Natural rubber anti-vibration pad material and preparation method thereof

A technology of natural rubber and vibration damping pad, applied in the field of rubber materials, can solve the problems of affecting the vibration damping effect, large compressive stress, and the rubber is not resistant to ozone, etc., and achieves the suppression of the change of the cross-linking form, the low compression deformation rate, and the vulcanization speed. accelerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

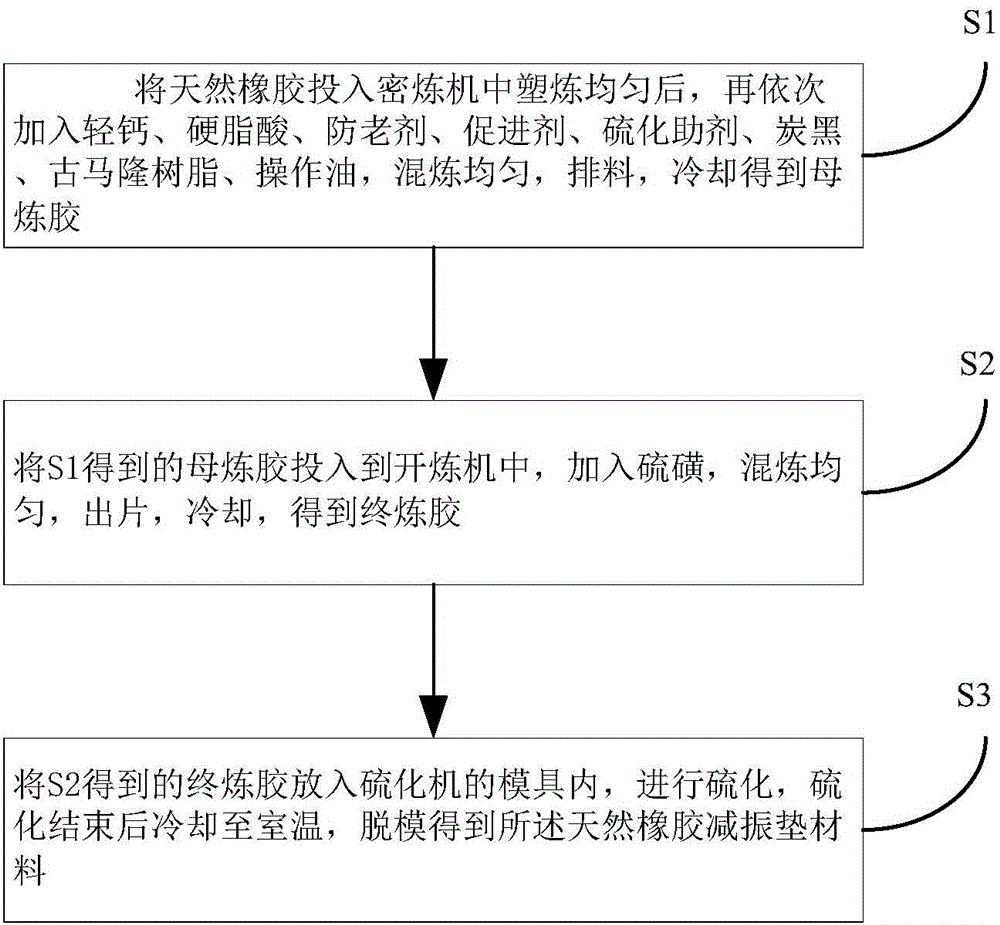

[0034] In the specific implementation process, refer to figure 1 , the preparation method of above-mentioned natural rubber damping cushion material comprises the steps:

[0035] S1. Put the natural rubber into the internal mixer and masticate evenly, then add light calcium, stearic acid, anti-aging agent, accelerator, vulcanization aid, carbon black, coumarone resin, and process oil in sequence, and mix evenly. Discharging, cooling to obtain masterbatch;

[0036] S2, put the masterbatch obtained in S1 into the open mill, add sulfur, mix evenly, release the sheet, cool, and obtain the final rubber mix;

[0037] S3. Put the final mixed rubber obtained in S2 into a mold of a vulcanizer, vulcanize, cool to room temperature after vulcanization, and demould to obtain the butadiene natural rubber vibration damping pad material.

