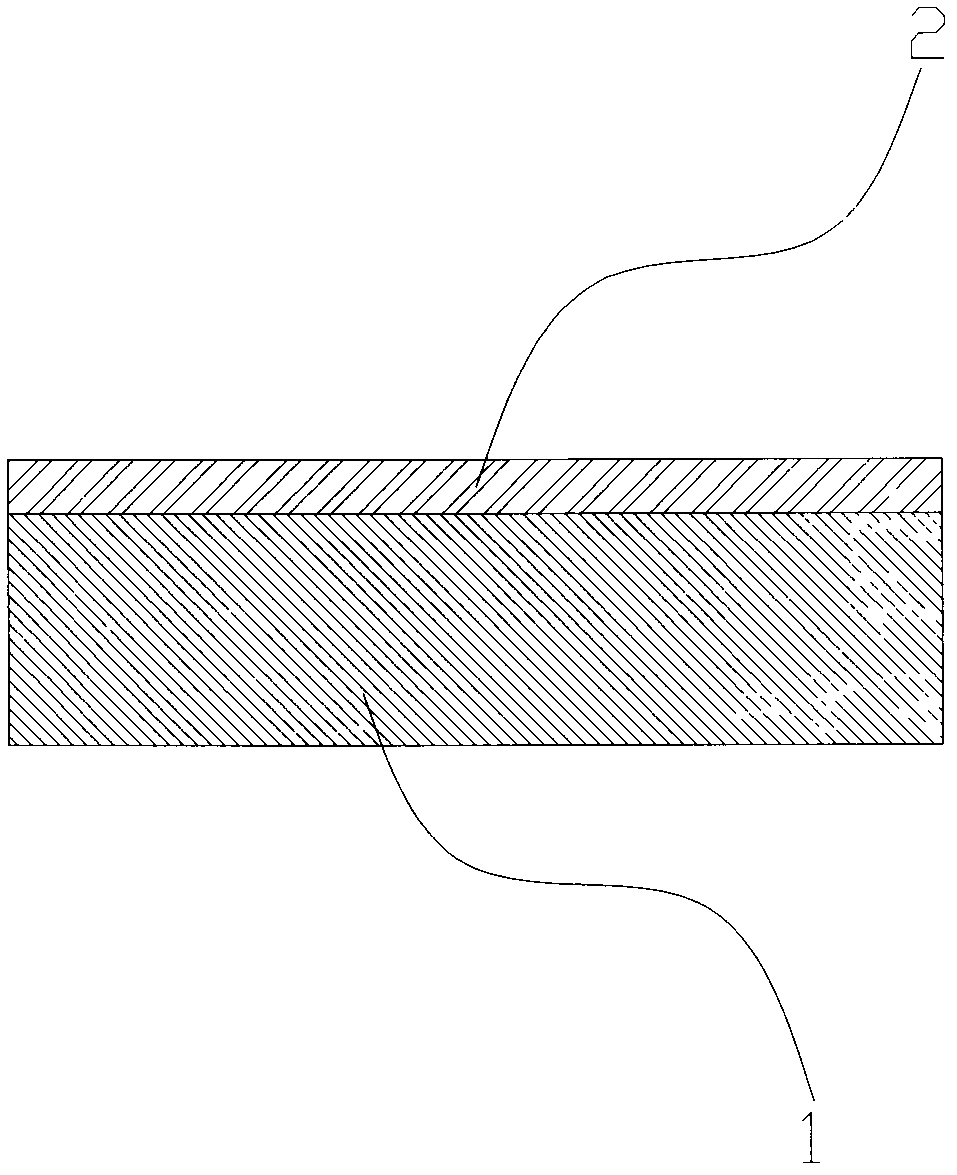

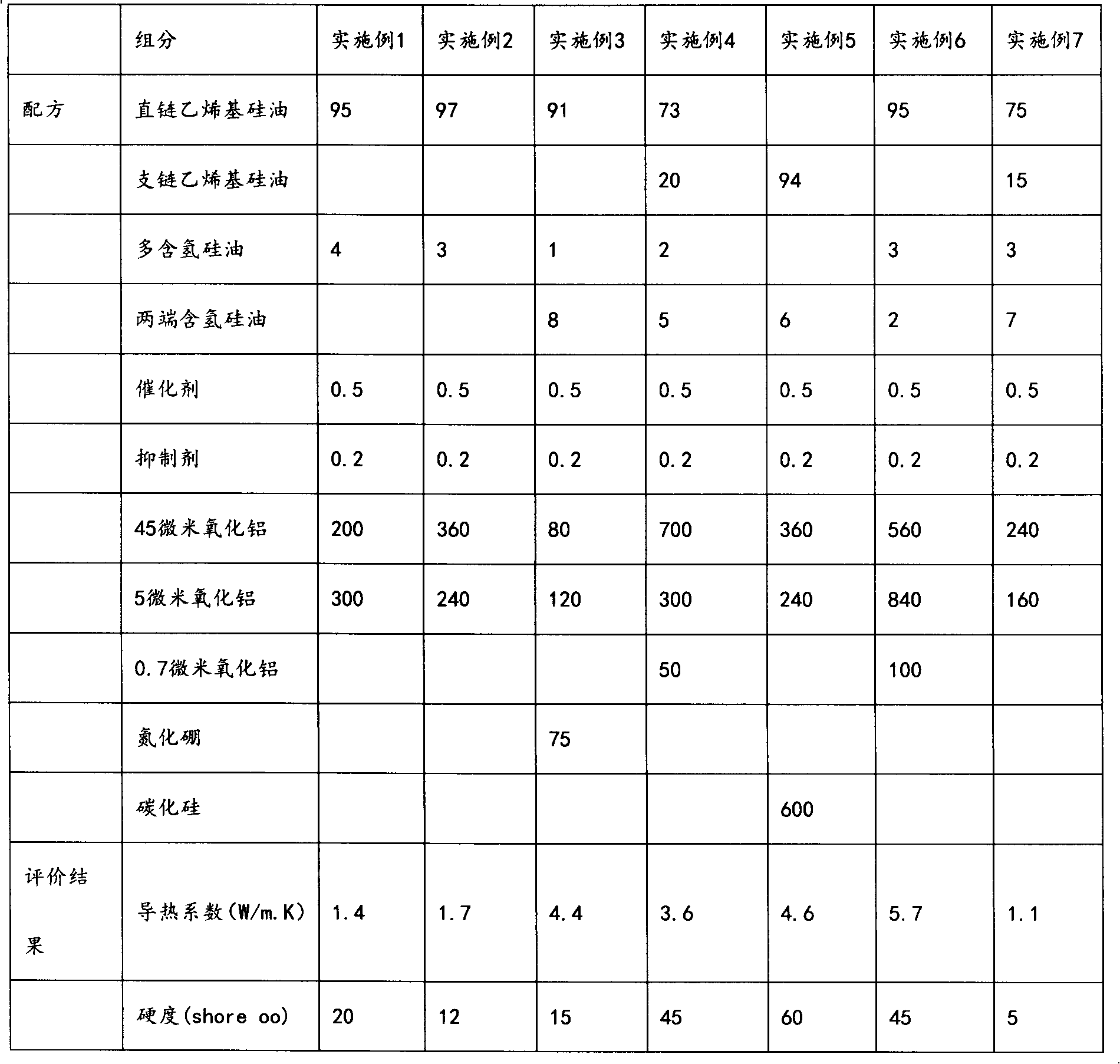

[0023] figure 1 A thermally conductive silicone roll according to an embodiment of the present invention is schematically shown. As shown in the figure, one side is an adhesive layer 1, and the other side is a non-stick layer 2. The adhesive layer 1 contains liquid silicone, solid heat-conducting powder and flame retardant, and the non-stick layer 2 contains high-temperature vulcanized silicone rubber and heat-conducting solid powder. , the high temperature vulcanized silicone rubber is selected from the compound rubber, and the liquid silicone includes a first organopolysiloxane composition, a second organopolysiloxane composition, an inhibitor, a catalyst and silicone oil. The first organopolysiloxane composition contains one or both of linear vinyl silicone oil and branched vinyl silicone oil; the second organosiloxane composition contains at least one hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com