Preparation method of fast curing dealcoholization type transparent room-temperature silicon sulfide rubber

A rapid curing, room temperature vulcanization technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the curing speed of silicone adhesive does not have fast curing, etc., to achieve strong adhesion and shockproof performance Good, excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

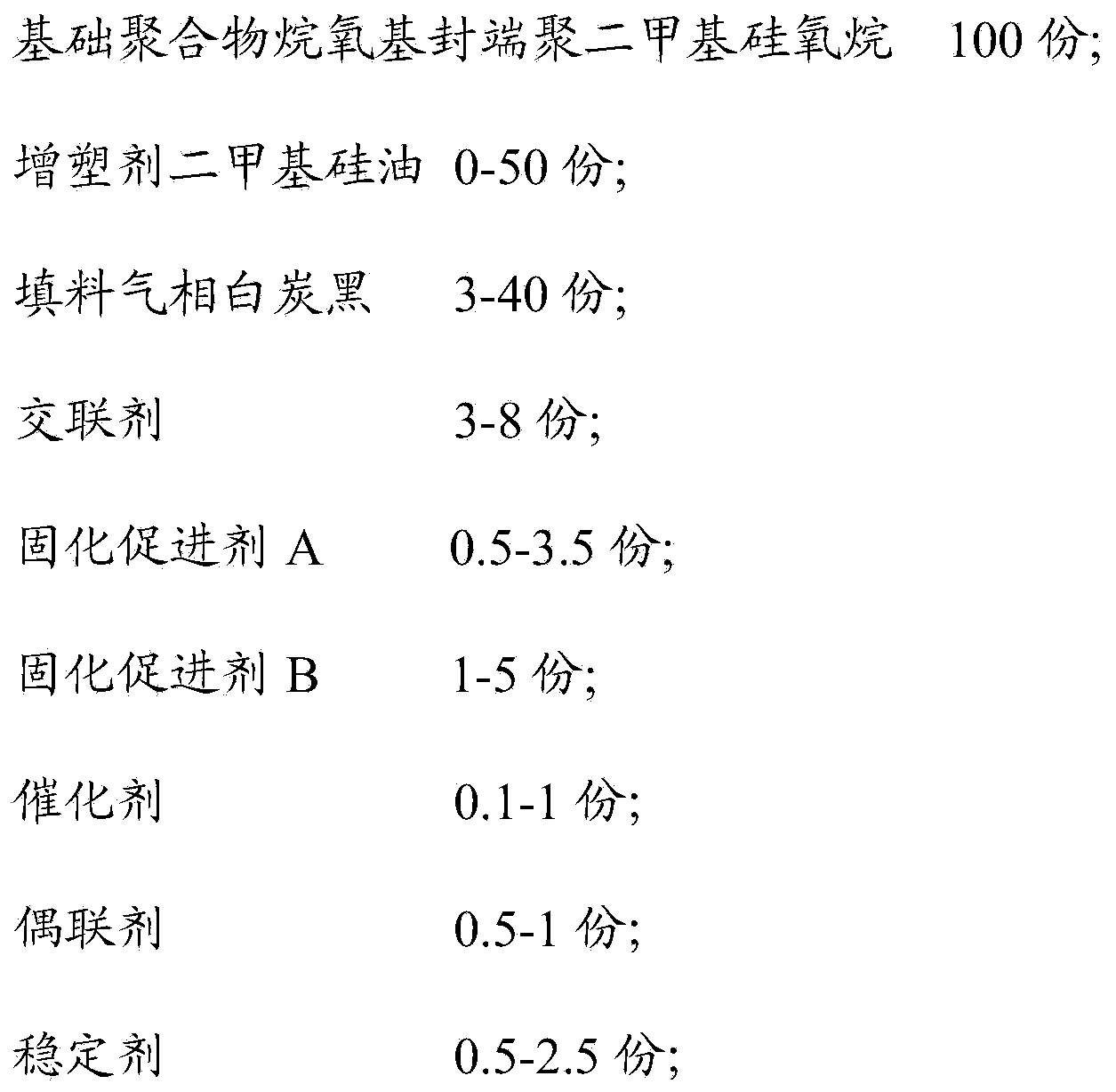

Method used

Image

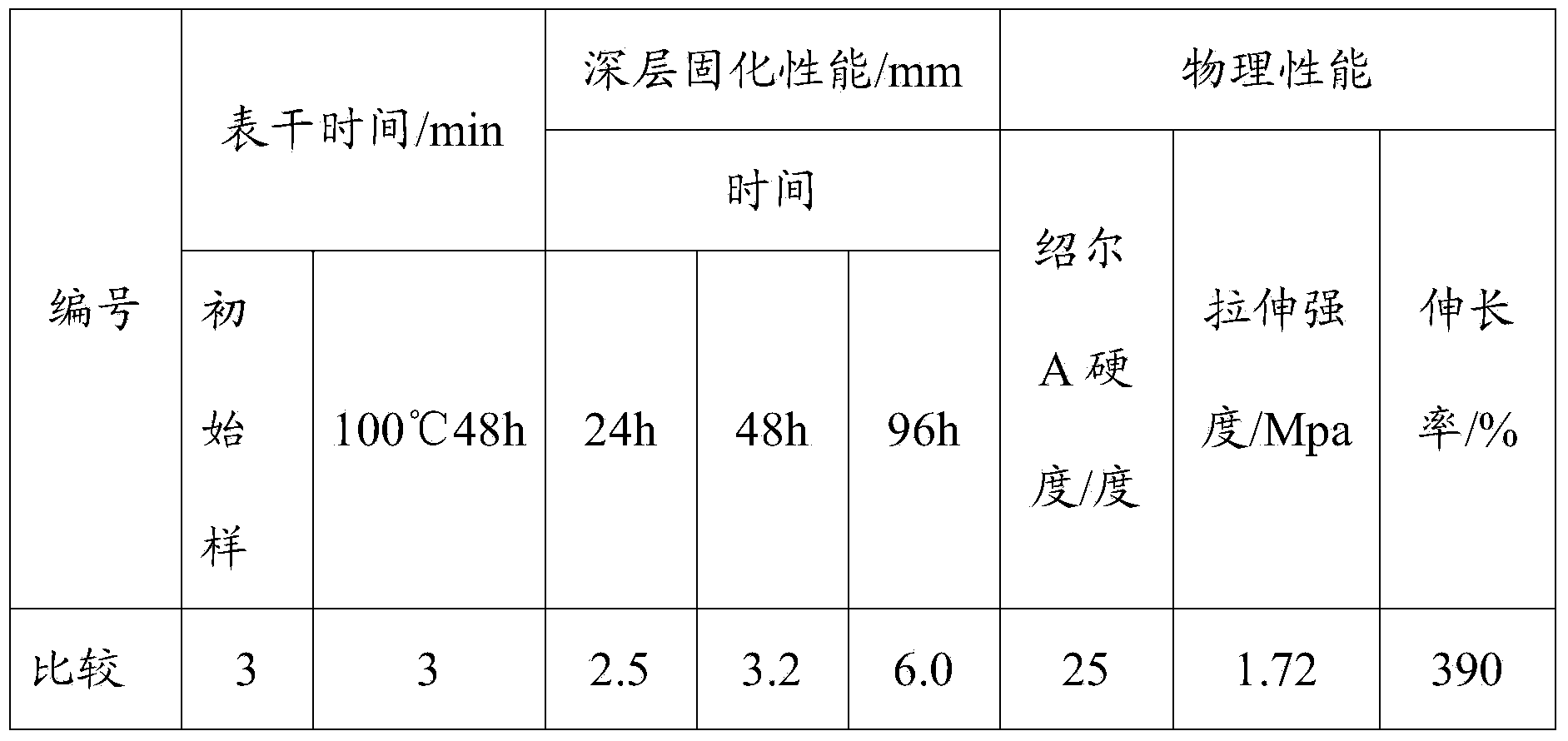

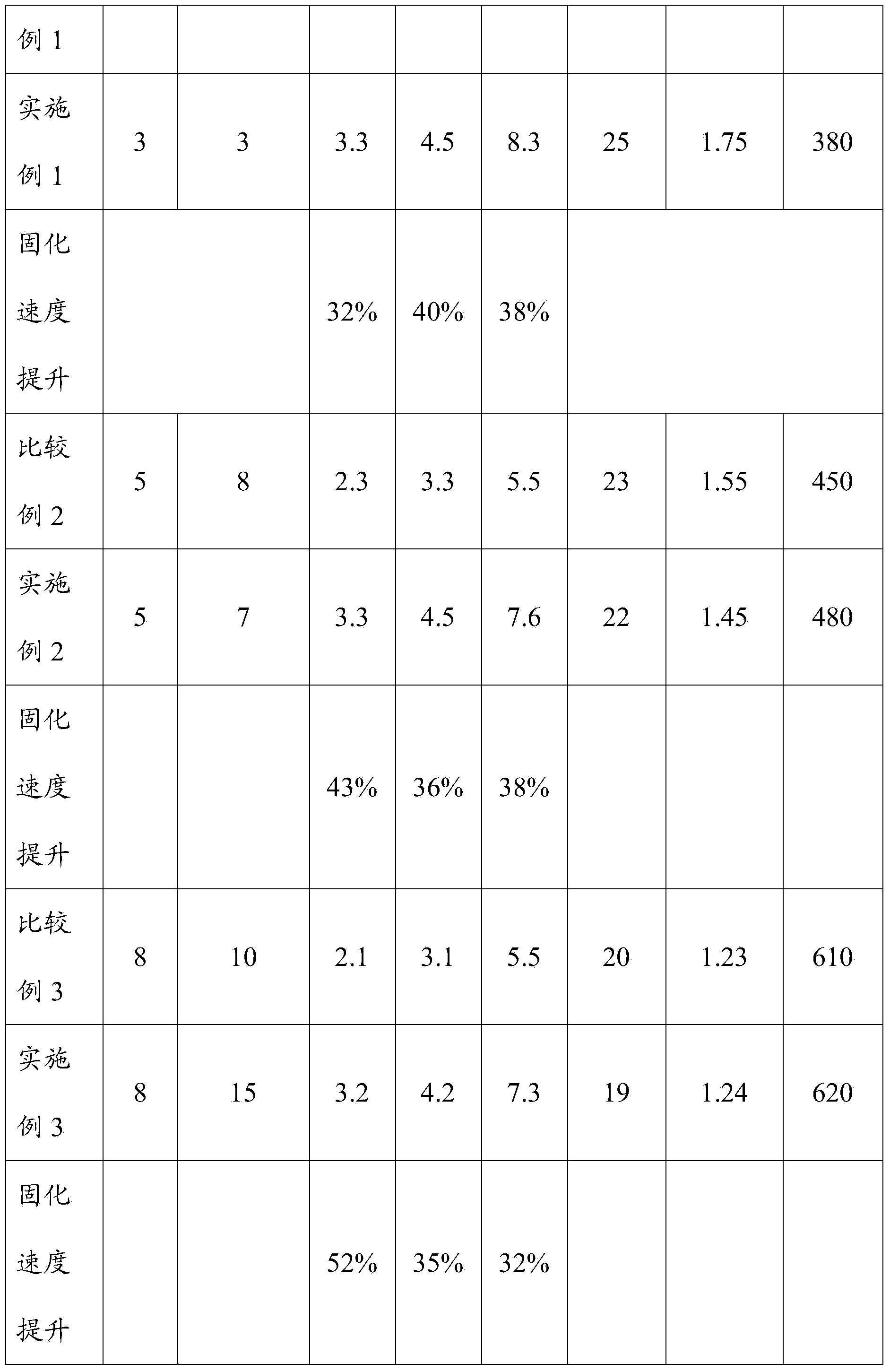

Examples

Embodiment 1

[0026] Add 100 parts of 20000cps alkoxy-terminated polydimethylsiloxane at 25°C, add 3 parts of methyltrimethoxysilane, mix well, add 18 parts of 150㎡ / g fumed silica, and mix well. Add 0.25 parts of