Low-moisture-permeability single-component dealcoholization type room-temperature silicon sulfide rubber sealing agent and preparation method thereof

A room temperature vulcanization and dealcoholization technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as poor high temperature and high humidity resistance, low moisture permeability, and low water vapor transmission rate , to achieve the effect of low moisture permeability, good high temperature and high humidity resistance, and good moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

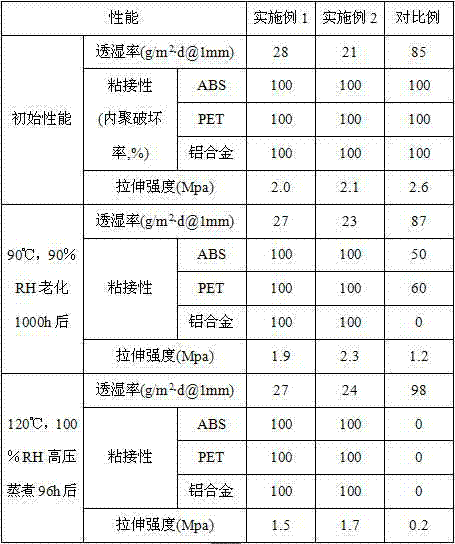

Examples

Embodiment 1

[0029] Select α, ω-divinyl polydimethylsiloxane with a viscosity of 10000mpa s, dimethyl silicone oil with a viscosity of 100mpa s, silane-modified polyisobutylene with a molecular weight of 10000, vinyl silicon chloroplatinic acid The oxane chelate is a platinum catalyst, and the specific component ratio is as follows:

[0030] A. 100 parts of α, ω-divinyl polydimethylsiloxane;

[0031] B. 6 parts of hydrotrimethoxysilane;

[0032] C. 1.5 parts of platinum catalysts;

[0033] D. 8 parts of simethicone oil;

[0034] E. 20 parts of silane-modified polyisobutylene;

[0035] F. 5 parts of vinyltrimethoxysilane;

[0036] G. 1.5 parts of aminopropyltriethoxysilane;

[0037] H. 80 parts of calcium carbonate, 10 parts of fumed white carbon black;

[0038] 1. 2 parts of tetraisopropyl titanate.

[0039] N 2 Add A, B, and C into the reaction kettle under protection, stir evenly, raise the temperature to 50°C, and 2 Continue to stir and react for 4-6 hours under protection,...

Embodiment 2

[0041] Select α, ω-divinyl polydimethylsiloxane with a viscosity of 5000mpa s, dimethyl silicone oil with a viscosity of 100mpa s, silane-modified polyisobutylene with a molecular weight of 10000, vinyl silicon chloroplatinic acid The oxane chelate is a platinum catalyst, and the specific component ratio is as follows:

[0042] A. 100 parts of α, ω-divinyl polydimethylsiloxane;

[0043] B. 6 parts of hydrotrimethoxysilane;

[0044] C. 1.5 parts of platinum catalysts;

[0045] D. 10 parts of simethicone oil;

[0046]E. 25 parts of silane-modified polyisobutylene;

[0047] F. 5 parts of vinyltrimethoxysilane;

[0048] G. 1.5 parts of aminopropyltrimethoxysilane;

[0049] H. 80 parts of calcium carbonate, 8 parts of fumed white carbon black;

[0050] I. 3 parts of bis(ethyl acetoacetate) diisopropyl titanate.

[0051] N 2 Add A, B, and C into the reaction kettle under protection, stir evenly, raise the temperature to 50°C, and 2 Continue to stir and react for 4-6 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com