Embodiment 1

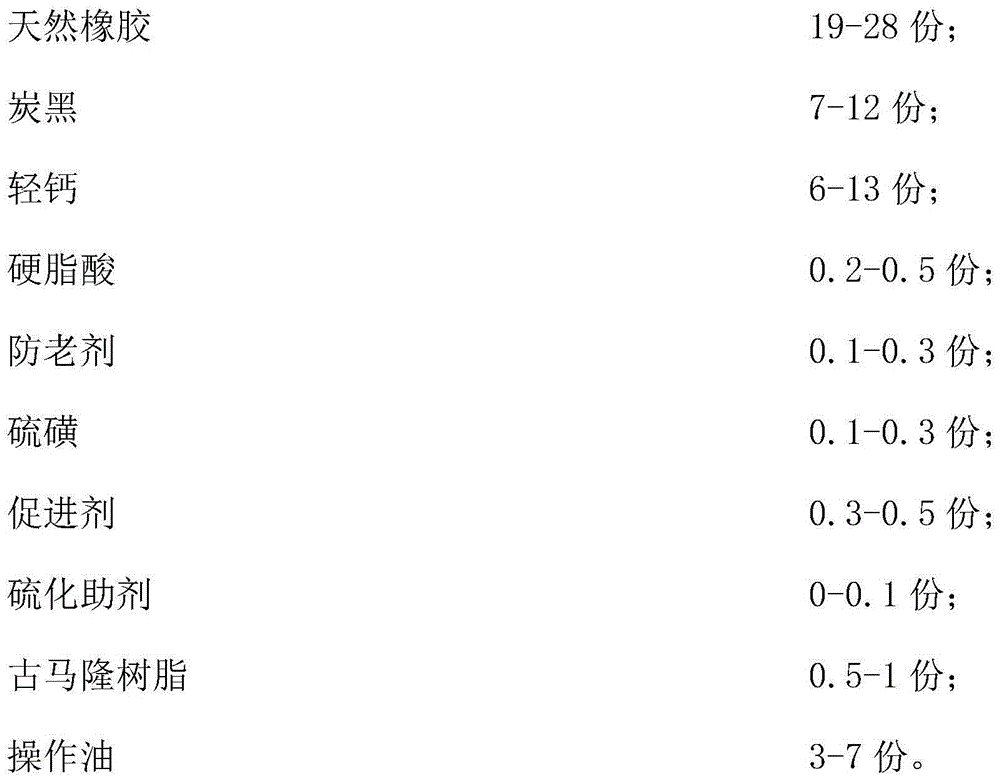

[0040] A kind of natural rubber damping cushion material, its raw material comprises by weight:

[0041]

[0042]

[0043] Wherein, the chloroprene rubber of 6% weight percent is also contained in the described natural rubber; The paraffin content in paraffin oil is 70%, aromatic hydrocarbon content is 3%, naphthene 26%; The kinematic viscosity at 100 ℃ is 5mm 2 / s.

[0044] In the present embodiment 1, the preparation method of above-mentioned natural rubber damping cushion material comprises the steps:

[0045] S1. Put the natural rubber into the internal mixer and masticate at 80°C for 45 minutes, then add light calcium, stearic acid, anti-aging agent, accelerator, vulcanization aid, carbon black, coumarone resin, and process oil in sequence, Mix at 90°C for 25 minutes, discharge, and cool to obtain masterbatch;

[0046] S2. Put the masterbatch obtained in S1 into an open mill, add sulfur, knead at 40°C for 20 minutes, release the sheet, and cool to obtain the final...

Embodiment 2

[0049] A kind of natural rubber damping cushion material, its raw material comprises by weight:

[0050]

[0051] Wherein, the natural rubber contains 8% by weight of butadiene rubber; the paraffin content in the paraffin oil is 65%, the aromatic content is 8%, and the cycloalkane is 25%; the kinematic viscosity at 100°C is 20mm 2 / s.

[0052] In the present embodiment 2, the preparation method of above-mentioned natural rubber damping cushion material comprises the steps:

[0053] S1. Put the natural rubber into the internal mixer and masticate at 100°C for 35 minutes, then add light calcium, stearic acid, anti-aging agent, accelerator, carbon black, coumarone resin, and operating oil in sequence, and heat at 110°C Mixing for 15min, discharging, and cooling to obtain masterbatch;

[0054] S2. Put the masterbatch obtained in S1 into an open mill, add sulfur, knead at 60°C for 10 minutes, release the sheet, and cool to obtain the final batch;

[0055] S3. Put the final mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com