acetylacetonate chelate of dibutyltin dilaurate, 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 1.5 parts of hexamethyldisilazane, 0.5 parts of acetic acid Methyl ester, 0.3 parts of polyethylene glycol with a viscosity of 300cps, after mixing evenly, remove low boilers at -0.097Mp, and pack.

Embodiment 2

[0030] 100 parts of alkoxy-terminated polydimethylsiloxane with a viscosity of 50000cps at 25°C, add 3 parts of methyltrimethoxysilane, 15 parts of dimethyl silicone oil with a viscosity of 1000cps at 25°C, mix well, add 200㎡ 18 parts / g fumed silica, mix well. Add 0.27 parts of acetylacetone chelate of dibutyltin dilaurate, 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 1.5 parts of hexamethyldisilazane, acetone 0.5% , Hydrophilic polyether silicone oil 0.5%, after mixing evenly, remove low boilers at -0.097Mp, pack.

Embodiment 3

[0034] 100 parts of alkoxy-terminated polydimethylsiloxane with a viscosity of 80000cps at 25°C, add 3 parts of methyltrimethoxysilane, 50 parts of dimethyl silicone oil with a viscosity of 1000cps at 25°C, mix well, add 200㎡ 22 parts / g fumed silica, mix well. Add 0.30 parts of acetylacetone chelate of dibutyltin dilaurate, 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 0.5 parts of γ-aminopropyltrimethoxysilane, 1.5 1 part of hexamethyldisilazane, 0.5 part of methyl ethyl ketone, 0.5 part of methyl acetate, 0.3 part of polyethylene glycol with a viscosity of 500 cps at 25°C, remove low boilers at -0.097Mp, and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com